BP and GA based blade machining cutting quantity optimization selection method

A technology for optimizing selection and blades, applied in genetic models, data processing applications, special data processing applications, etc., can solve problems such as the inability to dynamically describe the change of the output objective function, and the low utilization rate of numerical control technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

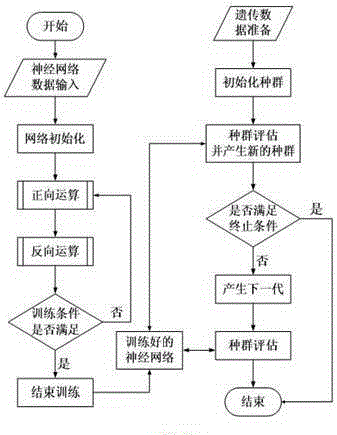

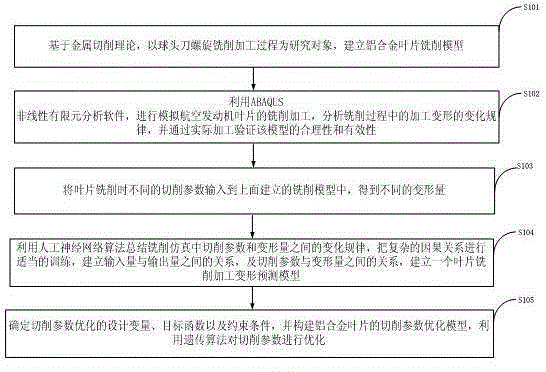

[0115] combined with figure 1 To illustrate this case, the embodiment of the present invention is implemented in this way, a method for optimizing the cutting amount of blade machining based on BP and GA, the steps of the method include:

[0116] S101. Based on the metal cutting theory, taking the helical milling process of the ball nose cutter as the research object, establishing the milling model of the aluminum alloy blade;

[0117] S102. Using ABAQUS nonlinear finite element analysis software, simulate the milling process of the aeroengine blade, analyze the variation law of the machining deformation in the milling pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com