Device for transporting milk

A milk and equipment technology, applied in applications, household appliances, kitchen appliances, etc., can solve the problems of expensive appliances and can not be used in households, and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

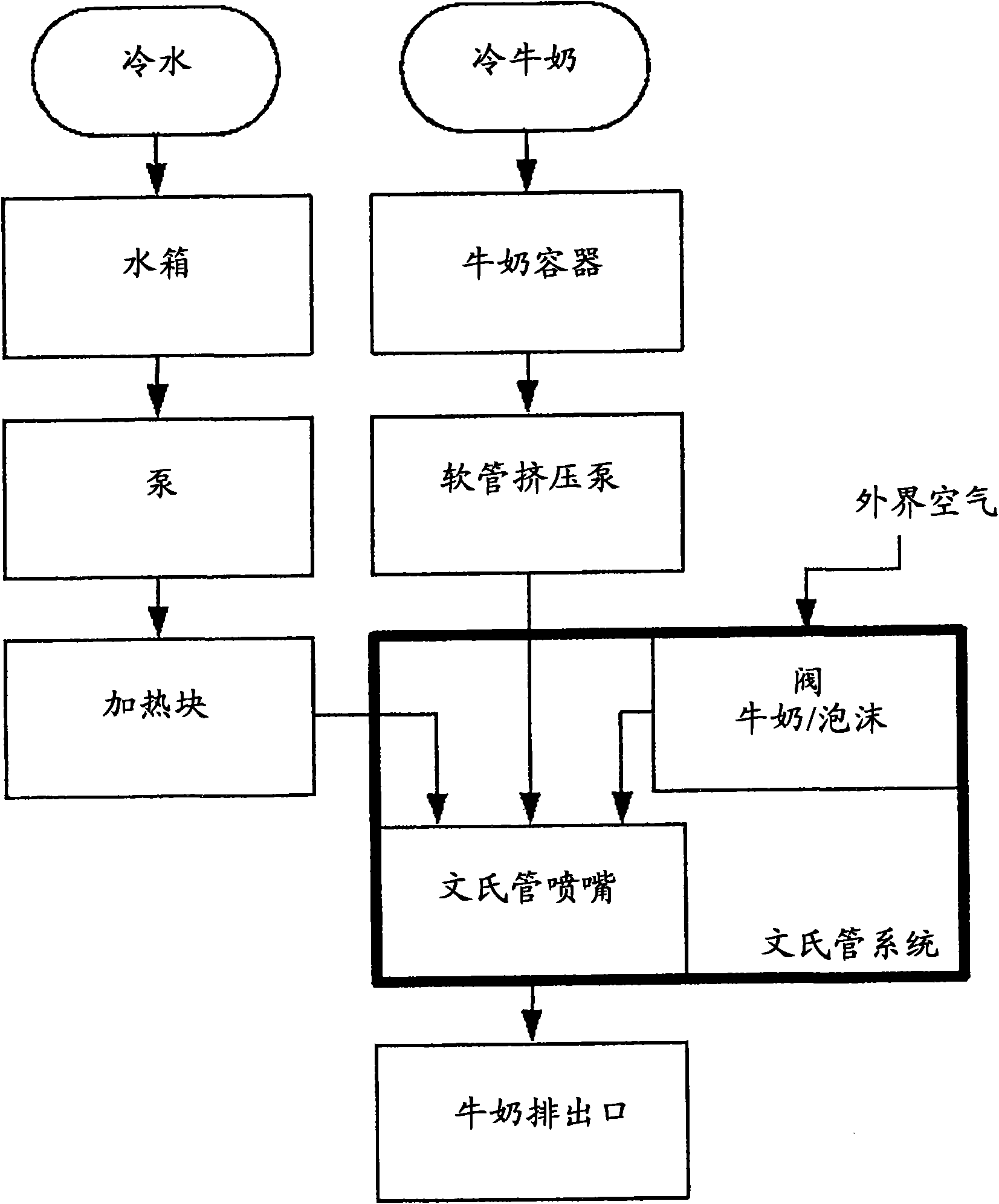

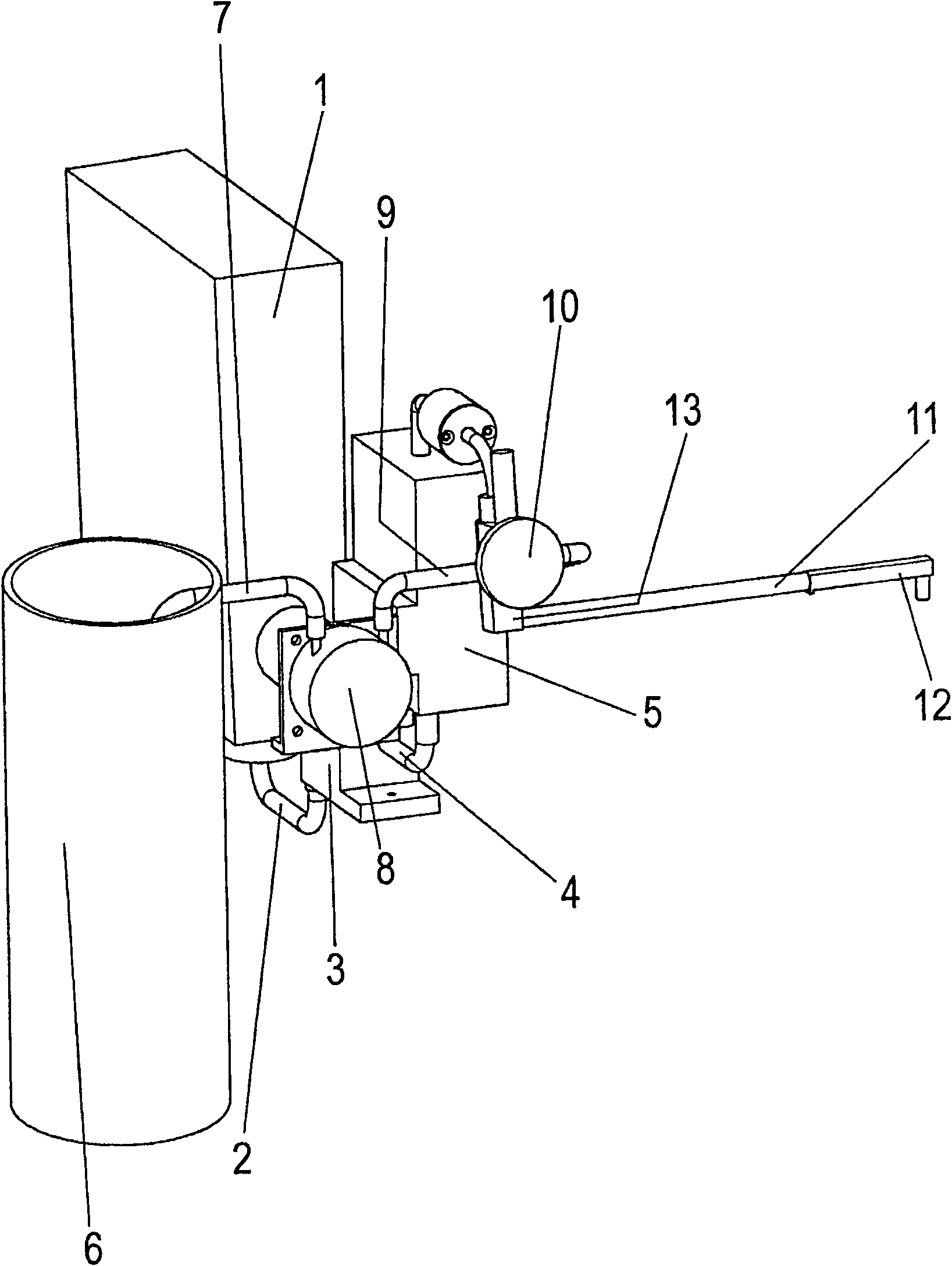

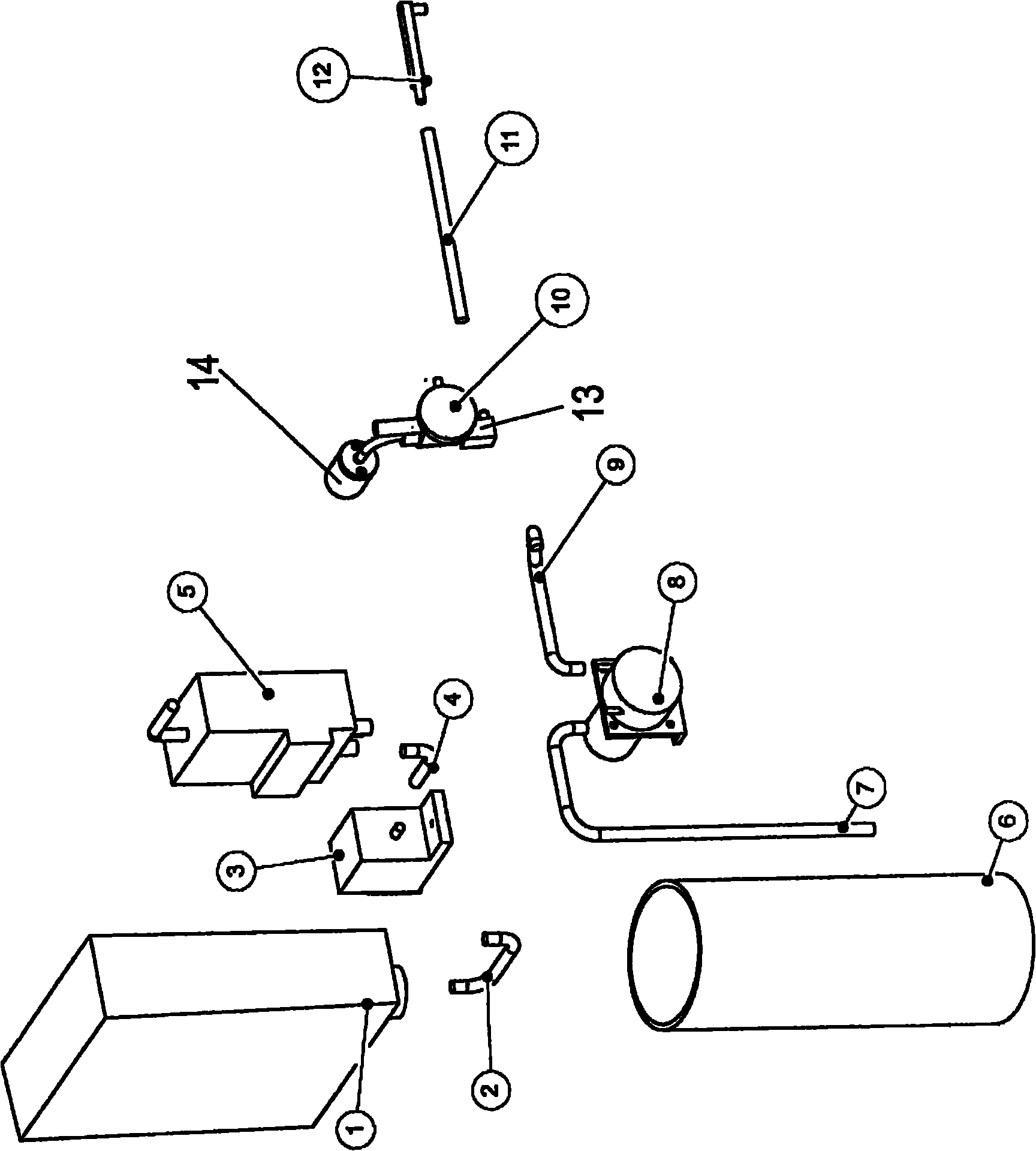

[0017] figure 1 A flow diagram of a device for conveying milk according to the invention is shown in . Cold water is pumped from the water tank to a thermoblock, where the water can optionally be heated, in particular for the production of hot steam. This hot steam is then conveyed to a nozzle, especially a venturi nozzle.

[0018] In the second route, cold milk enters a milk container which is connected by a tube to a hose squeeze pump. Squeeze the pump through this hose to deliver cold milk to the spout.

[0019] The nozzles are components of a venturi system in which, in addition to water and milk, also external air can be sucked in and mixed with milk or water.

[0020] Thus, cold or hot water, hot steam, cold milk, hot milk or hot milk froth can be conveyed at the milk outlet after the venturi system. This makes it possible to prepare a wide variety of hot or cold beverages based on milk mixtures. The device for conveying milk can especially be combined with an autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com