Automatic hot melting welding machine and welding method

A hot-melt welding, automatic technology, applied in mechanical equipment, pipeline connection layout, pipe/pipe joint/pipe fittings, etc., can solve the problem of time-consuming and laborious manual operation, can not guarantee welding quality, etc., to achieve convenient operation, convenient and fast control , the effect of improving the degree of visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

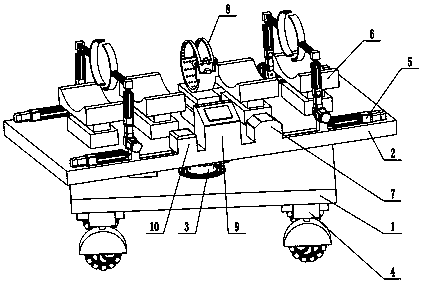

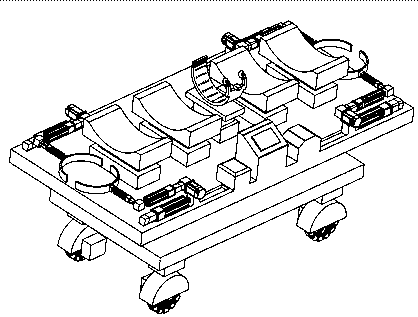

[0057] see figure 1 It is an automatic hot-melt welding machine in an embodiment, including:

[0058] upper bottom plate 2;

[0059] The clamping unit 5 is arranged on the upper base plate 2. Specifically, there are four clamping units 5. Two clamping units 5 are respectively installed on the left and right sides of the upper end surface of the upper base plate 2. The clamping unit 5 can be used to treat The two sections of pipes to be welded are clamped and fixed respectively, which increases the stability of the pipes during hot-melt welding.

[0060]The support unit 6 is arranged on the upper base plate 2; specifically, there are four support units 6, and two support units 6 are respectively installed on the left and right sides of the middle position of the upper end surface of the upper base plate 2, through which the welding The two sections of pipe are supported separately, which increases the stability during hot-melt welding.

[0061] The fixing device 8 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com