Vibration type wrinkling machine

A creping machine and vibration mechanism technology, which is applied in the directions of mechanical processing/deformation, textile and papermaking, fabric surface trimming, etc., can solve the problems of limited wrinkling degree and limited improvement of adsorption performance, and achieve strong adsorption and ductility. , Good wrinkling effect, strong adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

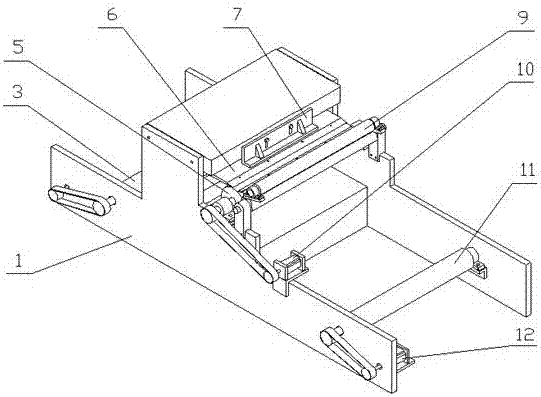

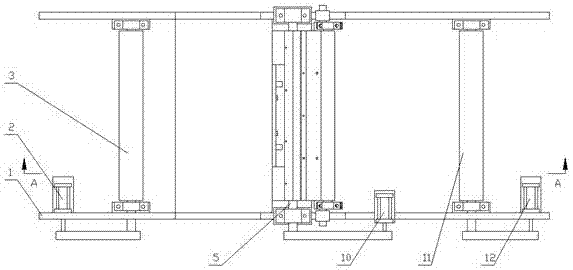

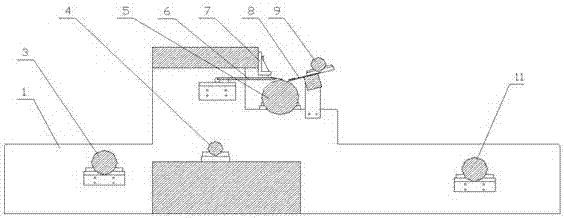

[0024] Such as figure 1 , figure 2 , image 3 As shown, it includes frame 1, unwinding device, front tension roller 4, transmission device, pressing mechanism 6, vibration mechanism 7, lifting mechanism 8, rear tension roller 9 and winding device; the unwinding device is set At the head of the frame 1, the front-end tension roller 4 is arranged on the right side of the unwinding device, and the middle part of the frame 1 is provided with a conveying roller 5, and above the conveying roller 5, a pressing mechanism 6 and a vibrating mechanism are sequentially arranged from left to right. 7 and the lifting mechanism 8, the upper right side of the lifting mechanism 8 is provided with a rear end tension roller 9, and the afterbody of the frame 1 is provided with a winding device.

[0025] Such as figure 1 , image 3 As shown, the unwinding device includes an unwinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com