Production method of a broad PVA polarized light film

A technology of polarizing film and production method, which is applied to polarizing elements, optics, optical elements, etc., to achieve the effects of easy industrial production, precise heating temperature, and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

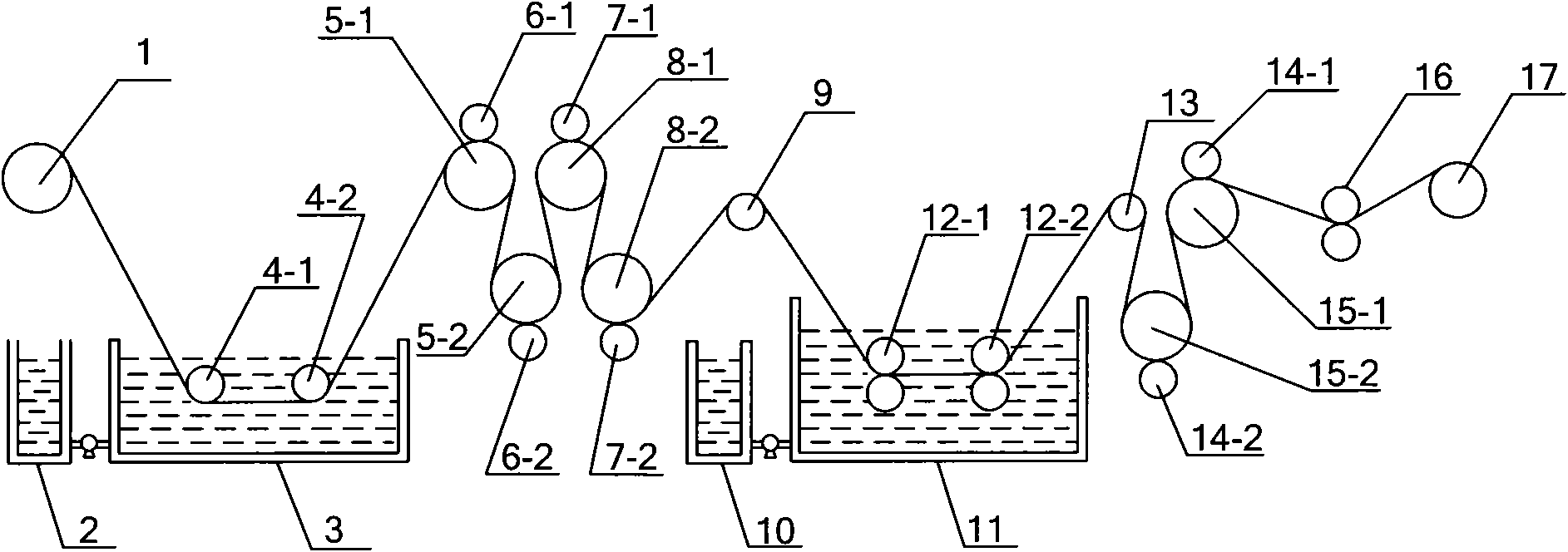

[0012] like figure 1 Shown, the production equipment of PVA polarizing film comprises unwinding device 1, primary solution tank 3, primary heating roll, secondary heating roll, secondary solution tank 11, heat setting roll, traction device 16 and Curling device 17 .

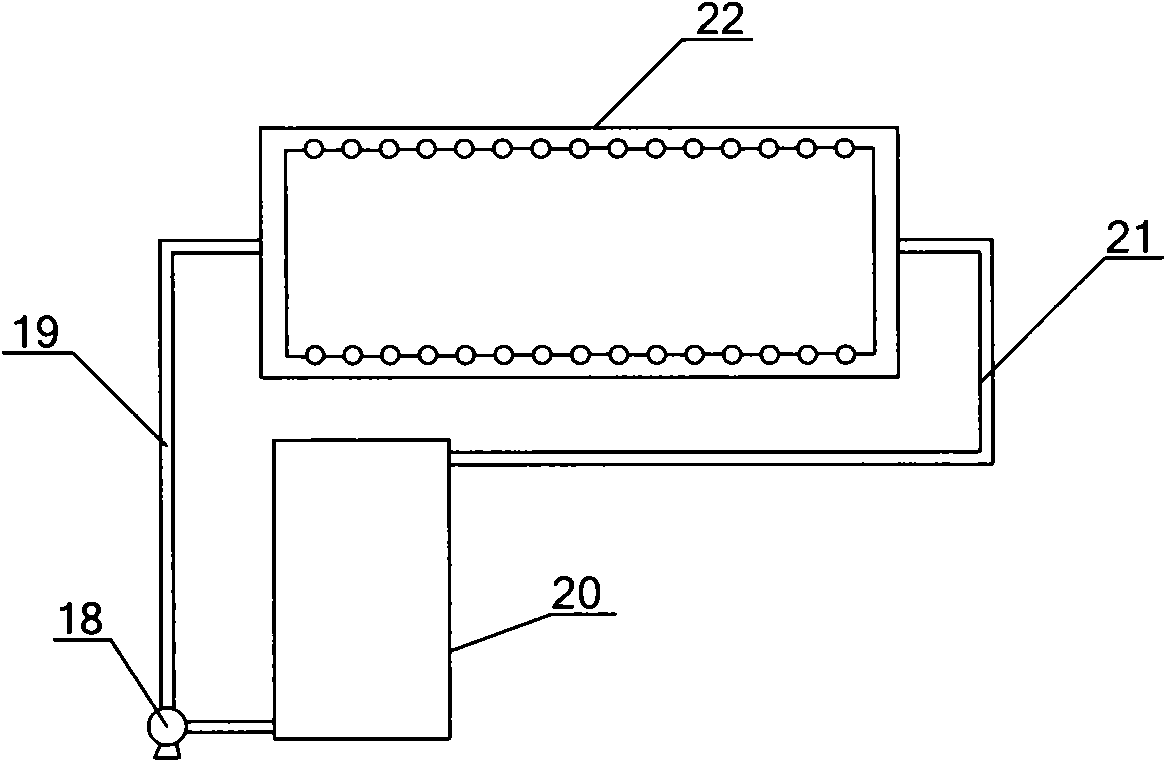

[0013] The unwinding device 1 is arranged on one side of the primary solution tank 3 . At normal temperature, the primary solution tank 3 is filled with KI and I 2 Saturated solution, KI and I 2 The weight ratio is 2~8:1. The primary solution tank 3 is in communication with the primary liquid replenishment tank 2, and the primary liquid replenishment tank 2 is used to adjust and replenish KI and I in the primary solution tank 3 2 saturated solution. The secondary solution tank 11 is filled with a saturated solution of boric acid at a temperature of 55-65°C. The secondary solution tank 11 is connected to the secondary liquid replenishment tank 10, and the secondary liquid replenishment tank 10 is used to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com