Multi-way PID (proportion integration differentiation) temperature control device and control method thereof

A technology of a temperature control device and a temperature control method, which is applied in the field of multi-channel PID temperature control devices, can solve the problem that the dynamic temperature balance of the heating plate is consistent, the PID controller does not have real-time synchronous adjustment, and the balanced control of the heating plate cannot be well realized. Temperature and other problems, to achieve the effect of shortening the heating time, precise heating temperature, and improving balance and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

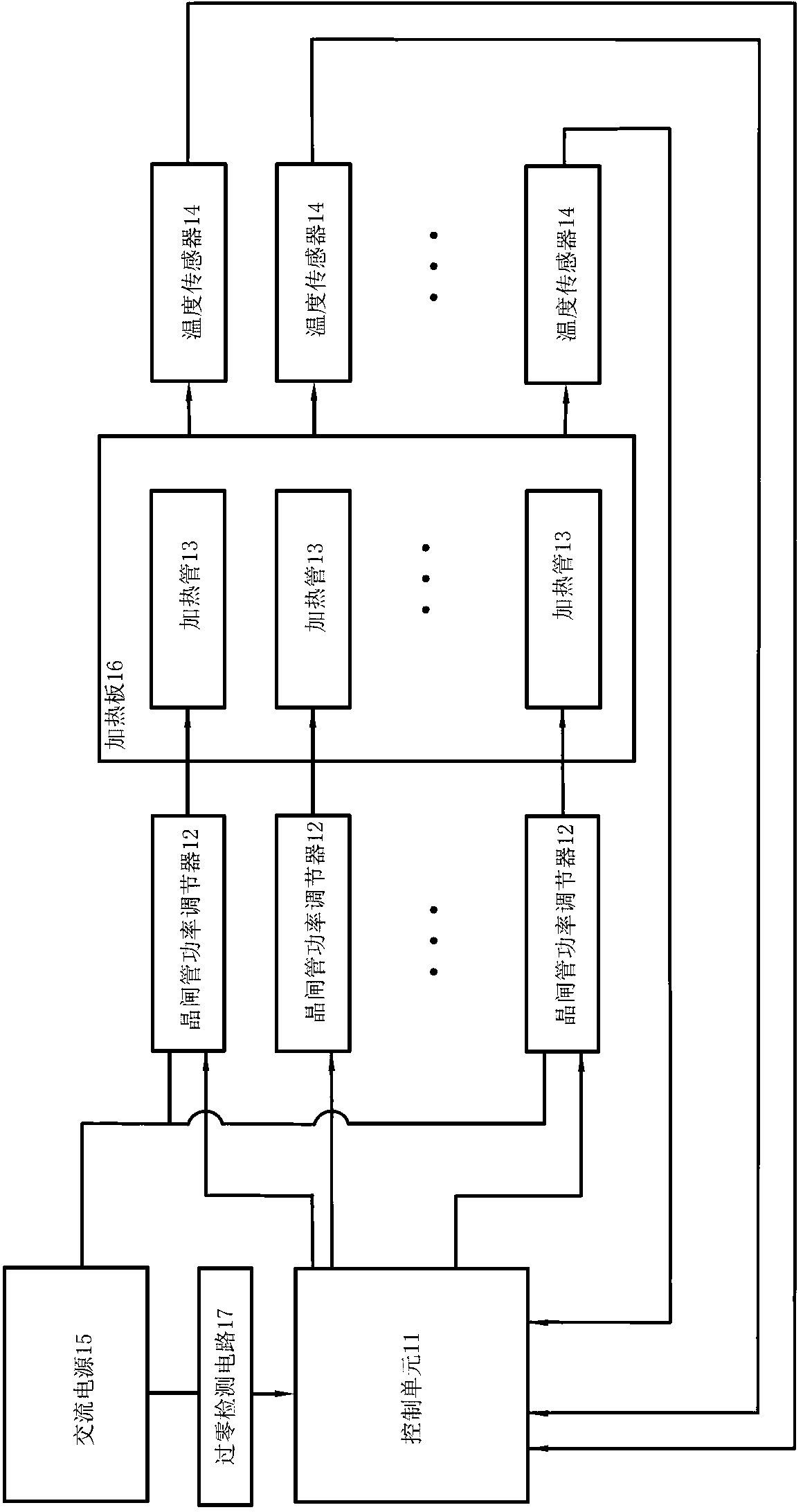

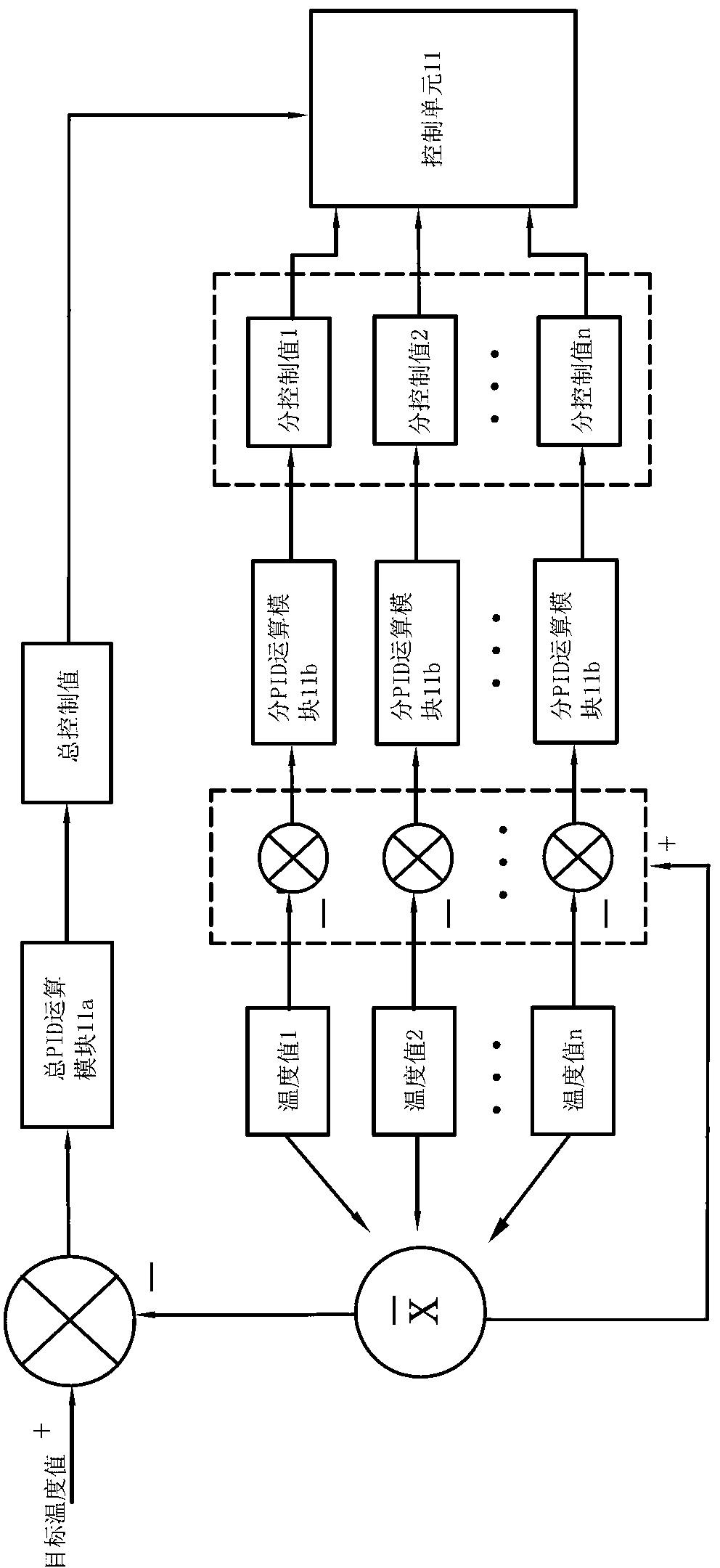

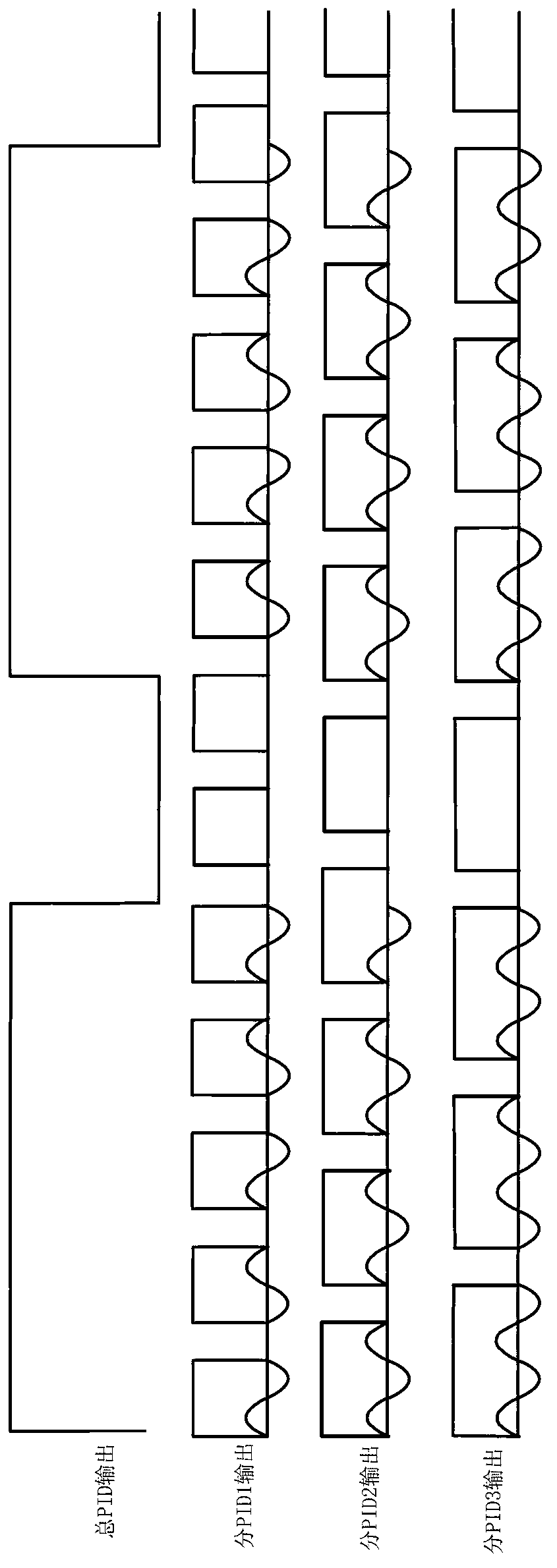

[0033] Such as figure 1 , 2 As shown, the multi-channel PID temperature control device includes a control unit 11, an AC power supply 15, several temperature sensors 14, several thyristor power regulators 12 and several heating tubes 13, and each heating tube 13 corresponds to a temperature sensor 14 and Thyristor power regulator 12, each temperature sensor 14 is connected with the input terminal of control unit 11 respectively, each thyristor power regulator 12 is connected with the output terminal of control unit 11 respectively, AC power supply 15 and heating tube 13 are respectively connected with thyristor power regulation The control unit 11 receives the temperature value sent by each temperature sensor 14 and calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com