Patents

Literature

66results about How to "Accurate flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

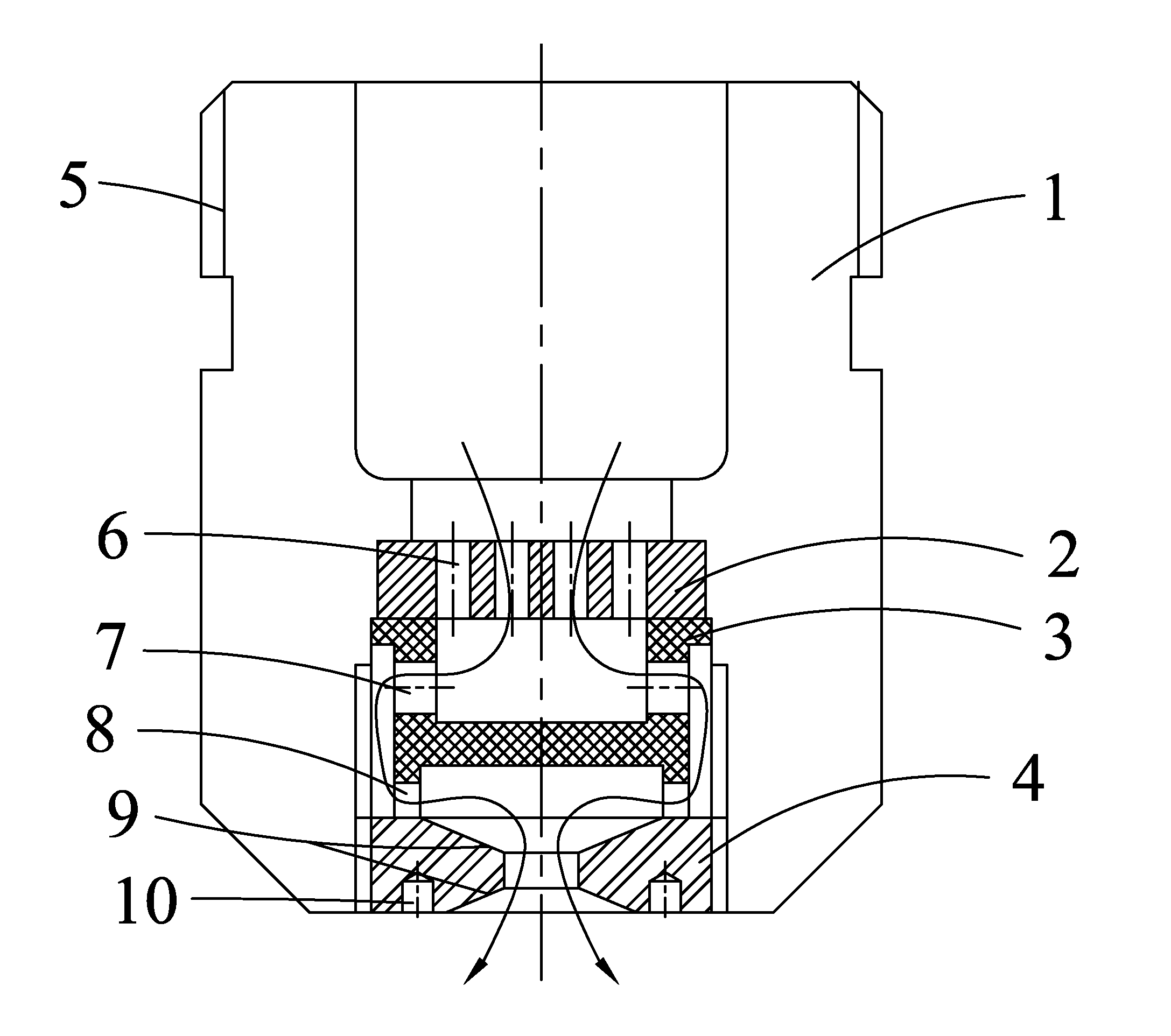

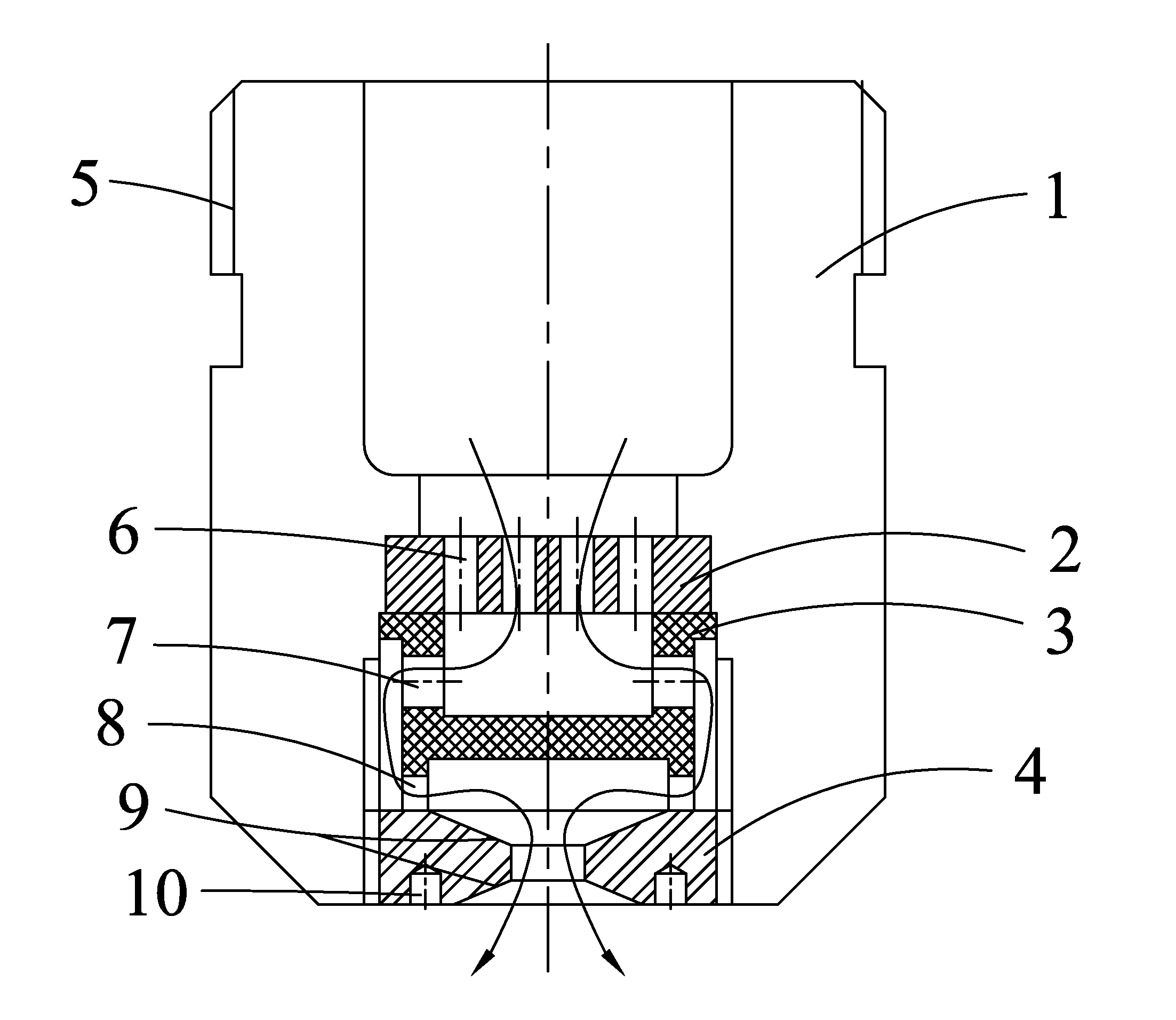

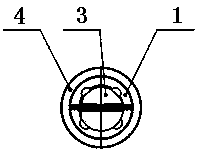

Multistage decompression and micro flow atomizing nozzle

InactiveUS20160375449A1Extended service lifeAccurate flowSpray nozzlesVena contracta diameterOrifice plate

An atomizing nozzle including a nozzle body, a flow orifice plate, a multi-stage decompression sleeve and a dual-conical surface nozzle head. One end of the nozzle body opposite to the dual-conical surface nozzle head is provided with an external thread; one end of the nozzle body close to the dual-conical surface nozzle head is provided with an internal hole and an internal thread. The external thread of the nozzle body is connected to external equipment. The flow orifice plate, the multi-stage decompression sleeve and the dual-conical surface nozzle head are arranged in the internal hole. The flow orifice plate is arranged on one end of the dual-conical surface nozzle close to the external thread of the nozzle body. The multi-stage decompression sleeve is arranged on the flow orifice plate.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

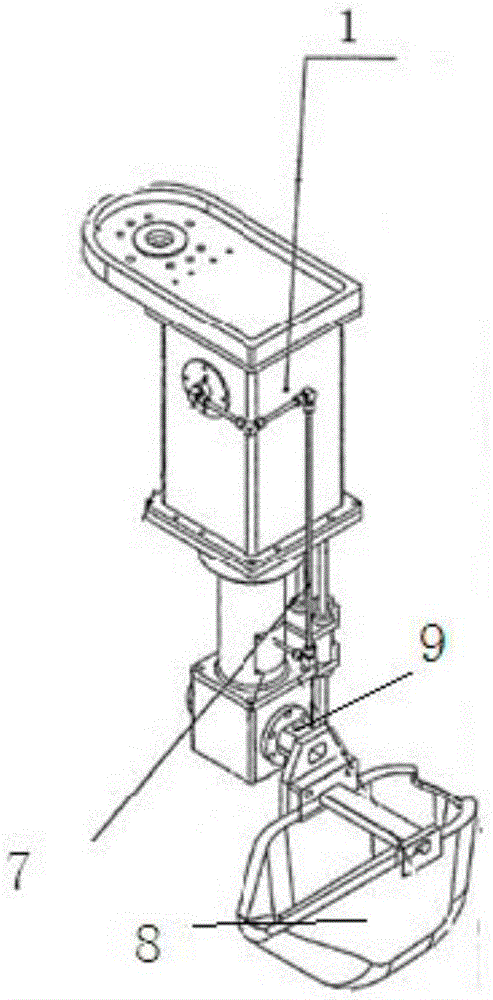

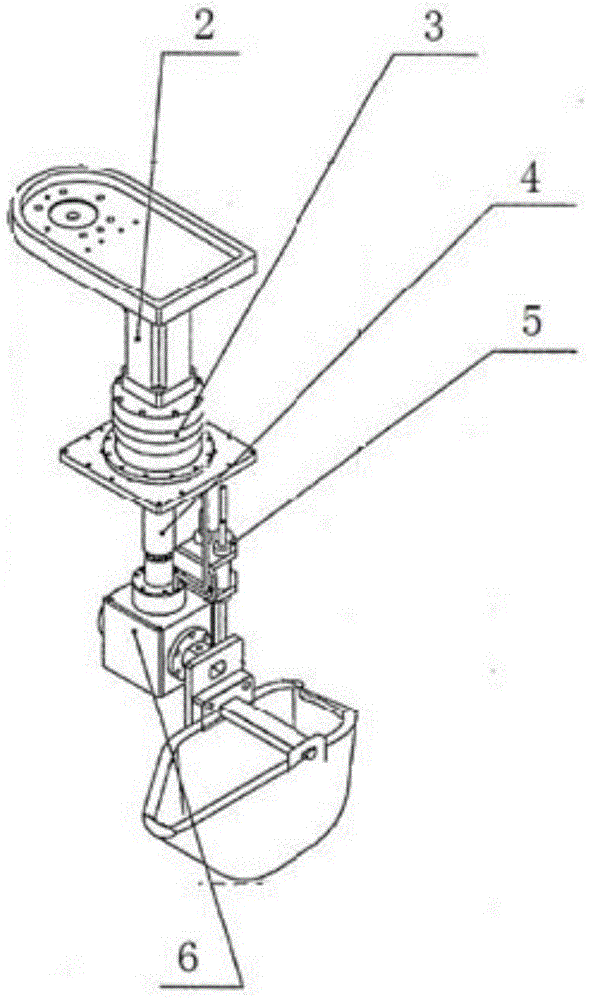

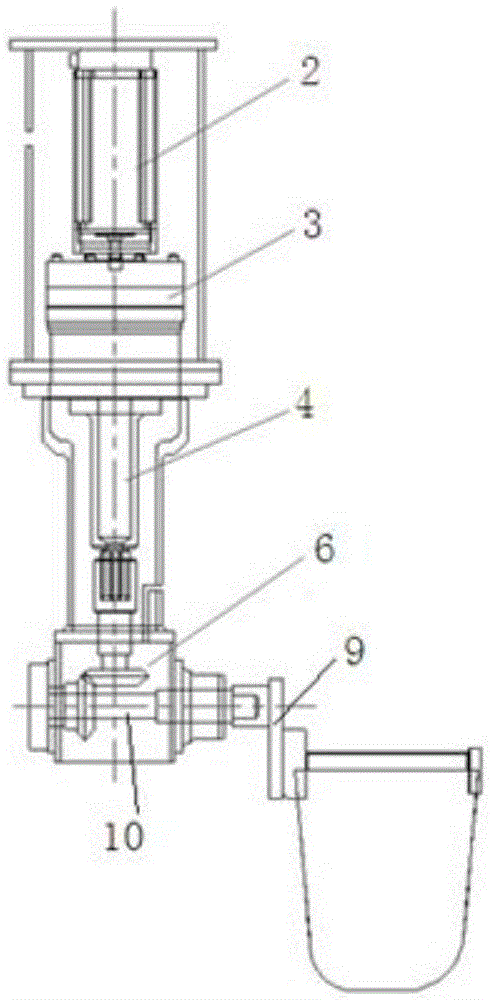

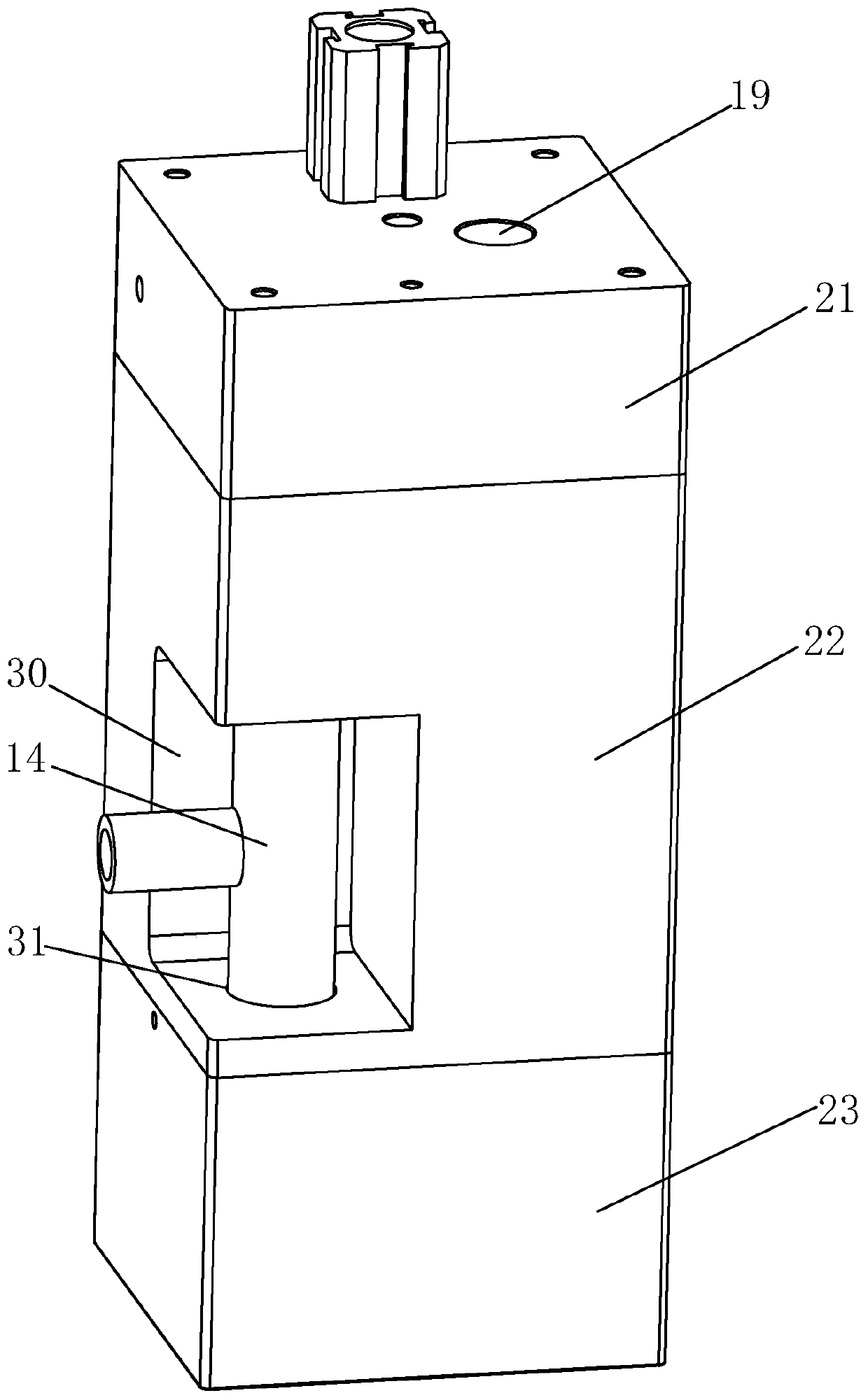

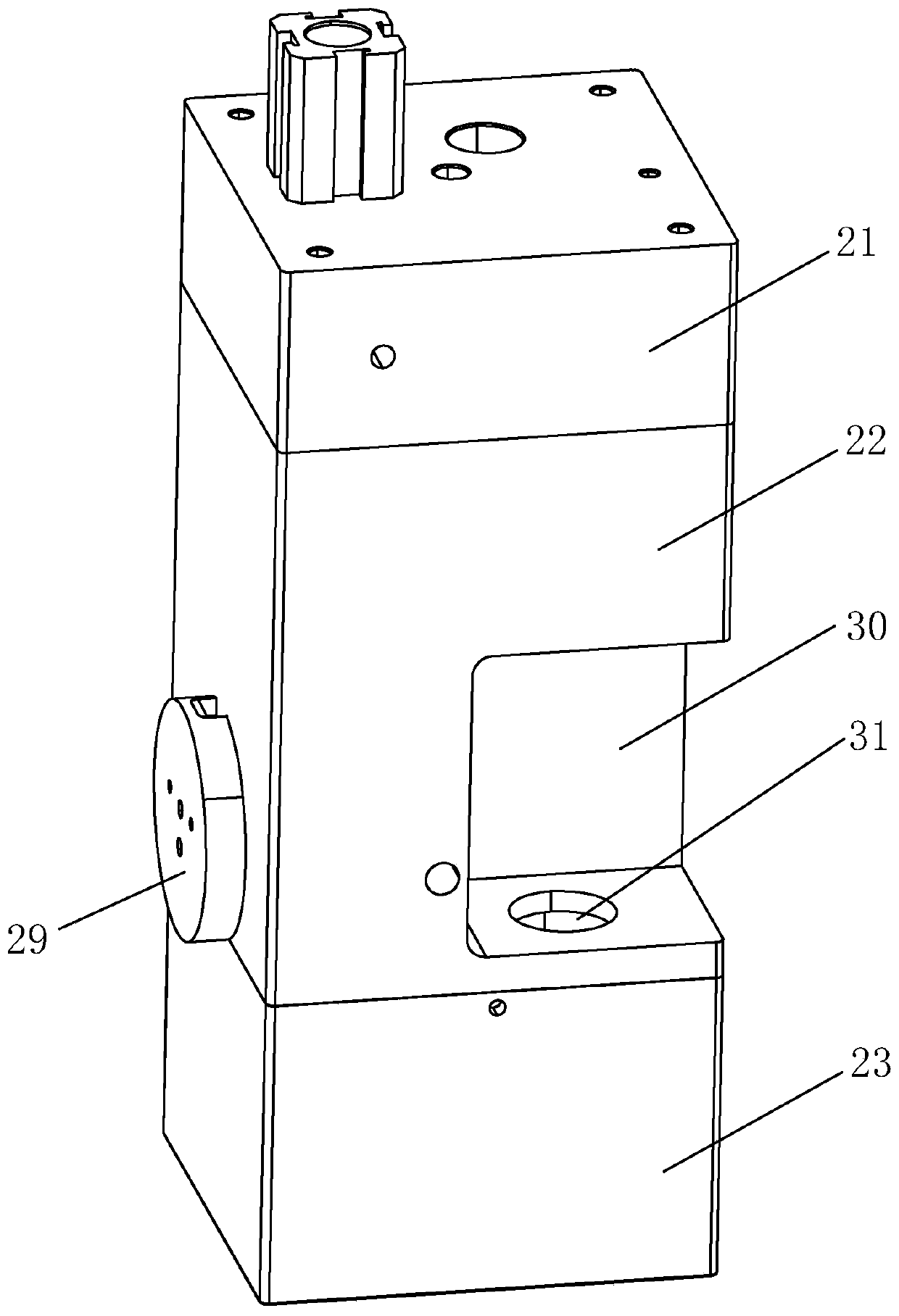

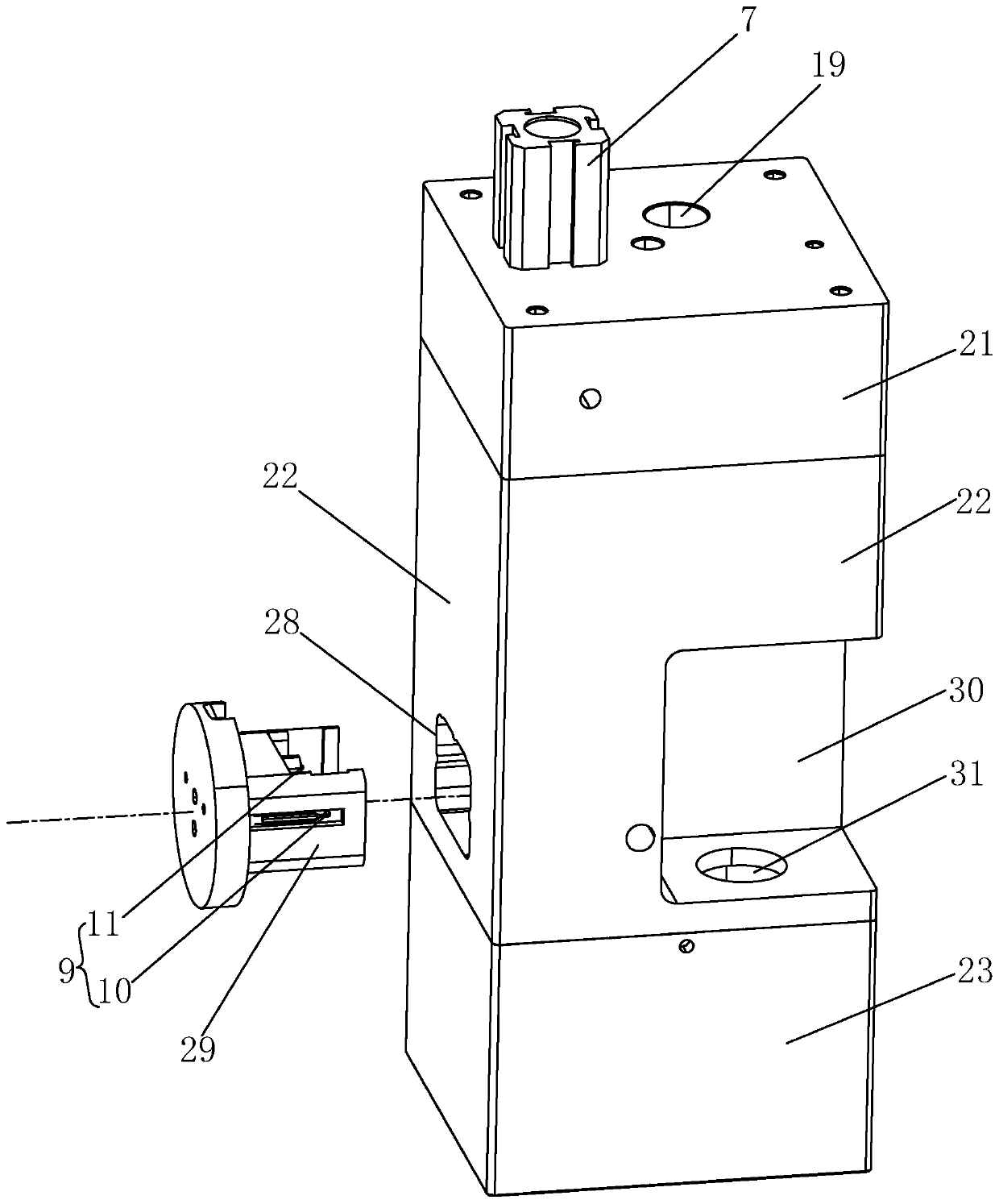

Pouring device

InactiveCN105537572AImprove stabilityHigh precisionMolten metal supplying equipmentsGear wheelDrive motor

The invention relates to a pouring device, in particular to a pouring device controlled by a robot. The pouring device comprises a rack which is internally provided with a driving motor, a speed reducer, a transmission shaft and an input shaft in sequence from top to bottom. One end of the input shaft is provided with a pouring ladle. The transmission shaft is connected with the input shaft through a conical gear transmission structure. After kinetic energy provided by the driving motor is subjected to speed reduction through the speed reducer, the transmission shaft is driven to rotate, and the input shaft is driven by the conical gear transmission structure to rotate so that the pouring ladle can be driven to rotate and the pouring technology can be performed. A first conical gear and a second conical gear with the transmission ratio being 1:1 can be kept rotating at the same speed, and therefore the molten aluminum ladling action can be stably achieved; due to cooperation of a liquid level detection probe and a limiting detection probe, molten aluminum ladling precision is higher. Because molten aluminum is very high in temperature during casting, a compressed air cooling pipeline and a draught fan are used for continuously cooling the molten aluminum pouring device, radiated heat is reduced, and the pouring device is suitable for high-temperature occasions.

Owner:SHANGHAI FANUC ROBOTICS

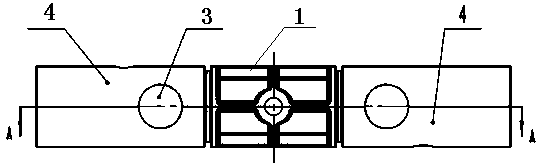

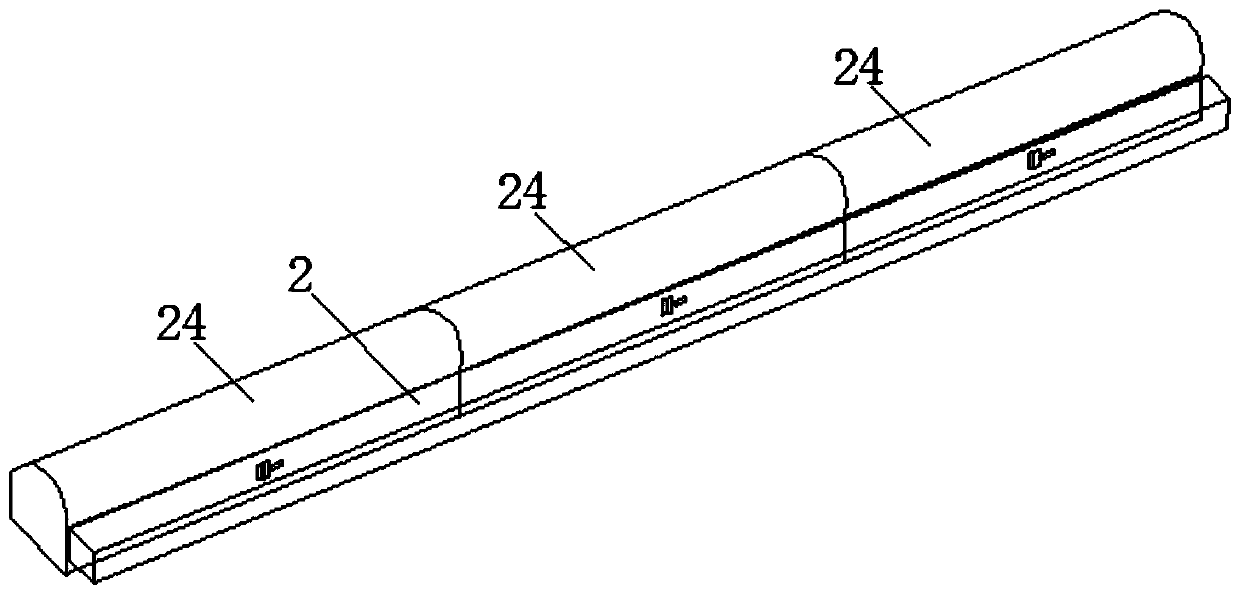

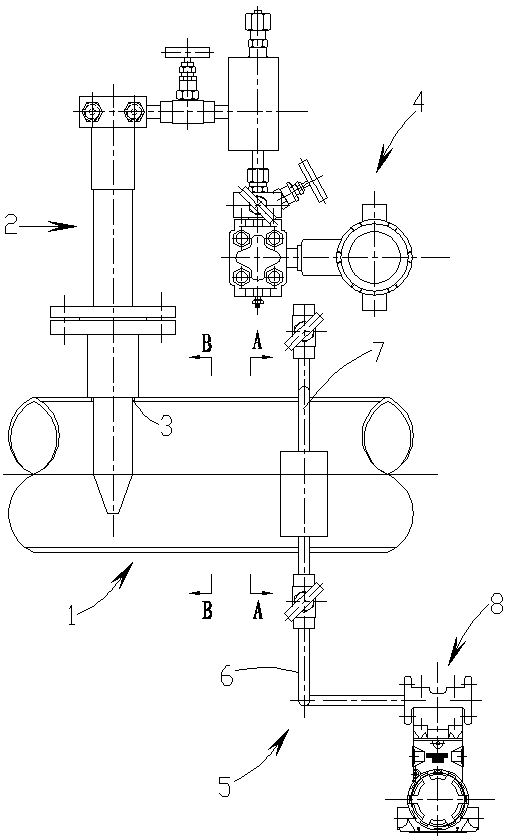

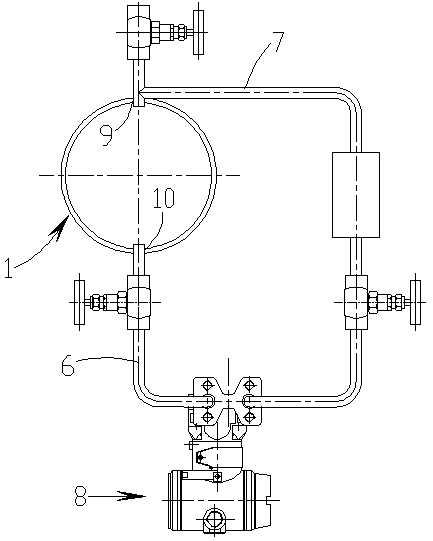

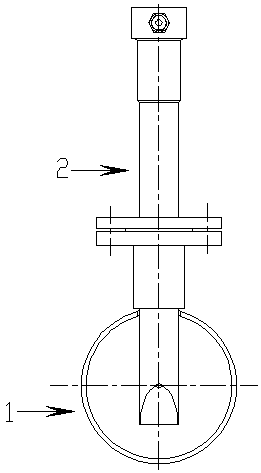

Bullet type flow stabilizer

ActiveCN103983312AHigh precisionAccurate measurementVolume/mass flow measurementWater flowEngineering

The invention discloses a bullet type flow stabilizer which is provided with a flow stabilizing pipe body, a reflecting mirror frame, a reflecting mirror and a reflecting cavity pipe body. The bullet type flow stabilizer is characterized in that a bullet-shaped flow stabilizing body is arranged on the other face of the reflecting mirror frame, the bottom end of the bullet-shaped flow stabilizing body is an oblique face, the bullet-shaped flow stabilizing body is fixedly connected with the other face of the reflecting mirror frame through the oblique face, so that the backs of bullet heads of the bullet-shaped flow stabilizing body are against the flow stabilizing pipe body respectively, the center line of the bullet-shaped flow stabilizing body and the center line of the flow stabilizing pipe body are matched, vibration of an ultrasonic wave reflecting face caused by water flow impacting is greatly lowered, meanwhile, fluid pulsation magnitude is lowered, fluctuant fluid forms relatively-stable fluid in the flow stabilizing pipe through the bullet-shaped flow stabilizing body, namely a Reynolds number Re is lowered to be close to 2300, at the time, ultrasonic wave energy is transmitted in fluid with a relatively-stable speed mean value and is not interfered by external changing factors, and accordingly fluid flow speed can be measured accurately.

Owner:WEIHAI PLOUMETER

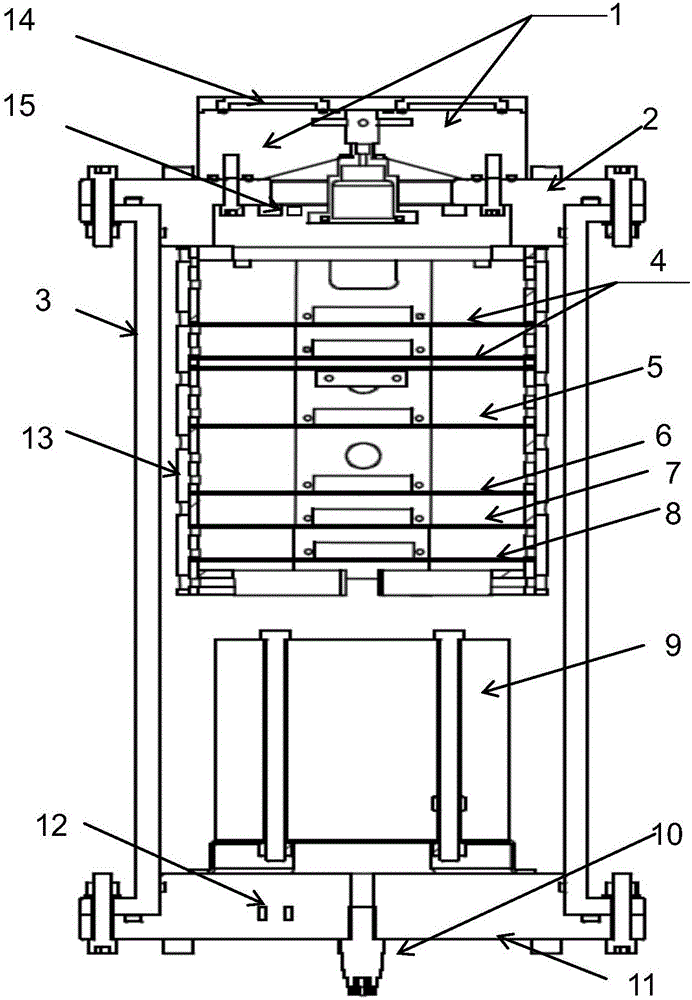

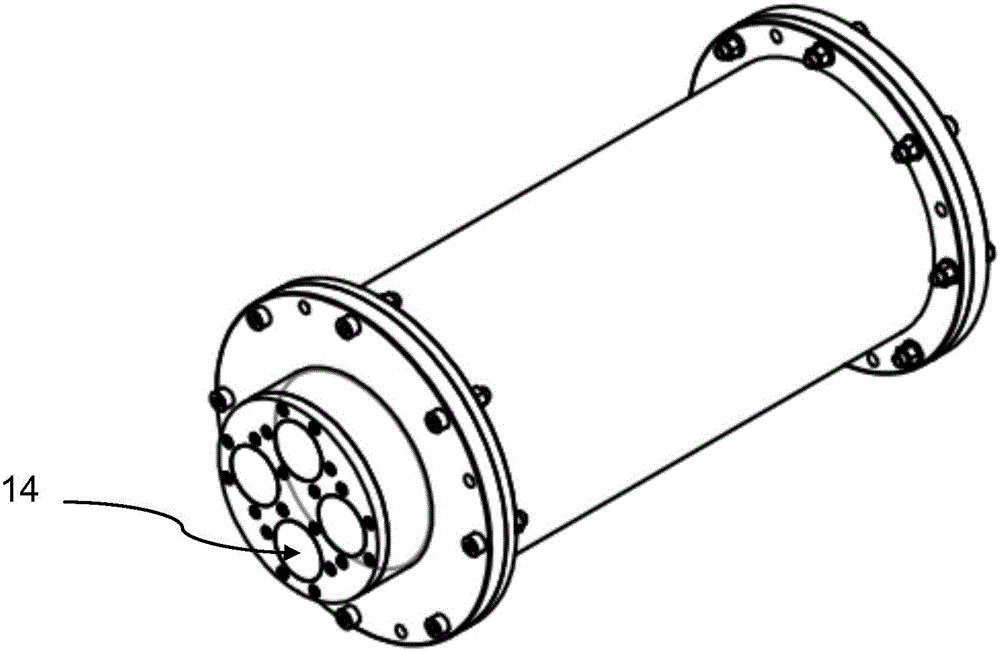

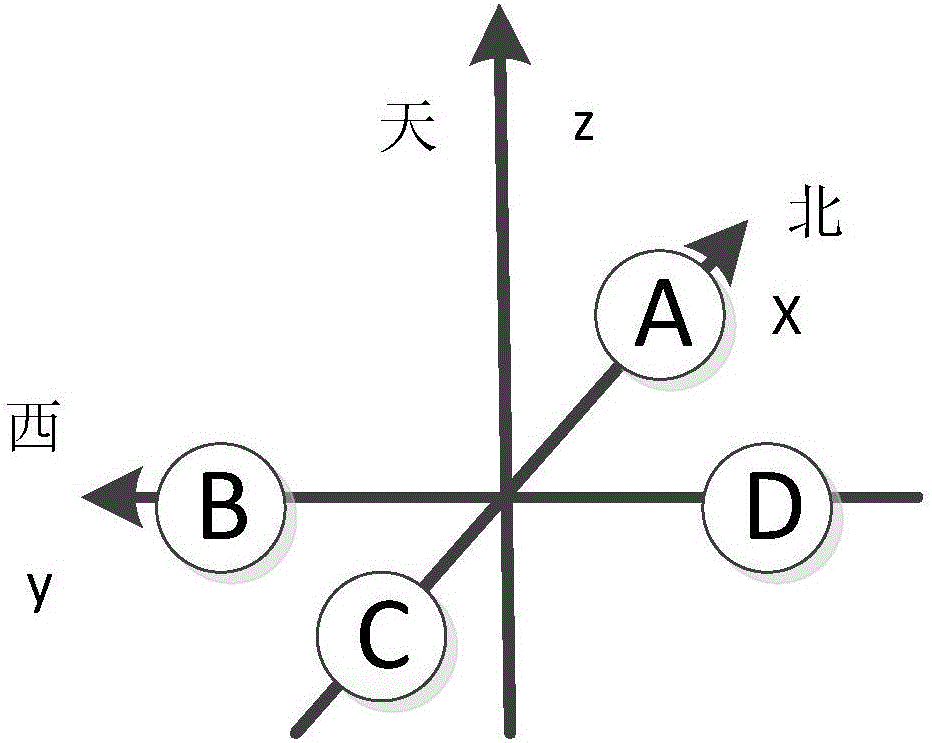

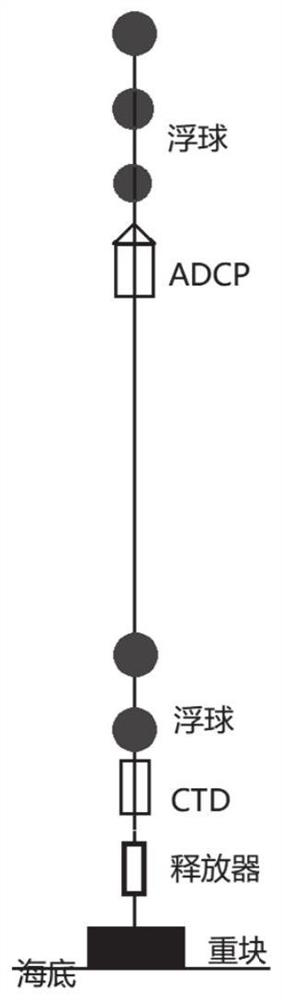

Current surveying method by means of acoustic Doppler current meter

InactiveCN105842477AAccurate measurementAccurate flow rateFull-field flow measurementCurrent velocityCurrent meter

The invention relates to the technical field of oceanographic observation and especially relates to a current surveying method by means of an acoustic Doppler current meter. The method comprises following steps: the current meter calculates the beam bottom depth and the beam bottom speed according to four beam echo signals obtained by a transducer in combination with the current meter set parameter information, gestures, temperature, pressure information and sound velocity information; generates a three-dimensional vector speed and then performs coordinate transformation; smoothes and filters current surveying data and finally outputs current surveying results. According to the method, acoustic Doppler frequency shift principles are adopted for measuring current velocity; ocean dynamic environment parameters and current data can be observed for a long time by deploying acoustic Doppler current meters in submerged buoy systems to obtain ocean dynamic environment parameters such as temperature, pressure, current velocity and flow direction in the deploying sea areas; the acoustic Doppler current meter has a direct reading work mode and a self-contained work mode, and has high current surveying accuracy and flexible operation.

Owner:OCEAN UNIV OF CHINA

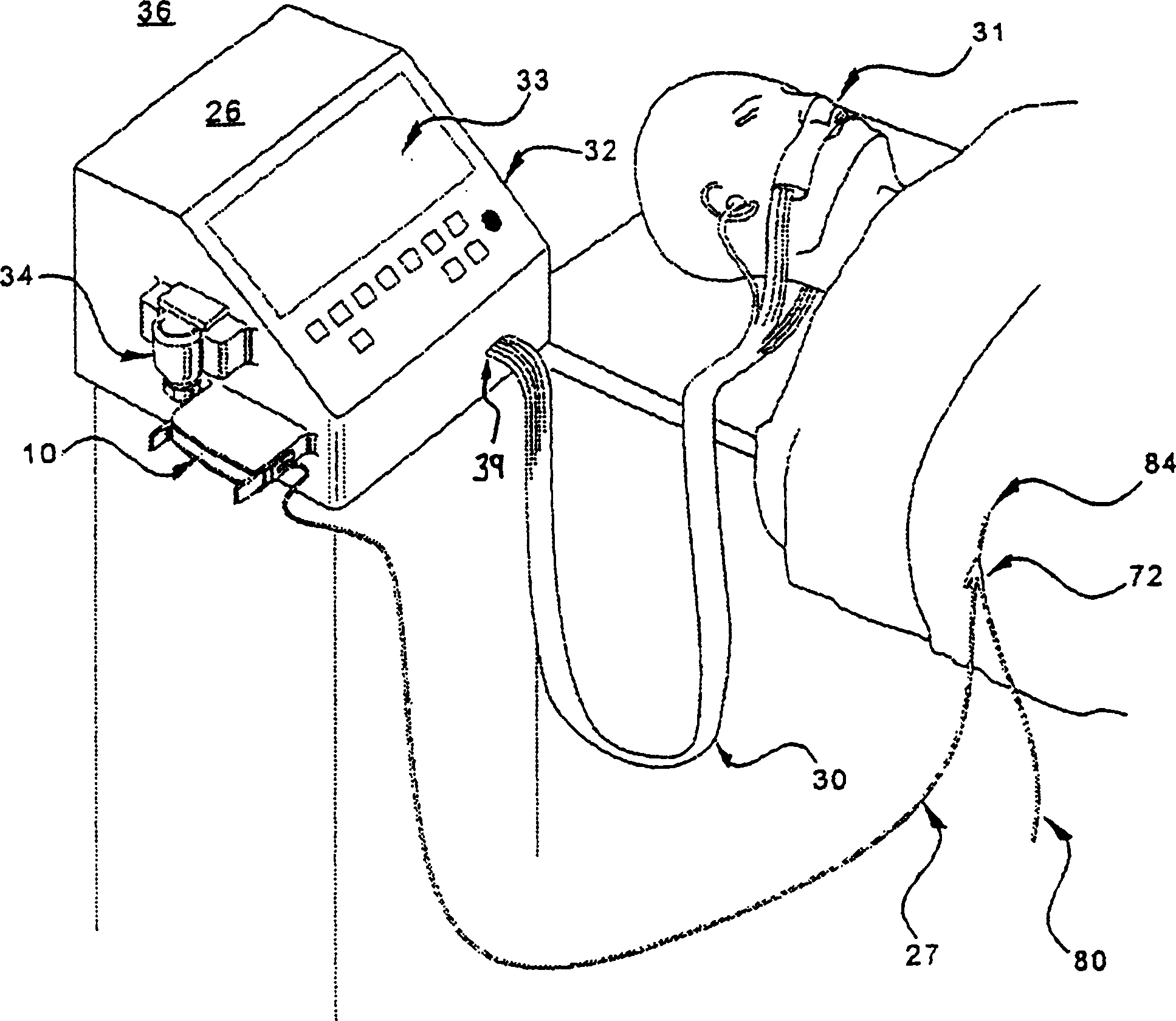

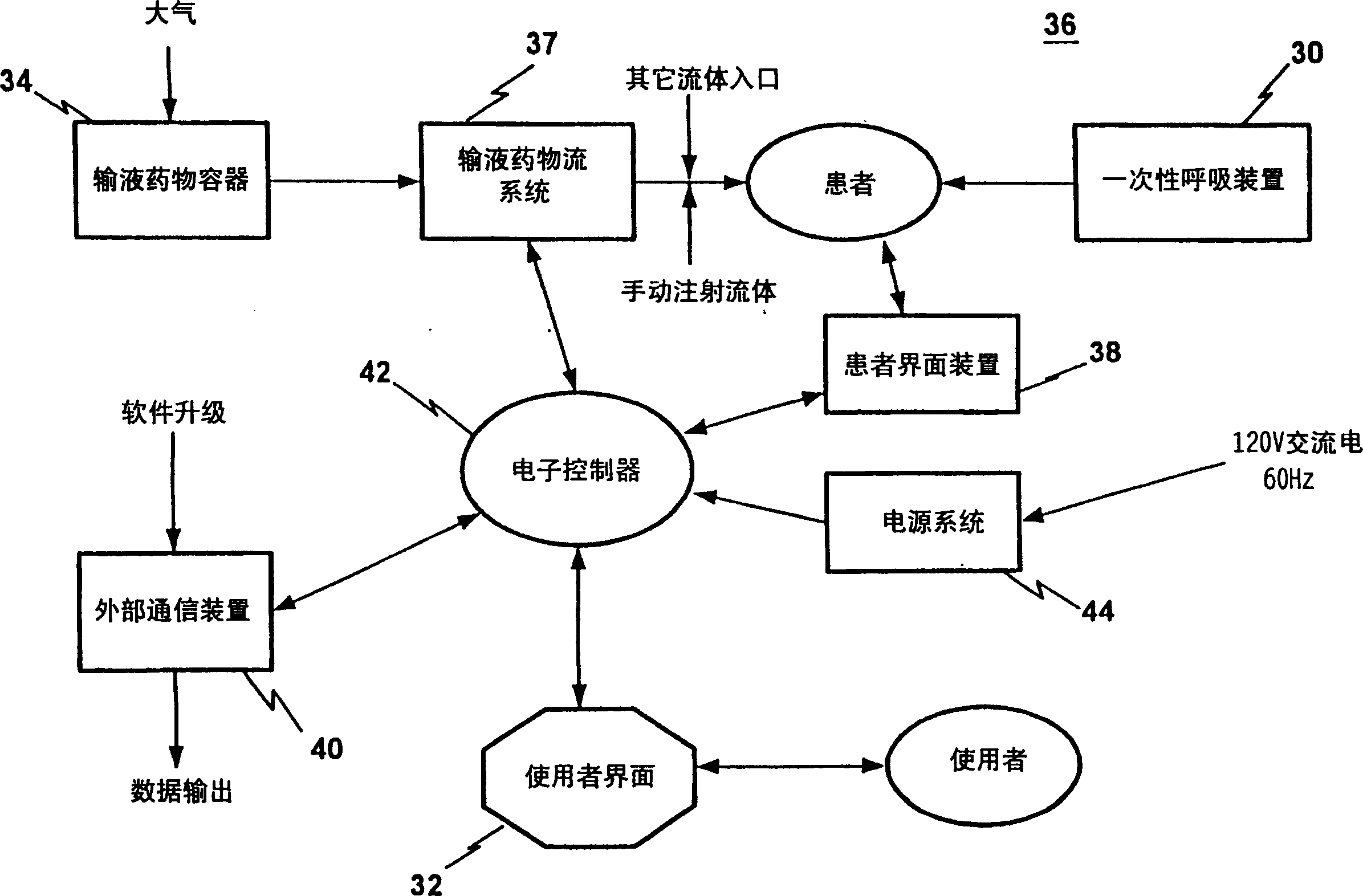

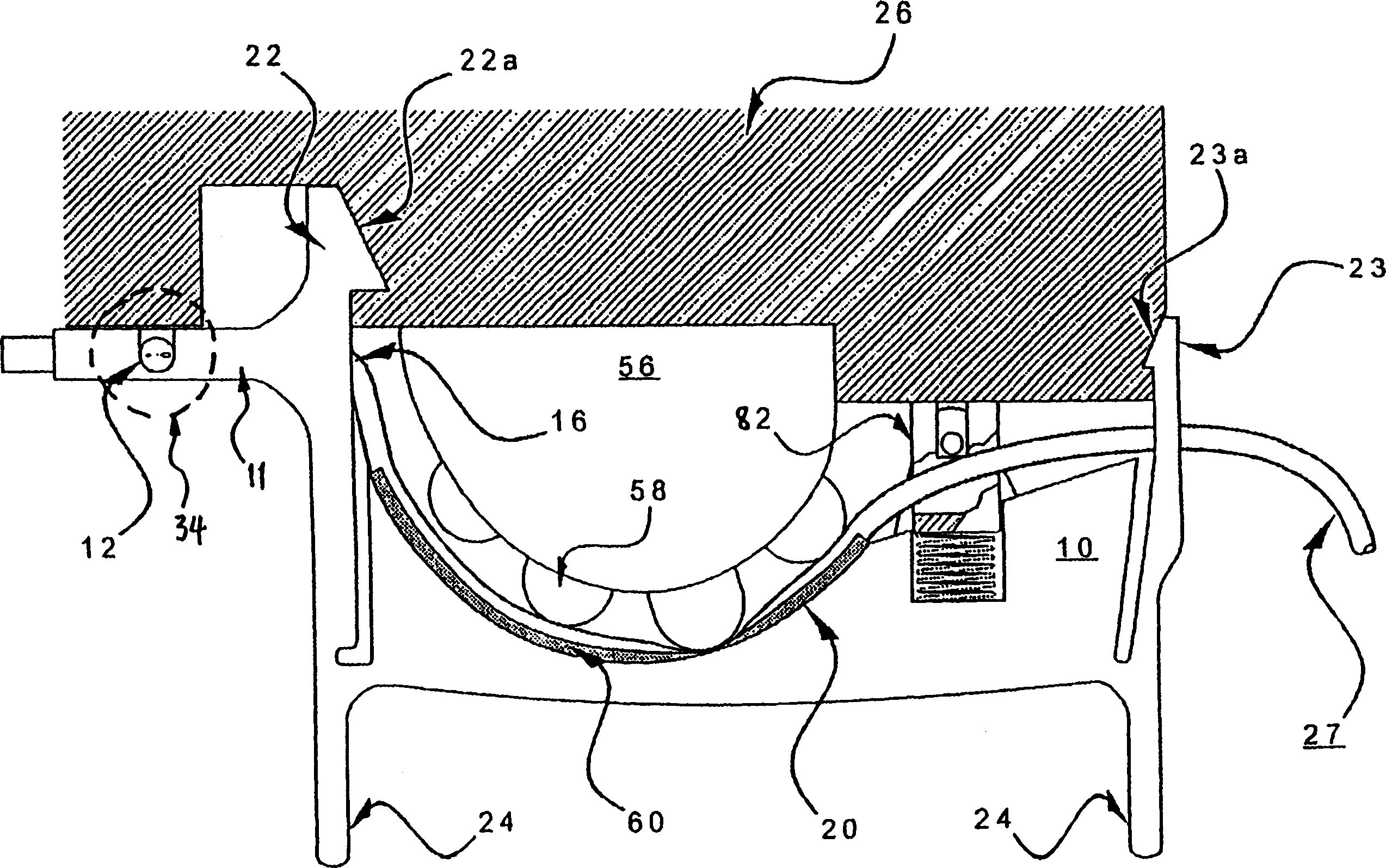

Apparatuses and methods for providing IV infusion administration

InactiveCN1561237APrevent removalAvoid teleportationDrug and medicationsMedical devicesQuality assuranceIV Infusion

An infusate cassette is described for use with an IV infusion system which controls the process of administering a drug to a patient. The cassette and other aspects of the infusion system may include disposable components, external redundant volume tracking, air removal and automated purge and prime capabilities, component removal lockout mechanisms, and / or redundant automated anti-free flow devices. An IV manifold comprising an imbedded high cracking pressure anti-free flow valve is also described for use with the infusion system. The cassette, IV manifold, and other aspects of the infusion system may be provided with quality assurance mechanisms for use with integrated IV infusion.

Owner:SCOTT LAB

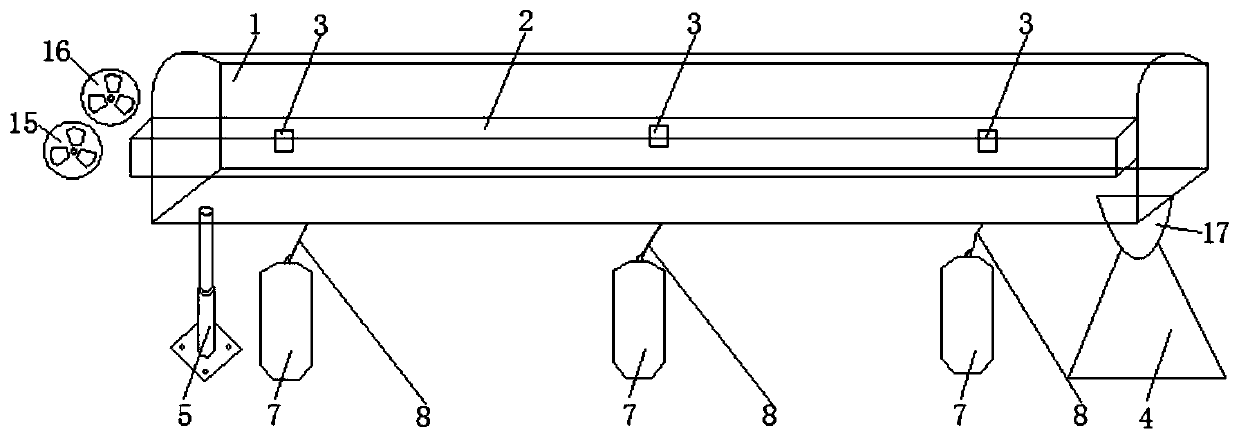

Multifunctional tunnel fire side key smoke discharge simulation platform

PendingCN110459116AGood smoke exhaust effectImprove smoke exhaust effectEducational modelsCombustionEngineering

The invention relates to a multifunctional tunnel fire side key smoke discharge simulation platform comprising a tunnel main body, a smoke discharge channel, a fire source simulation device, an air supply device and a fire detection device; one end of the tunnel main body can move up and down, at least one opening is formed in the bottom of the tunnel main body, and the fire source simulation device is arranged at the opening and is used for simulating a fire; the two ends of the smoke discharge channel are both open, one side of the smoke discharge channel is open, the other side of the smokedischarge channel is closed, the open side of the smoke discharge channel is fixedly installed on one side of the tunnel main body, and a plurality of smoke outlets in communication with the smoke discharge channel are uniformly formed in one side of the tunnel main body at intervals; the air supply device is arranged at one end of the tunnel body and is used for supplying air to the tunnel body,and the fire detection device is arranged in the tunnel main body and is used for detecting the fire situation in the tunnel main body. The simulation platform in the invention has the beneficial effects that the situation of fire combustion in the tunnel main body under different conditions is simulated, the distribution condition of the smoke gas and the fire law in the tunnel main body are observed, and a theoretical experimental basis is provided for construction of actual tunnels.

Owner:WUHAN UNIV OF SCI & TECH

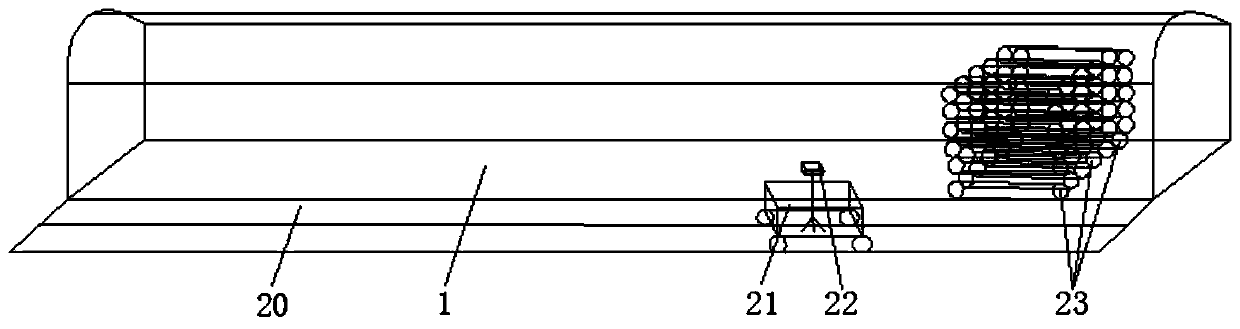

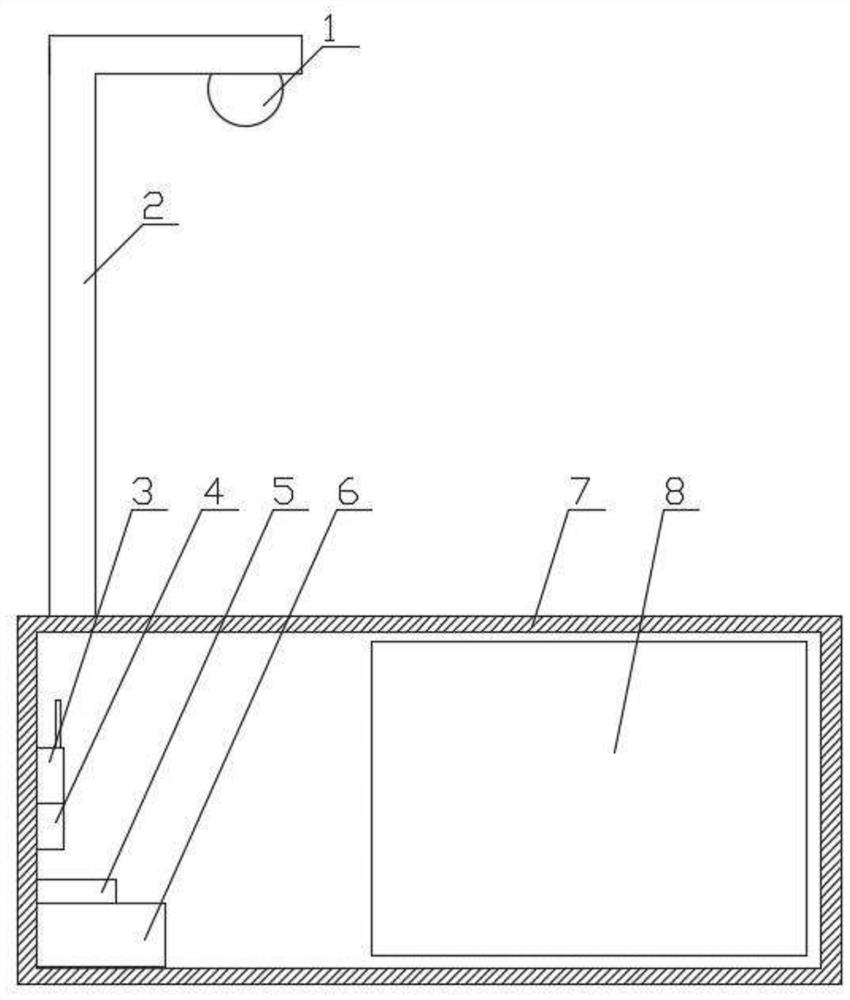

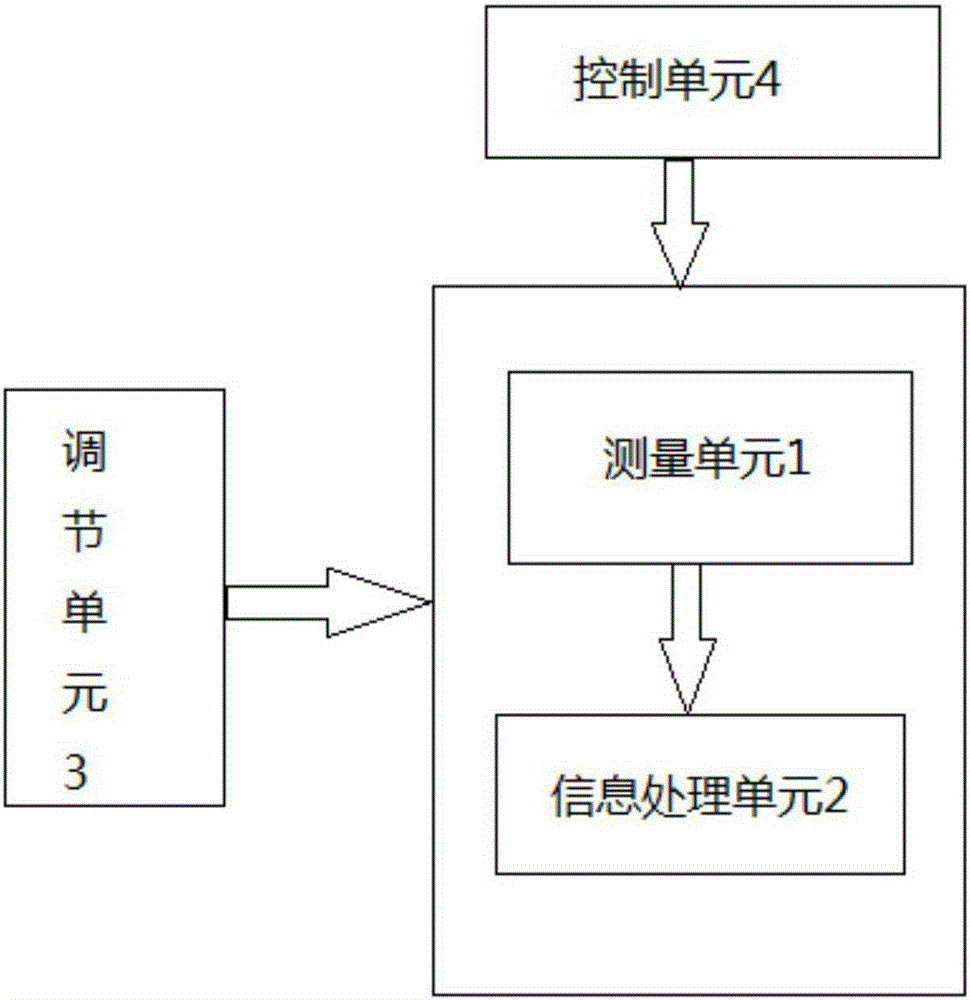

Riverway flow velocity video monitoring device and method based on deep learning

ActiveCN112147365AAccurate flow rateAccurate flowClosed circuit television systemsFluid speed measurementVideo monitoringCommunication unit

The invention provides a riverway flow velocity video monitoring device based on deep learning. The riverway flow velocity video monitoring device comprises a monitoring terminal and a monitoring center. The monitoring terminal comprises an equipment box body, a support rod is arranged above the equipment box body, a monitoring unit is arranged at the upper end of the support rod, and a control unit, a power supply unit and a communication unit are arranged in the equipment box body; a beacon supplementing unit is also arranged in the equipment box body; the control unit is connected with themonitoring unit, the communication unit and the beacon supplementing unit, and the control unit is connected with a monitoring center through the communication unit; and the monitoring unit comprisesa monitoring camera arranged at the upper end of the support rod. The invention further provides a riverway flow velocity video monitoring method based on deep learning. By means of the riverway flowvelocity video monitoring device and method, normal work can be done at night and in heavy rain and heavy fog weather, work can be continuously done for a certain time under the condition that mains supply is interrupted, the accidental risk resistance is high, returned data can be compared with historical data in previous years, and a reference role is played for dispatchers.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

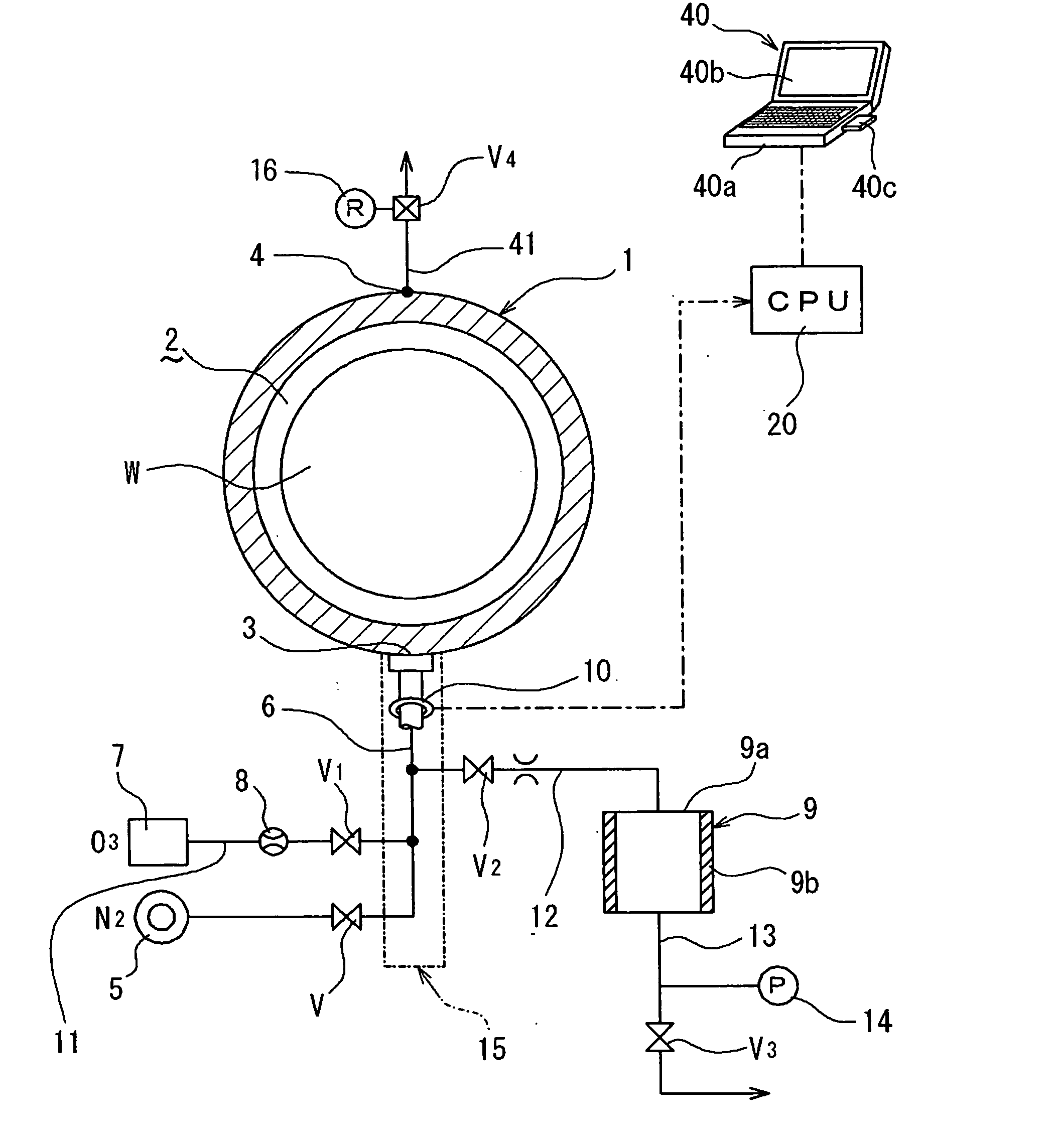

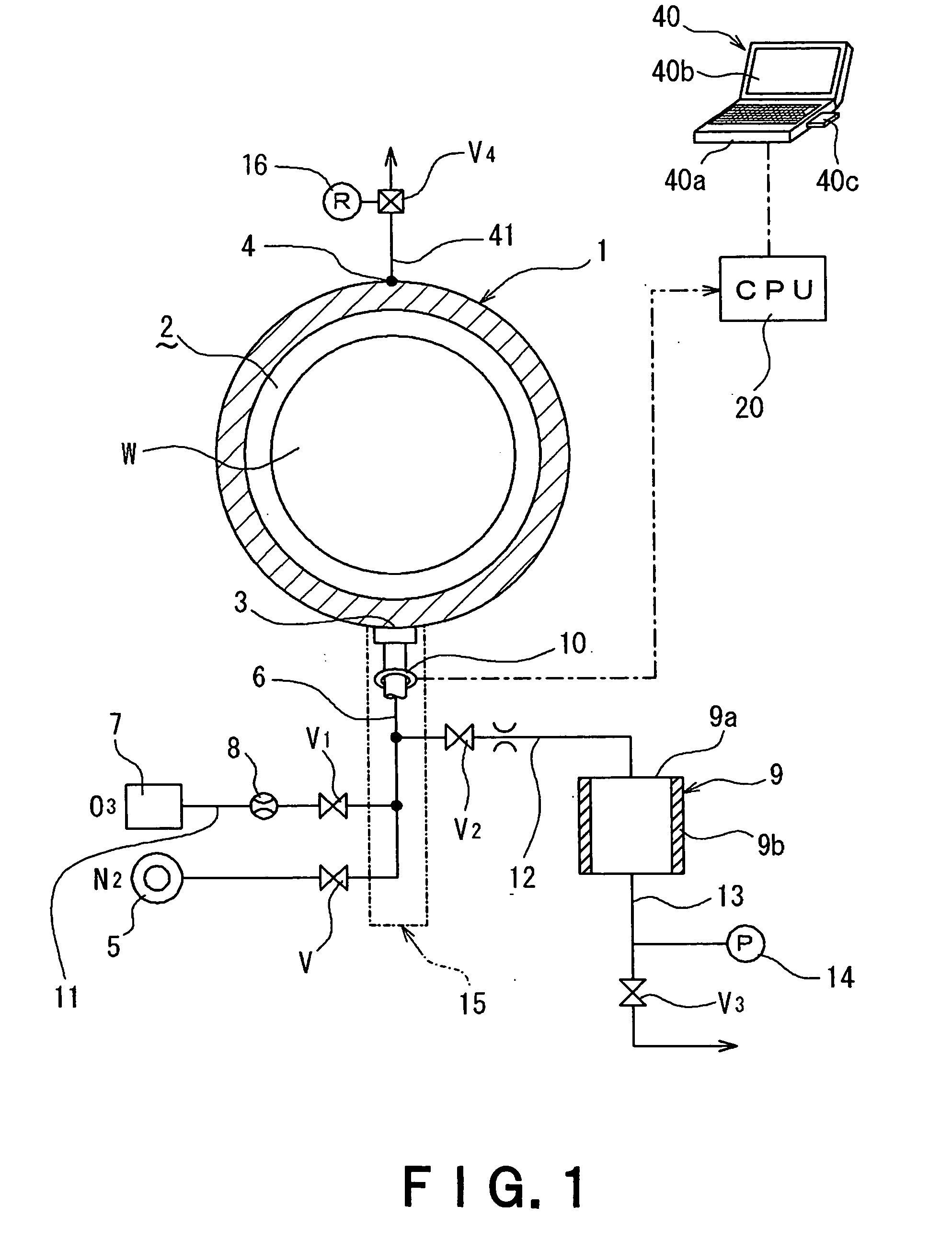

Processing-fluid flow measuring method

InactiveUS20070181147A1Accurate flow rateAccurately determinedVolume/mass flow by thermal effectsSemiconductor/solid-state device manufacturingProcess engineeringStream flow

An object to be processed such as a semiconductor wafer is processed by supplying a process fluid such as an ozone gas and a water vapor into a process vessel from a supply source through a supply pipe. During the process, a temperature of the process fluid flowing through the supply pipe is detected. By previously measuring and recording a relationship between a temperature of the process fluid and a flow rate of the process fluid, for example, a flow rate of the process fluid can be determined based on the detected temperature of the process fluid.

Owner:TOKYO ELECTRON LTD

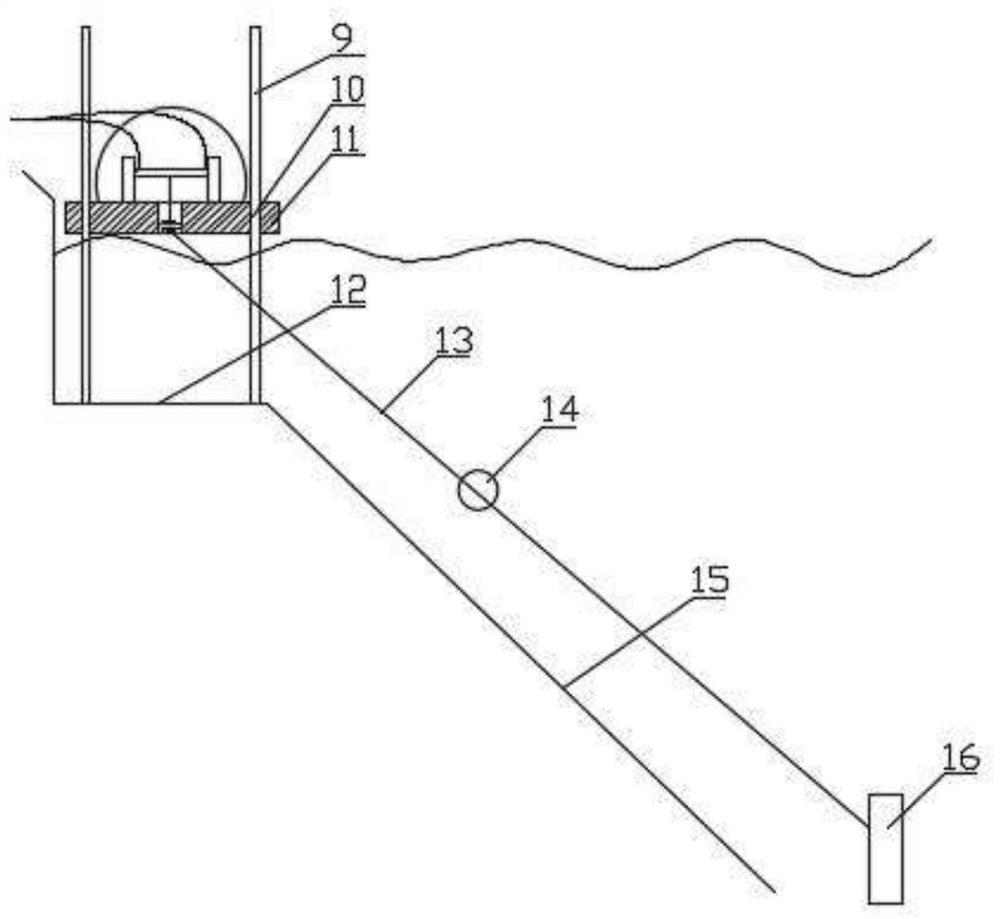

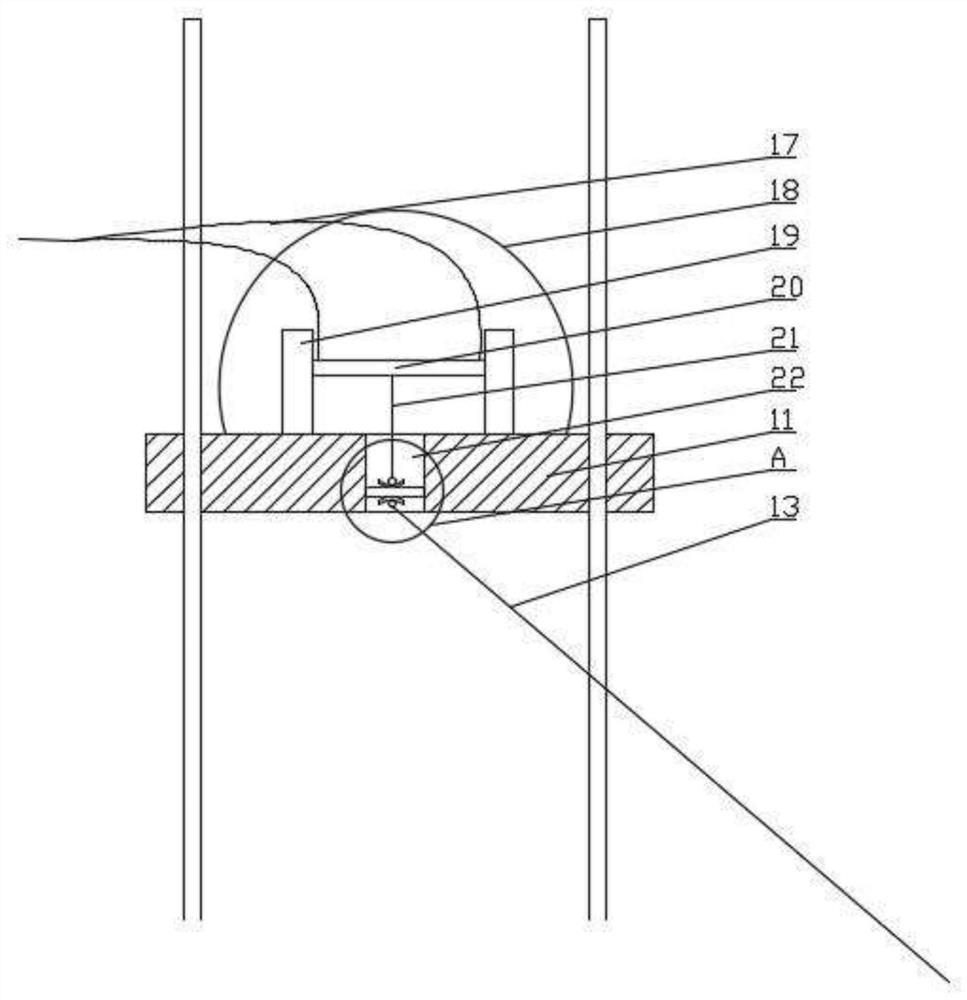

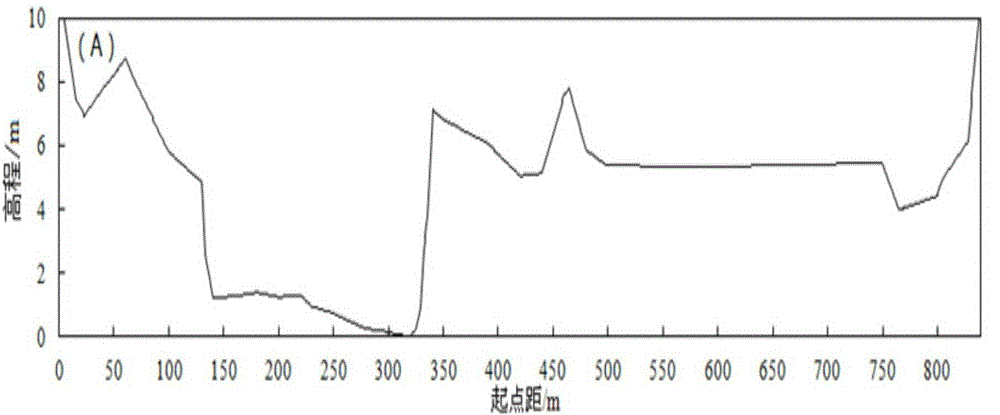

Method for testing river discharge by combination of hydraulic model and river surface flow rate measured based on videos

ActiveCN109827554AAccurate calculationEasy to useOpen water surveyClosed circuit television systemsWireless transceiverComputer science

Owner:NANJING HYDRAULIC RES INST

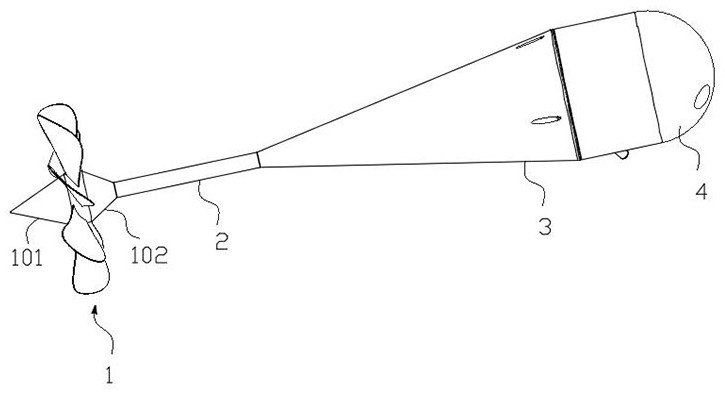

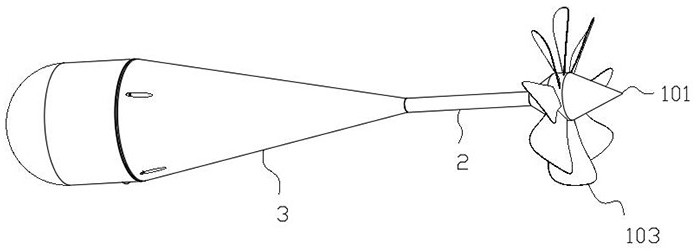

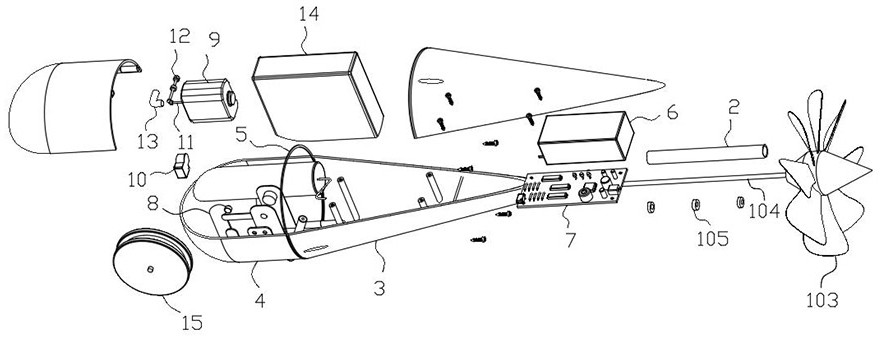

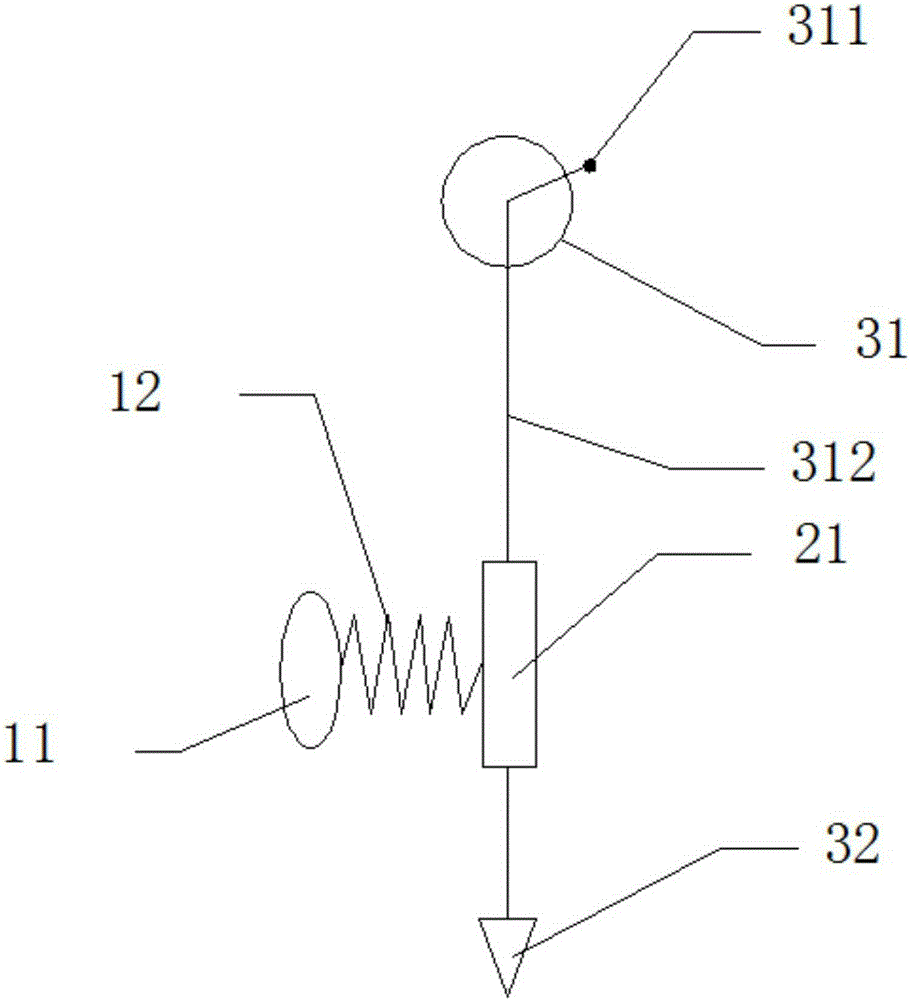

Intelligent flow velocity measuring device and river flow measuring method

ActiveCN112014589AReduce total usageAvoid protectionVolume/mass flow measurementFluid speed measurementMeasurement deviceRiver routing

The invention discloses an intelligent flow velocity measuring device, which comprises an outer shell body which is detachably and hermetically connected to form a streamline shape, wherein a propeller is driven by water flow to rotate and drive a connected power generation mechanism; the power generation mechanism is electrically connected with a circuit board used for detecting voltage generatedby the power generation mechanism, converting the voltage into flow velocity data and storing the flow velocity data; and the circuit board is further connected with a control terminal. The inventionfurther provides a river flow measuring method, which obtains low velocity distribution of the river cross section by means of the intelligent flow velocity measuring device, and calculates precise flow. According to the river flow measuring method provided by the invention, the riverbed depths at different positions can be obtained through using the intelligent flow velocity measuring device, the contour of the whole riverbed is obtained in a multi-point sampling mode, and precise flow data of the riverway is obtained by combining the depths of sampling measurement points and actual flow velocity distribution of flow velocity information on the cross section of the riverway, so that the problem of insufficient water utilization and protection caused by flow measurement distortion is avoided.

Owner:四川嘉纳环保咨询有限公司

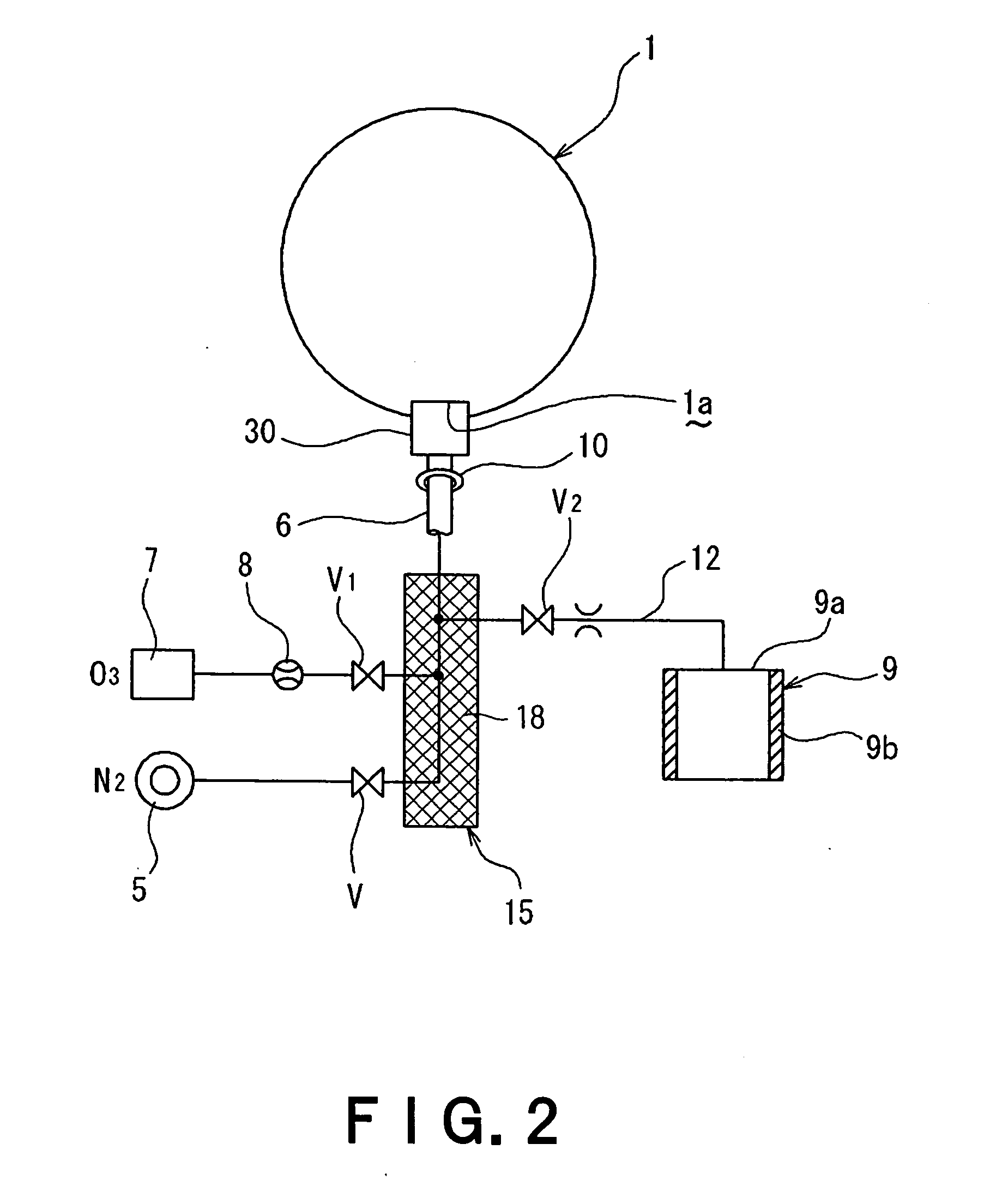

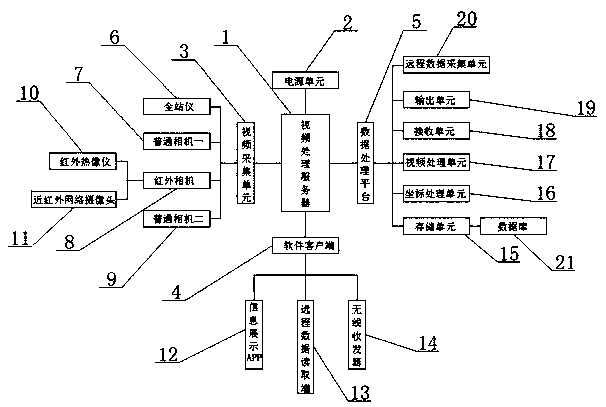

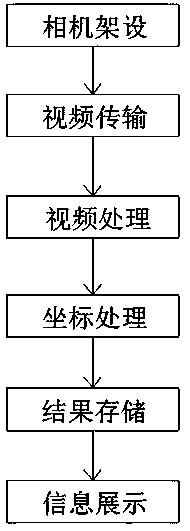

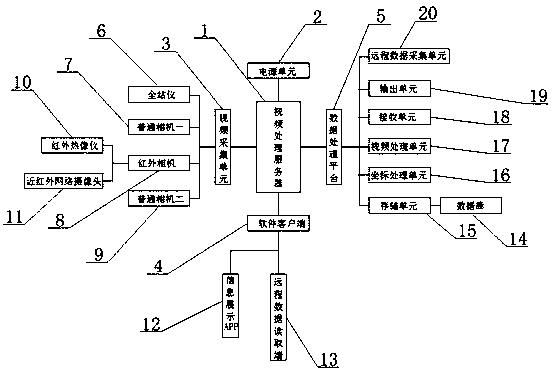

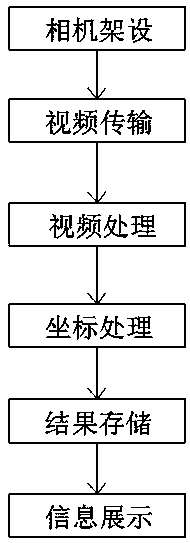

Video-based river velocity and flow test system

InactiveCN109000624AAccurate calculationEasy to useOpen water surveyClosed circuit television systemsTraffic capacityVideo processing

The invention provides a video-based river velocity and flow test system. The test system comprises an intelligent terminal; the intelligent terminal comprises a video processing server, a power supply unit, a video acquisition unit, a software client and a data processing platform; the video acquisition unit comprises a total station, a common camera I, an infrared camera and a common camera II;the infrared camera comprises an infrared thermal imager and a near-infrared camera; the software client comprises an information display APP and a remote data reading end; the data processing platform comprises a storage unit, a coordinate processing unit, a video processing unit, a receiving unit, an output unit and a remote data acquisition unit; and the storage unit comprises a database. The calculation precision and speed of the river velocity and flow test system are greatly improved; and the river velocity and flow test system has the advantages of being low in system cost and easy to arrange.

Owner:NANJING HYDRAULIC RES INST

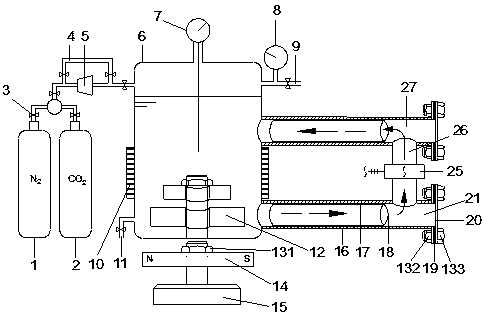

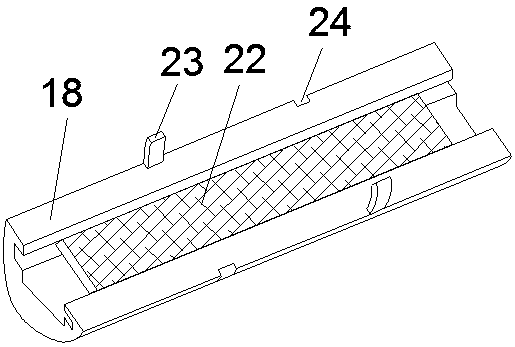

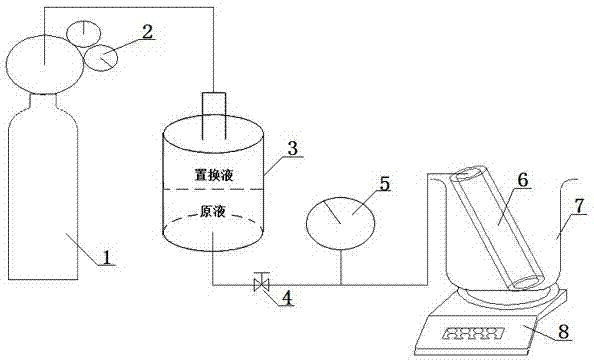

Acid-rock reaction speed and kinetic parameter measuring device

The invention relates to an acid-rock reaction speed and kinetic parameter measuring device comprising a gas cylinder, a bypass pipeline, a compressor, a reaction kettle, a heating ring, a stirring rotor, a magnetic steel, a micro motor, a core holder and a heat preservation layer. There are three types of core holder that can hold cylindrical core and plate core. According to the acid-rock reaction speed and kinetic parameter measuring device, the flow of acid liquid in reservoir and the chemical reaction between acid liquid and rock in the reservoir under different reservoir temperatures andpressure conditions can be simulated more truly. The device can be used for not only the simulation of the acid-rock reaction of single-plate core, but also the simulation of crack of double-plate core.

Owner:SOUTHWEST PETROLEUM UNIV

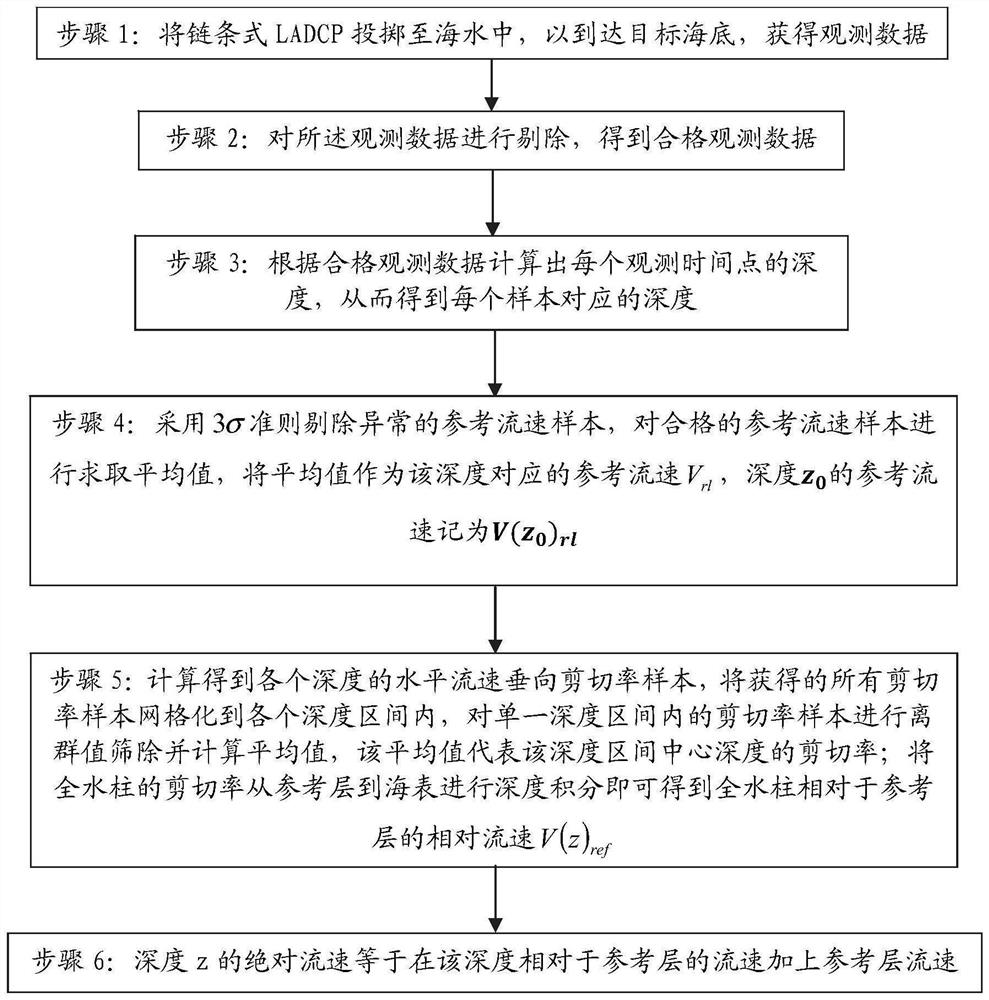

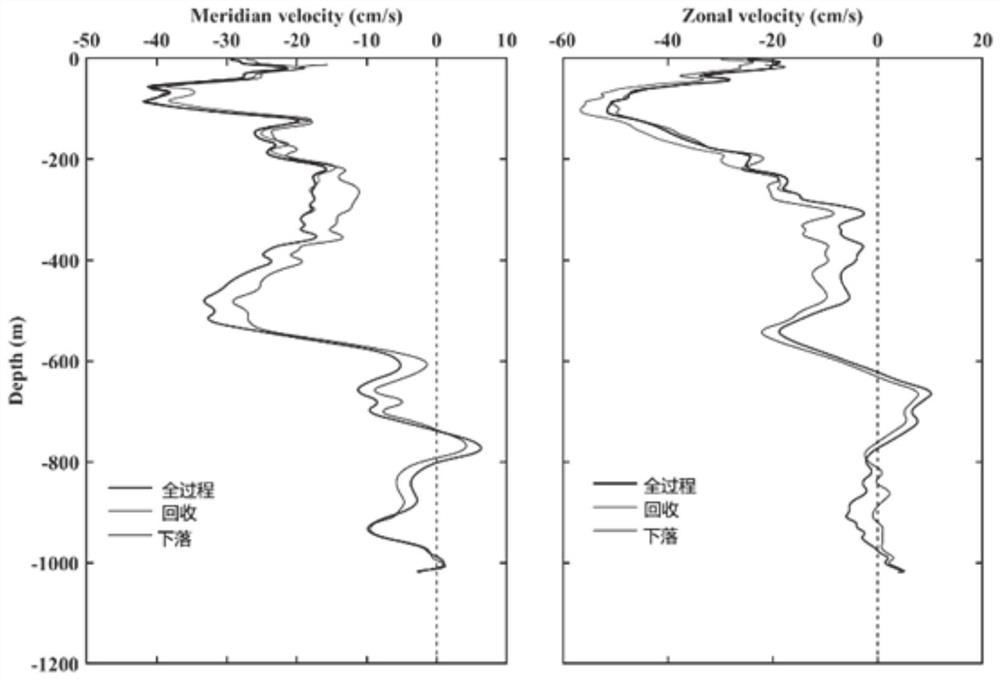

Post-processing method of disposable LADCP ocean current profile observation data

ActiveCN114488300AAccurate flow rateMany flow rate samplesOpen water surveySeismic signal processingObservation dataShear rate

The invention discloses a post-processing method for discarded LADCP ocean current profile observation data, and the method comprises the steps: throwing a chain-type LADCP into seawater, and obtaining observation data; removing the observation data to obtain qualified observation data; calculating the depth of each observation time point according to the qualified observation data so as to obtain the depth corresponding to each sample; calculating an average value of the qualified flow velocity samples, and taking the average value as a reference flow velocity corresponding to the depth; calculating to obtain the shear rate of each layer as the current layer, obtaining a plurality of shear rate samples, gridding all the obtained shear rate samples into a depth interval, and performing depth integration on the shear rate of the full water column from the reference layer to the sea surface to obtain the relative flow velocity of the full water column relative to the reference layer; the absolute flow rate at the depth z equals the flow rate at the depth relative to the reference layer plus the reference layer flow rate. The method is not influenced by ship traction, and does not depend on bottom tracking or GPS information.

Owner:SECOND INST OF OCEANOGRAPHY MNR +1

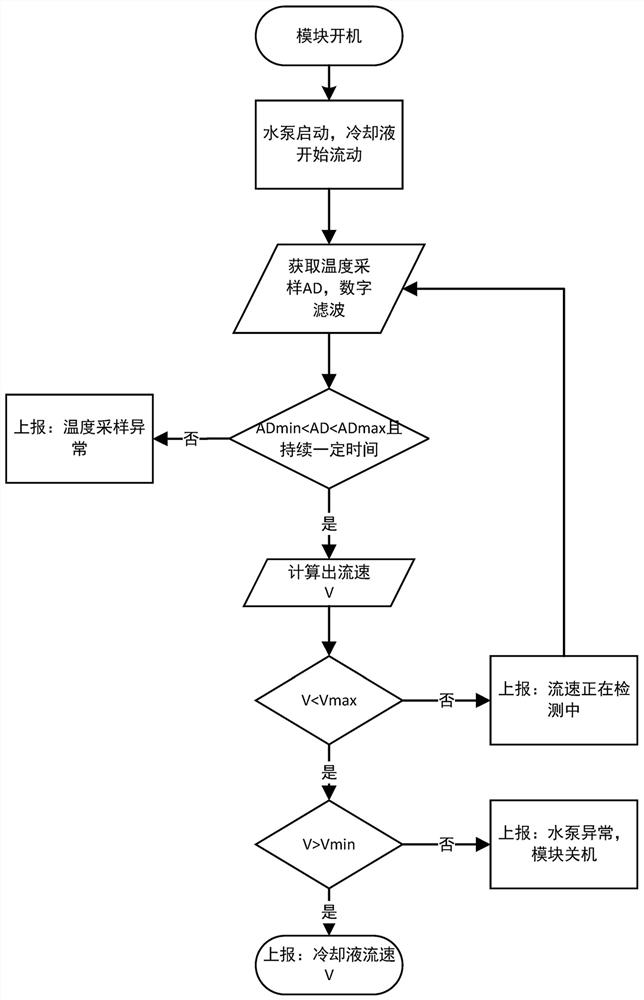

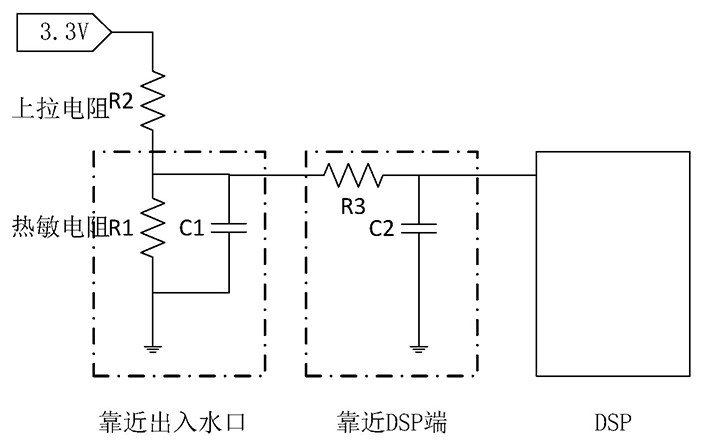

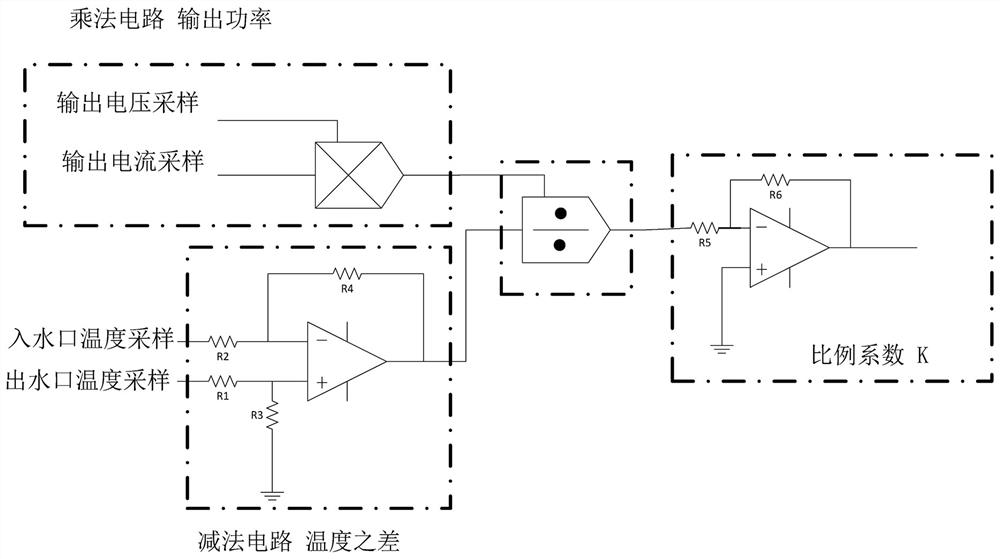

Water cooling system and method for detecting flow velocity of cooling liquid of water cooling system

PendingCN114136389AReduce volumeEliminate detectionVolume/mass flow by thermal effectsFluid speed measurement using thermal variablesThermodynamicsEngineering

The invention discloses a water cooling system and a cooling liquid flow velocity detection method thereof. The method for detecting the flow velocity of the cooling liquid of the water-cooling system comprises the following steps: building a heat conversion model between the water-cooling system and a device to be cooled according to a thermodynamic principle; according to the relationship between the flow of the cooling liquid of the water cooling system and the heat absorbed by the water cooling system, the relationship between the flow of the water cooling system and a heat conversion model is obtained; monitoring and acquiring values of parameters related to the heat conversion model in the water cooling system and the device to be cooled; substituting the values of the related parameters into the heat conversion model to obtain the flow of the water cooling system; and calculating the flow velocity of the cooling liquid according to the obtained flow. The method is easy to implement, and the flow velocity of the cooling liquid can be accurately obtained.

Owner:SHENZHEN VMAX NEW ENERGY CO LTD

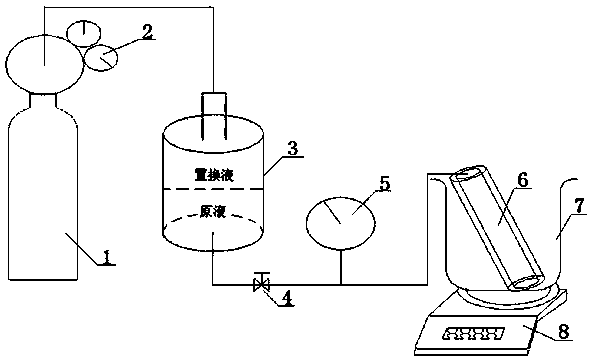

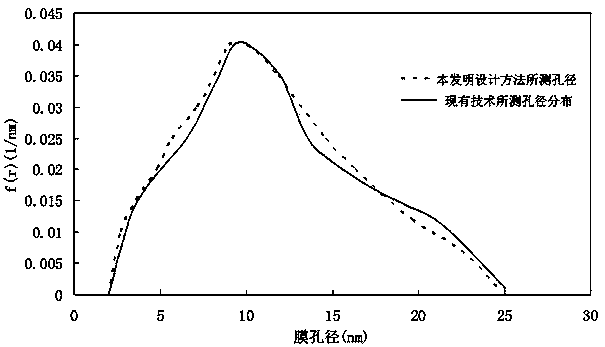

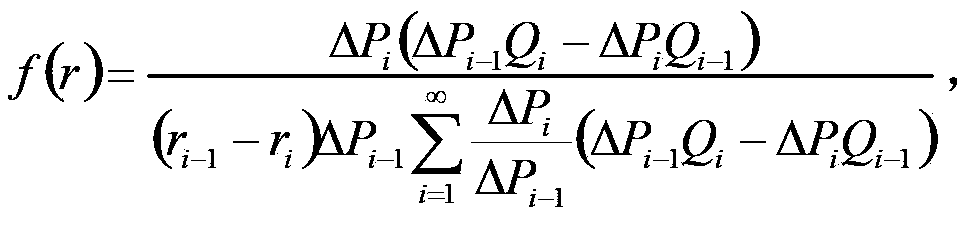

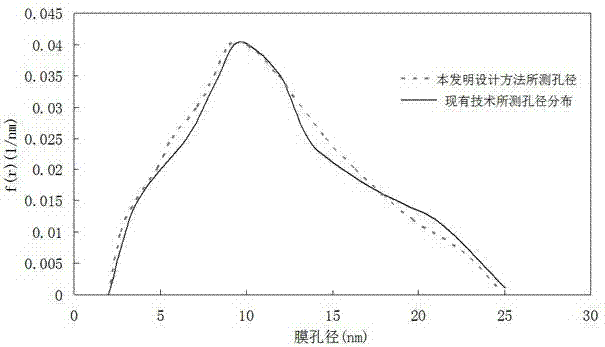

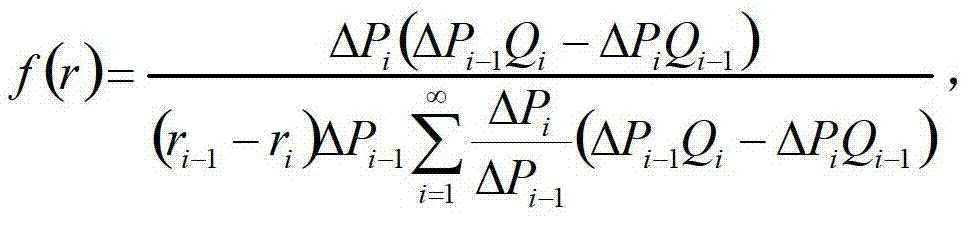

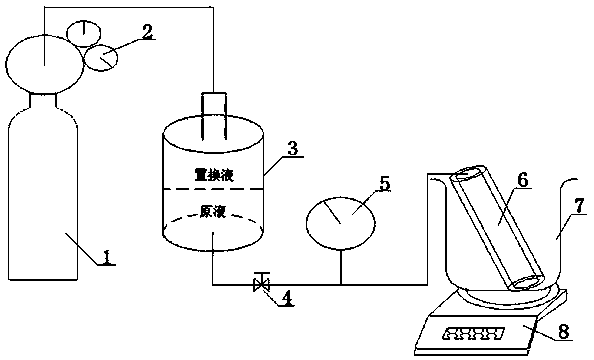

Ultrafiltration membrane pore size distribution determination method

ActiveCN103372376AData fluctuation is smallHigh precisionSemi-permeable membranesPermeability/surface area analysisChemical physicsUltrafiltration

The invention relates to an ultrafiltration membrane pore size distribution determination method. Based on an existing liquid-liquid replacement principle, aiming at the pushing pressure of the obtained replaced liquid and the flow rate of the corresponding replaced liquid, a pore size distribution determination model is designed; compared with an original method, the method has the advantages that fluctuation of the obtained pore size distribution data is low, accuracy is high, implement is easy, and an obvious effect is achieved.

Owner:HOHAI UNIV

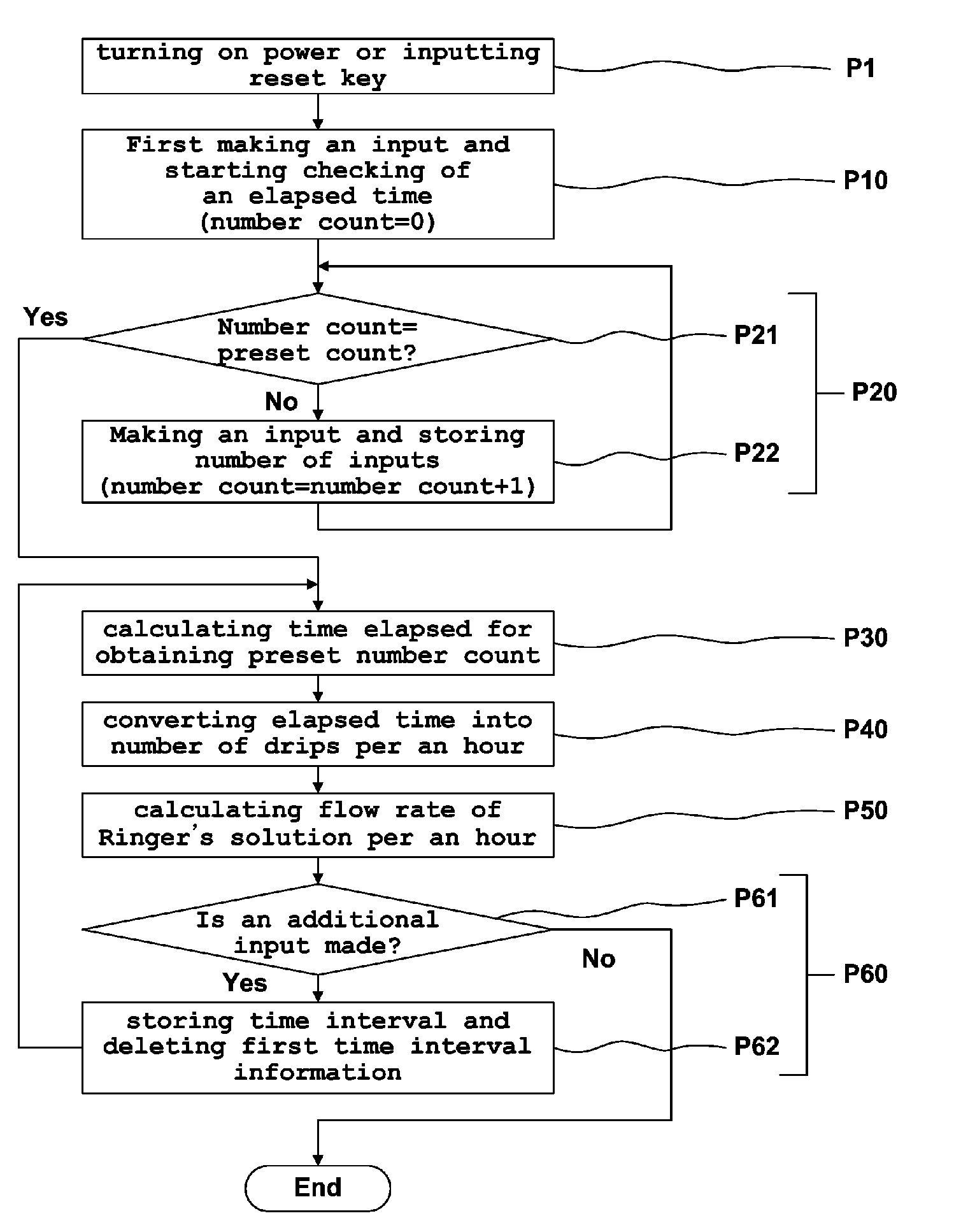

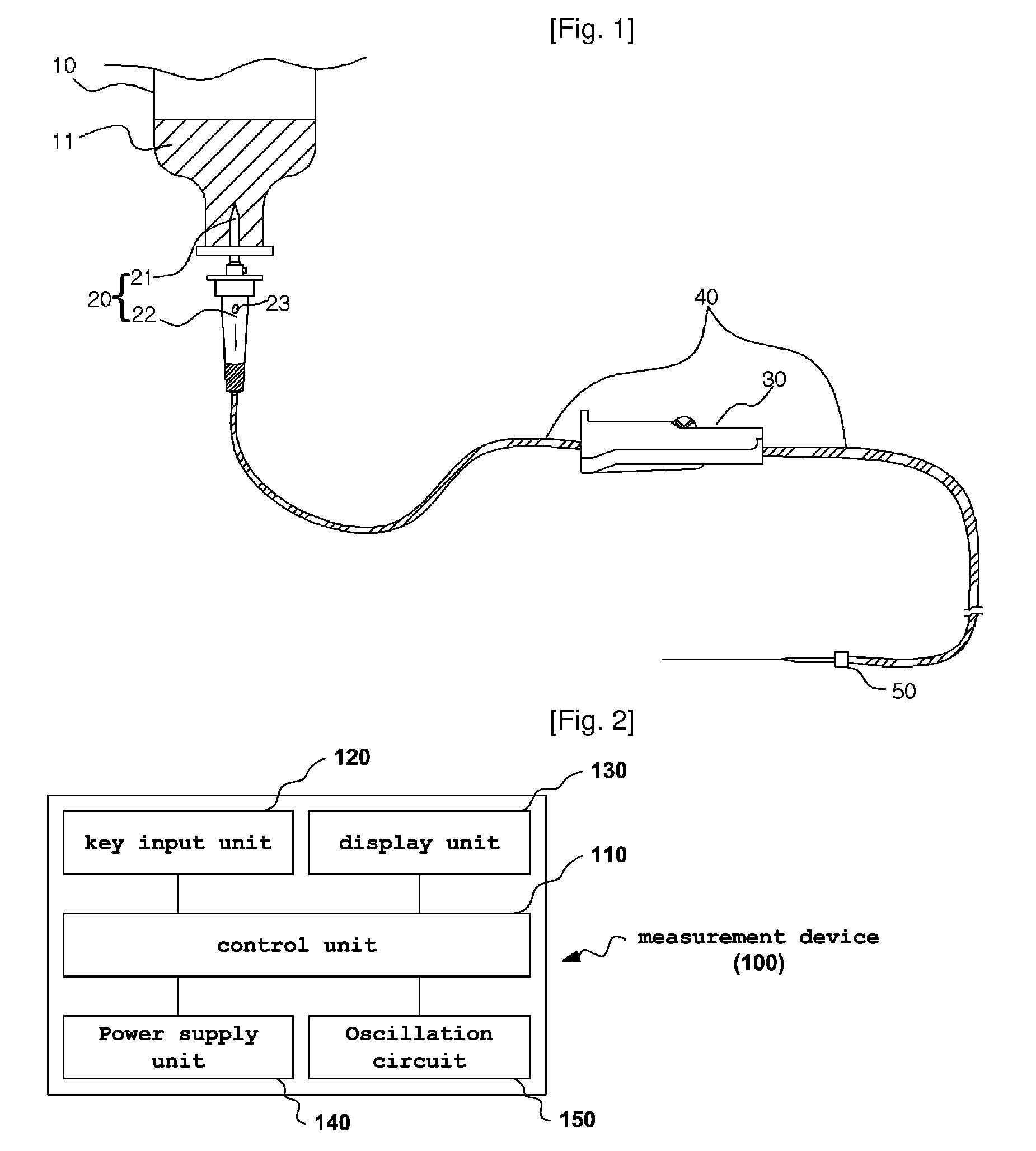

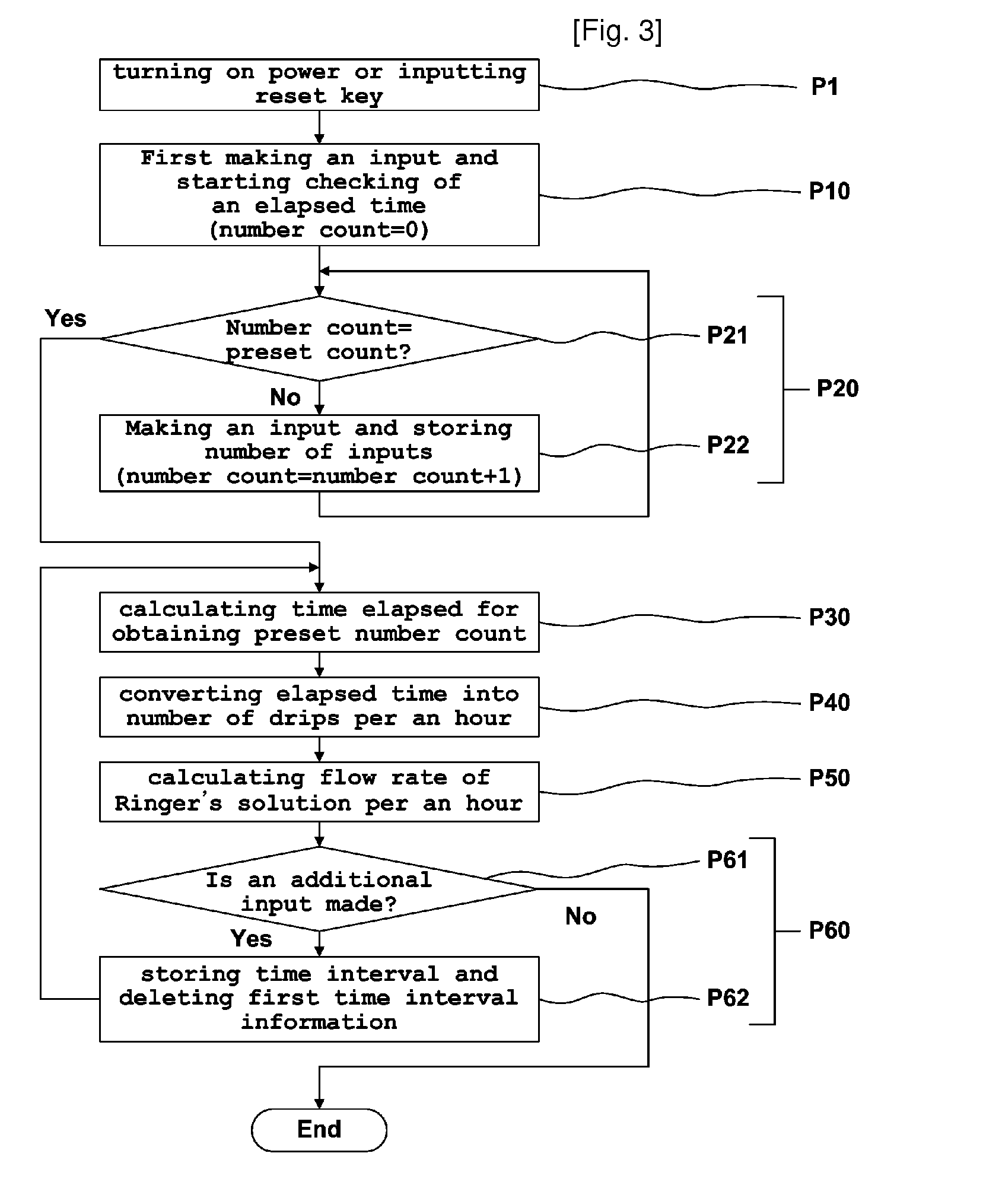

Device for measuring the flow rate of ringer solution

InactiveUS20100063752A1Small volumeEasy to operateFlow propertiesVolume/mass flow measurementRinger's solutionComputer science

A device for measuring a flow rate of Ringer's solution includes a key input unit including a number input key through which a user can make an input each time when a drip drips in a drip chamber; a power supply unit for supplying power; an oscillation circuit for oscillating a signal having a preset frequency; a display unit for quantitatively outputting a calculated flow rate of Ringer's solution; and a control unit for calculating an elapsed time when the input is made through the number input key of the key input unit for a preset number of times, calculating the number of drips per an hour using the preset number of times and the calculated elapsed time, acquiring a quantitative flow rate of Ringer's solution by multiplying a preset volume of each drip and the calculated number of drips, and outputting the acquired flow rate to the display unit.

Owner:LEE IN OK

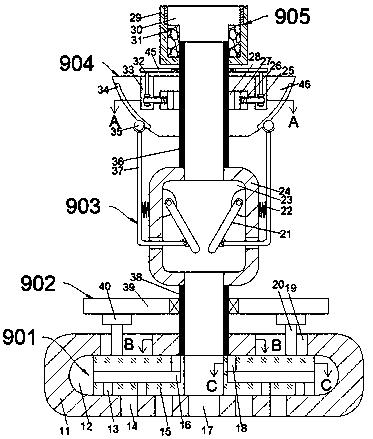

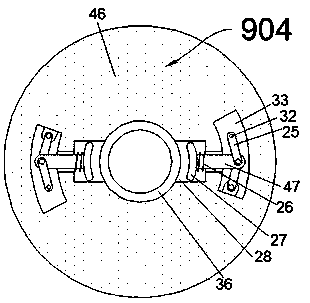

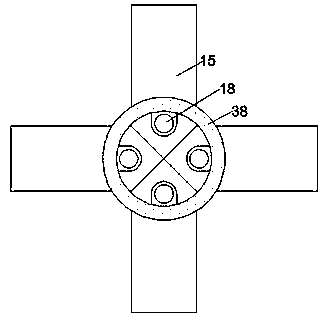

Spray head device of wax injection machine for precision casting

ActiveCN110421119AMeet the process requirements of simultaneous processingChange gap sizeFoundry mouldsFoundry coresMultiple injectionWax

The invention discloses a spray head device of a wax injection machine for precision casting. The spray head device of the wax injection machine for the precision casting comprises a shunting block, wherein a regulation cavity is formed in the shunting block, the inner wall of the top end of the regulation cavity communicates with the outside world and is provided with four slide chutes which arecentrosymmetric, a slide rod is connected in each slide chute in a sliding mode, and a valve core assembly located in the regulation cavity and used for changing the quantity of spraying outlets is arranged on each slide rod. The spray head device of the wax injection machine for the precision casting adopts a thread transmission cooperation mode, accurately controls switching between a single injection hole mode and a multiple injection hole mode, meets technical demands for synchronous processing of multiple molds, uses rotatable baffle structures symmetrically arranged in the rectangular cavity, changes the size of a gap between each two adjacent baffles to change flow speed, and meanwhile uses a control switch of a ball structure to control each baffle structure, achieves precision flow speed control by utilizing the principle that distance increase values in the horizontal direction are identical in all descending segments of the ball, and accordingly meets technical demands forthe precision casting of the wax injection machine.

Owner:河北联硕机械制造有限公司

Ultrafiltration membrane pore size distribution determination method

ActiveCN103372376BData fluctuation is smallHigh precisionSemi-permeable membranesPermeability/surface area analysisChemical physicsUltrafiltration

Owner:HOHAI UNIV

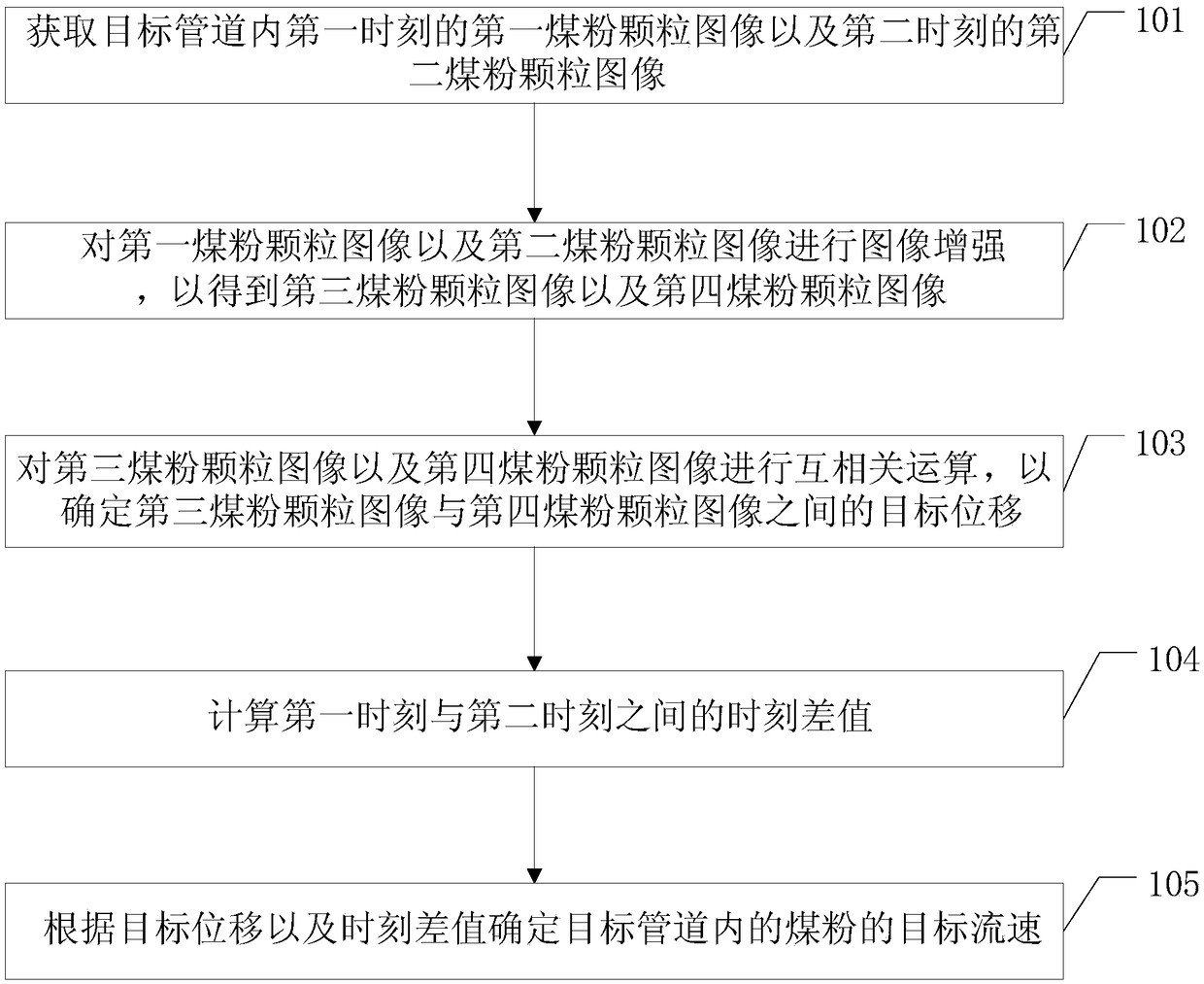

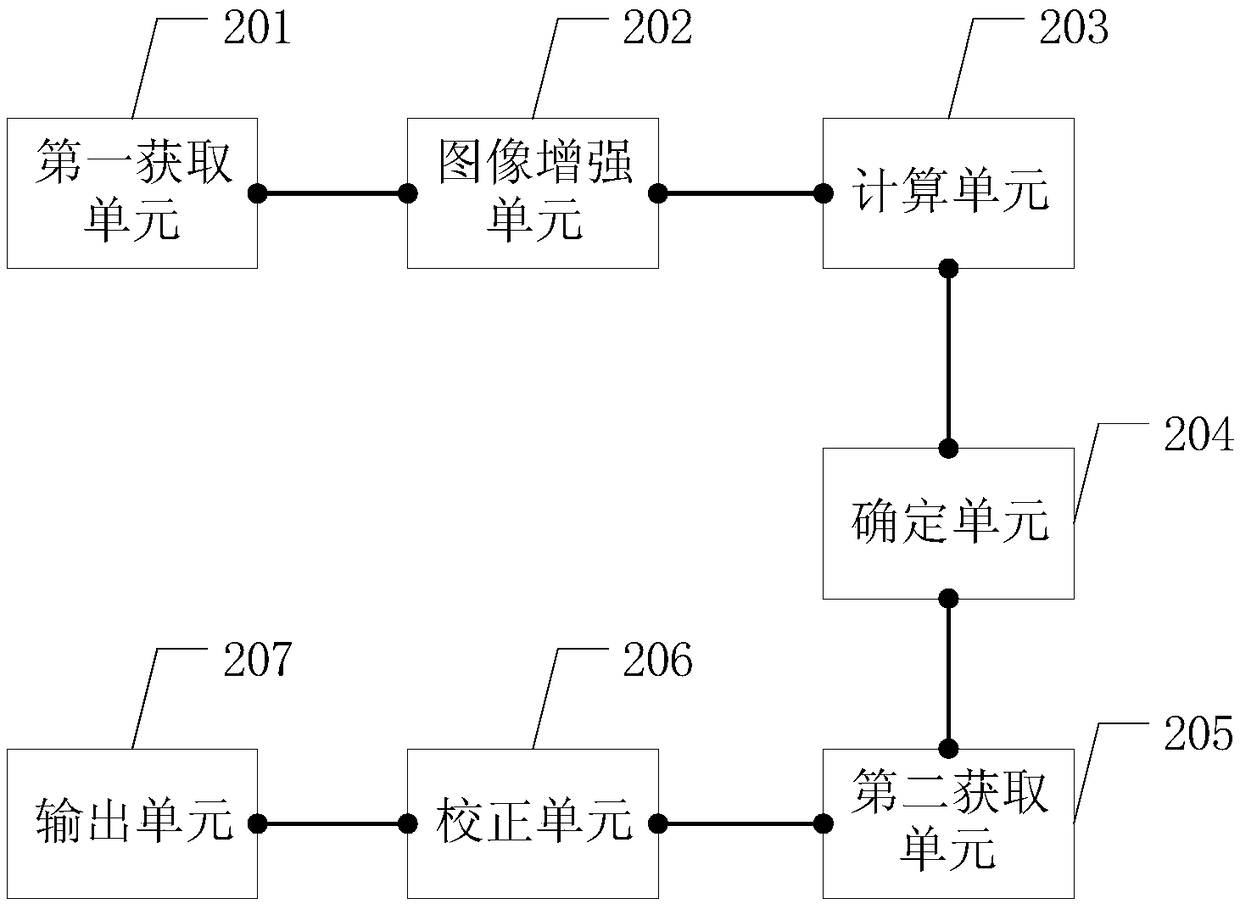

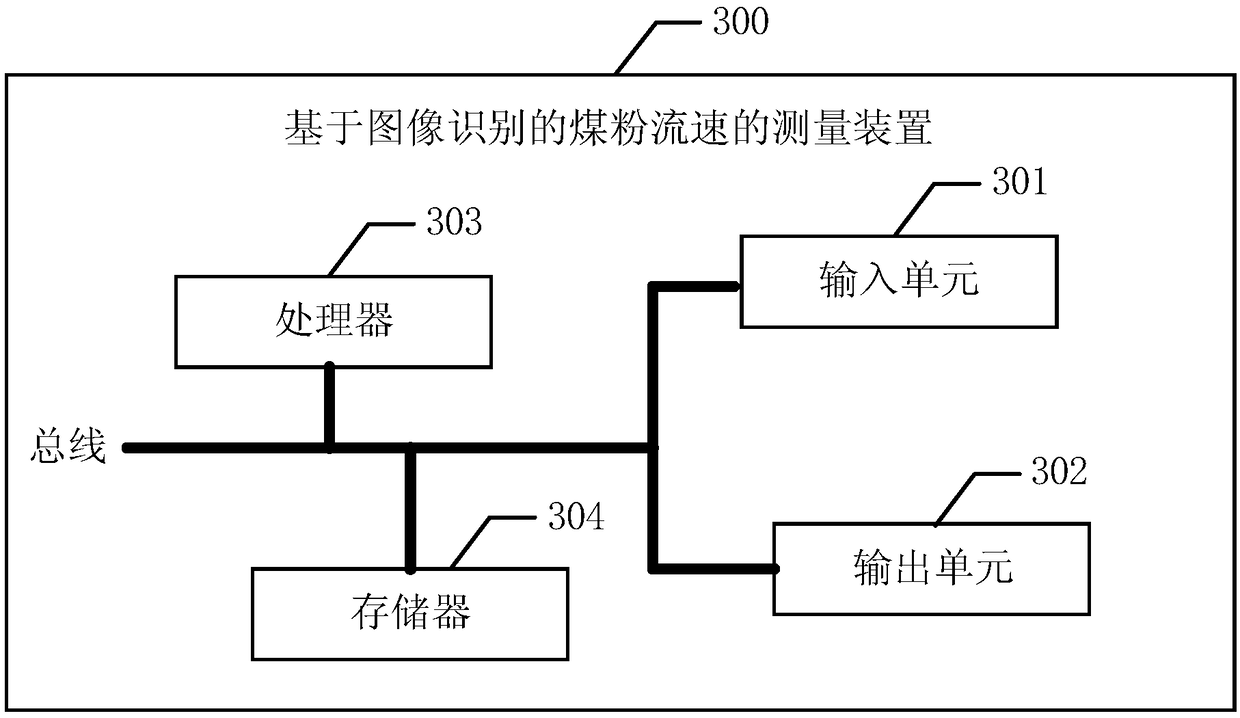

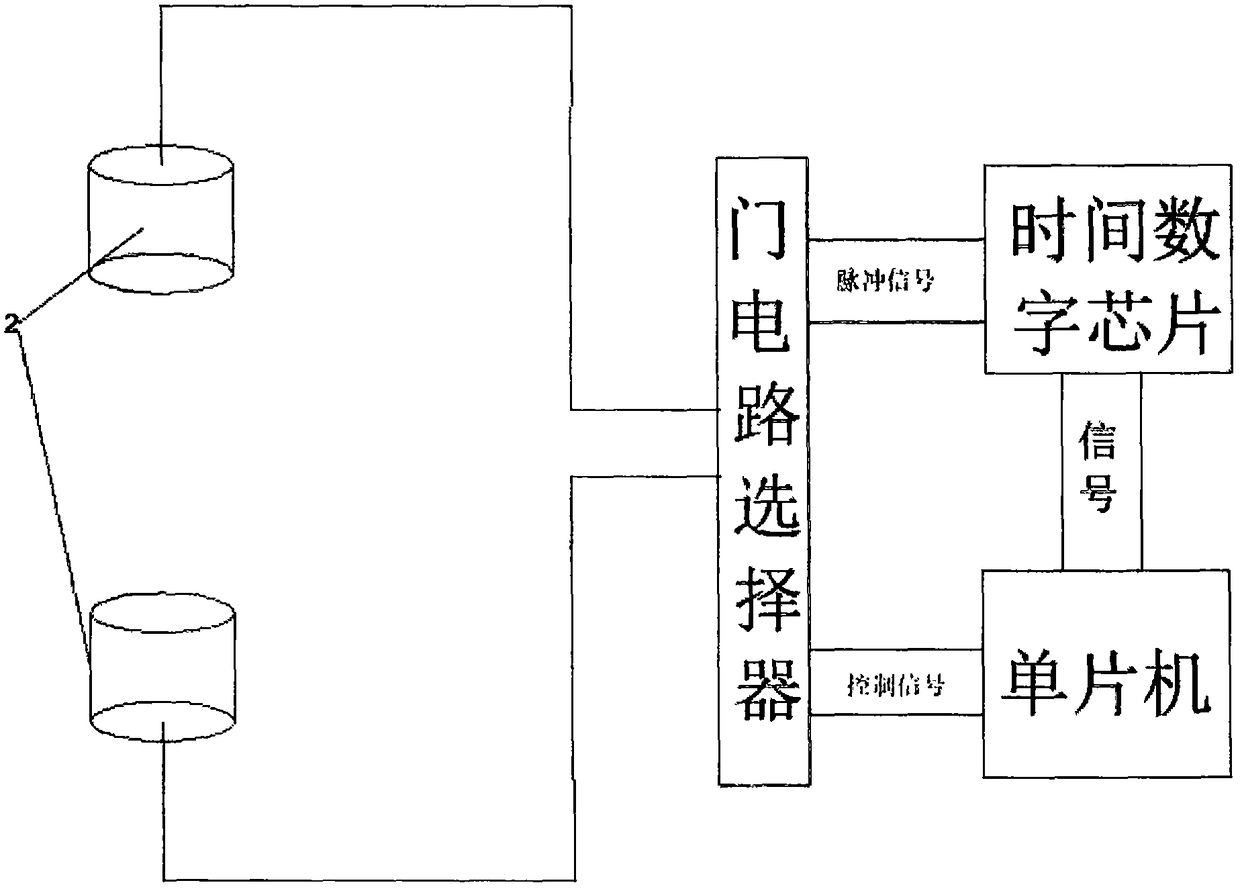

A method and a device for measuring the velocity of pulverized coal based on image recognition

InactiveCN109035324AAccurate flow rateImprove running stabilityImage enhancementImage analysisImage basedTime difference

The embodiment of the invention provides a method and a device for measuring the velocity of pulverized coal based on image recognition, which is used for measuring the pulverized coal flow rate in apulverized air duct. The method comprises the following steps of: acquiring a first pulverized coal particle image at a first time and a second pulverized coal particle image at a second time in a target pipe; Performing image enhancement on the first pulverized coal particle image and the second pulverized coal particle image to obtain a third pulverized coal particle image and a fourth pulverized coal particle image; Performing a cross correlation operation on the third pulverized coal particle image and the fourth pulverized coal particle image to determine a target displacement between thethird pulverized coal particle image and the fourth pulverized coal particle image; Calculating a time difference between the first time and the second time; Determining a target flow rate of pulverized coal in the target pipe according to the target displacement and the time difference.

Owner:润电能源科学技术有限公司

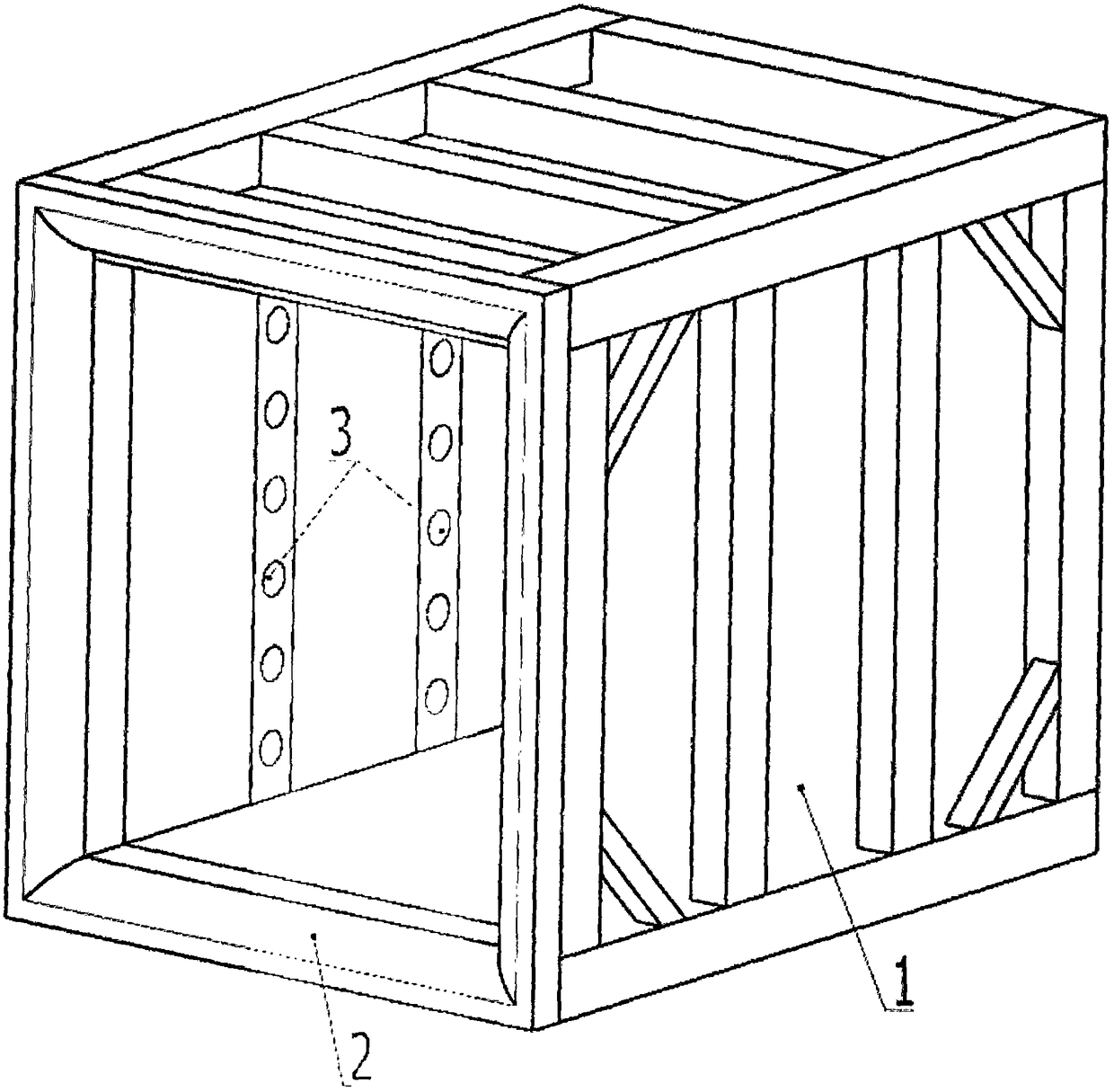

Acoustic wave matrix-based liquid flow measurement device and method

PendingCN108387279AFlow Accurate ResponseAvoid problems with different flow ratesVolume/mass flow measurementMeasurement deviceAcoustic wave

The invention discloses an acoustic wave matrix-based liquid flow measurement device and method and belongs to the technical field of flow measurement. The acoustic wave matrix-based liquid flow measurement device comprises a rectangular water measurement tank internally in a hollow structure allowing fluid to flow through, and two groups of ultrasonic probes arranged on two opposite side surfacesinside the water measurement tank; the two groups of ultrasonic probes are in matrix arrangement and one-to-one correspondence, the connecting line between two corresponding ultrasonic probes forms an included angle to the flowing direction of fluid; the ultrasonic probes are connected with a measuring unit inside a control box. By performing flow measurement through the acoustic wave matrix produced by the ultrasonic probes, the acoustic wave matrix-based liquid flow measurement device can be applied to measuring different positions and different velocities at the same height to accurately reflect the overall velocity of the fluid and further to achieve the aim of accurate measurement. Besides, the acoustic wave matrix-based liquid flow measurement device is simple in structure, practical, convenient, and accurate in measurement.

Owner:HEBEI KEDING ELECTROMECHANICAL TECH CO LTD

Method for determining pore diameter of ultra-filtration membrane

ActiveCN103394290AHigh precisionHigh measurement accuracySemi-permeable membranesPermeability/surface area analysisPressure generationFiltration membrane

The invention relates to a method for determining the pore diameter of an ultra-filtration membrane. According to the method provided by the invention, a brand-new driving pressure generation manner is adopted based on an existing liquid-liquid displacement principle and aiming at a driving pressure in displacement liquid; measurement and obtaining aiming at a high-precision value of the driving pressure of the ultra-filtration membrane are realized by measuring two parts including a pressure for pushing the displacement liquid and a pressure aiming at a membrane pore of the ultra-filtration membrane by the displacement liquid, so as to further directly improve the determination precision which finally aims at the pore diameter of the ultra-filtration membrane. The method for determining the pore diameter of the ultra-filtration membrane provided by the invention is convenient to realize based on the prior art and has the practical and effective effects on the improvement of the determination precision of the pore diameter of the ultra-filtration membrane.

Owner:HOHAI UNIV

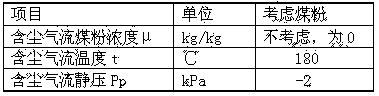

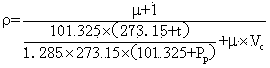

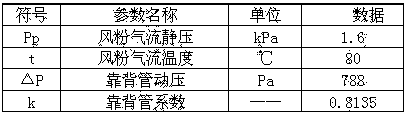

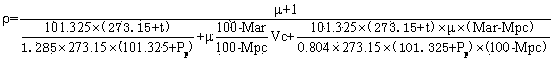

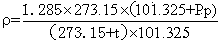

Calculation method for dust-containing airflow density of primary air tube of intermediate coal pulverizing system

InactiveCN103954532ADensity is accurateAccurate flow rateSpecific gravity measurementPower stationEngineering

The invention relates to a calculation method for the dust-containing airflow density of a primary air tube of an intermediate coal pulverizing system in a power station boiler. The technical scheme of the invention is as follows: total mass Mz in the air powder airflow and the total volume Vz of the air powder airflow are calculated to obtain the density rho of the air powder airflow, and then the flow speed v of the air powder airflow of the primary air tube is calculated. In the method disclosed by the invention, the volume part of the dust-containing airflow comprises two parts: one part is hot air, the other part is pulverized coal, and the volume of the pulverized coal is very low relative to the hot air; the mass part of the dust-containing airflow also comprises two parts: one part is hot air, the other part is pulverized coal, and the volume of the pulverized coal can be ignored. The calculation method has the advantage that the influence of the addition of the pulverized coal after the mixing of the air powder of the primary air tube on the dust-containing airflow density is considered, thus calculation for the dust-containing airflow density is more scientific and accurate, and the calculated dust-containing airflow speed is also more accurate, thus control on the air quantity of a power plant is more precise, and the safety and economical efficiency of the running of the power plant are improved.

Owner:STATE GRID CORP OF CHINA +2

Flow velocity measuring apparatus used in environment flow evaluation method

ActiveCN105158502AReduce measurement impactAccurate pressureFluid speed measurementWater flowStreamflow

The present invention provides a flow velocity measuring apparatus used in an environment flow evaluation method, comprising: a pressure disc used for measuring the flow pressure, and outputting measured pressure information; and a data processing instrument connected with the pressure disc, wherein the data processing instrument comprises a pressure processing module used for receiving and processing the pressure information and calculating a flow velocity value. The flow velocity measuring apparatus of the present invention performs unified processing for pressure information obtained from multiple measurements, and converts the pressure information into flow velocity information to obtain more accurate flow velocity, thereby reducing error and enabling the finally obtained flow velocity to be closer to an actual flow velocity.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

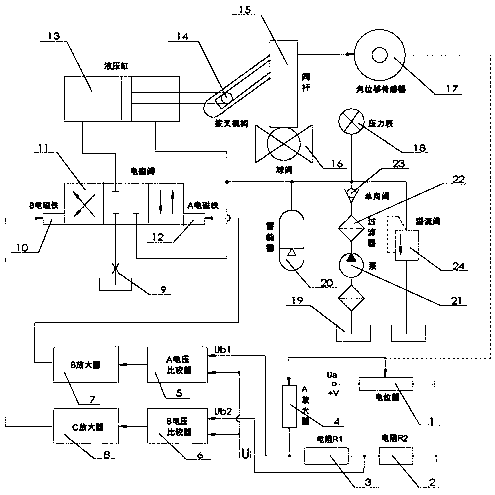

Precision control system for aperture of large ball valve

ActiveCN109307093AAccurate flow ratePrecise proportional controlOperating means/releasing devices for valvesHydraulic cylinderAudio power amplifier

The invention discloses a precision control system for aperture of a large ball valve. The precision control system disclosed by the invention comprises a potentiometer, an A amplifier, a three-position tee electromagnetic valve, a hydraulic cylinder, a shift fork mechanism and an angular displacement sensor, wherein the potentiometer is used to detect a rotation angle of a valve rod of the ball valve; a piston rod in the hydraulic cylinder can be moved back and forth horizontally so as to drive motion of the shift fork mechanism and then the shift fork mechanism drives rotation of the valve rod of the ball valve, so the aperture of the ball valve can decrease or increase; input of the A amplifier is generated from the potentiometer and enters two comparators respectively after voltage distribution; and through comparison with the size of a command voltage, the state of the three-position tee electromagnetic valve can be determined and thus actions of the hydraulic cylinder can be controlled. The system disclosed by the invention is characterized by the simple structure, reliable performance, low cost and easy control

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

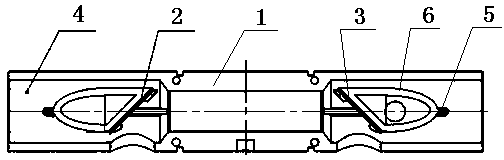

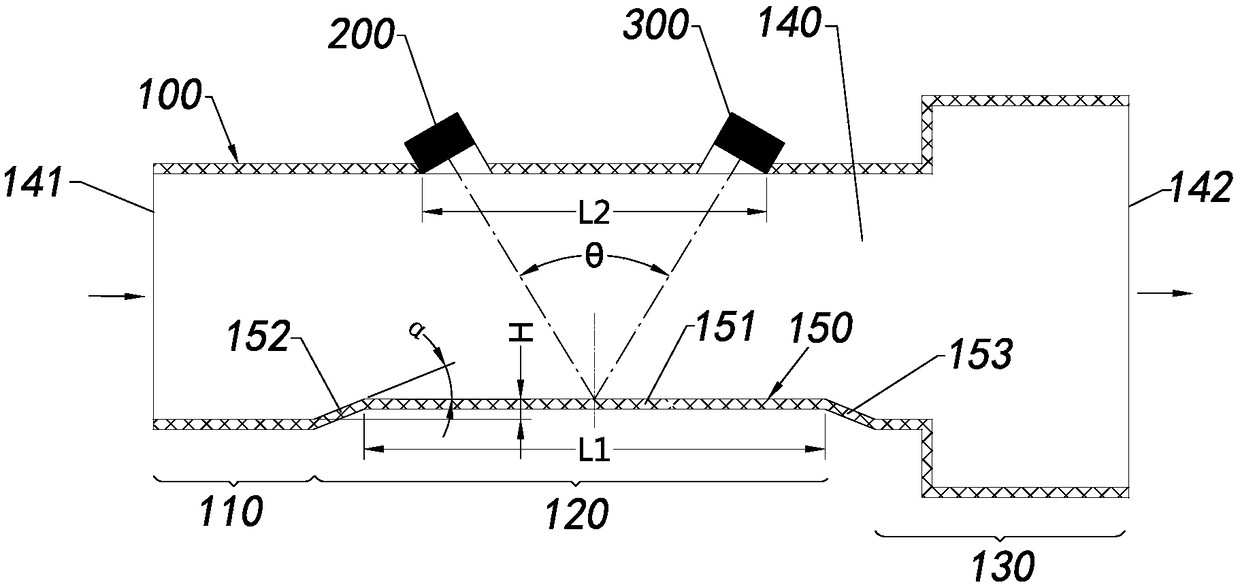

Ultrasonic metering device

PendingCN108871475AIncrease the itineraryMeet the requirements of measurement accuracyVolume/mass flow measurementSurface velocityTransducer

The invention discloses an ultrasonic metering device, belongs to the technical field of meter, and solves the problem that an existing ultrasonic metering device cannot meet measurement accuracy requirement of small flows such as flow of a household gas meter. The ultrasonic metering device comprises a casing and a transducer arranged on the casing, wherein the casing is provided with a meteringpassage for fluid to pass through, and the casing forms an inflow section and a measuring section along the fluid flow direction. The transducer comprises a transmitting vibrator and a receiving vibrator, and the transmitting vibrator and the receiving vibrator are mounted on the same side of the measuring section, so that the propagation path of the ultrasonic wave is V-shaped. The flow area of the inflow section is S1, and the flow area of the measuring section is S2, wherein S2 is less than S1, so that the surface velocity of the fluid flowing through the measuring section and the flight time difference during the ultrasonic measurement is increased, thereby improving the measuring accuracy. The device particularly satisfies the measurement accuracy requirements of small flows.

Owner:GOLDCARD HIGH TECH

Ink viscosity detection device

PendingCN111380780ARealize the function of real-time online detection of ink viscosityImprove detection efficiencyDirect flow property measurementEngineeringMechanical engineering

The invention relates to an ink control device, in particular to an ink viscosity detection device. The ink viscosity detection device comprises an ink inlet, an ink outlet, an overflow chamber, an ink storage chamber and an ink outlet channel. A top opening of the ink storage chamber, a top opening of the ink outlet channel and the ink inlet are all communicated with the overflow chamber, the topopening of the ink outlet channel is higher than the top opening of the ink storage chamber, and the top opening of the ink storage chamber is higher than the ink inlet. A liquid leakage opening is formed in the bottom of the ink storage chamber, a plunger driven by an air cylinder is plugged in the liquid leakage opening, a photoelectric sensor is arranged below the liquid leakage opening, the photoelectric sensor comprises a signal transmitter and a signal receiver, and a vertical liquid column formed in the air after ink leaks out of the liquid leakage opening is located between the signaltransmitter and the signal receiver. According to the invention, real-time online detection of the ink viscosity is realized, the detection efficiency of the ink viscosity is improved, and the accuracy of ink viscosity calculation is ensured.

Owner:悦美红智能数控科技(江苏)有限公司

Phase change flow saturated steam flowmeter

ActiveCN109540229AAccurate flowAccurate flow rateVolume/mass flow by differential pressureDifferential pressureEngineering

The invention discloses a phase change flow saturated steam flowmeter, comprising a horizontal short round tube and a Bitoba flow sensor inserted into the horizontal short round tube from the top wallof the horizontal short round tube. The Biotaba flow sensor is connected to a first differential pressure transmitter. The flowmeter further comprises a liquid level measuring device mounted on the horizontal short round tube for measuring the liquid level in the horizontal short round tube. The Bitoba flow sensor comprises a pressure head, a full pressure guiding tube, and a static pressure guiding tube connected to the full pressure guiding tube. The left side and the right side of the lower section of the pressure head have full pressure holes and static pressure holes. The inside of the pressure head has a full pressure channel and a static pressure channel. A full pressure balance hole and a static pressure balance hole are provided on the left and right sides of the pressure head. The full pressure balance hole and the static pressure balance hole are respectively connected with the top of the full pressure channel and the static pressure channel. The Bitoba flow sensor furthercomprises a full pressure water storage hole and a static pressure water storage hole extending from the top of the pressure head to the lower part of the full pressure balance hole and the static pressure balance hole. The full pressure guiding tube and the static pressure guiding tube respectively extend into the full pressure water storage hole and the static pressure water storage hole. The phase change flow saturated steam flowmeter can accurately measure the flow rate of the saturated steam in a pipeline.

Owner:LIAONING BITOBAR TECH CO LTD

Method for computing air powder airflow velocity of primary air pipe of direct blowing type powder manufacturing system

ActiveCN103954791ADensity is accurateAccurate flow rateFluid speed measurement using pressure differenceSpecific gravity measurementPower stationAirflow

The invention relates to a method for computing the air powder airflow velocity of a primary air pipe of a power station boiler direct blowing type powder manufacturing system. According to the technical scheme, the total mass Mz of the air powder airflow and total volume Vz of the air powder airflow are computed to obtain the density Rho of the air powder airflow, and the air powder airflow velocity, shown in the specification, of the primary air pipe is computed. According to the computing method, the air powder airflow speed is accurately measured, and most importantly, the density of the air powder airflow is scientifically and reasonably computed. The deviation caused by the fact that the coal dust mass is ignored in the prior art in the computing method is corrected. The measuring and computing result is more accurate and more reliable, and the safety and the economical efficiency of power plant operation are improved.

Owner:STATE GRID CORP OF CHINA +2

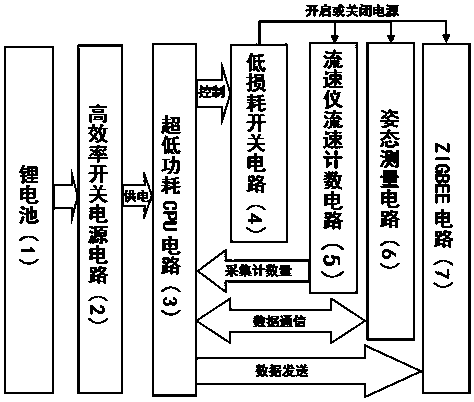

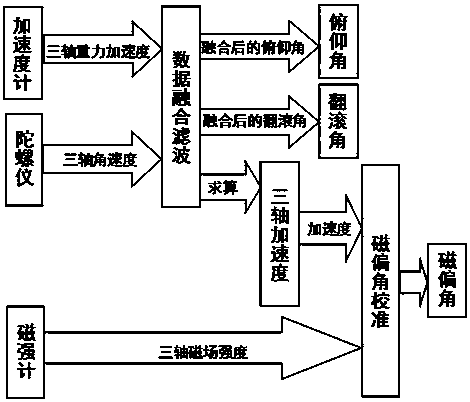

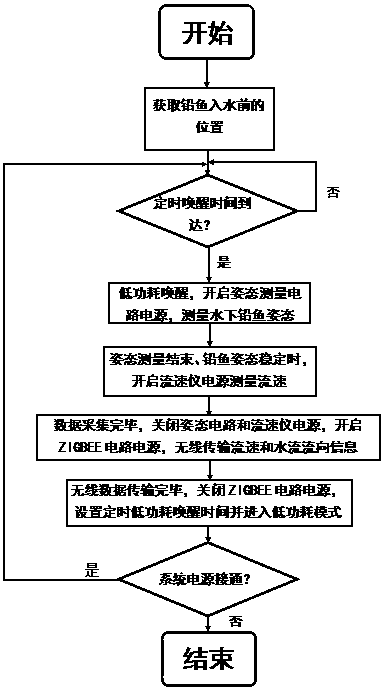

A three-dimensional attitude-based intelligent lead fish current measurement method and its circuit

The invention relates to an intelligent fish lead flow measuring method based on a three-dimensional posture and a circuit thereof and belongs to the technical field of hydrological information. The circuit provided by the invention comprises a switch power supply circuit, a CPU circuit, a switch circuit, a current meter flow-rate counting circuit, a posture measuring circuit and a ZIGBEE circuit. The method provided by the invention comprises the following steps: firstly, acquiring the position before the fish lead enters water; after CPU enters a normal working mode, collecting the three-dimensional dynamic posture data and calculating a three-dimensional dynamic posture angle of the fish lead through a data fusion algorithm; judging the stability of the fish lead through the pitch angle and the rolling angle; measuring the flow rate after stabilizing; packaging the flow rate of the fish lead, the pitch angle and the magnetic bias angle into a data packet with a short package structure and sending to a ZIGBEE coordinator of a hydrometric station. The invention provides a high-efficient reliable realizing scheme for acquiring accurate flow rate and water flow direction information under the complex hydrological environment.

Owner:昆明华域自动化技术有限公司

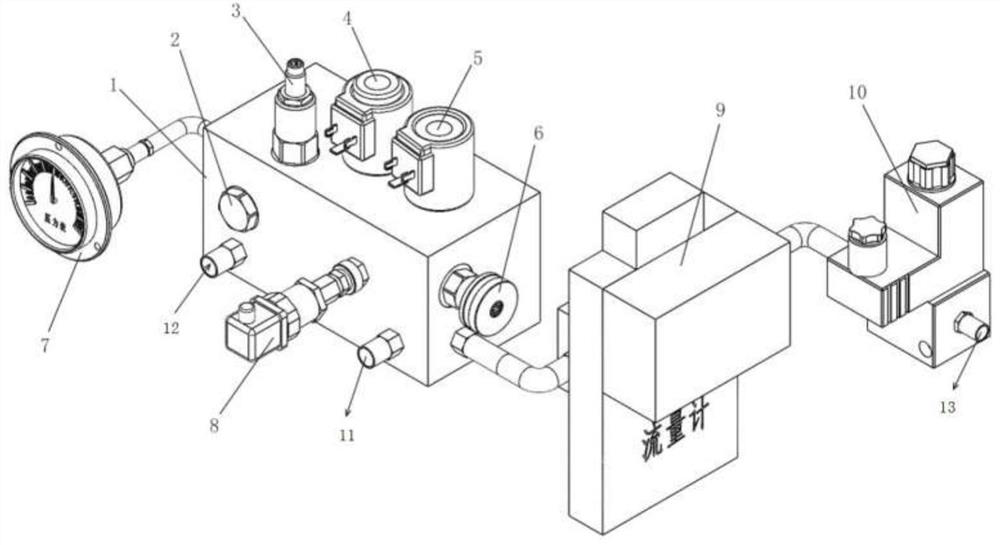

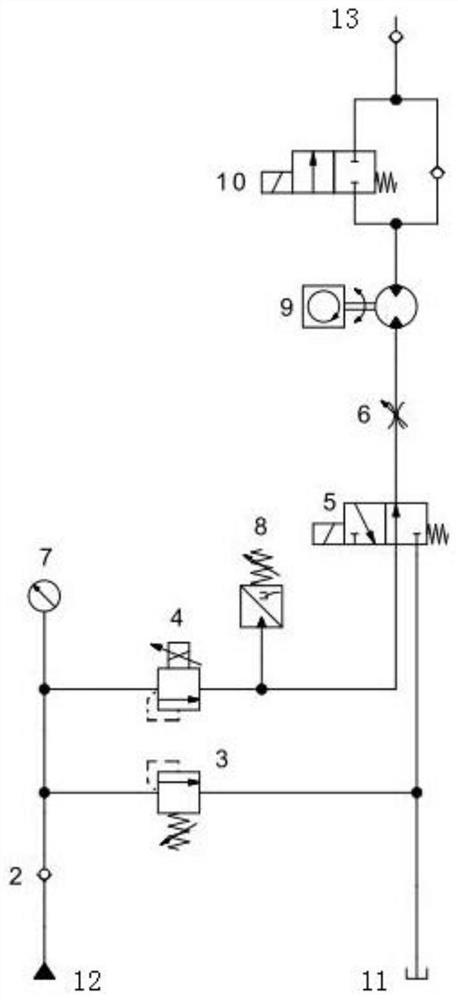

Mechanical hydraulic precision flow control system and control method

PendingCN112412931AStable working pressureAccurate flowFluid-pressure actuator testingServomotor componentsControl systemEngineering

The invention provides a mechanical hydraulic precision flow control system and control method. The mechanical hydraulic precision flow control system and control method are suitable for oil injectionequipment. The mechanical hydraulic precision flow control system comprises an oil way block, a one-way valve, an overflow valve, a proportional pressure reducing valve, an electromagnetic reversingvalve, a throttling valve, a pressure gauge, a pressure sensor, a flow meter and an electromagnetic on-off valve, wherein an output port of conveying equipment communicates with an inlet of the systemthrough a pipeline; and oil liquid flows in from the inlet of the system and flows out from an outlet after being adjusted by the precision flow control system. According to the mechanical hydraulicprecision flow control system and control method, the oil liquid is controlled through the system, the pressure sensor and a hydraulic control system are matched so that the oil liquid has stable workpressure, the flow meter and the hydraulic control system are matched so that the oil liquid has accurate flow and flow speed, and the electromagnetic on-off valve can rapidly control opening and closing of an oil way. In the technical scheme, when the pressure and flow of the oil liquid in the pipeline change, real-time control can be achieved, corresponding pressure, flow and flow speed adjustment is made, and the stable output requirement is met.

Owner:JINLING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com