A high-frequency direct current heating auxiliary rolling processing device and processing method thereof

A technology of processing device and rolling device, which is applied in metal processing and other directions to achieve accurate heating temperature, obvious surface strengthening effect, and better effect.

Active Publication Date: 2019-07-16

SOUTH CHINA UNIV OF TECH

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these composite rolling processing devices have strict requirements on the size of the processed parts, and there are natural defects for short shafts, especially shaft parts with small diameters

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0050] In this embodiment, the rolling form is column rolling; the rolling head corresponding to the rolling device is a ceramic cylindrical rod. The ceramic cylindrical rod has a diameter of 2-5 mm and a length of 8-10 mm; in this embodiment, the ceramic cylindrical rod has a diameter of 3 mm and a length of 8 mm.

[0051] The parts not mentioned in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

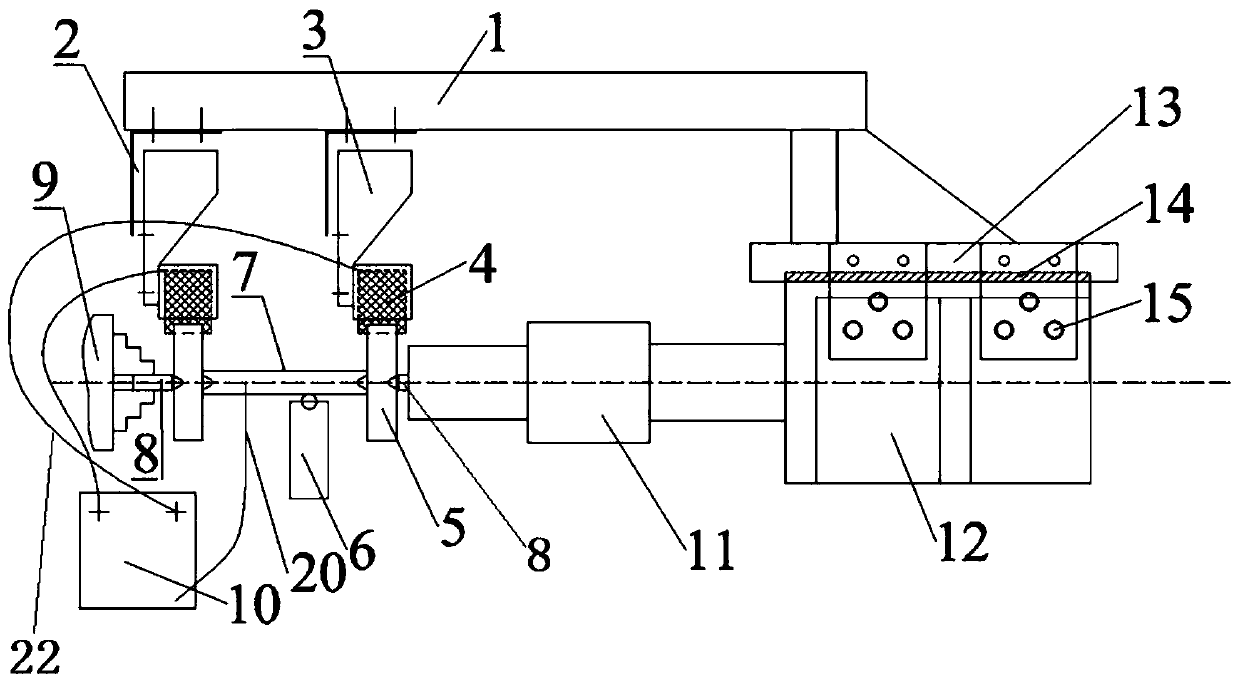

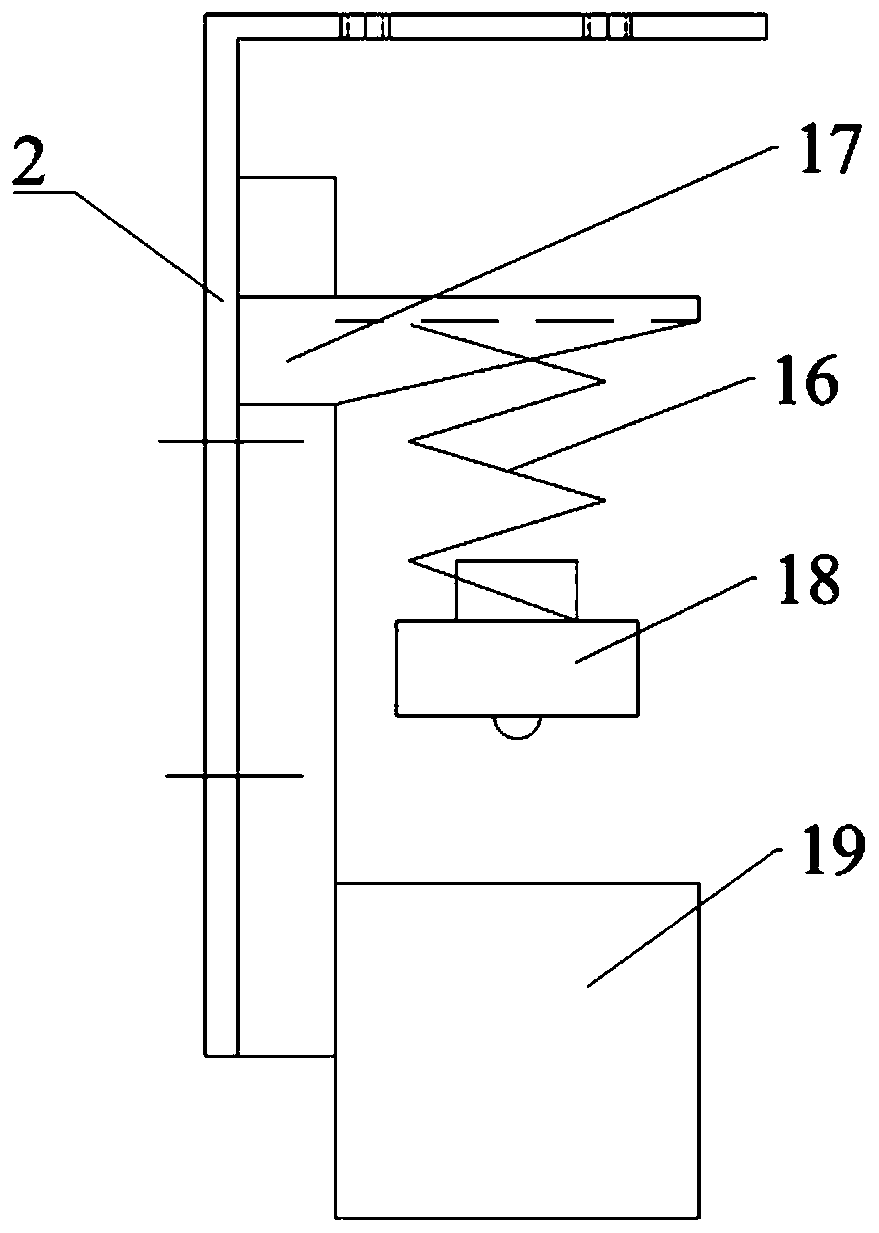

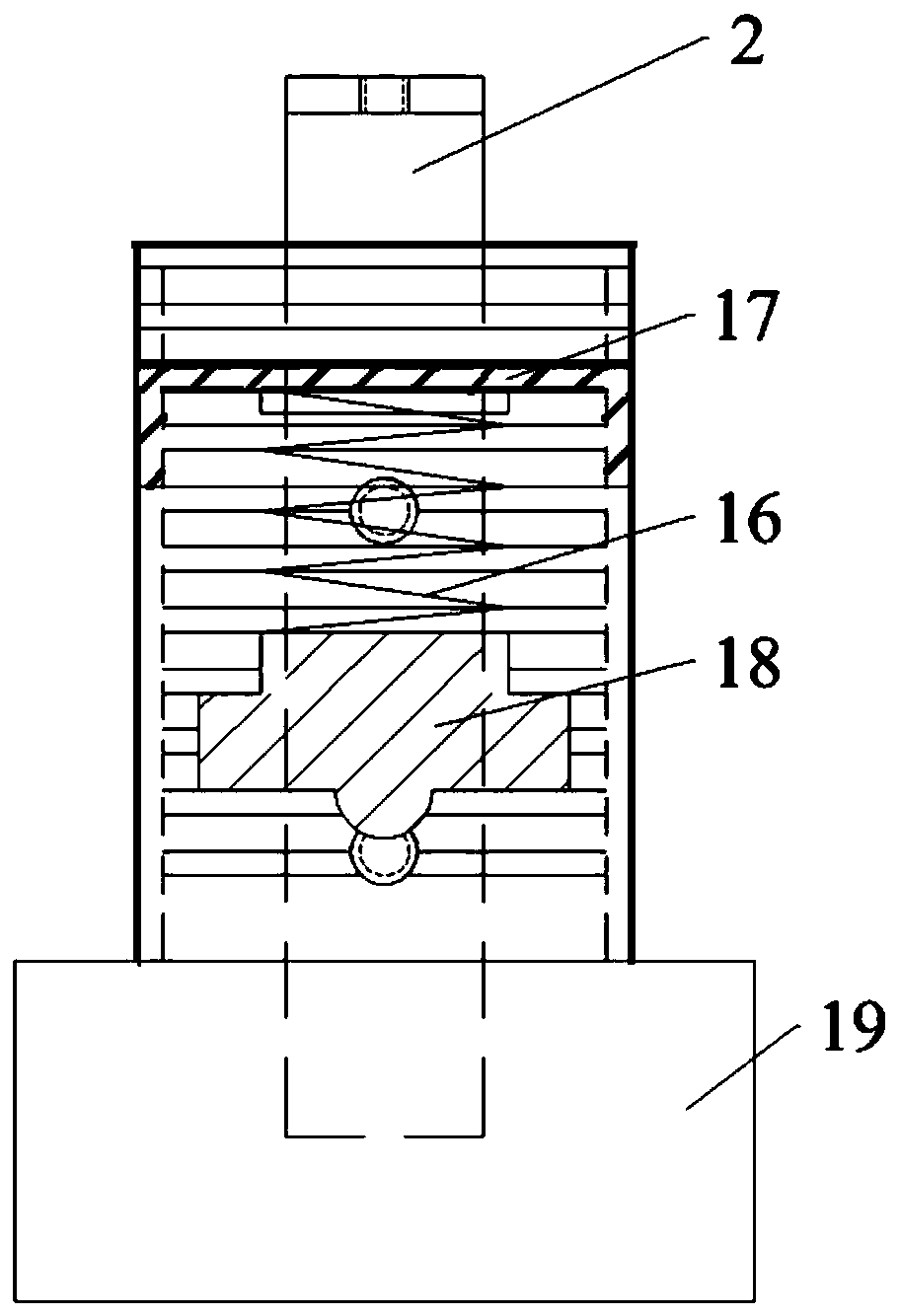

The invention relates to a high-frequency direct-current heating auxiliary rolling device added on a machine tool. The high-frequency direct-current heating auxiliary rolling device comprises a rolling device, a heating component and a loading component; the rolling device is fixedly mounted on a cutter frame of the machine tool; and a rolling head is towards parts to be machined. The heating component comprises a high-frequency direct-current power supply, two copper electrodes and two electric brushes; and the high-frequency direct-current power supply, the two electric brushes, the two copper electrodes and the parts to be machined are connected through leads to form a closed loop. The loading component comprises an electric brush frame, two insulation fixed thimbles and an insulation revolving thimble; and in the horizontal direction of the machine tool, a machine tool tail base, the insulation revolving thimble, the first insulation fixed thimble, the first copper electrode, the parts to be machined, the second copper electrode, the second insulation fixed thimble and a power tool power chuck are coaxially clamped in sequence. The invention further relates to a machining method of the high-frequency direct-current heating auxiliary rolling device. The device is simple in structure, convenient to operate and high in practicability, and belongs to the field of metal machining equipment.

Description

technical field [0001] The invention relates to the field of metal processing equipment, in particular to a high-frequency direct current heating auxiliary rolling processing device and a processing method thereof. Background technique [0002] Rolling is a process of locally and continuously pressing the surface of a part with a high-hardness and smooth surface, causing the surface of the part to undergo plastic deformation and generate compressive residual stress and cold work hardening, thereby achieving mechanical surface strengthening of the part. The method can improve the wear resistance, fatigue resistance and corrosion resistance of parts, and is of great significance to prolonging the service life of metal parts and ensuring more reliable and safe operation of mechanical equipment. [0003] With the development of the times and science and technology, for the surface strengthening of some special materials (high hardness), the simple rolling surface strengthening t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P9/02B23P25/00

CPCB23P9/02B23P25/003

Inventor 肖志瑜王震黄传收温利平朱权利

Owner SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com