Anti-ultraviolet fabric, finishing method thereof, and anti-ultraviolet fabric product

An anti-ultraviolet and fabric technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of unsatisfactory utilization of attapulgite efficacy, cumbersome operation of fabric finishing technology, and high finishing cost, so as to improve anti-ultraviolet performance, improve Anti-ultraviolet performance, the effect of anti-ultraviolet performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment provides a kind of finishing method of anti-ultraviolet fabric, and it comprises the following steps:

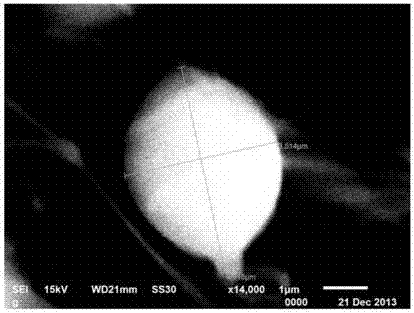

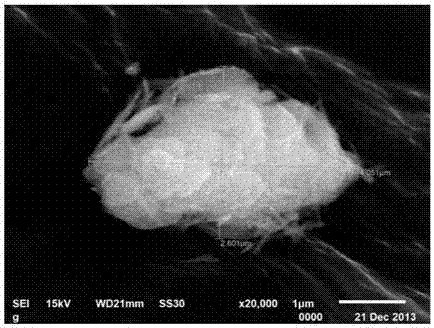

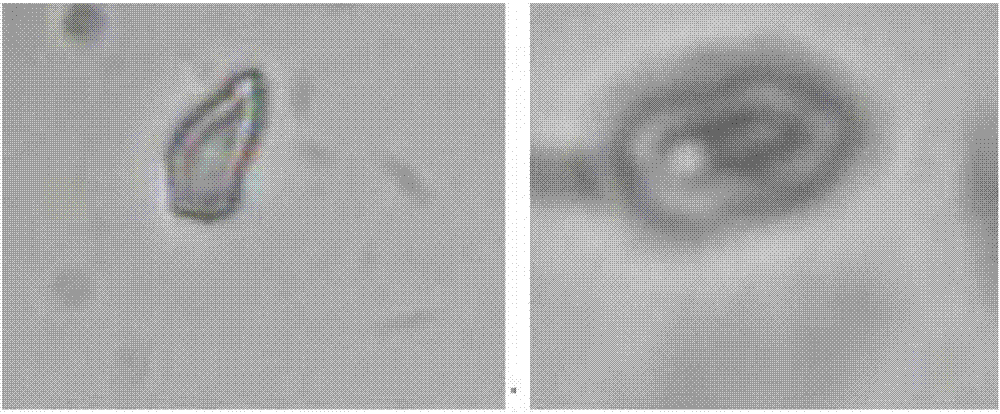

[0048] Mix chitosan, sodium tripolyphosphate and attapulgite evenly, wherein the mass ratio of attapulgite, sodium tripolyphosphate and chitosan is 0.1:0.1:1, polymerize at a temperature of 20°C for 0.5h, and The polymerized solution was ultrasonically treated for 5 minutes to obtain an attapulgite-chitosan microcapsule solution.

[0049] Soak the fabric to be modified in the attapulgite-chitosan microcapsule solution for 0.5h, take it out and dry it.

[0050] This embodiment provides a finishing method for fabrics, which includes the above-mentioned finishing method for UV-resistant fabrics.

Embodiment 2

[0052] The present embodiment provides a kind of finishing method of anti-ultraviolet fabric, and it comprises the following steps:

[0053] Mix chitosan, sodium pyrophosphate and attapulgite evenly, wherein the mass ratio of attapulgite, sodium pyrophosphate and chitosan is 2:2:1, polymerize at 60°C for 1 hour, and polymerize the The solution was ultrasonically treated for 60 min to obtain attapulgite-chitosan microcapsule solution.

[0054] Soak the fabric to be modified in the attapulgite-chitosan microcapsule solution for 2 hours, take it out and dry it.

[0055] This embodiment provides a finishing method for fabrics, which includes the above-mentioned finishing method for UV-resistant fabrics.

Embodiment 3

[0057] The present embodiment provides a kind of finishing method of anti-ultraviolet fabric, and it comprises the following steps:

[0058] The natural attapulgite was heated at 300° C. for 6 hours and dried to obtain heat-activated attapulgite.

[0059] Mix chitosan, water glass and heat-activated attapulgite evenly, wherein the mass ratio of heat-activated attapulgite, water glass and chitosan is 1:1:1, polymerize at 40°C for 1h, and polymerize After the solution was ultrasonically treated for 40 min, attapulgite-chitosan microcapsule solution was obtained.

[0060] Soak the fabric to be modified in the attapulgite-chitosan microcapsule solution for 1 hour, take it out and dry it.

[0061] This embodiment provides a finishing method for fabrics, which includes the above-mentioned finishing method for UV-resistant fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com