Electric heating DPF control device

A control device, DPF technology, applied in the direction of muffler, exhaust device, engine components, etc., can solve the problems of small space, frequent start and stop, large original row, etc., to achieve enhanced applicability and stability, uniform heating temperature, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

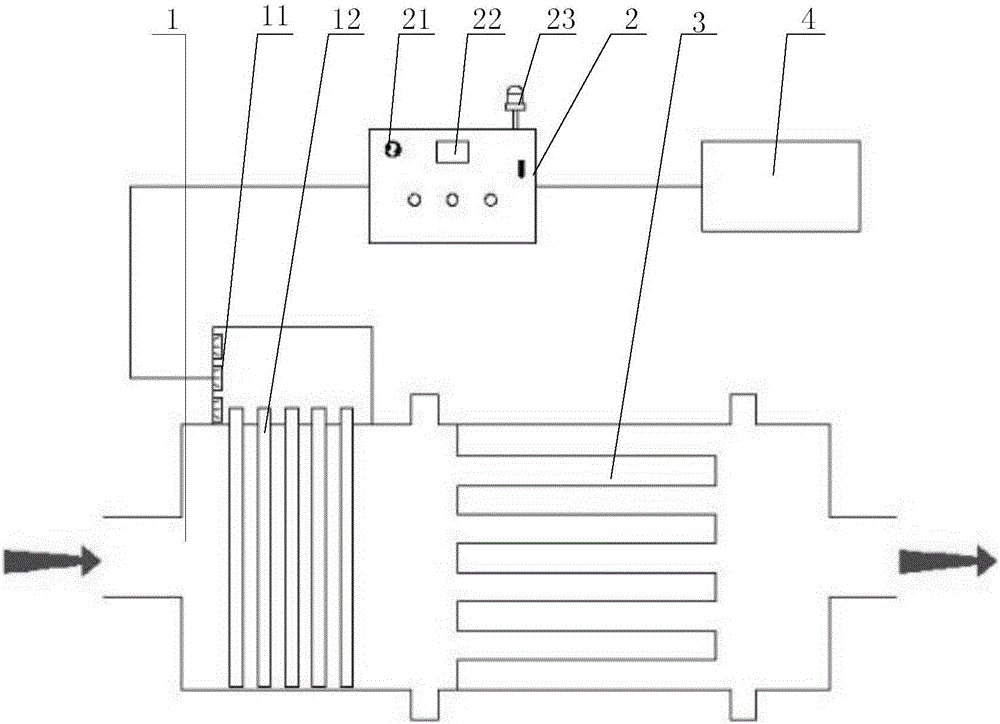

[0017] In specific implementation, combine figure 1 , An electric heating DPF control device, including a heating chamber 1, a control cabinet 2, a diesel particulate filter 3, and a power grid 4. A heating tube 12 and a temperature sensor 11 are installed in the heating chamber 1. A controller 21, an indicator light 23, and a display 22 are installed in the control cabinet 2. The power grid 4 supplies power for the control cabinet 2 and the heating tube 12, and the temperature sensor 11 and the controller 21 are connected through a signal line. The outlet end of the heating chamber 1 is connected with a diesel particulate filter (DPF) 3. The heating tube 12 may be a mosquito coil type electric heating coil. The indicator light 23 may be a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com