Dust collector structure

A technology for vacuum cleaners and dust cups, which is applied to the installation of vacuum cleaners, suction filters, and electrical equipment. It can solve the problems of high cost and difficulty in disassembling and separating dust cup components and motor components, and achieves the effect of easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

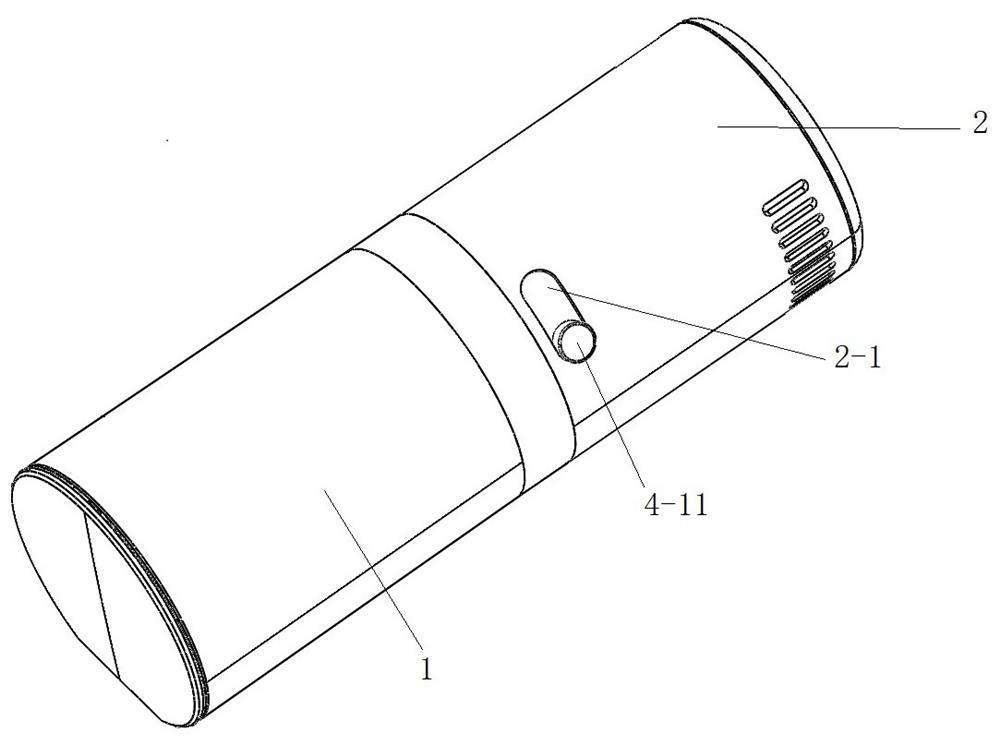

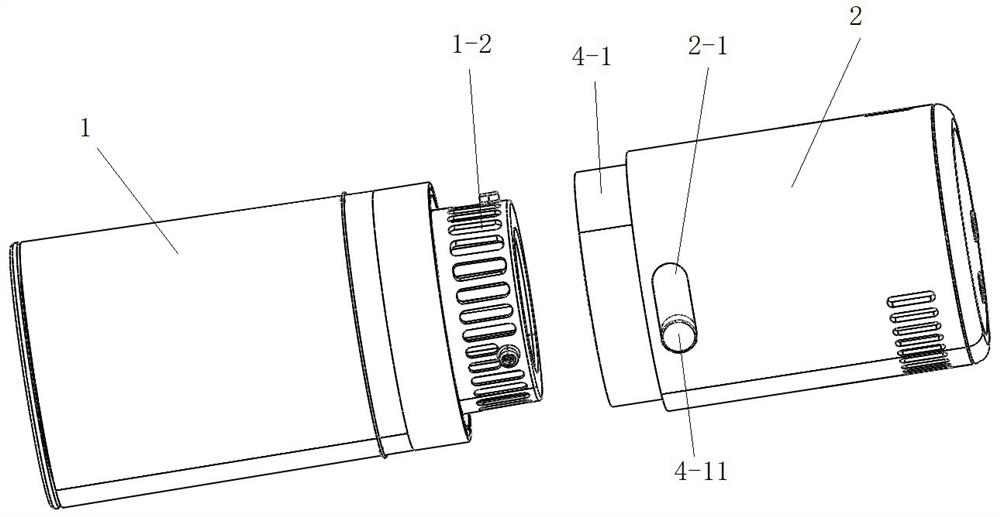

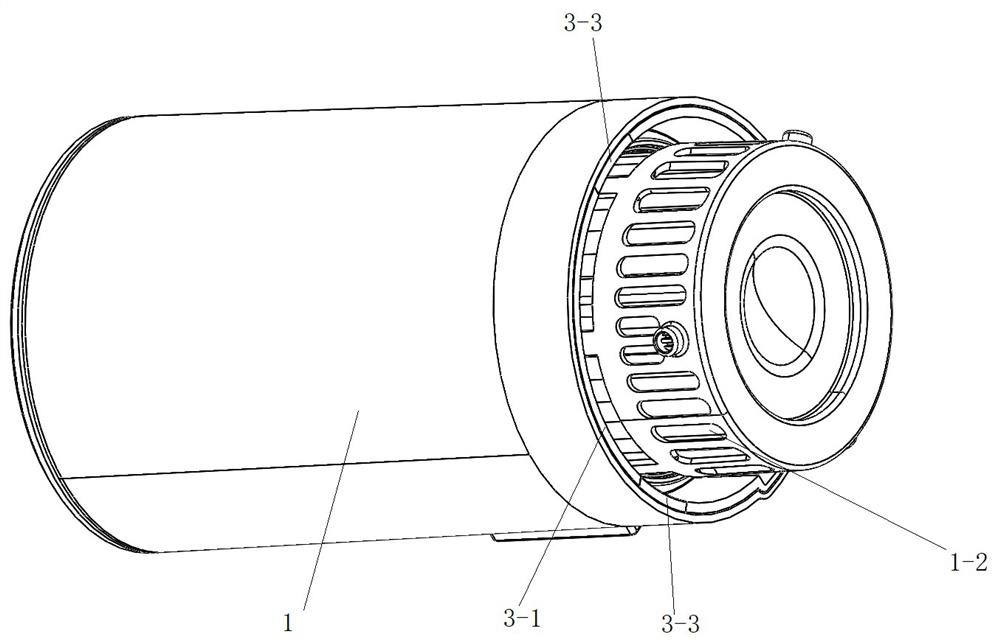

[0028] Such as Figure 1 to Figure 4As shown in , the structure of the vacuum cleaner of the present invention includes a dust cup assembly 1 and a motor assembly 2, on which a filter element 1-2 is installed, and the dust cup assembly 1 and the motor assembly 2 are magnetically connected by a magnetic attraction assembly 3. The magnetic attraction assembly 3 includes a first magnet mounting base 3-1, a second magnet mounting base 3-2 and several magnetic blocks 3 respectively mounted on the first magnet mounting base 3-1 and the second magnet mounting base 3-2 -3; the first magnet mounting base 3-1 is installed on the opening end of the dust cup assembly housing, and several magnetic blocks 3-3 are evenly fixed on the first magnet mounting base 3-1; the second magnet mounting base 3-2 Installed on the open end of the motor assembly housing, several magnetic blocks 3-3 are uniformly fixed on the second magnet mounting base 3-2; the magnetic block on the first magnet mounting b...

Embodiment 2

[0033] The differences between this embodiment and the vacuum cleaner structure in Embodiment 1 are as Figure 6 As shown, several mutually attracting magnetic blocks 3-31 and several mutually repelling magnetic blocks 3-32 are evenly installed on the rotating wall 4-2. The phase-attracting magnetic blocks 3-31 are engaged with the magnetic blocks 3-3 on the first magnet mounting base 3-1 in one-to-one correspondence, so that the dust cup assembly 1 and the motor assembly 2 are magnetically connected. Toggle the dial 4-11, and the dial 4-11 drives the rotatable wall 4-2 to rotate on the outer wall of the fixed wall 4-1, so that the phase-attracting magnetic block 3-31 can be connected with the first magnet mounting seat 3-1 The magnetic blocks 3-3 on the top are misaligned with each other, and at the same time, the magnetic blocks 3-32 and the magnetic blocks 3-3 on the first magnet mounting base 3-1 are mutually repelled one by one, so that the dust cup assembly 1 and the mot...

Embodiment 3

[0035] The difference between this embodiment and the structure of the vacuum cleaner in Embodiment 1 is that the rotating assembly 4 is arranged on the first magnet mount 3-1, and the fixed wall 4-1 is installed on the inner wall of the opening end of the dust cup assembly housing. The button chute 2-1 is arranged on the housing of the dust cup assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com