Method for computing air powder airflow velocity of primary air pipe of direct blowing type powder manufacturing system

A technology of milling system and calculation method, applied in the direction of measuring fluid velocity by pressure difference, measuring device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The method of the present invention is used to calculate the flow rate of air powder air flow in a direct blowing type pulverizing system of a boiler in a certain company's power station:

[0066] (1) Determination of relevant parameters:

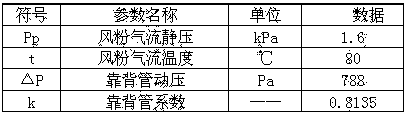

[0067] Table 1 Example 1 parameter measurement result

[0068]

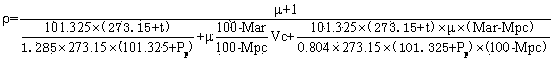

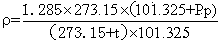

[0069] (2) Bring the parameters into the following calculation formula for calculation:

[0070]

[0071] Result: Dusty airflow density ρ=1.5833 kg / m 3 ;

[0072] Use this result to calculate the airflow velocity ,get =25.67 m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com