Ferrite-based stainless steel plate, steel pipe, and production method therefor

A manufacturing method, stainless steel technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of undisclosed hot rolling conditions, etc., and achieve the effects of excellent formability, increased degree of freedom in forming, and effective component manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

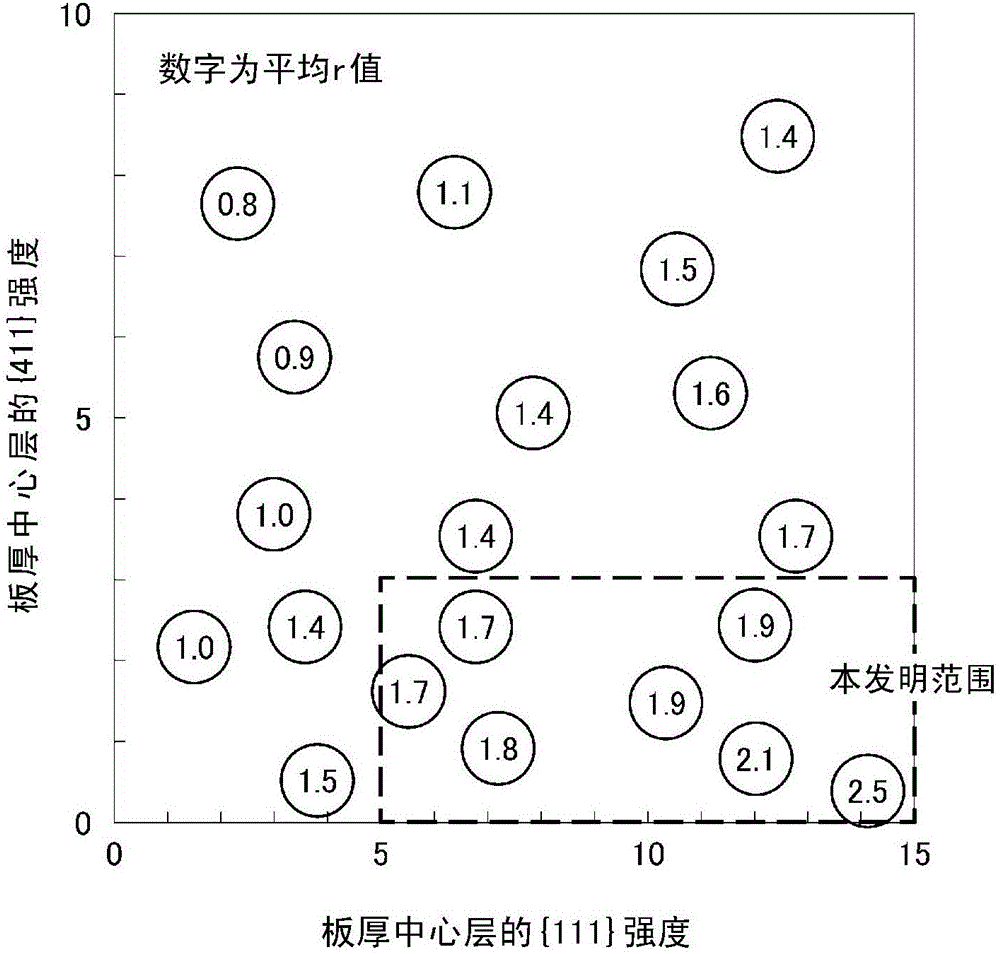

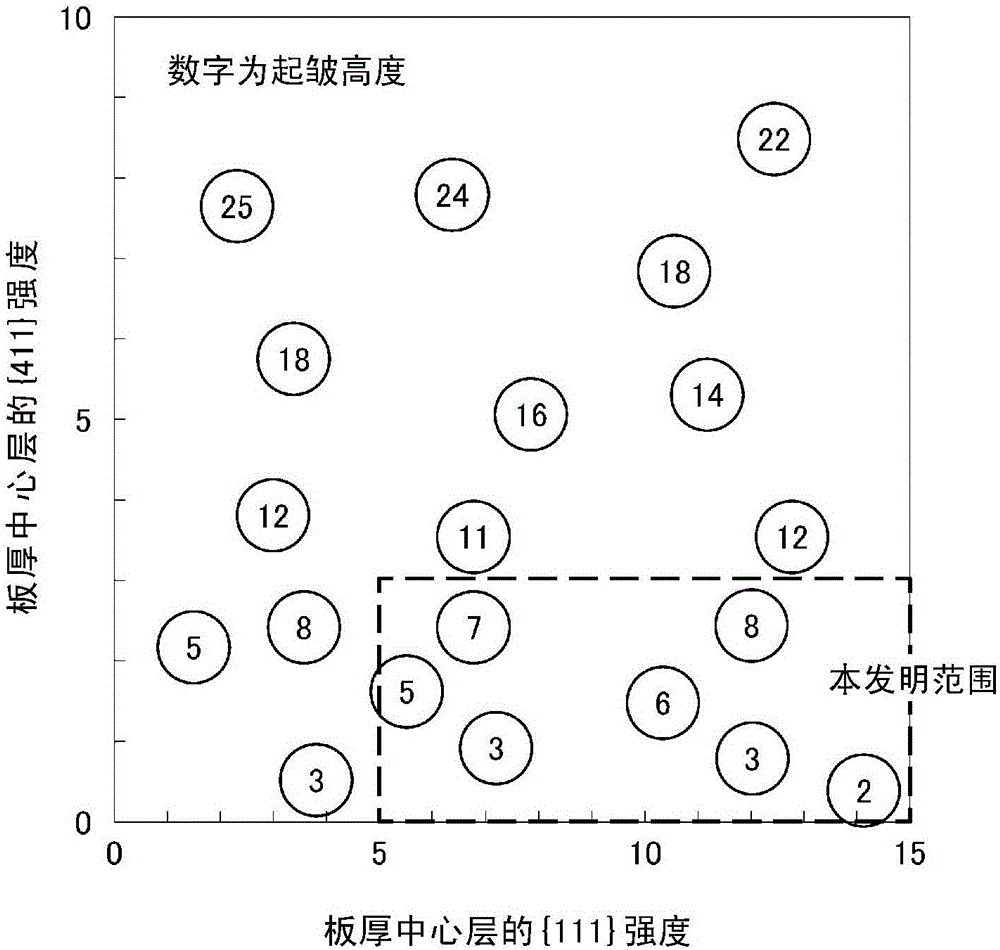

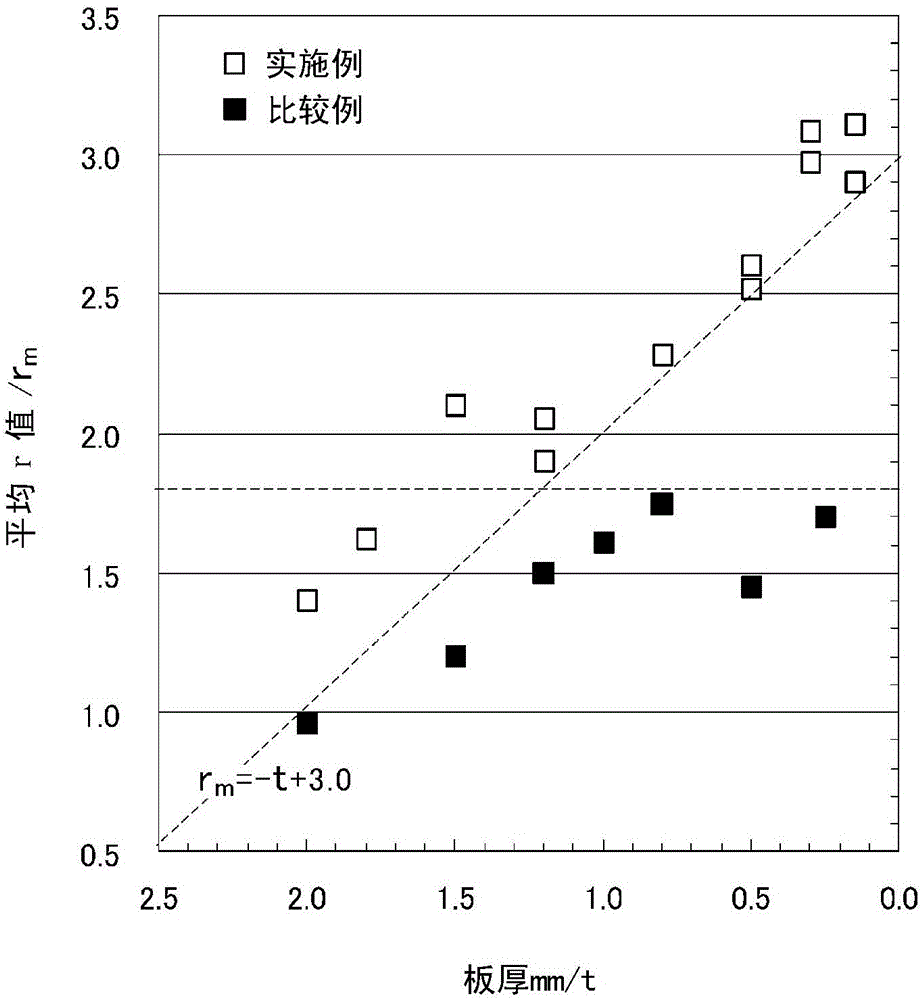

[0169] Examples of the above-mentioned first aspect of the invention will be described below.

[0170] The steels with the composition shown in Table 1-1 and Table 1-2 are melted and cast into slabs, and after hot rolling, cold rolling, intermediate annealing, final cold rolling, and final annealing are performed without annealing the hot-rolled slabs, A product plate of 1.2 mmt was obtained. In addition, regarding the hot rolling conditions, the rough reduction rate / finish reduction rate were also studied, and the characteristics of each steel were investigated. Each steel was manufactured under the manufacturing conditions shown in Table 2-1, Table 2-2, and Table 2-3. The evaluation methods of {111} strength and {411} strength, average r value, and wrinkling in the vicinity of the plate thickness center are as described above.

[0171]

[0172]

[0173]

[0174]

[0175]

[0176] The steel of the example of the present invention has a high r value and a low ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com