Automatic backwashing liquid-returning filter

A backwashing and filter technology, which is applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problem that the liquid return filter does not have backwashing and automatic backwashing functions, and cannot realize online cleaning and online cleaning. Replacement of the filter element and maintenance, can not be switched in parallel and alternately used, etc., to achieve the effect of good sewage discharge, reduced maintenance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

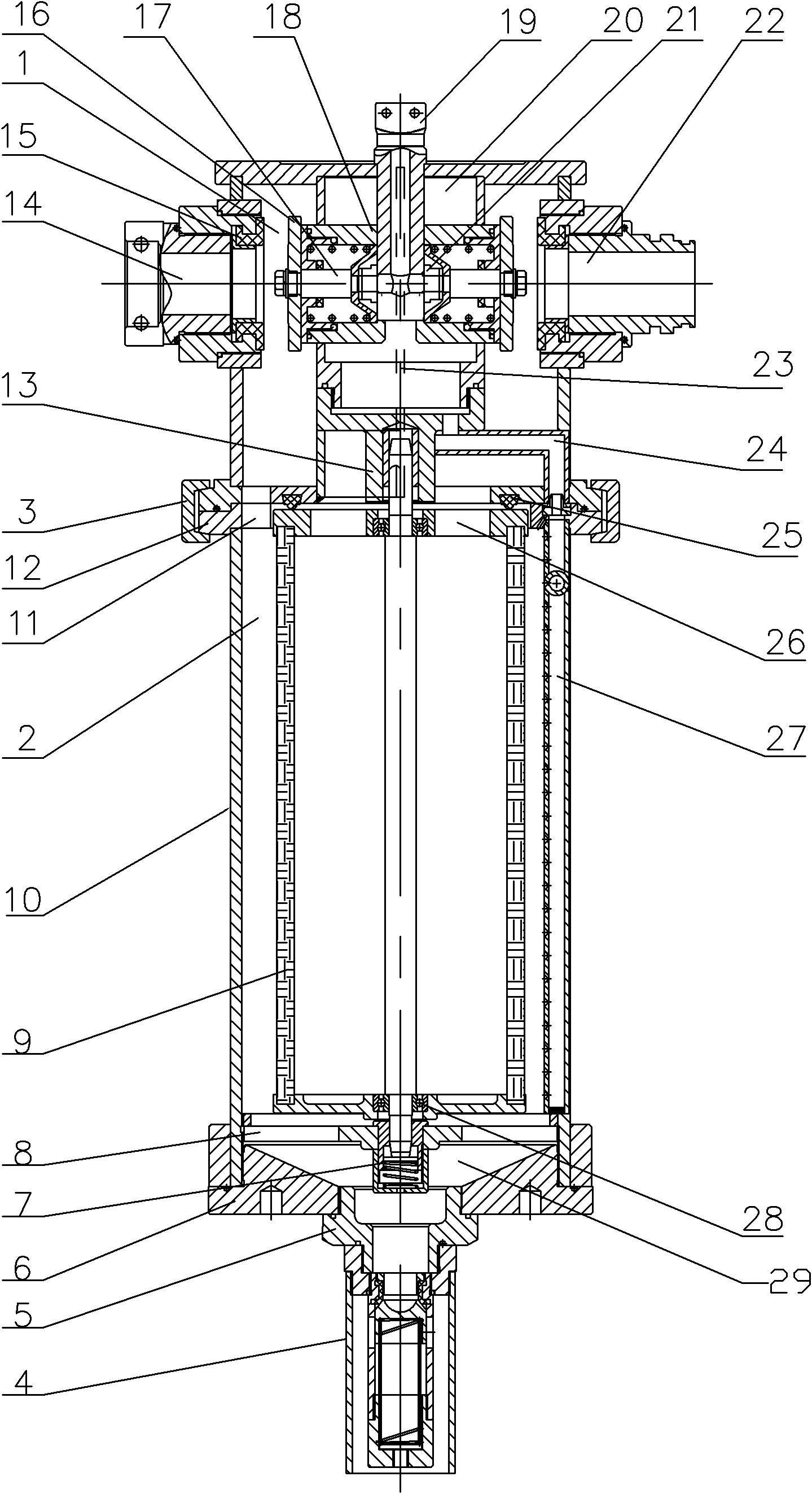

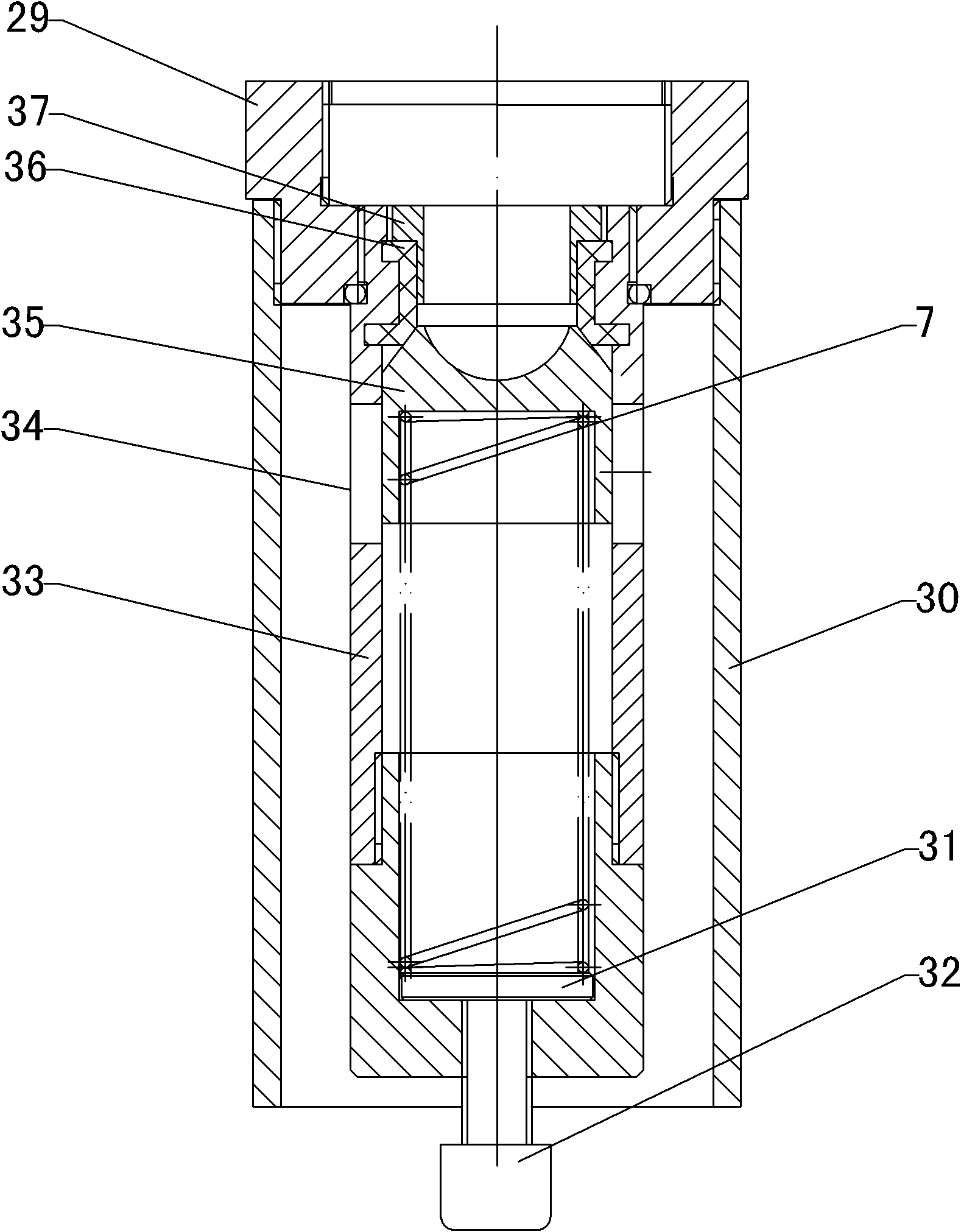

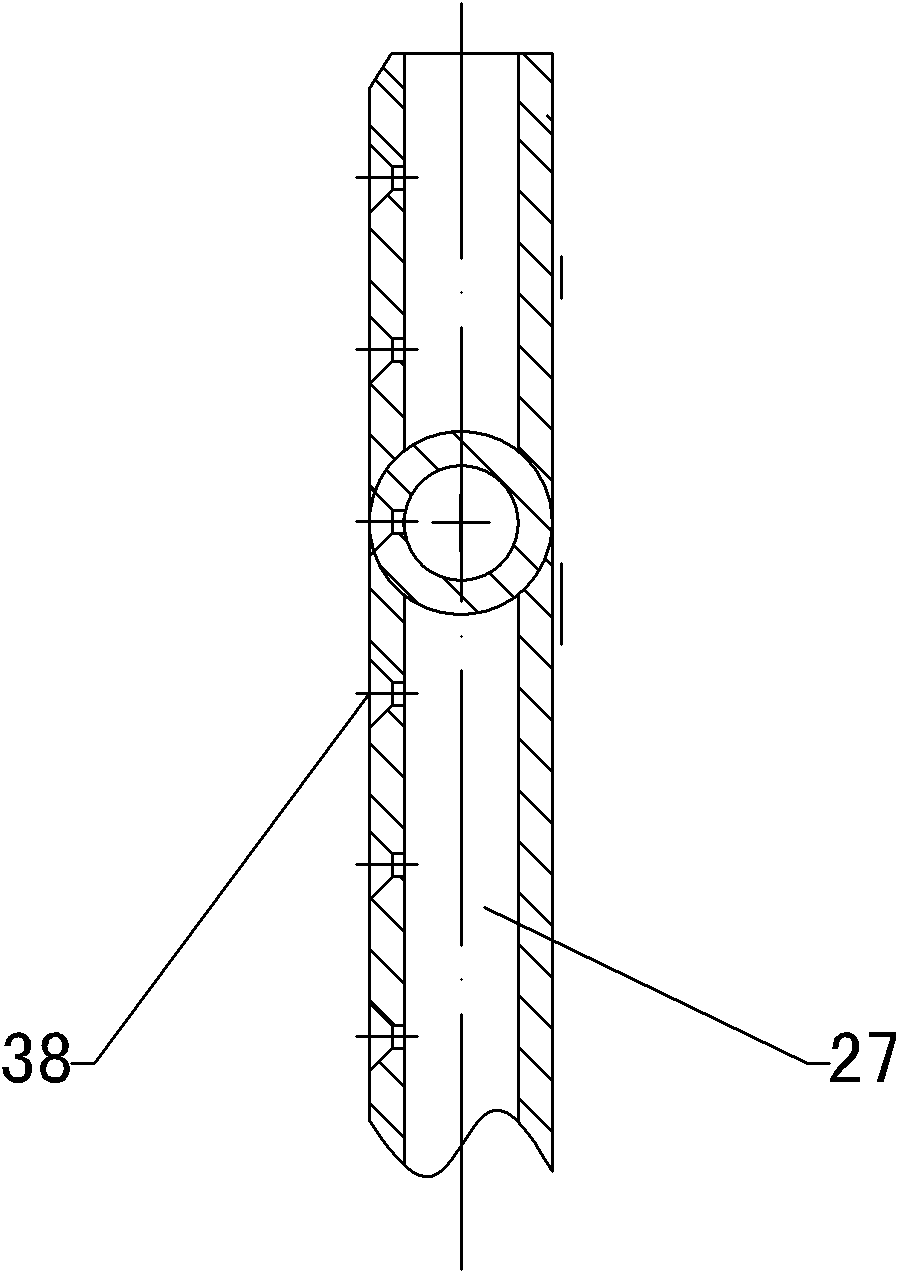

[0023] Refer to attached Figure 1~4 :

[0024] The automatic backwash liquid return filter includes a cylinder body 10, a filter element 9 and a drain valve 4. The cylinder body 10 is divided into upper and lower parts, correspondingly provided with a flange plate 12, fastened and fixed with a quick clamp 3, and fixed on the cylinder body The interior of 10 is divided into a liquid inlet and outlet chamber 1 and a filter chamber 2. The upper part of the liquid inlet and outlet chamber 1 is symmetrically provided with a liquid inlet 14 and a liquid outlet 22 on both sides, and is equipped with a rubber sealing sleeve 15. The interior of the inlet and outlet liquid chamber 1 is equipped with two groups The backwashing device forms a backflushing chamber 20 in the liquid inlet and outlet chamber 1, and the cavity between the liquid inlet and outlet chamber 1 and the backflushing chamber 20 is separated into a liquid inlet chamber and a liquid outlet chamber by a partition 23, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com