Household paper making machine

A technology for household paper and paper machines, applied in the field of paper machines, which can solve problems such as softness, bulkiness and water absorption, wrinkle depth cannot be controlled, and wrinkles cannot be designed and replaced. High strength, effect of increasing bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

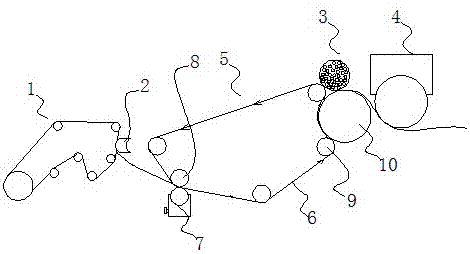

[0019] Such as figure 1 As shown, the household paper machine of the present invention includes a forming section 1, a conveying section 2, a drying section 3 and a crimping section 4 arranged in sequence; a mold belt section 5 is arranged between the conveying section 1 and the drying section 3; The model belt part 5 includes an automatic power model belt 6; the bulk of the plastic grain product can be significantly improved through the model belt, and the wrinkling effect is better, so the longitudinal strength of the paper web is higher, and the bottom of the input end of the automatic power model belt 6 is A shoe pressure roller 7 is installed; the inner side of the automatic power model belt 6 is facing the shoe pressure roller and a counter pressure roller 8 is installed; the drying part 3 is composed of a Yankee cylinder 10; the inner side of the automatic power model belt 6 is facing One end of the Yankee cylinder is installed with a flat transfer press roll 9; since t...

Embodiment 2

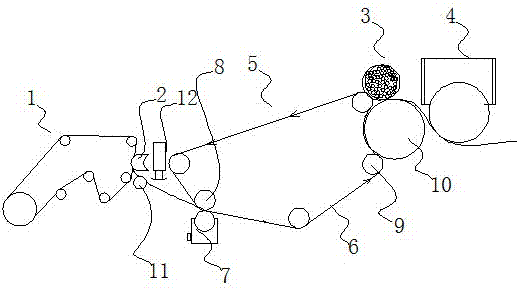

[0021] Such as figure 2 As shown, in the household paper machine of the present invention, a vacuum dewatering roller 11 is installed between the conveying part 2 and the model belt part 5 . A hot air cover 12 is installed between the vacuum dewatering roll 11 and the model belt part 5; the paper web from the forming section first passes through a vacuum dewatering roll, passes through the hot air cover 12, and improves the dewatering capacity in the shoe press area, and then passes through the shoe press area. Combined with the model belt; then the flat press roll transfers the paper web to the Yankee cylinder, where the pressing strength is very low, only 45kN / m, and the main pressing process is at the front shoe press.

Embodiment 3

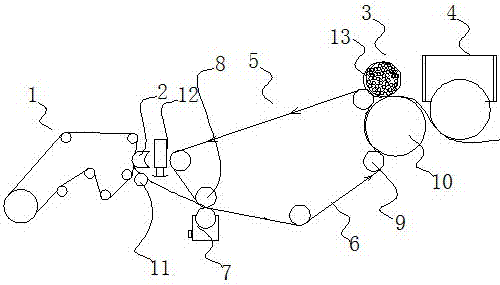

[0023] In the tissue papermaking machine of the present invention, the forming section 1 is composed of a crescent former, and an inverted headbox is used.

[0024] Wherein, the crimping portion 4 is formed by a belt reel. The belt body of the automatic power model belt 6 is a replaceable structure. The pressure of the shoe press roll 7 and the counter press roll 8 is not less than 200kN / m; the pressure of the Yankee cylinder 10 and the flat transfer press roll 9 is not greater than 45kN / m. The shoe pressure roller 7 is installed on the lifting base. The forming section 1 comprises a forming wire assembly, a headbox and a plurality of guide rolls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com