Energy-efficient sulfonation reaction device and method for naphthalene water reducers

A naphthalene-based water-reducing agent and sulfonation reaction technology, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical processes, etc., can solve the problem of low heat utilization efficiency and uneven heating , long reaction time of the synthesis process, etc., to achieve the effect of improving efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

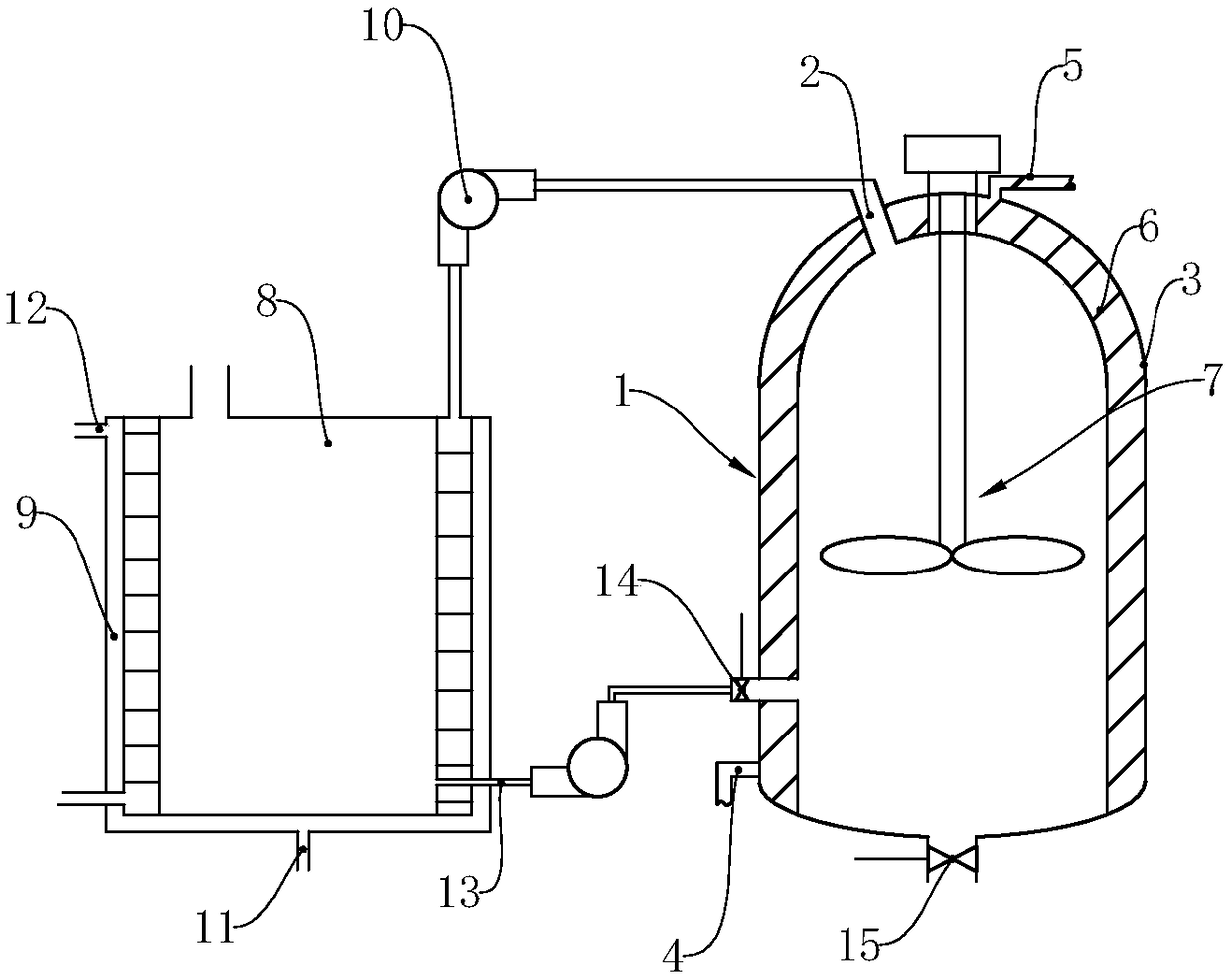

[0031] A high-efficiency and energy-saving naphthalene-based water reducer sulfonation reaction device, including a sulfonation reactor 1, the top of the sulfonation reactor 1 is provided with a waste gas outlet 2; the outer wall of the sulfonation reactor 1 is provided with a jacket 3 , the lower part of the jacket 3 is provided with a heat transfer oil inlet 4, and the top of the jacket 3 is provided with a heat transfer oil outlet 5, and the heat transfer oil inlet 4 and the heat transfer oil outlet 5 are respectively connected with the heat transfer oil heating cycle device The outlet is connected to the inlet; the jacket 3 is provided with a baffle 6 extending spirally from the heat transfer oil inlet 4 to the heat transfer oil outlet 5, and the baffle 6 separates the jacket 3 into a spiral flow road. The sulfonation reactor 1 is provided with a stirring device 7 . It also includes a naphthalene melting tank 8; the outer wall of the naphthalene melting tank 8 is provided...

Embodiment 2

[0033] (1) Put solid industrial naphthalene into the naphthalene melting kettle, and enter high-temperature steam (above 100° C.) from the steam inlet into the heating channel of the naphthalene melting kettle. When the temperature in the naphthalene melting kettle reaches 80° C., the industrial naphthalene starts Melting; when the industrial naphthalene is completely melted, it is transported from the material outlet to the sulfonation reactor through a gear pump.

[0034] (2) Import high-temperature heat-conducting oil with a temperature of 135°C into the jacket of the sulfonation reaction kettle from the heat-conduction oil inlet, heat the sulfonation reaction kettle, and simultaneously weigh it according to the weight ratio of industrial naphthalene:concentrated sulfuric acid of 1.0 For 98% concentrated sulfuric acid, heat up to 128°C, start stirring, and start to add concentrated sulfuric acid dropwise; the sulfuric acid is added dropwise for 0.9 hours, and then react at a...

Embodiment 3

[0037](1) Put solid industrial naphthalene into the naphthalene melting kettle, and enter high-temperature steam (above 100° C.) from the steam inlet into the heating channel of the naphthalene melting kettle. When the temperature in the naphthalene melting kettle reaches 80° C., the industrial naphthalene starts Melting; when the industrial naphthalene is completely melted, it is transported from the material outlet to the sulfonation reactor through a gear pump.

[0038] (2) Import high-temperature heat-conducting oil with a temperature of 140°C into the jacket of the sulfonation reaction kettle from the heat-conduction oil inlet, heat the sulfonation reaction kettle, and simultaneously weigh it according to the weight ratio of industrial naphthalene:concentrated sulfuric acid of 1.05 For 98% concentrated sulfuric acid, heat up to 135°C, start stirring, and start to add concentrated sulfuric acid dropwise; the sulfuric acid is added dropwise for 0.5h, and then the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com