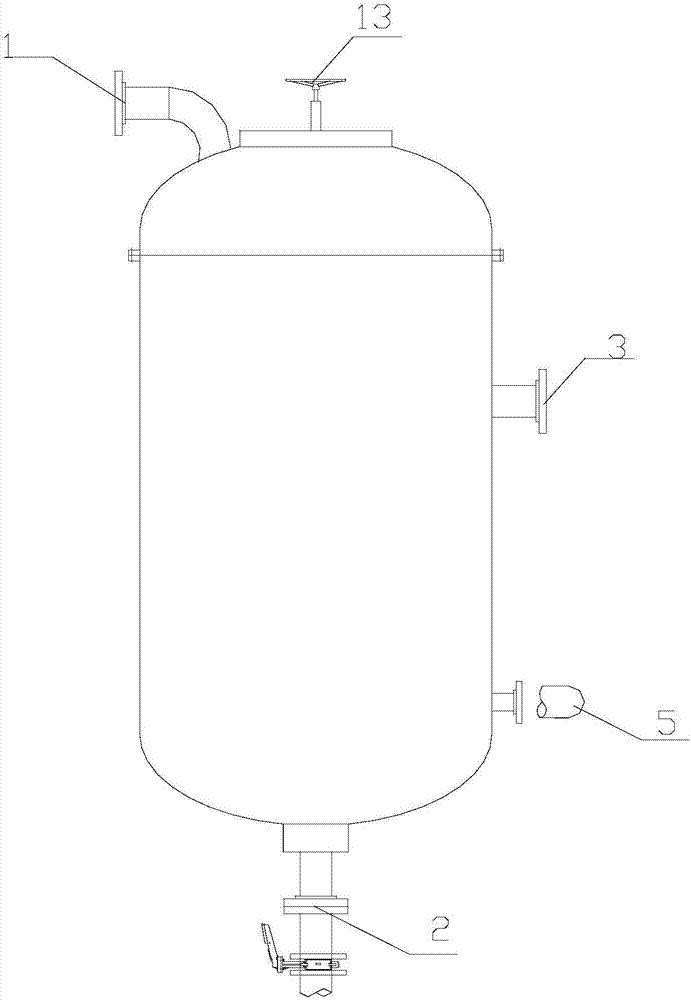

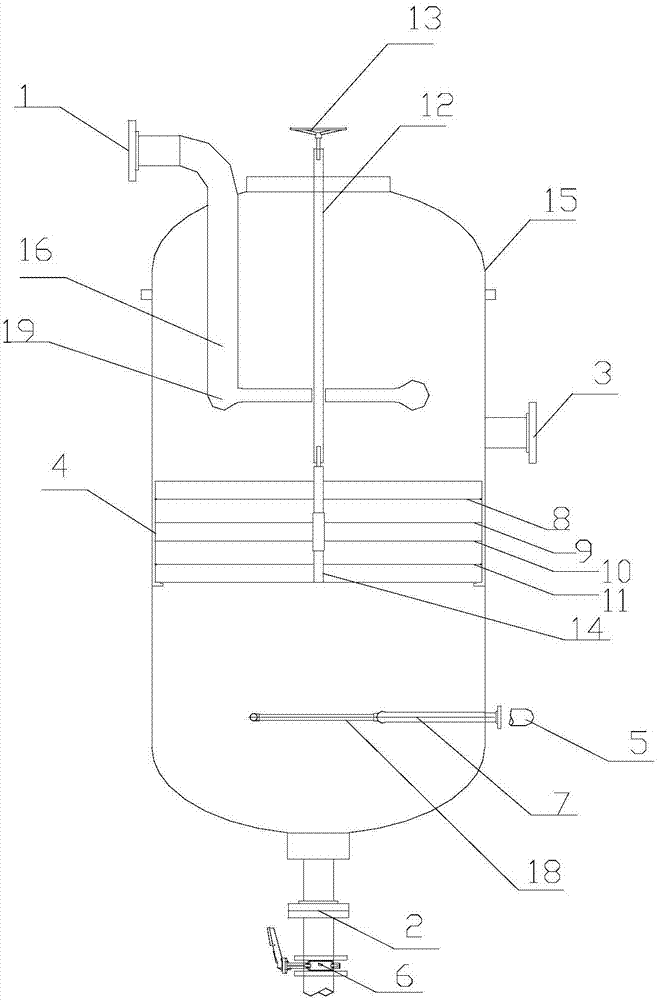

Front filter back flushing device and method

A pre-filter and filter device technology, applied in the field of backwashing, can solve the problems of long backwashing time and complex backwashing filter structure, and achieve the effects of small size, improved water transparency and turbidity, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

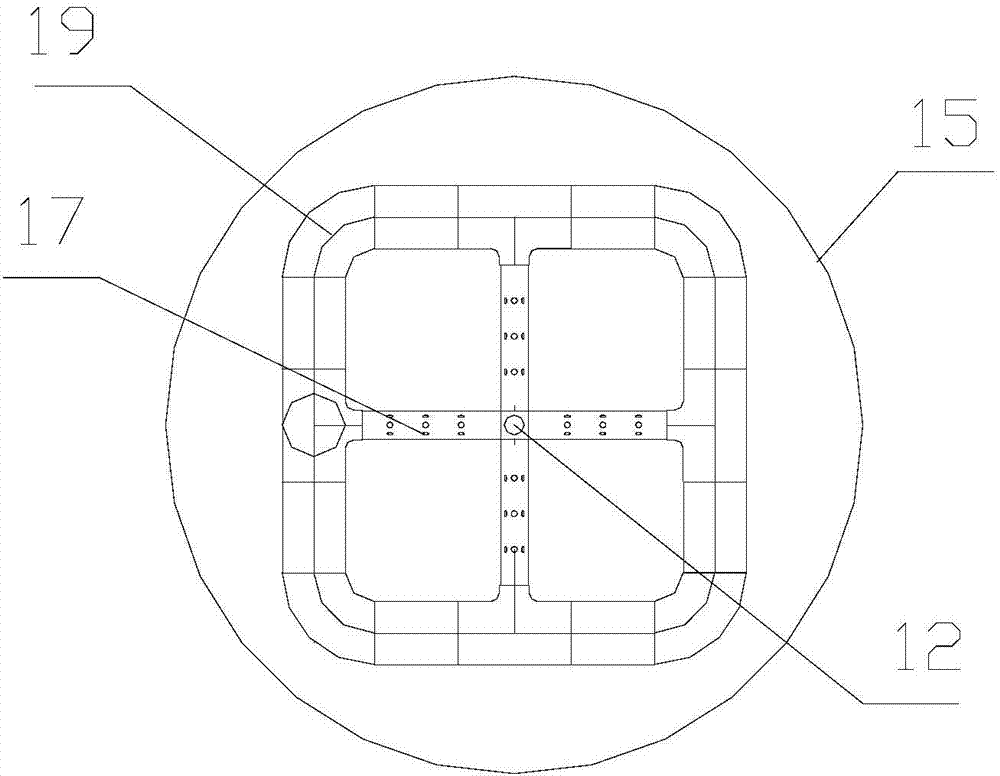

Method used

Image

Examples

Embodiment 1

[0074] The total length of a certain river is 15.74 kilometers, the width of the treated section of the river is about 15-20m, the depth of the river is 1.5-2.0m, and the flow rate of the section is about 0.14m 3 / s, the daily average flow is about 12000m 3 / d. The river course is polluted by the inferior V-class tributaries in the upper reaches, affected by the direct and mixed discharge of domestic sewage, service industry sewage, domestic sewage, etc., and ammonia nitrogen seriously exceeds the standard. The project uses a biochemical method to degrade ammonia nitrogen. Due to the large amount of sediment in the river, the filling in the equipment is blocked, which makes the equipment unable to operate normally.

[0075] According to the biochemical method, the influent flow rate of the equipment is 12000t / d, and a pre-filter backwashing device with a specification of 12000t / d is used.

[0076] Starting from the stable operation of the device of the present invention, a b...

Embodiment 2

[0086] A certain river course runs north-south, with a total length of 5.78 kilometers. The channel width of the treatment section is about 20m, the channel depth is 0.5-2.3m, and the flow rate of the section is about 0.05m3 / s. The main ammonia nitrogen index of the river is inferior V class. The project uses biochemical equipment to cut the river section. As the river was affected by rainy days, the amount of Nisha increased sharply, and there were algal blooms in summer. Affected by the above factors, biochemical equipment often has stuffing blockages and water leakage on the top of the equipment.

[0087] According to the biochemical method, the influent flow rate of the equipment is 1500t / d, and a pre-filter backwashing device with a specification of 1500t / d is used.

[0088] From the stable operation of the device of the present invention, a backwashing operation is carried out every 3 days, the air flushing intensity is 10L / (S.m2), the water flushing intensity is 4L / (S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com