Smart filtering compensation module structure

A compensation module, intelligent filtering technology, applied in harmonic reduction devices, AC networks to reduce harmonics/ripples, boards/panels/desks of substations/switching devices, etc. The installation personnel are inconvenient to carry and install, and it is not conducive to the cost control of the manufacturer, so as to achieve the effect of novel structure, elimination of hidden safety hazards and low processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

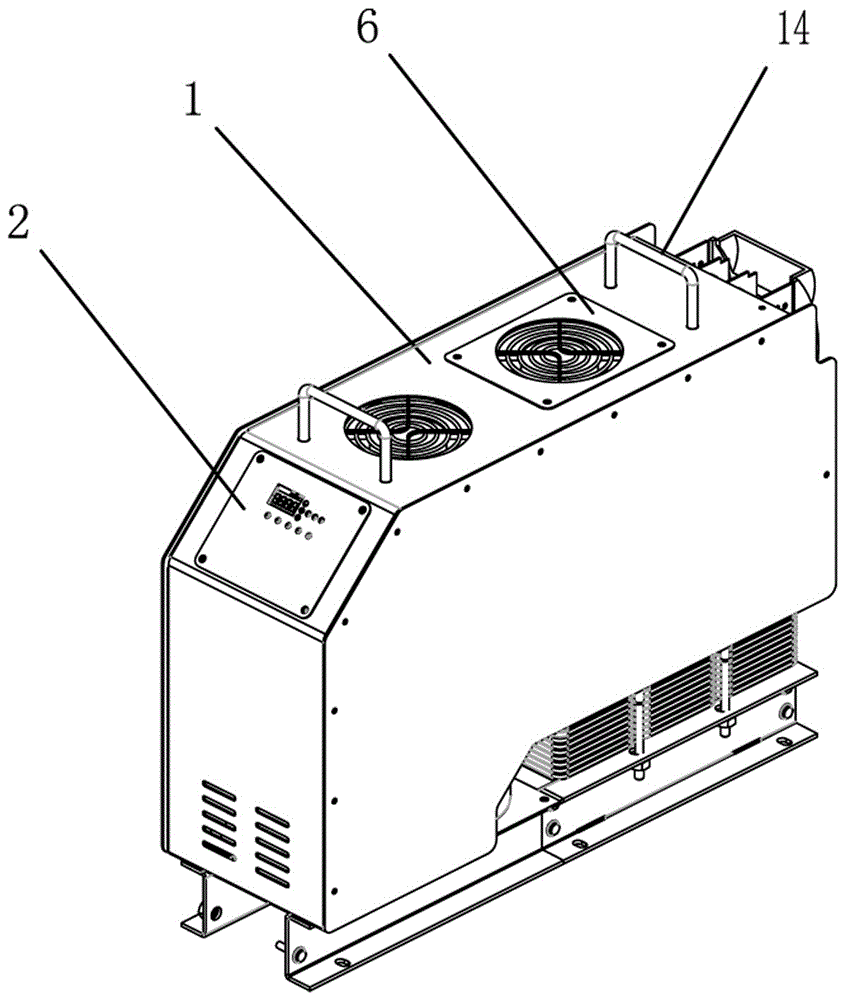

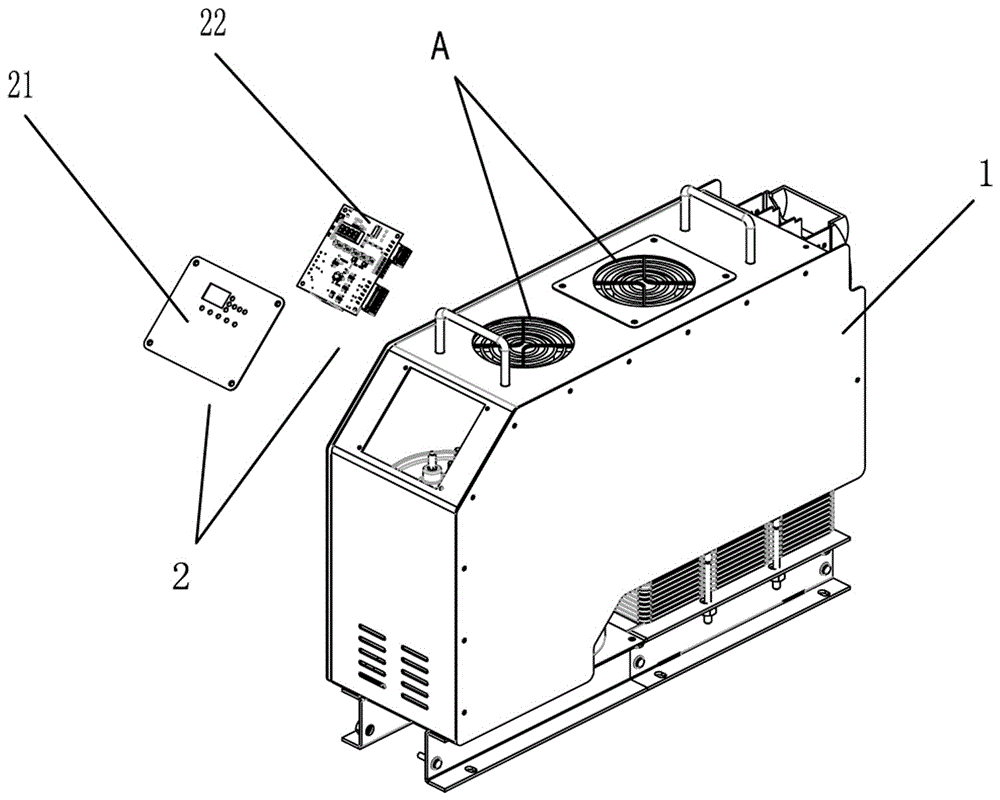

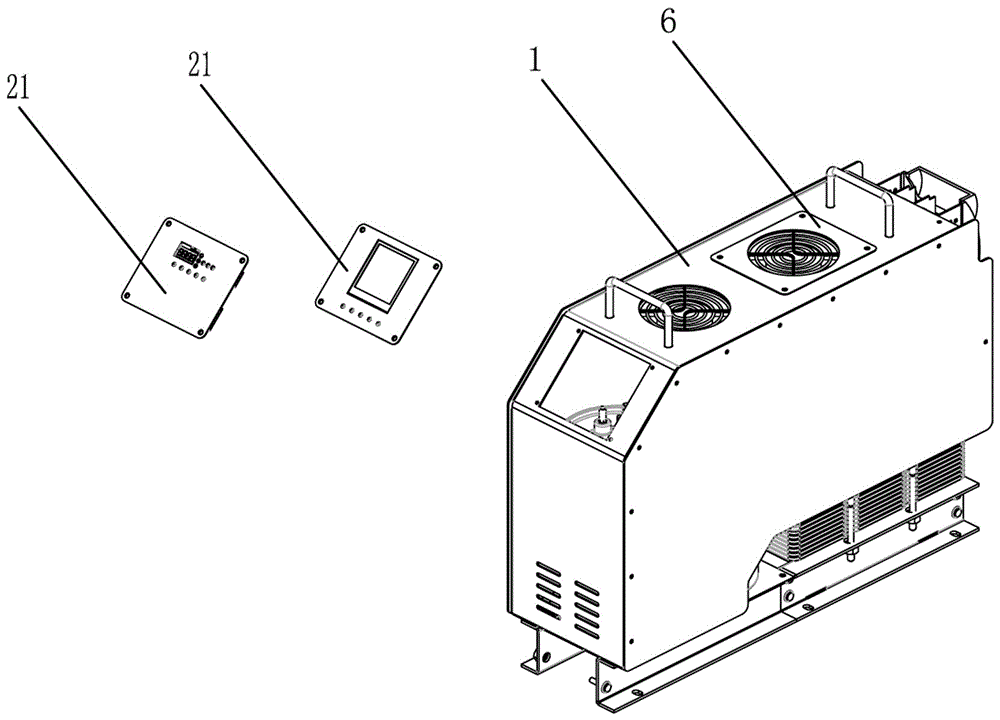

[0047] Such as Figure 1 to Figure 15 As shown in the figure, an intelligent filter compensation module structure includes a housing 1, and a capacitor C, a reactor 18, a thyristor 17, a trigger board 10 and a knife fuse switch 11 arranged in the housing 1, and it is characterized in that it also includes The main control unit 2, the fan assembly A and the knife fuse switch panel 9, the trigger plate 10 and the knife fuse switch pass 11 are fixed on the shell 1 through the knife fuse switch panel 9, the fan assembly A is installed on the surface of the shell 1, and the reactor 18 is connected with the fuse switch panel 9. The silicon controlled silicon 17 is electrically connected through the copper bar 16 , and the main control unit 2 is electrically connected with the knife fuse switch 11 , the silicon controlled silicon 17 , the trigger board 10 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com