Residual stress testing method

A technology of residual stress and test pieces, applied in the direction of testing material hardness, measuring devices, instruments, etc., can solve problems such as lack of depth, less systematic and comprehensive research, and weak experimental tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The residual stress test method of the present invention is as follows.

[0014] A certain load is applied to the test point of the test piece by the indenter, so that the indenter produces plastic deformation on the surface of the test piece; a spherical crown-shaped indentation is formed, and a stress field is generated around the indentation.

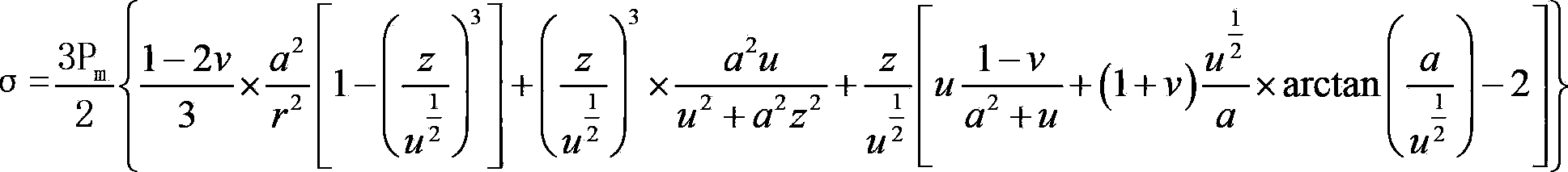

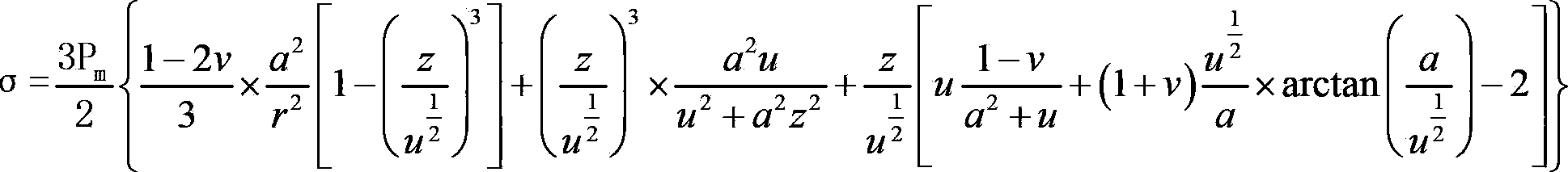

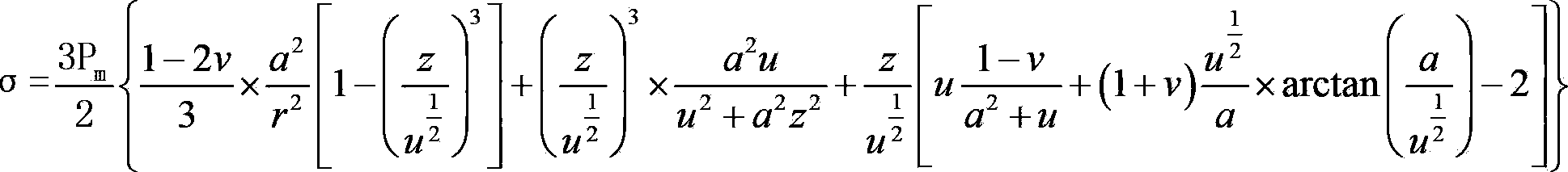

[0015] The residual stress σ can be calculated by the following formula,

[0016] σ = 3 P m 2 { 1 - 2 v 3 × a 2 r 2 [ 1 - ( z u 1 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com