Ink viscosity detection device

A detection device, a technology of ink viscosity, applied in the direction of DC flow characteristics measurement, etc., can solve the problems of unable to calculate ink viscosity in time, slow ink diffusion speed, and difficult to calculate diffusion range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

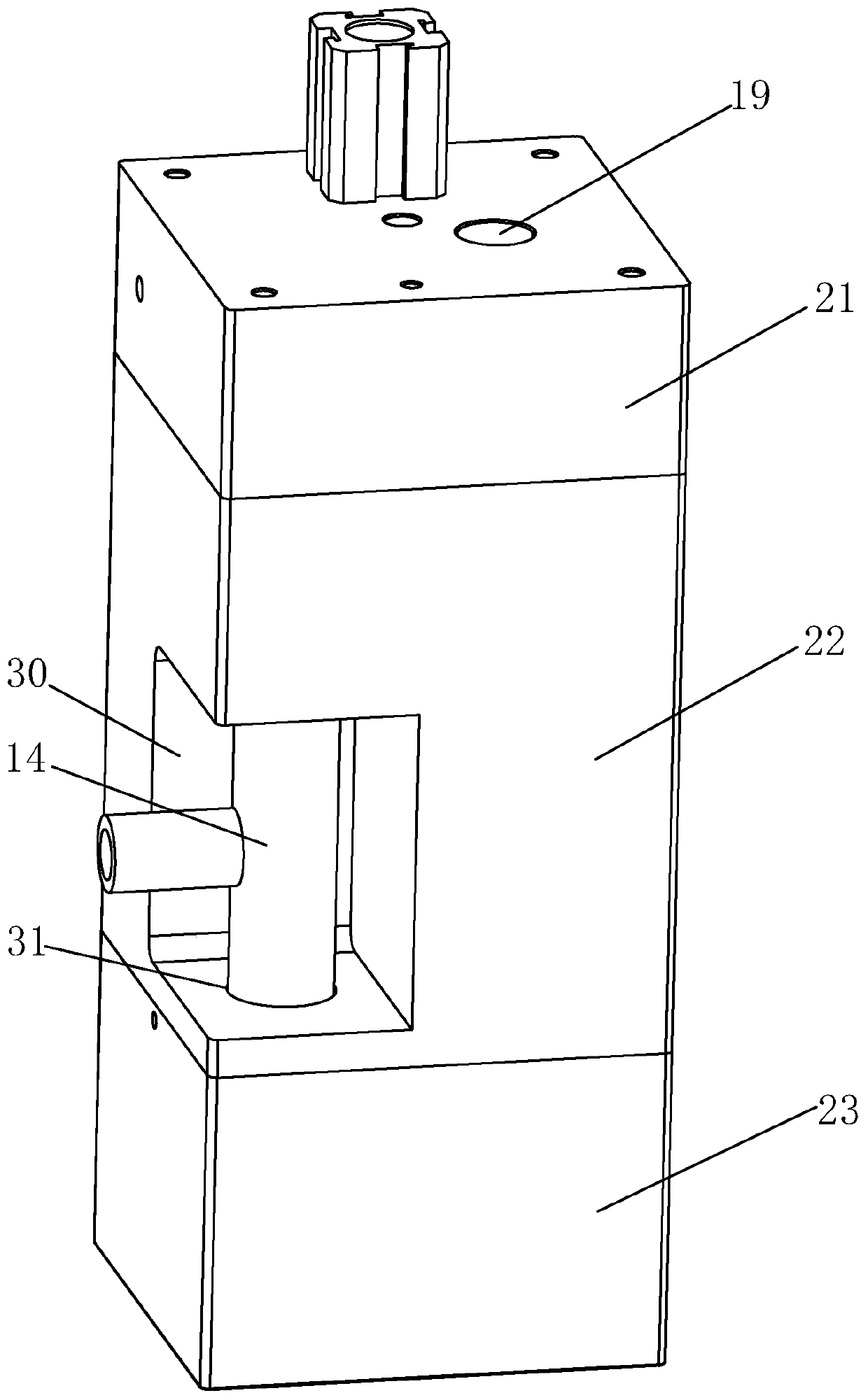

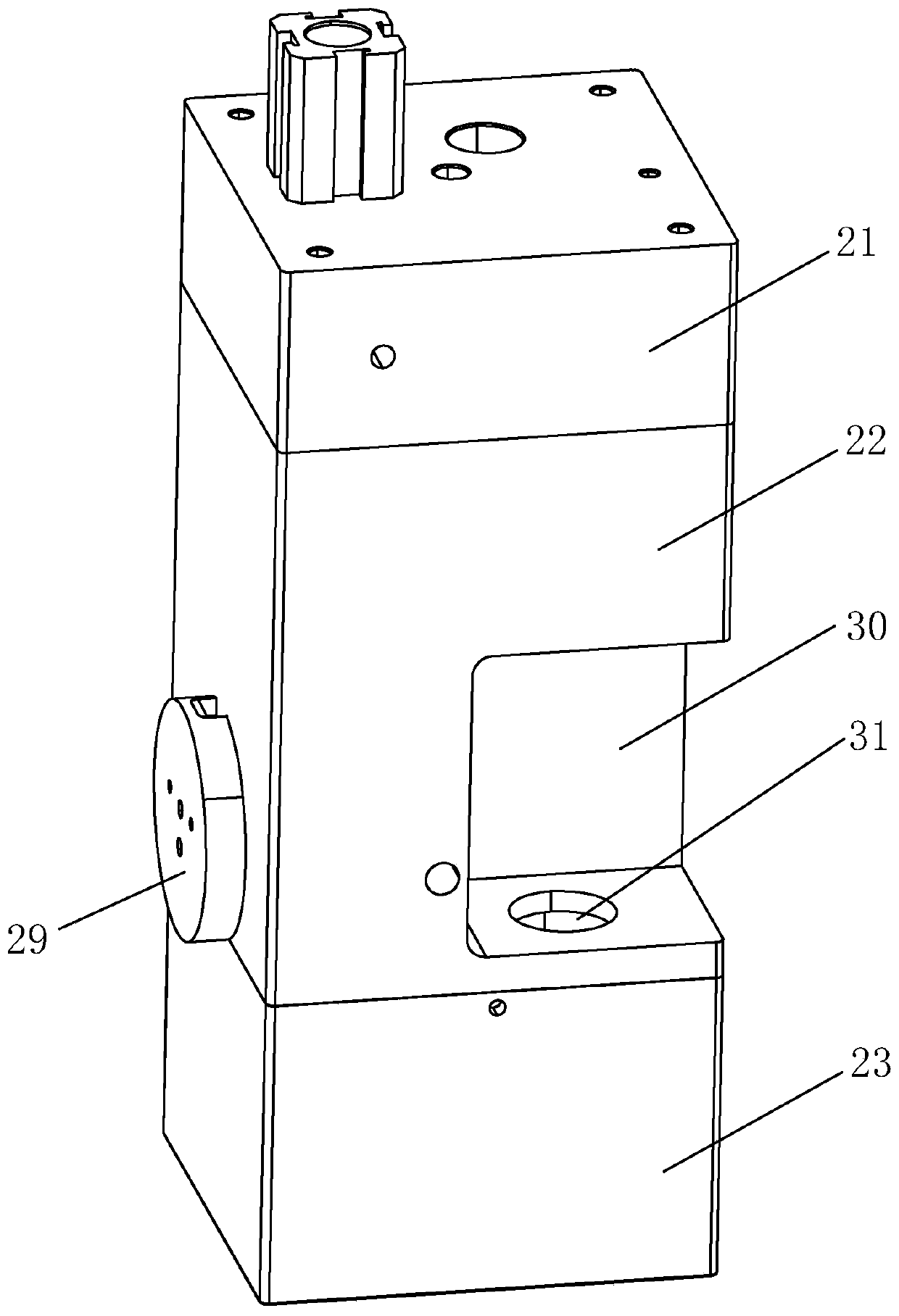

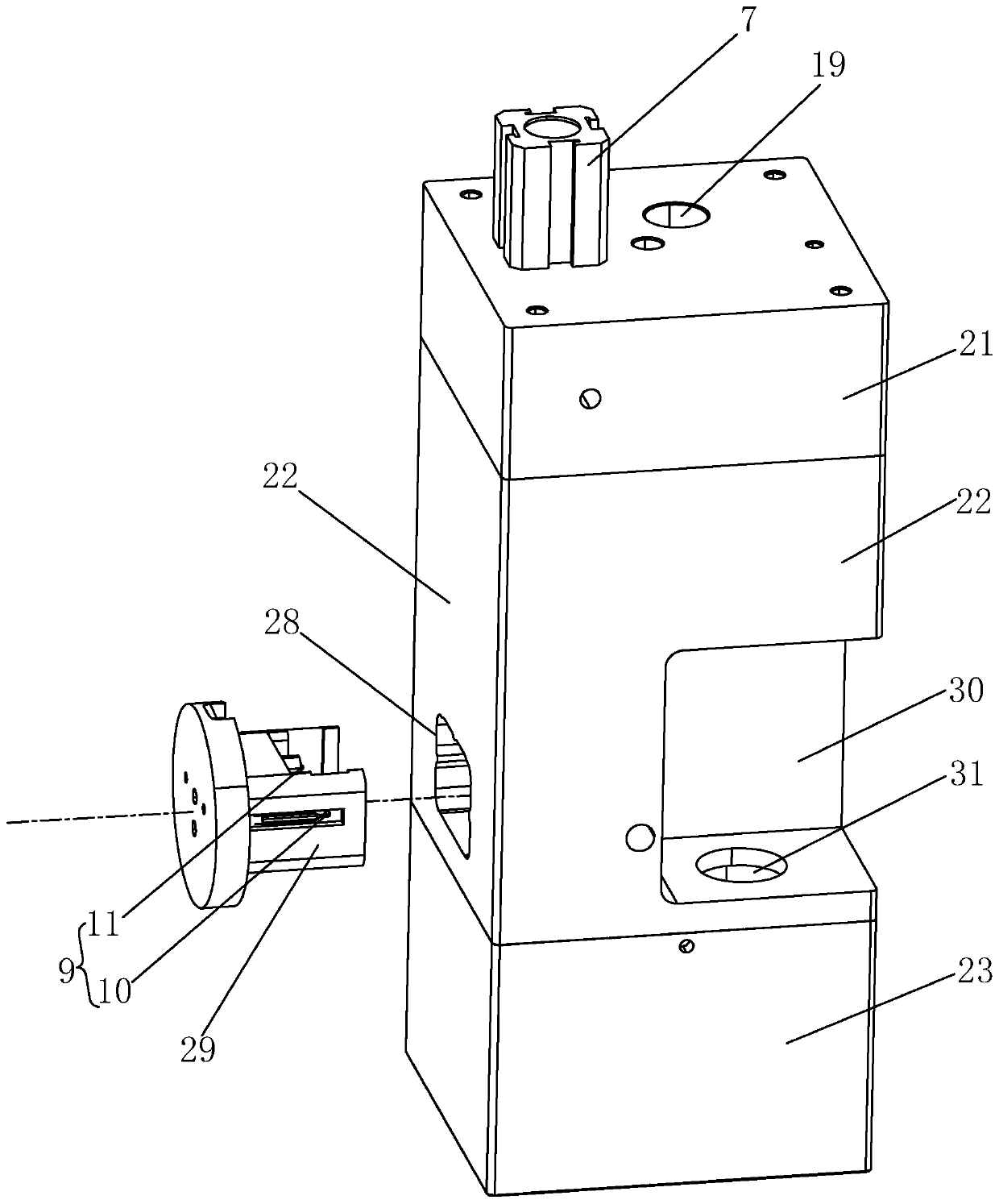

[0043] refer to figure 1 , is an ink viscosity detection device disclosed in the present invention, comprising an upper block 21, a middle block 22, and a lower block 23 distributed sequentially from top to bottom, and the three are detachably connected by screws.

[0044] Such as image 3 As shown, the side of the middle block 22 has a slot 28 and a concave receiving groove 30, and the slot 28 is used for inserting the extractable mounting seat 29, and the two sides of the mounting seat 29 are respectively fixed to the signal emission of the photoelectric sensor 9. device 10, signal receiver 11, three-way valve 14 is placed in the accommodation tank 30 (see figure 1 ).

[0045] Such as Figure 4 As shown, the top of the middle block 22 is grooved and the bottom surface of the upper block 21 encloses an overflow chamber 3, and the bottom surface of the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com