Full automatic corrupt brushing backwash water filter

A backwashing and fully automatic technology, which is applied in the direction of fixed filter elements, filtration and separation, chemical instruments and methods, etc., can solve problems such as no automatic backwashing function, troubles, and impact on production, so as to improve equipment utilization and reduce Effect of heavy labor and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

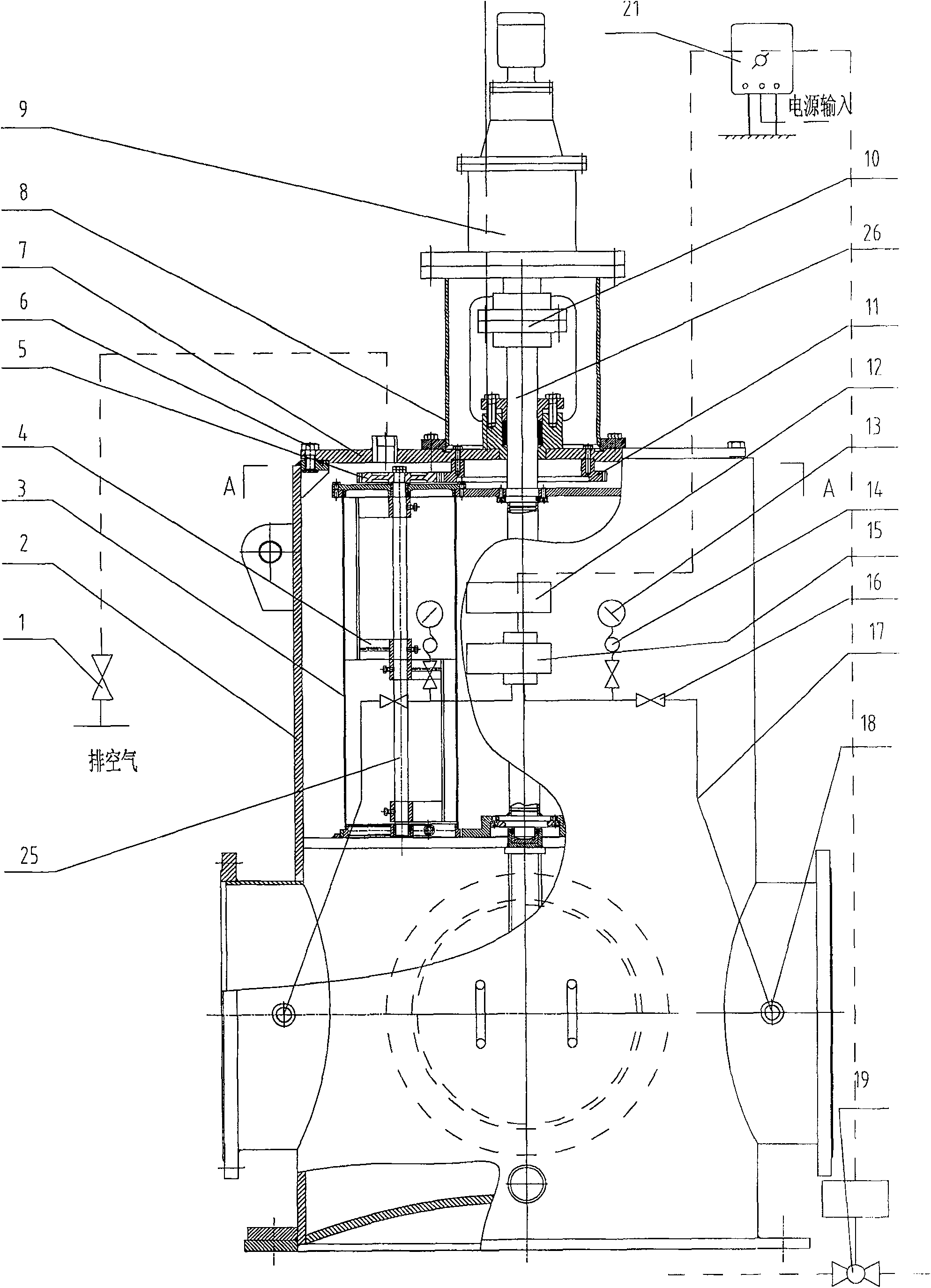

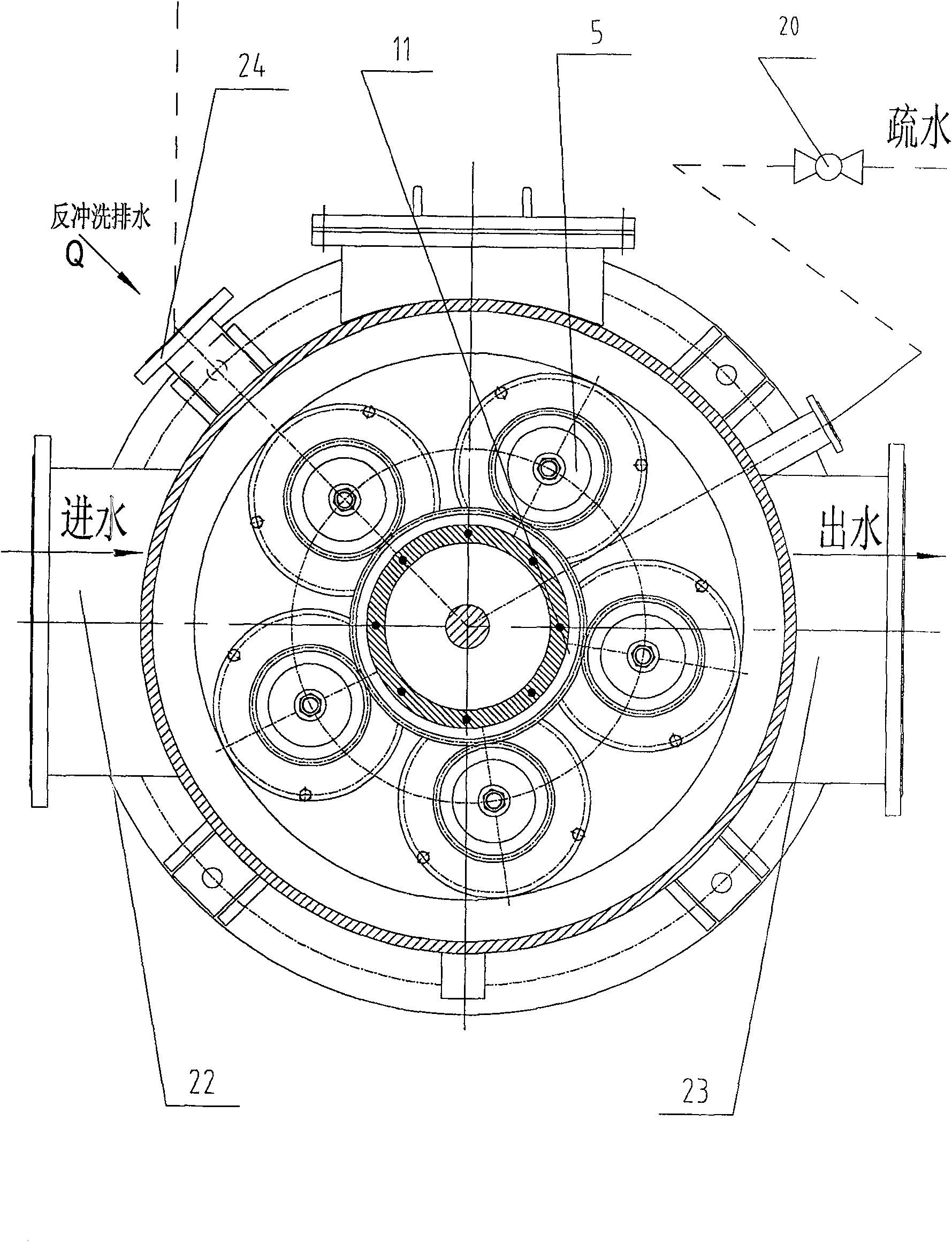

[0013] As shown in the figure: there is a filter screen 3 inside the housing 2, and its characteristic is that a reducer 9 is installed on the housing 2, several cylindrical filter screens 3 are evenly installed on the bracket, and the bracket and the main shaft 26 Connected together, the main shaft 26 is connected with the output end of the reducer 9; There is a rotating shaft 25 in each filter screen 3, and a brush 4 is arranged on the rotating shaft 25, and the end of the brush 4 contacts with the inner wall of the filter screen 3, and the rotating shaft 25 The end of the filter screen 3 is stretched out, and planetary gears 5 are arranged at the end of the rotating shaft 25, and each planetary gear 5 is respectively meshed with the large gear 11 fixed in the housing 2, and a water inlet 22 is provided at the bottom of the housing 2 With water outlet 23 and sewage outlet 24. In the process that the main shaft 26 drives the filter screen 3 to rotate, the working state of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com