Plate type phase-change thermal storage heat exchanger capable of supplying heat stably

A phase change heat storage and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat storage equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

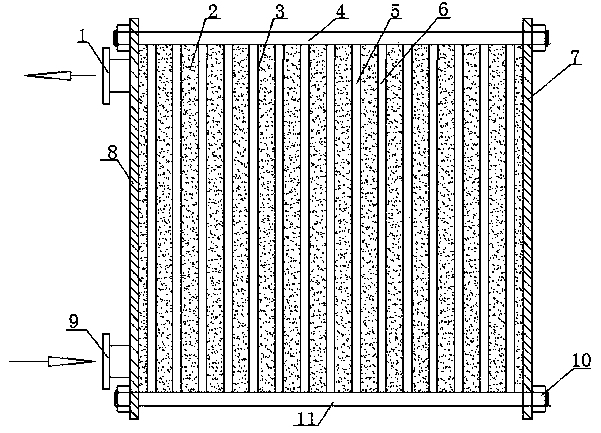

[0023] like figure 1 , Figure 4 The shown plate type phase change heat storage heat exchanger with stable heat supply includes a plurality of sealed boxes 3 arranged in parallel. The inside of the sealed box 3 is provided with a phase change heat storage body 2, and at the four corners of the sealed box 3 Corner holes 13 are arranged at each place, and a sealing member 16 is arranged between any two adjacent sealing boxes 3. The sealing member 16 isolates the two corner holes 13 on the same side of the sealing box 3, and any two adjacent Adjacent seals 17 form an included angle of 180° and are arranged in parallel, and the plurality of seal boxes 3 are surrounded by seals 17 to form spaced distribution of hot working medium flow chambers 5 and cold working medium flow chambers 6. The cavity thickness of the working medium flow chamber 5 and the cold working medium flow chamber 6 is 0 ~ 0.5 decimeters; it also includes an external frame, which compresses and seals the sealed...

Embodiment 2

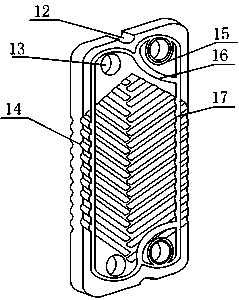

[0032] like figure 2 and image 3 As shown, on the basis of Embodiment 1, this embodiment adds an optimized seal, specifically: the same side end of the seal 17 is provided with an isolation seal 16, and the isolation seal 16 seals the same side of the box 3 The two corner holes 13 are isolated.

[0033] The sealing member 17 is arranged to match the structure of the sealing box 3, which can be circular, square or any other shape, and can be selected according to the specific usage; the sealing member 17 of this embodiment is of a square structure, and the four corner holes 13 are located at the 17, the two corner holes on the same side are isolated from the other two corner holes 13 by the isolation seal 16, so that the other two corner holes 13, the seal 16 and the isolation seal 16 form a flow cavity, and the isolated corner The hole 13 does not enter the flow chamber when the working fluid flows in, but directly enters the next adjacent flow chamber, so that the workin...

Embodiment 3

[0036] In this embodiment, the following structure is added on the basis of embodiment 1 or embodiment 2: both vertical sides of the sealed box 3 are provided with pulsator channels 14 .

[0037] The pulsator channel 14 of this embodiment brings two benefits: the first benefit is that the internal turbulence of the heat exchange working fluid can be accelerated, so that the working medium flows more comprehensively on the surface of the sealed box 3, and the working medium is not easy to scale; The second advantage is that the contact area between the working fluid and the phase-change heat storage body 2 is increased, thereby enhancing the heat transfer effect, making the heat storage and heat dissipation more rapid and uniform, and making the heat transfer more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com