Steel-concrete mixed structure underground box-shaped pipe gallery and its manufacturing method

A concrete and hybrid technology, applied in underwater structures, infrastructure engineering, water conservancy engineering, etc., can solve the inconvenience of maintenance personnel and maintenance equipment, cannot apply large-diameter cross-section and high fill, unfavorable pipe racks and pipelines Issues such as arrangement and setting can be achieved to reduce production difficulty, save materials and improve structural efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

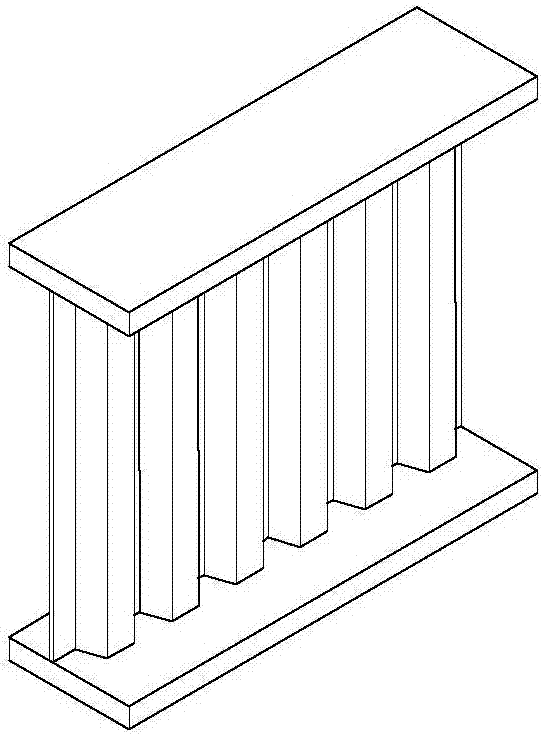

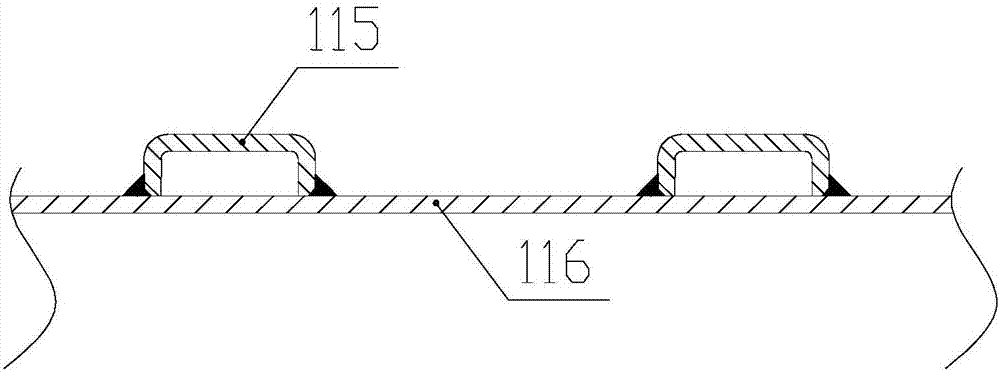

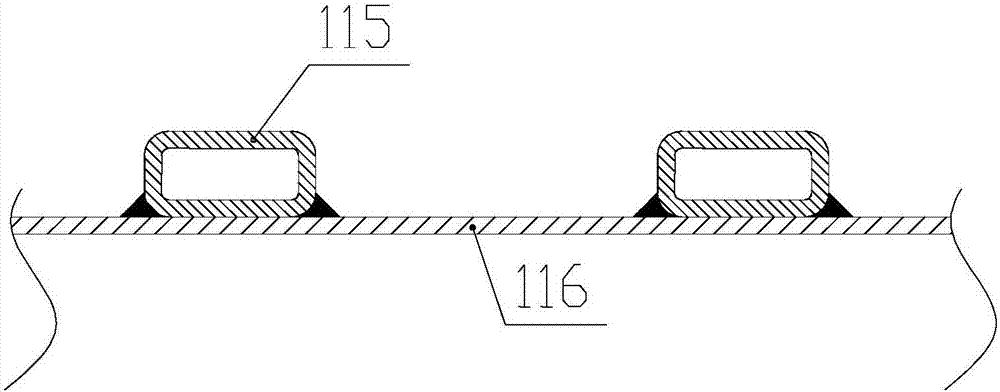

[0066] Such as Figure 13 As shown, the first steel-concrete mixed structure underground box-shaped pipe gallery described in the present invention includes a box-shaped pipe section 104 assembled from a top plate 101, a bottom plate 102 and two side plates 103. The top plate 101, bottom plate 102 and Both side plates 103 are straight, such as Figure 6 , Figure 7 shown. Wherein, the top plate 101, the bottom plate 102 and the two side plates 103 can also be small curvature arc-shaped sheets or straight sheets, wherein the arc-shaped sheets make the plates have higher torsional rigidity and stronger vertical instability resistance. At the same time, the quality of the weld can be improved to a certain extent and the stress concentration can be reduced. When the base plate 102 is straight, it can be used without paving, and its internal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com