Automatic drilling device for cylinder barrels of hydraulic cylinders

A technology for drilling equipment and hydraulic cylinders, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve problems such as low degree of automation, affecting hole depth accuracy, and low aperture accuracy, and achieve High work efficiency, convenient maintenance and management, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

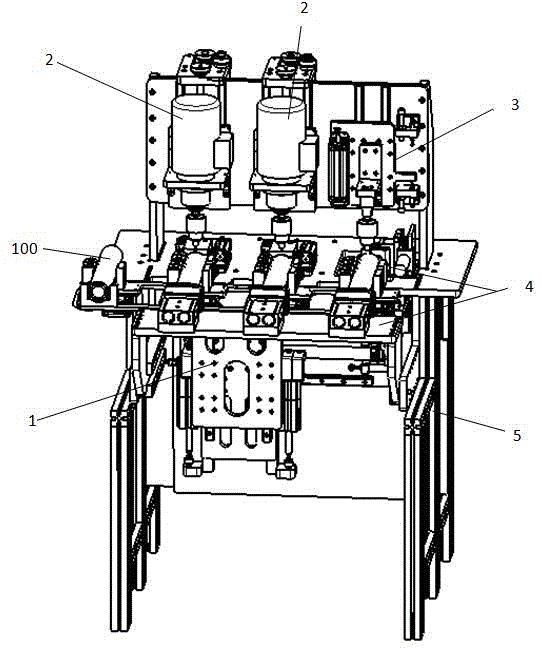

[0027] see Figure 1 to Figure 7 As shown, the hydraulic cylinder cylinder automatic drilling equipment of the present invention includes a main body frame 5, a progressive feeding unit 1, a drilling unit 2, a deburring and hole quality monitoring unit 3, and a cylinder positioning and clamping unit 4.

[0028] The main frame 5 is made of overlapping 45x90 and 45x45 aluminum alloy profiles. The unique texture of the aluminum alloy makes the appearance of the whole device simple, generous and full of texture.

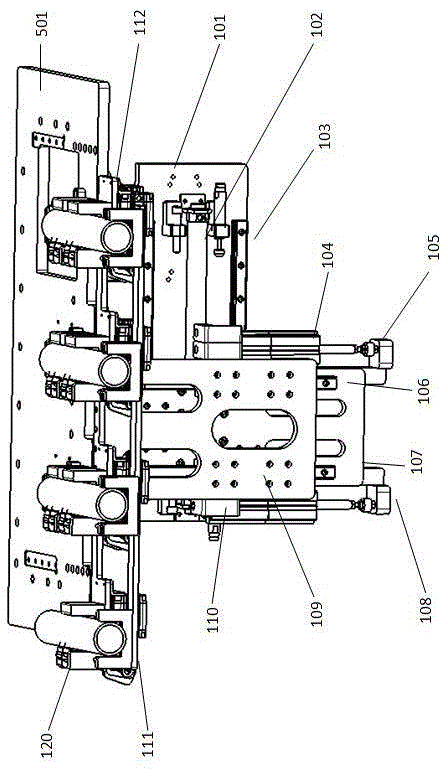

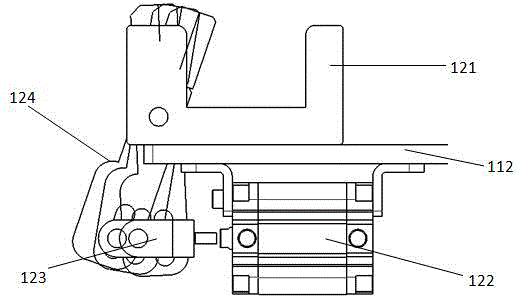

[0029] see figure 2 and image 3 As shown, the progressive feeding unit 1 is: the vertical plate C 107 is installed on the X guide rail slider 103, tightly connected by screws, and the front and rear positions of the vertical plate C 107 are adjusted by pads. The two X guide rail sliders 103 are parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com