Distributed controllable heat source temperature field design method and system

A technology of heat source temperature and design method, applied in control/regulation system, temperature control, non-electric variable control, etc., can solve problems such as difficulty in obtaining surrounding heat sources, inability to control terminals to obtain information of multiple heat sources, and lack of coordination and cooperation of multiple heat sources. , to achieve the effect of reasonable temperature distribution, accurate heating temperature and pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

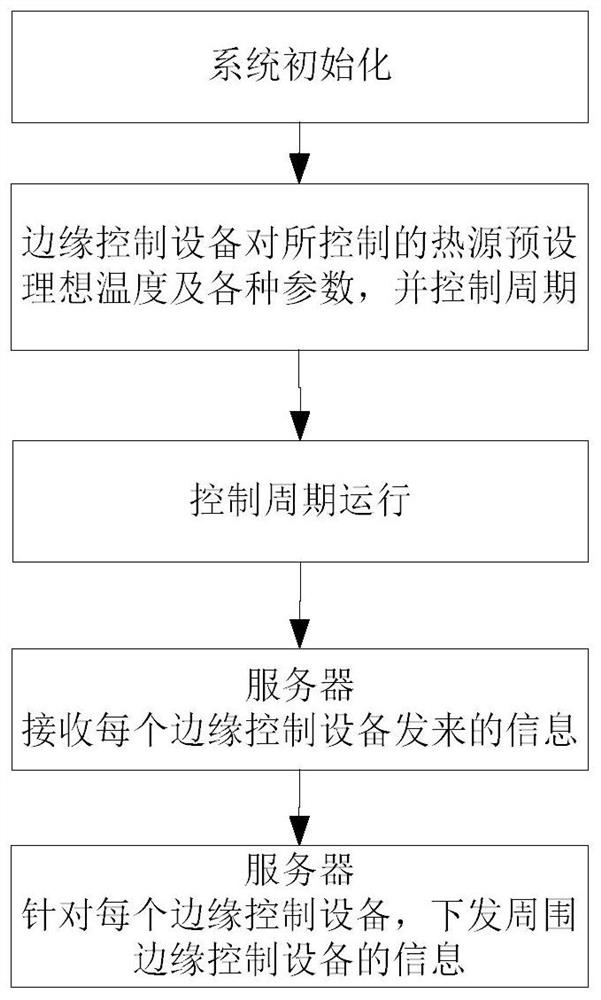

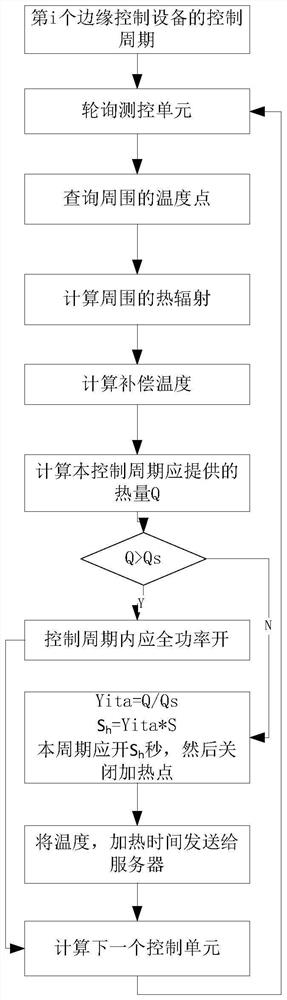

Method used

Image

Examples

Embodiment Construction

[0044] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

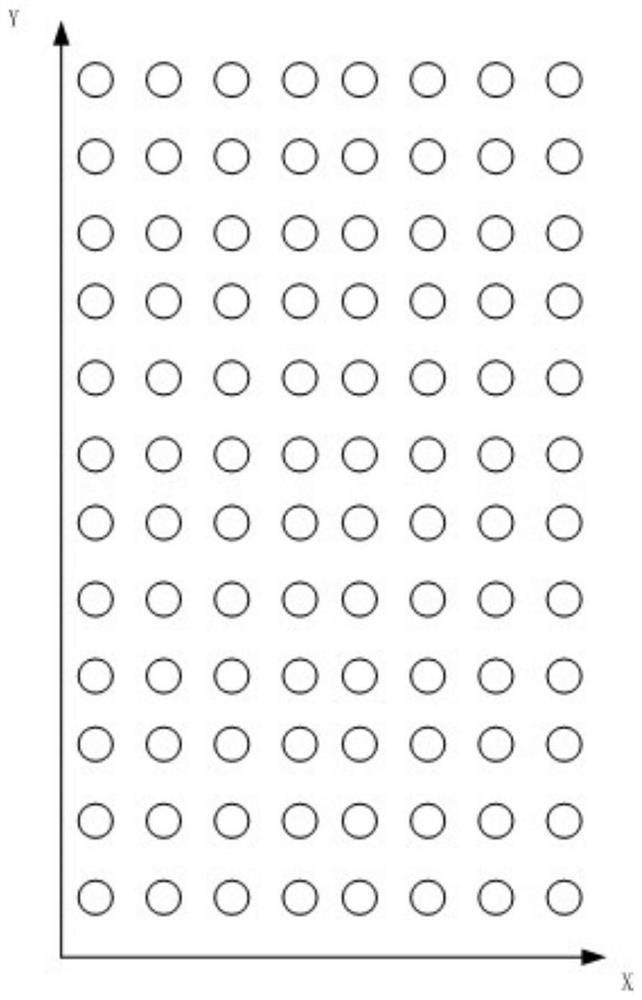

[0045] In the fields of metallurgy, chemical industry, etc., the operation of heating the workpiece is often encountered. The typical scene is to use fuel or electricity for heating. Under the control of PLC and other controllers, the controlled heat source is controlled to keep the workpiece The corresponding physical and chemical reactions are produced under constant temperature conditions. The applicant believes that all the heat sources in the traditional temperature field control system are centrally connected to the PLC control and controlled by the PLC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com