An adaptive tower crane hoisting system for civil engineering

A civil engineering, self-adaptive technology, applied in hoisting devices, transportation and packaging, load hanging components, etc., to reduce manual operations and improve transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

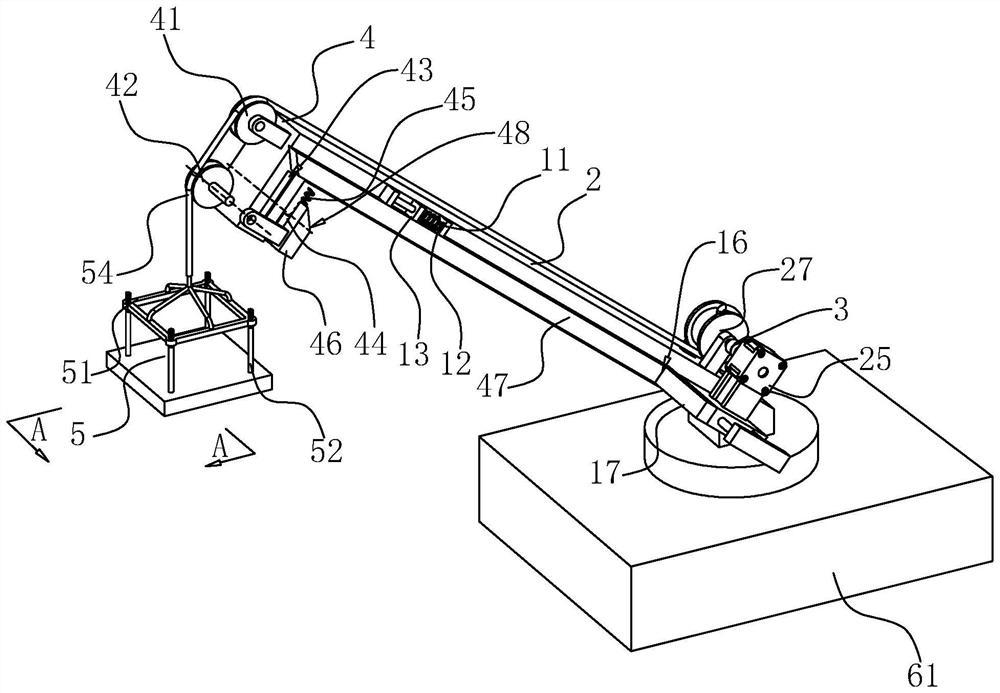

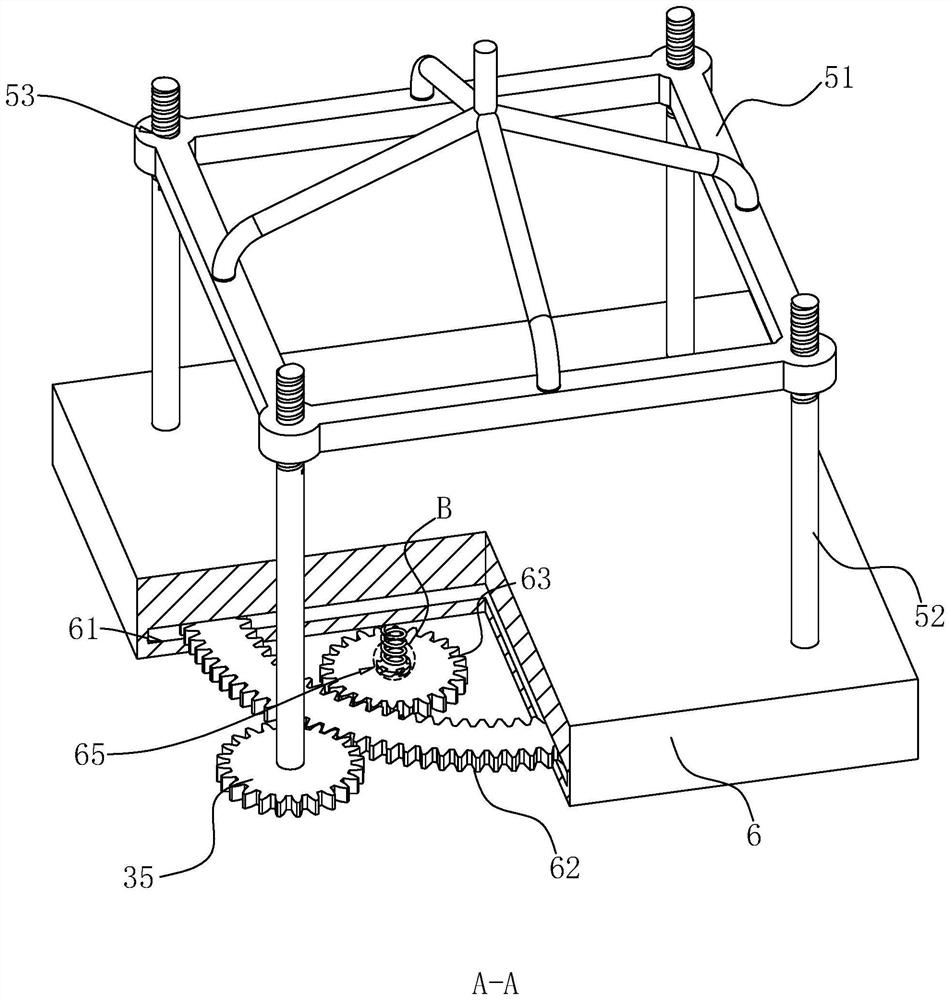

[0036] Attached to the following Figure 1-4 This application will be described in further detail.

[0037] The embodiments of the present application disclose an adaptive tower crane hoisting system for civil engineering. refer to figure 1, An adaptive tower crane hoisting system for civil engineering includes a fixed base 1 and a boom 2 rotatably installed on the top of the fixed base 1 .

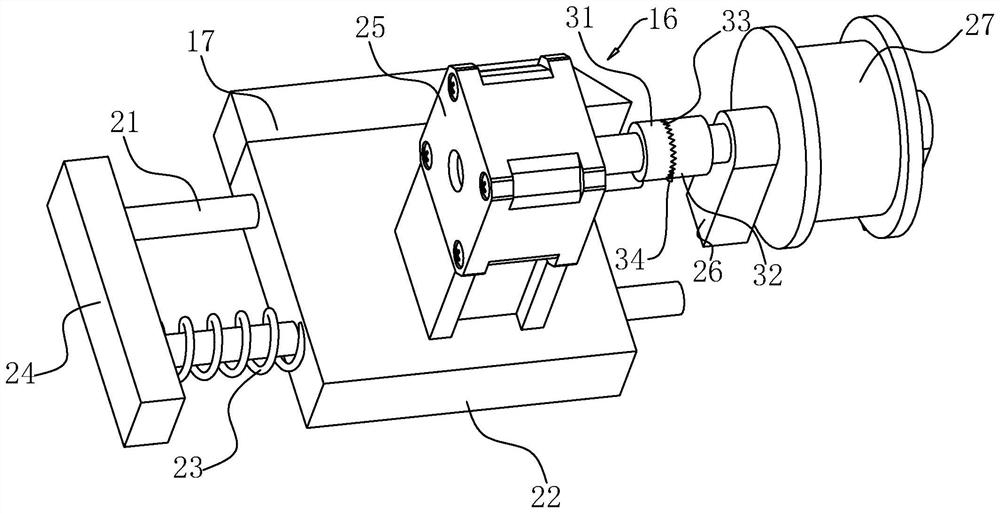

[0038] refer to figure 1 and figure 2 The bottom end of the side wall of the boom 2 is fixed with two sliding shafts 21 , and the boom 2 is connected with a sliding plate 22 through the sliding shafts 21 along its own width direction. A compression spring 23 is fixed on the side of the slide plate 22 away from the boom 2, a limit plate 24 is fixed at one end of the sliding shaft 21 away from the boom 2, and the end of the compression spring 23 away from the slide plate 22 is fixedly connected with the limit plate 24; After the 2 side moves, the compression spring 23 is in a compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com