On-line repairing method for fractured upper beam for hydraulic press casting and structure reinforcing device

A repair method and structural reinforcement technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as difficulty in strength, damage, and production stoppage of the upper beam, and reduce the risk of fracture risk, prolonging service life, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

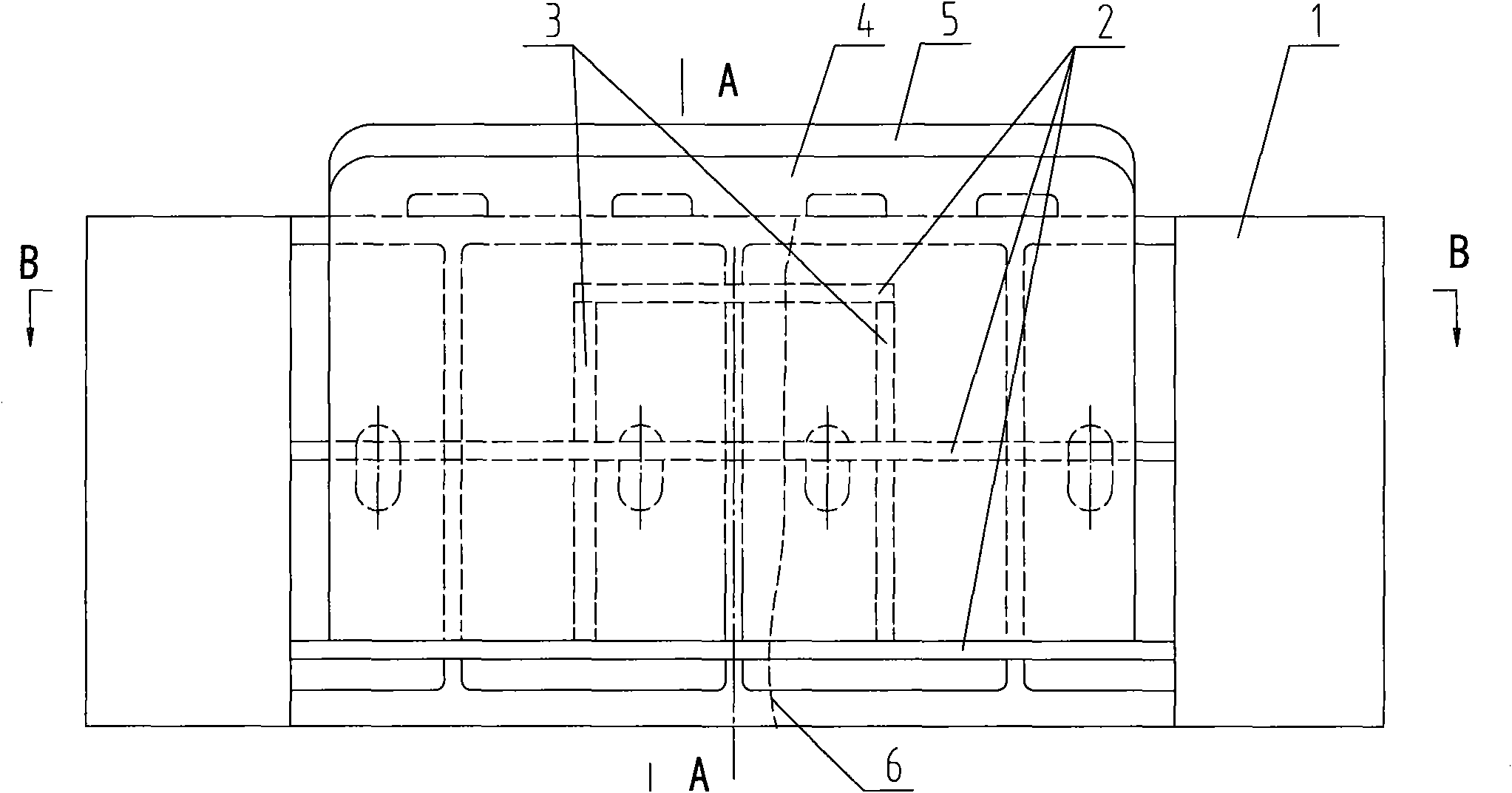

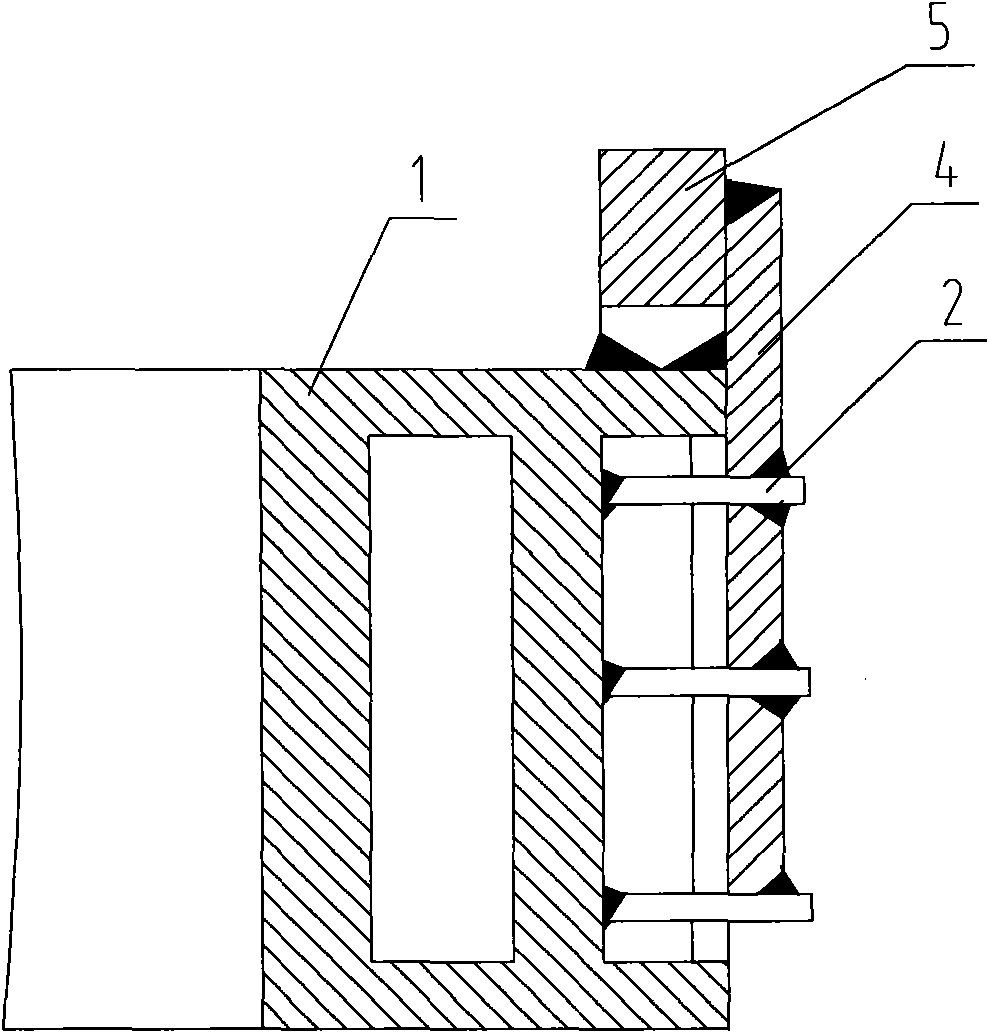

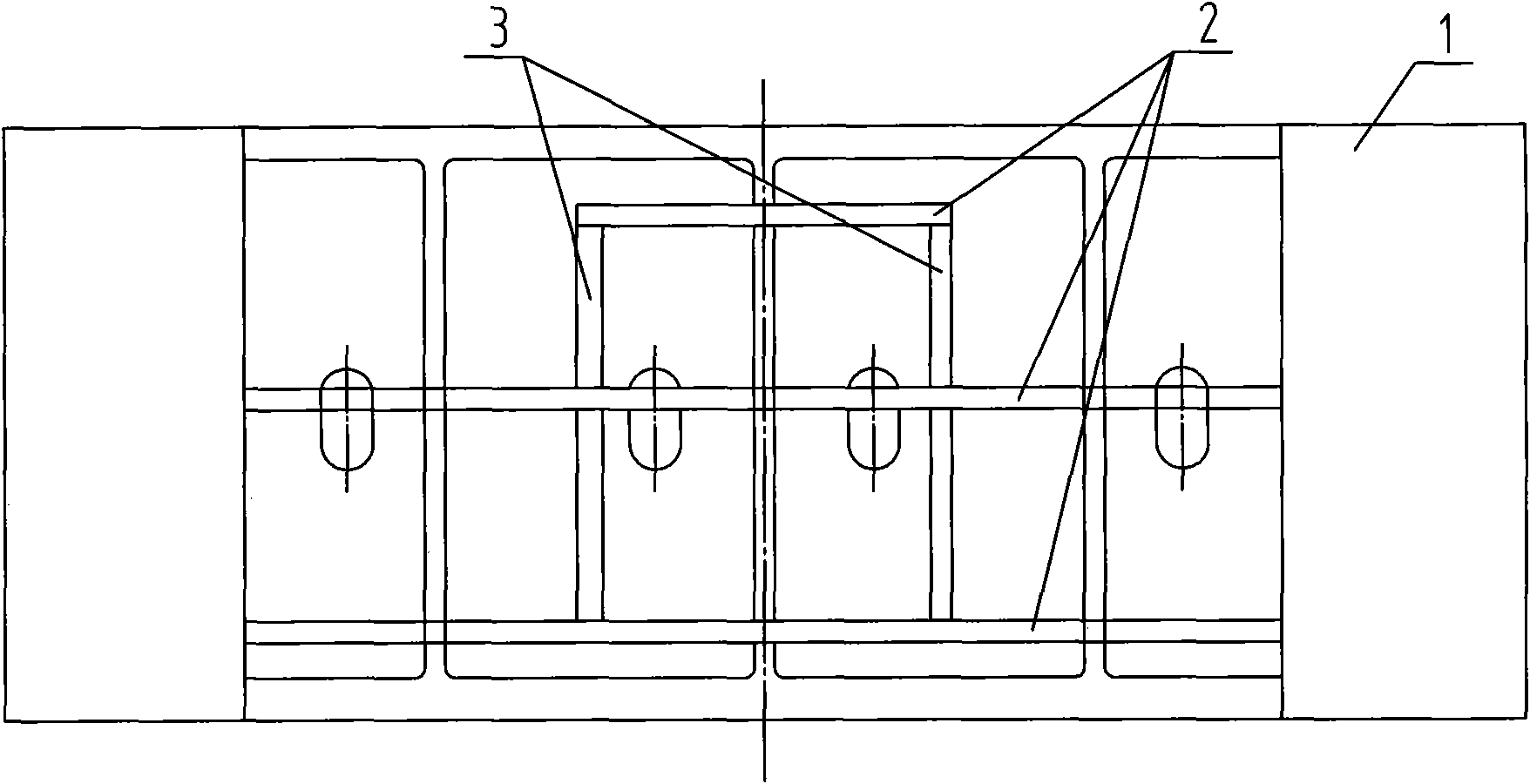

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0022] See figure 1 , figure 2 , hydraulic press casting upper beam fracture online repair method, according to the force of the upper beam and the cause of the cracks, when formulating the process, try to make the weld form a compressive stress weld, that is, weld close to the free state, so the assembly gap must be It is close to the welding shrinkage. According to this principle, use the process to pull the plate to reset the upper beam, and choose C0 with better welding operation. 2 Mixed gas shielded welding, and ER50-6, φ1.2mm welding wire with the same strength, and by setting a box-shaped structural reinforcement device in the alternating bending moment action area of the upper beam, the structural strength of the upper beam is improved, and online repair is realized. The specific repair steps are:

[0023] 1) see Figure 5 , reset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com