Tandem type electrolytic tank without wiring connection

A series type, electrolyzer technology, applied in the electrolysis process, electrolysis components, cells, etc., to achieve the effect of reducing workload, reducing connection resistance, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

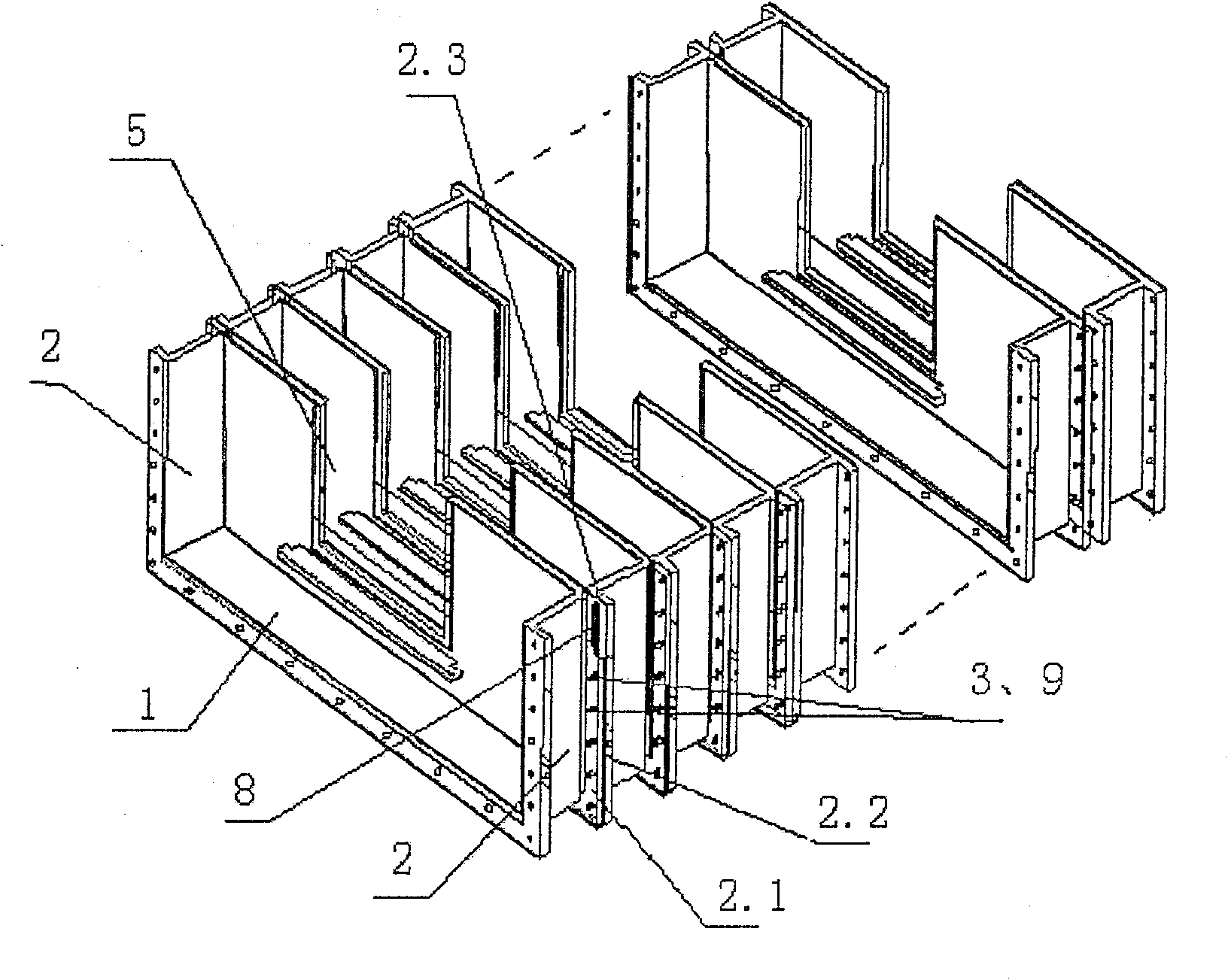

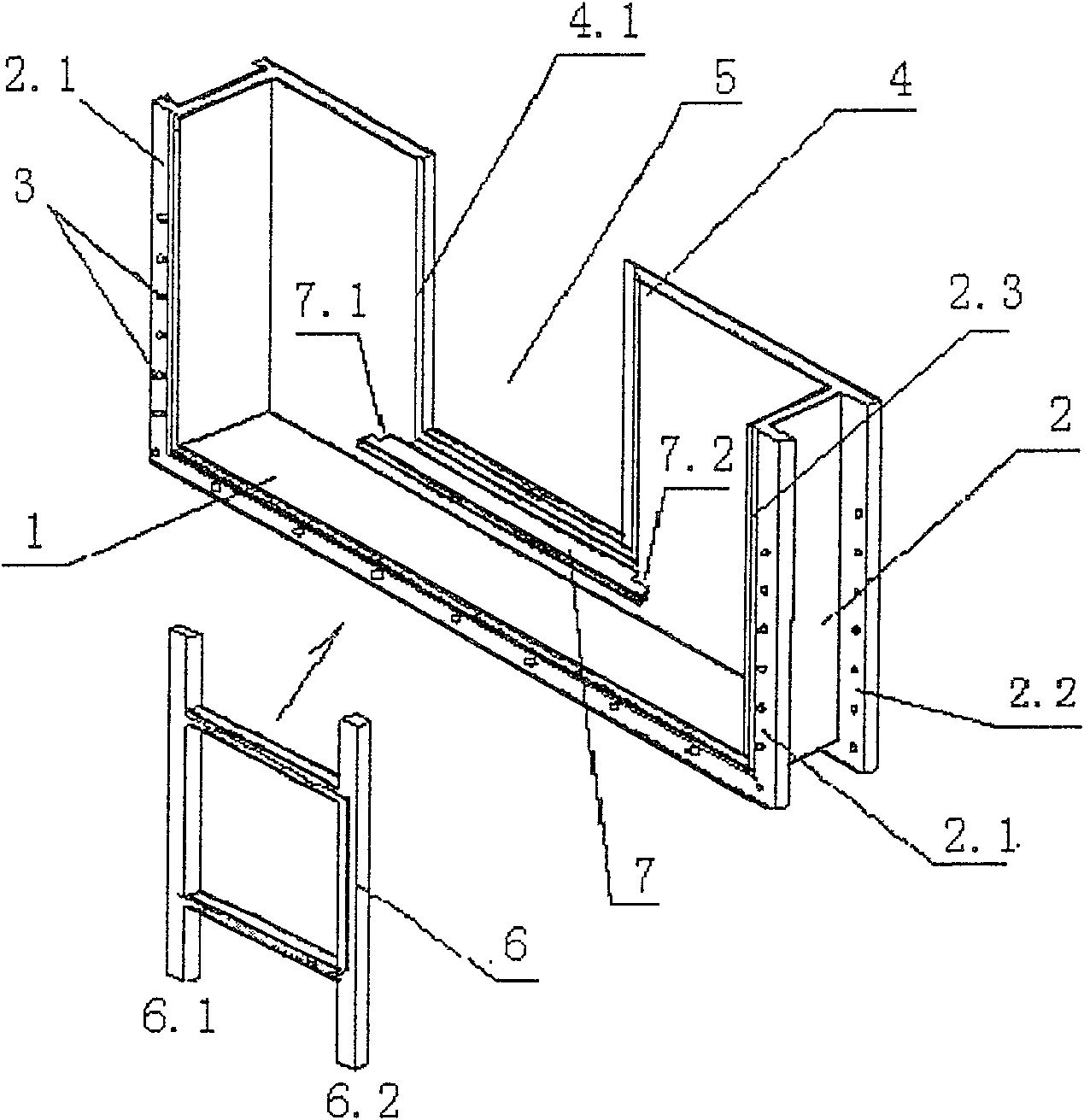

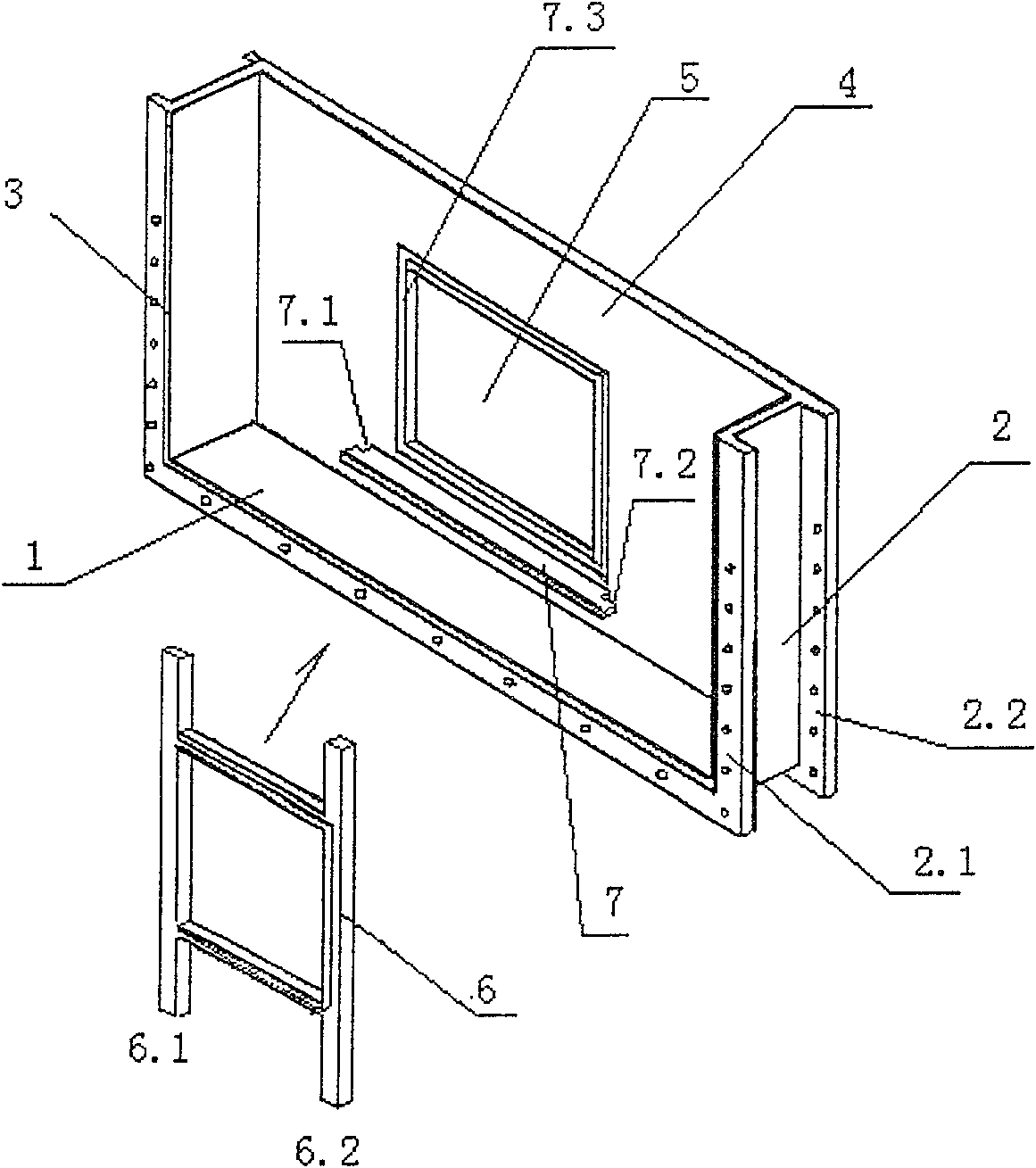

[0022] like figure 1 : The serial electrolytic cell without wire connection includes a plurality of electrolytic chambers, and the electrolytic chambers are connected by the electrolytic chamber components, and the electrolytic chamber components include a bottom plate 1, an upper open frame surrounded by two narrow side walls 2, The front and rear edges have outstretched connecting edges 2.1 and 2.2 that are perpendicular to the bottom plate 1 and the two side walls 2. There are connecting holes 3 on the connecting edges. An isolation plate 4 is arranged at the front of the frame, and an electrode plate is placed in the middle of the isolation plate 4. There are grooves 2.3 for placing corrosion-resistant silicone rubber sealing strips on the rear connecting edge 2.1 or / and the front connecting edge 2.2 of the two electrolytic chamber assemblies. Corrosion-resistant silicone rubber sealing strip 8 is padded between the rear connecting edge 2.1 of one electrolytic chamber asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com