Ultrafiltration membrane pore size distribution determination method

A technology of pore size distribution and measurement method, which is used in semi-permeable membrane separation, chemical instruments and methods, suspension and porous material analysis, etc. The effect of improving the measurement accuracy and the sensitivity of the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

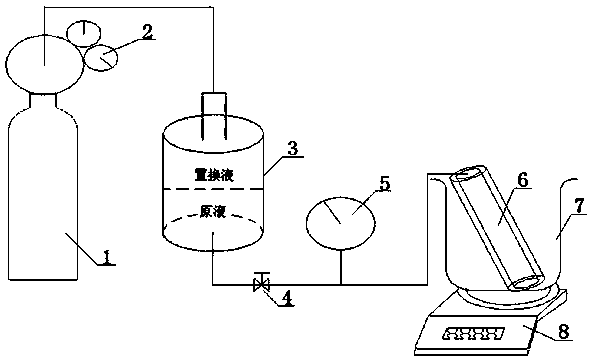

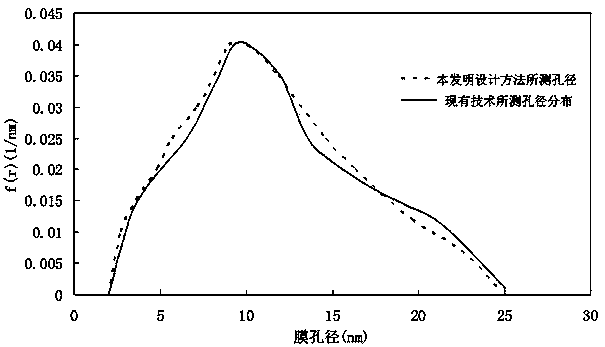

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] The present invention has designed a kind of ultrafiltration membrane pore size distribution determination method, comprises following method:

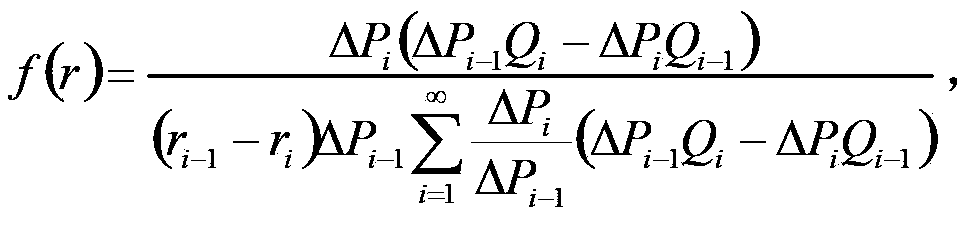

[0023] Step 1. Use immiscible original solution and replacement solution, wherein the original solution is used to fill each membrane hole on the ultrafiltration membrane, apply pressure to the replacement solution, and press the original solution in each membrane hole by one side of the ultrafiltration membrane Replacement, wherein the pressure applied to the replacement fluid is gradually increased according to the preset time period, and the pressure difference ΔP on both sides of the ultrafiltration membrane is recorded in each time period i , and with each pressure difference ΔP i Correspondingly, the flow rate Q of the replacement liquid that replaces the original ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com