Double-speed automatic degreasing centrifuge

A degreasing and centrifuge technology, applied in the field of two-speed automatic degreasing centrifuges, can solve the problems of decreased oil rejection, difficult manufacturing, unsuitable for large-scale, automated assembly line operations, etc., and achieves reasonable structure and overall effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

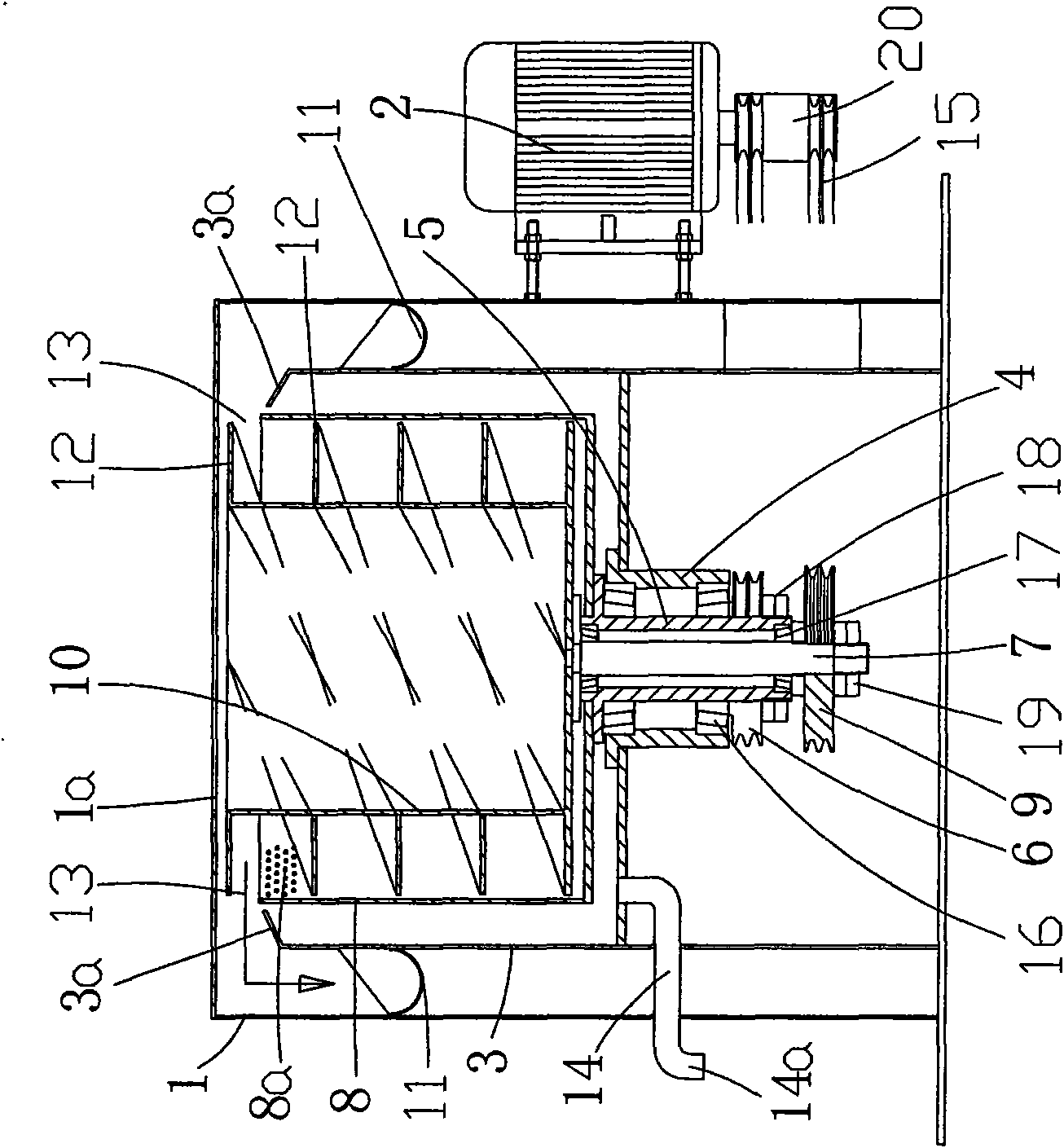

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

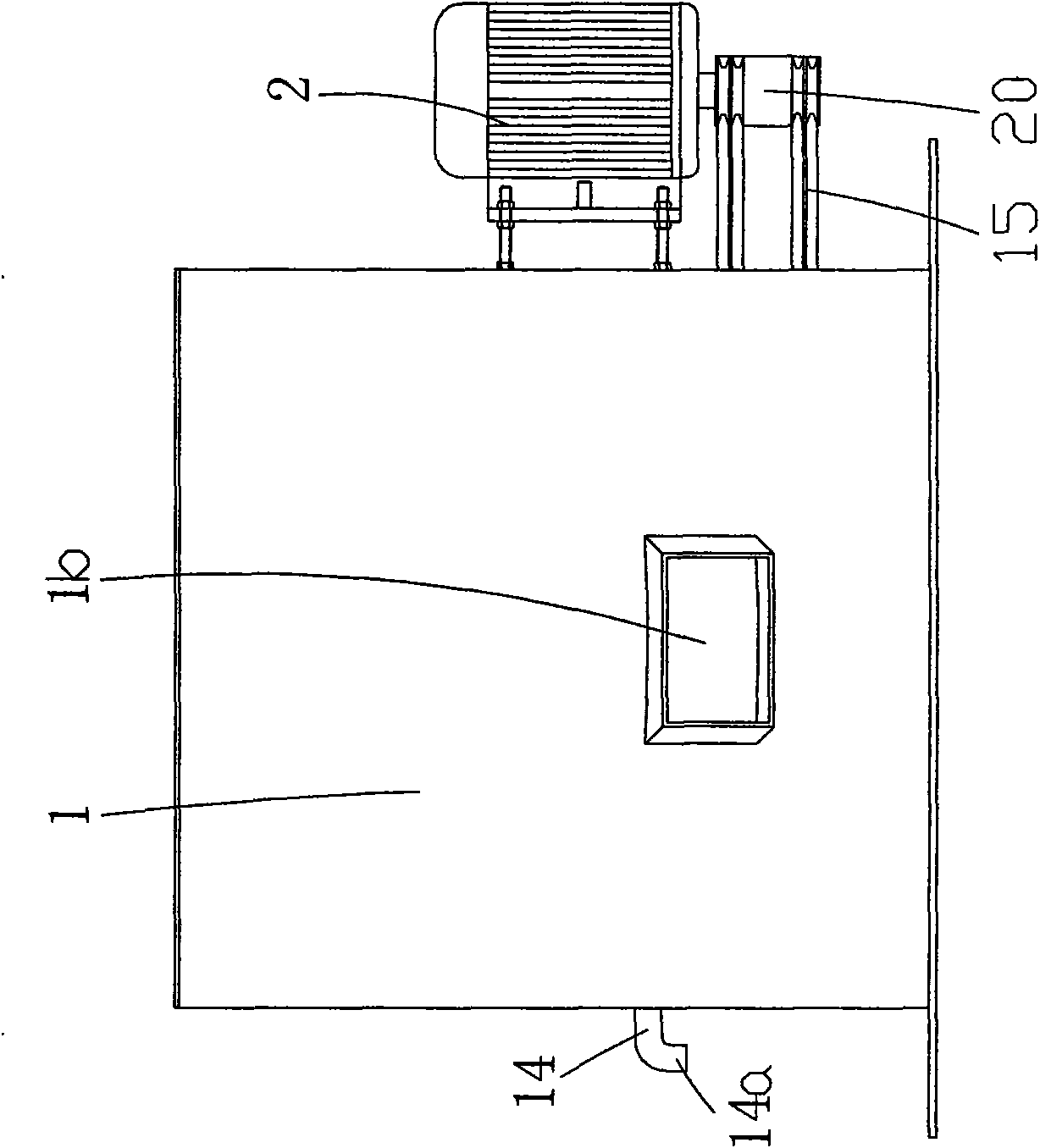

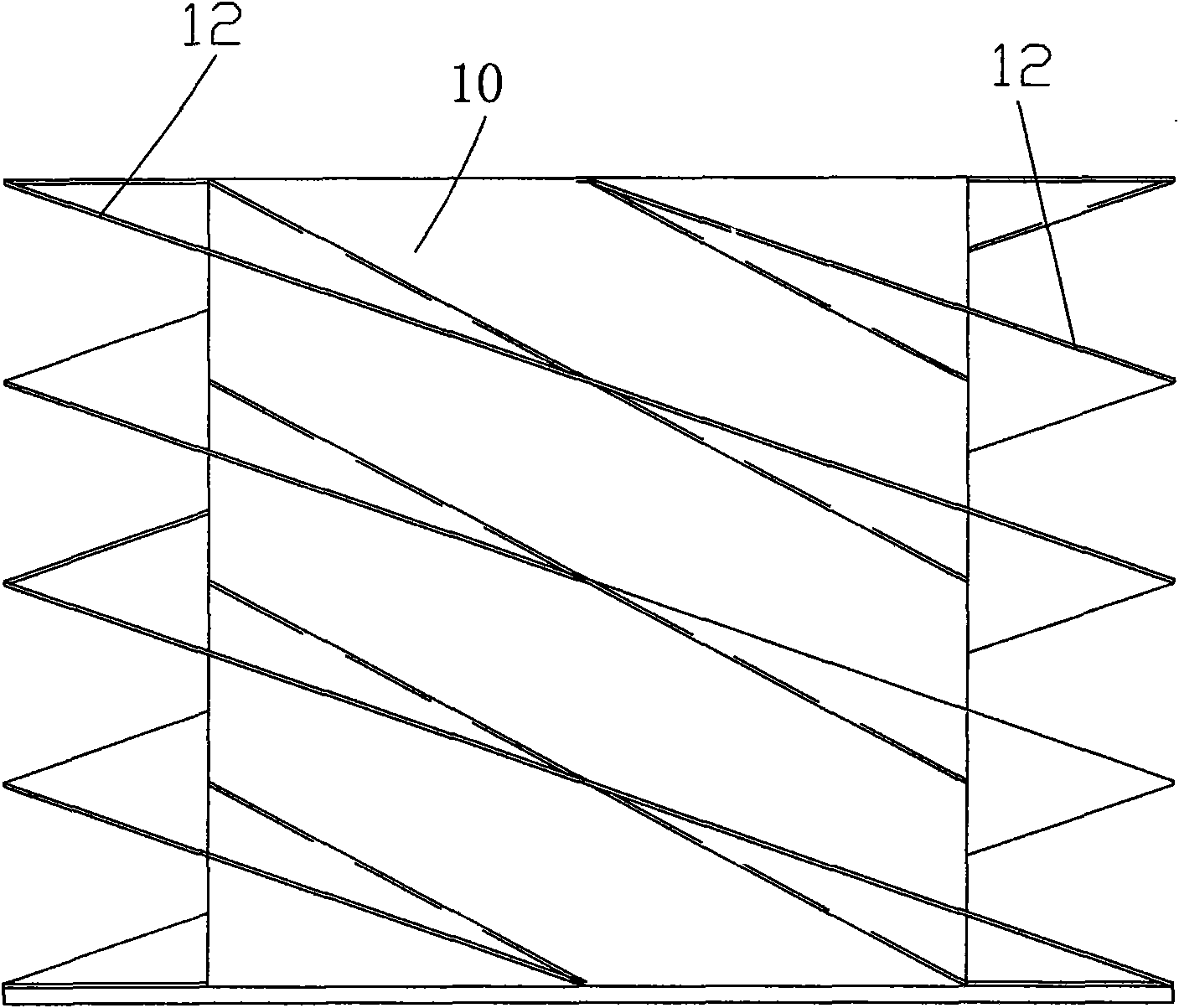

[0019] Such as Figure 1 to Figure 4 As shown, the description of the icon numbers is as follows: body casing 1, feeding port 1a, discharging port 1b, motor 2, oil tank 3, inclined ring edge 3a, outer bearing sleeve 4, centrifugal shaft 5, centrifugal shaft pulley 6, lifting shaft 7. Isolation barrel 8, mesh 8a, lifting shaft pulley 9, lifting frame 10, discharge channel 11, lifting plate 12, gap 13, oil outlet pipe 14, oil outlet 14a, belt 15, centrifugal rotor 16, lifting rotation Body 17, centrifugal tightening nut 18, lifting and tightening nut 19, motor pulley disc 20.

[0020] In the embodiment of the present invention, a double-speed automatic degreasing centrifuge includes a body casing 1 of a hollow structure, a motor 2 is fixed on the outer wall of the body casing 1, and an oil tank 3 is embedded and fixed in the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com