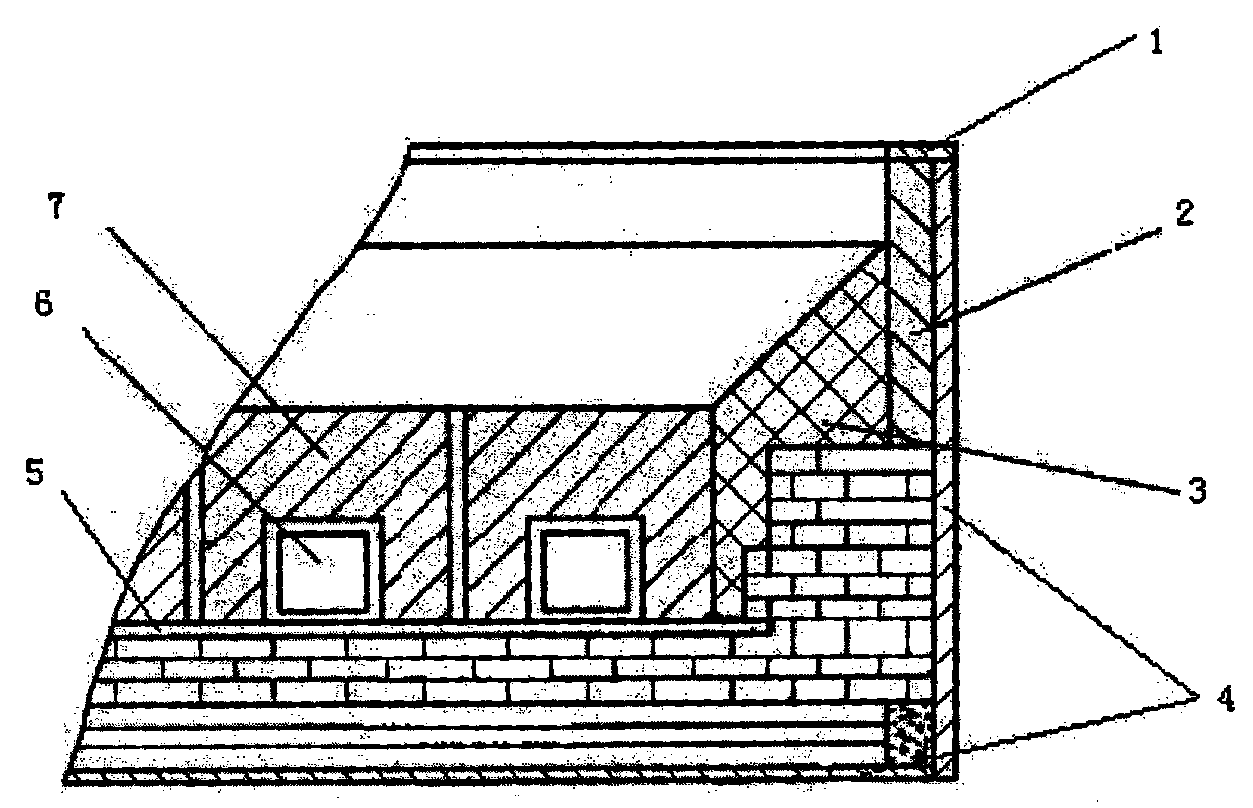

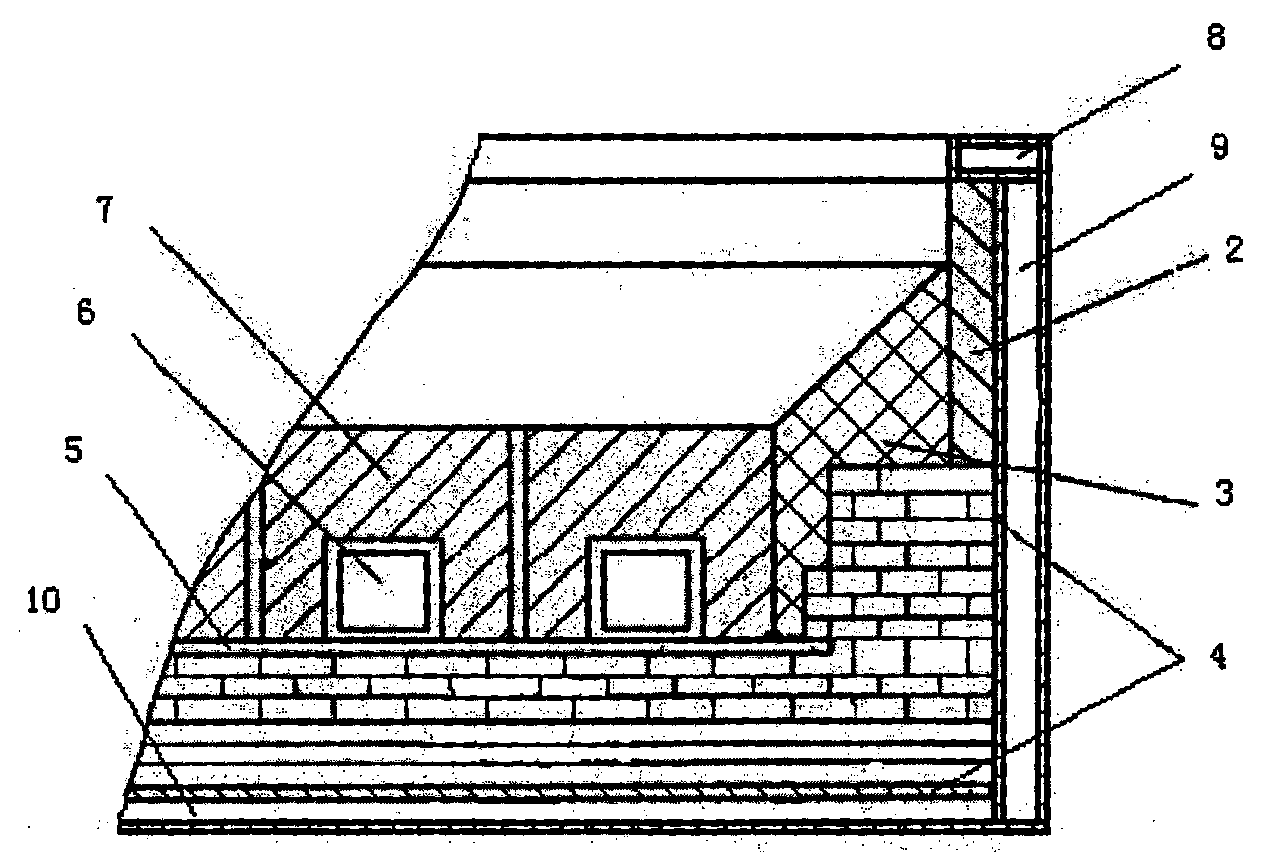

Forced heat transferring type aluminum electrolyzing groove

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of aluminum electrolytic production, to achieve the effects of recycling waste heat resources, improving current efficiency and electrolytic cell life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0031] The reference technical data of this example is: 400kA electrolytic cell, the cell shell size is 22.0×4.5×1.5m, the cell voltage is 4.0V, and the current efficiency is 94%. If only the heat exchanger is installed on the side, then: the heat dissipation power of the side is 320kW, and the flow rate of heat transfer oil is 2.4m 3 / h, the inlet temperature of the heat transfer oil is 50°C, and the outlet temperature is 250°C. If the energy utilization rate of hot oil is 50%, then 1280kWh of electricity can be saved per ton of aluminum, and energy consumption can be reduced by 10%.

experiment example 2

[0033] The reference technical data for this example is: 300kA electrolytic cell, the size of the cell shell is 15.5×4.5×1.5m, the cell voltage is 4.0V, and the current efficiency is 94%. If the entire steel shell is equipped with a heat exchanger, the heat dissipation power is 390kW, and the flow rate of heat transfer oil is 2.9m 3 / h, the inlet temperature of the heat transfer oil is 40°C, and the outlet temperature is 240°C. If the energy utilization rate of hot oil is 50%, the electricity saving per ton of aluminum is 2062kWh, reducing energy consumption by 16%.

experiment example 3

[0035] The reference technical data for this example are: a series of 300kA electrolyzers, the number of cells is 100, the size of the cell shell is 15.5×4.5×1.5m, the cell voltage is 4.0V, and the current efficiency is 94%. If the entire steel shell is equipped with a heat exchanger, the heat dissipation power is 39000kW, and the flow rate of heat transfer oil is 290m 3 / h, the inlet temperature of the heat transfer oil is 40°C, and the outlet temperature is 240°C. If the energy utilization rate of hot oil is 50%, the electricity saving per ton of aluminum is 2062kWh, and the total annual electricity saving is 1.685×10 8 kWh, equivalent to 60,000 tons of standard coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com