Device for online polishing of automobile transmission gear

A technology for automotive gearboxes and polishing devices, which is applied to belts/chains/gears, gear teeth, components with teeth, etc., which can solve problems such as low processing accuracy, thin carburized layer thickness, and long time consumption, so as to ensure the finished product The effect of reducing the surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

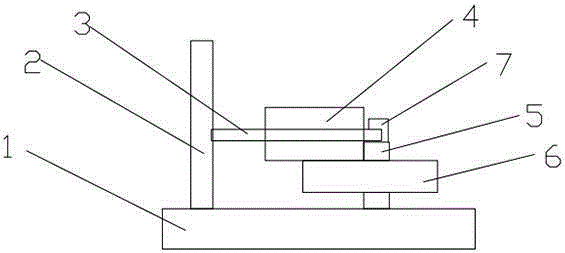

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, an on-line polishing device for automotive gearbox gears according to the present invention includes a base 1, a vertical plate 2 and a gear 6, the vertical plate 2 is arranged on the side of the base 1, and a horizontal bar is arranged in the middle of the vertical plate 2 3. The crossbar 3 is parallel to the base 1, the crossbar 3 is sleeved with a polishing wheel 4, the base 1 is provided with a rotating shaft 5, and the rotating shaft 5 is sleeved with a gear 6, and the rotating shaft 5 The top end is provided with a crossbar sleeve 7, and the crossbar sleeve 7 is sleeved on the top of the polishing wheel 4.

[0019] The top of the crossbar 3 is hooked to the upper end of the rotating shaft 5 to ensure the levelness of the crossbar, prevent the surface of the gear from having a certain inclination due to uneven gravity, increase t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com