Laser micromachining process of engine blade

A technology of engine blades and lasers, which is applied to laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of no automatic cleaning equipment, inappropriateness, deviation, etc., and achieve the effects of convenient disassembly, improved precision, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

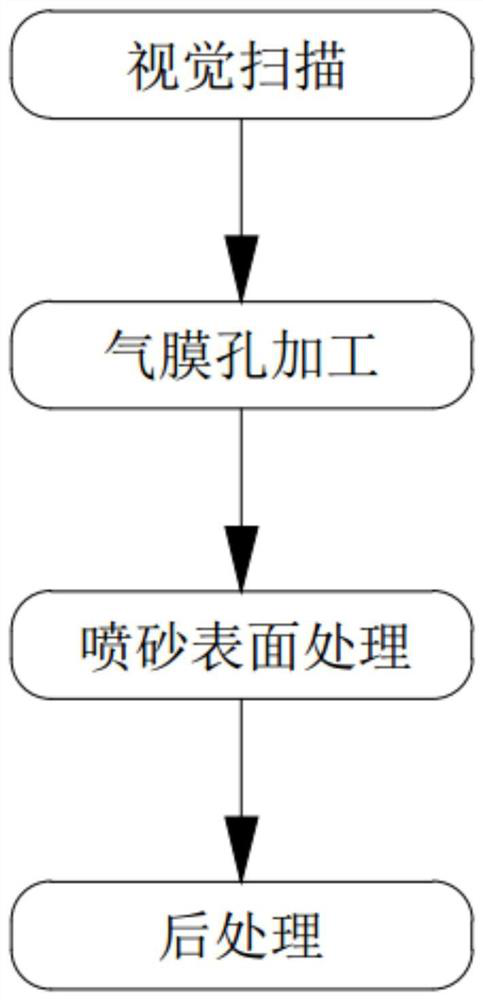

[0033] Such as figure 1 As shown, a laser micromachining process of an engine blade includes the following steps:

[0034] (1) Visual scanning: fix the product 100 to be processed on the fixture in the CNC machine tool, obtain the three-dimensional graphics of the product 100 by means of a three-dimensional scanner installed in the machine tool, and input the three-dimensional graphics to the control center of the CNC machine tool , the control center calculates and analyzes it after obtaining the three-dimensional graphics, obtains the NC machining parameters of the product 100 and generates a machining program;

[0035] (2) Gas film hole processing: According to the processing procedure, the laser drilling process is used to process the air fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com