A pushing mechanism of a clothing cutting dust remover

A technology of garment cutting and pushing mechanism, applied in the direction of sewing tools and other directions, can solve the problem of heavy workload and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

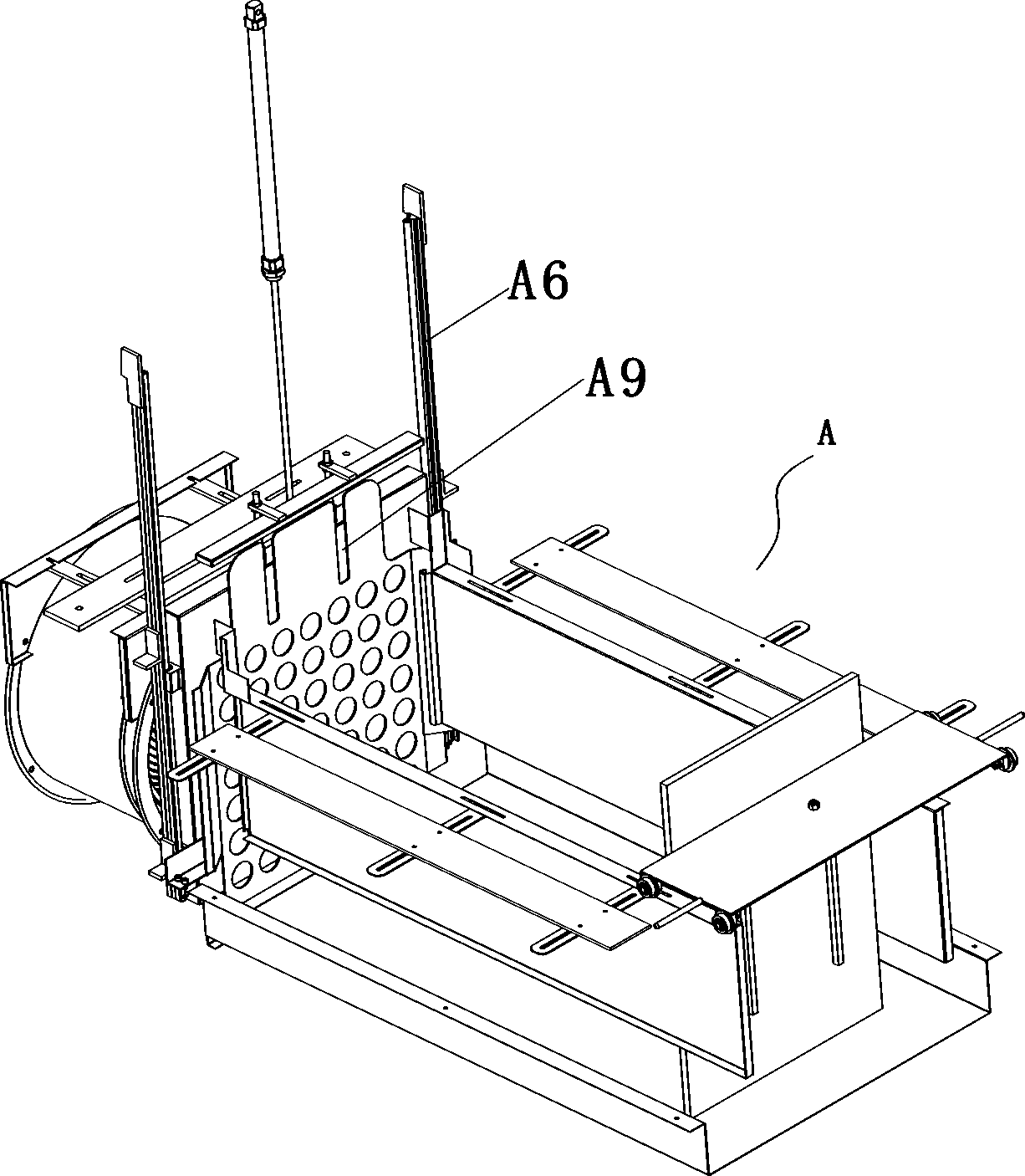

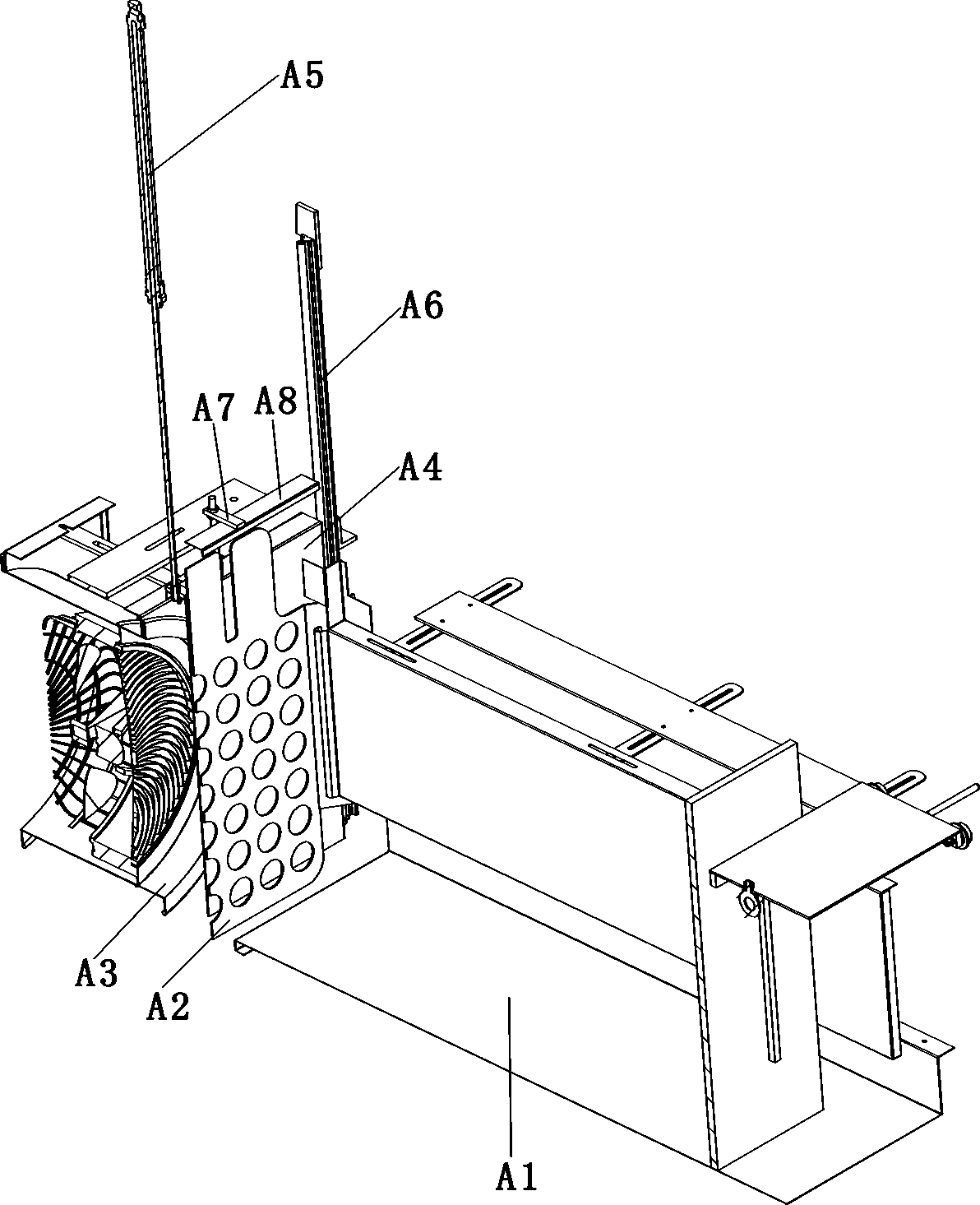

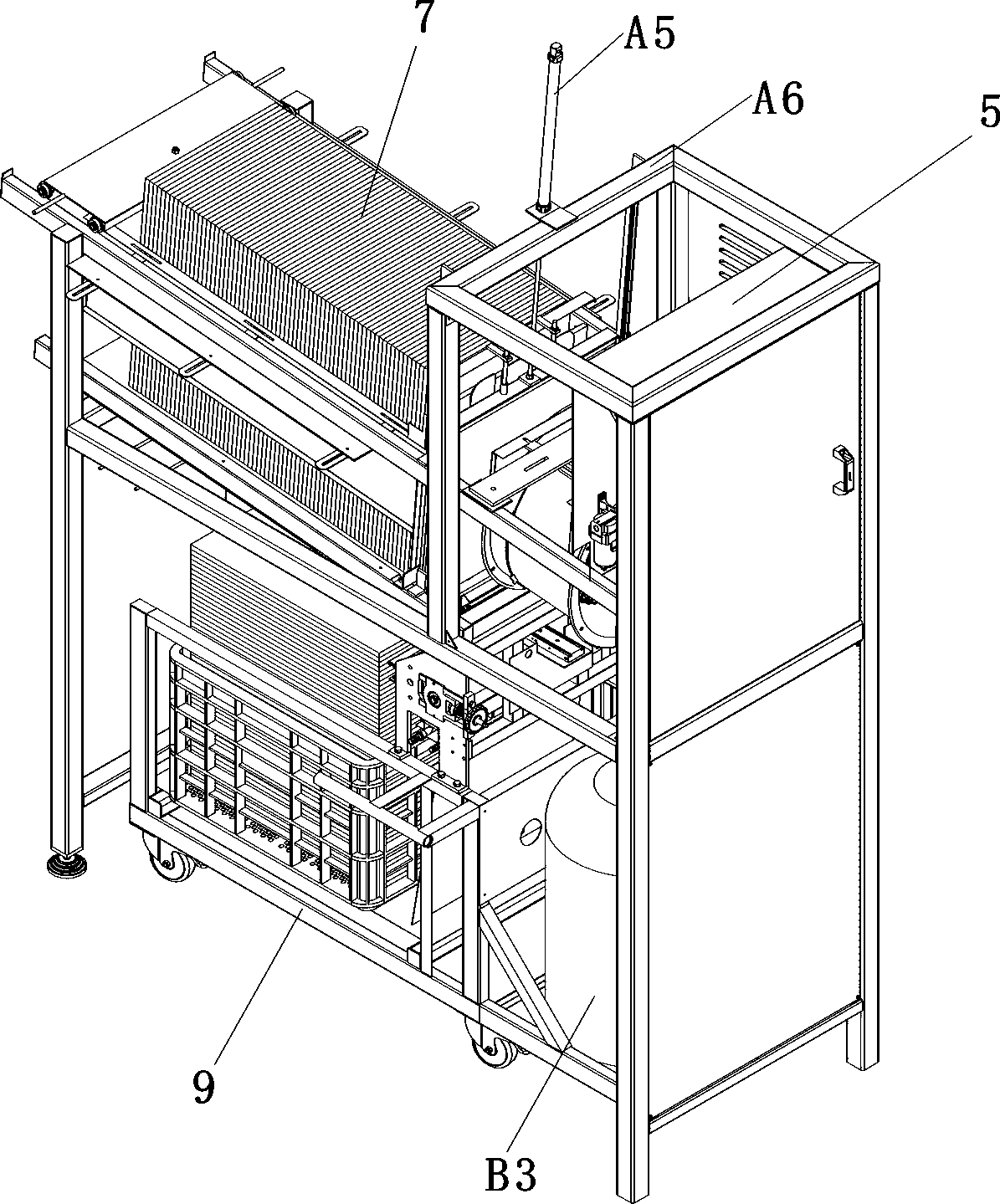

[0023] refer to figure 1 , figure 2 , image 3 and Figure 4 , the push mechanism A includes a feeding frame A1, a material plate A2, an exhaust fan A3, a windshield plate A4, a cylinder A5 and a fixed frame A6, wherein the material plate A2 is installed at the outlet of the feeding frame A1, and there are rows of The exhaust fan A3 faces the through hole of the material plate A2, the fixed frame A6 is installed between the material plate A2 and the exhaust fan A3, the windshield A4 is installed on the rails on both sides of the fixed frame A6, and the cylinder A5 is installed on the fixed On the top of the frame A6, the windshield A4 can move up and down along the rails on both sides of the fixed frame A6 under the control of the cylinder A5. In addition, the windshield A4 has a transverse action rod A8 connected by the suspension beam A7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com