Data simulation method based on OPC intelligent chemical equipment

A technology of chemical equipment and data simulation, applied in the direction of comprehensive factory control, comprehensive factory control, instruments, etc., can solve the problems of long manufacturing and debugging cycle, restricting production progress, affecting product quality, etc., to improve product quality and enhance product quality Stability, the effect of speeding up the production schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

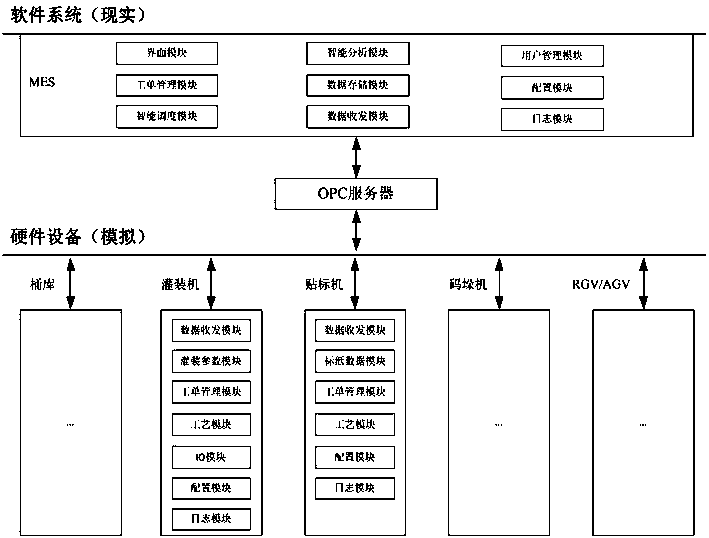

[0020] see figure 1 As shown, taking typical chemical equipment: filling machine and labeling machine as an example, by simulating the hardware equipment and its working process, the application of a data simulation method based on OPC intelligent chemical equipment of the present invention is described, including the MES system-based A software system, the software system includes an interface module, a work order management module, an intelligent scheduling module, an intelligent analysis module, a data storage module, a data sending and receiving module, a user management module, a configuration module, and a log module.

[0021] The simulated hardware equipment includes: barrel warehouse, filling machine, labeling machine, palletizer, and RGV / AGV equipment; the filling machine includes data transceiver module, filling para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com