Full automatic suction type self-cleaning filter

A self-cleaning filter and filter technology, applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of shutdown cleaning, small pollution holding capacity, low degree of system automation, etc., and achieve equipment use. The effect of long life, low sewage and water consumption, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

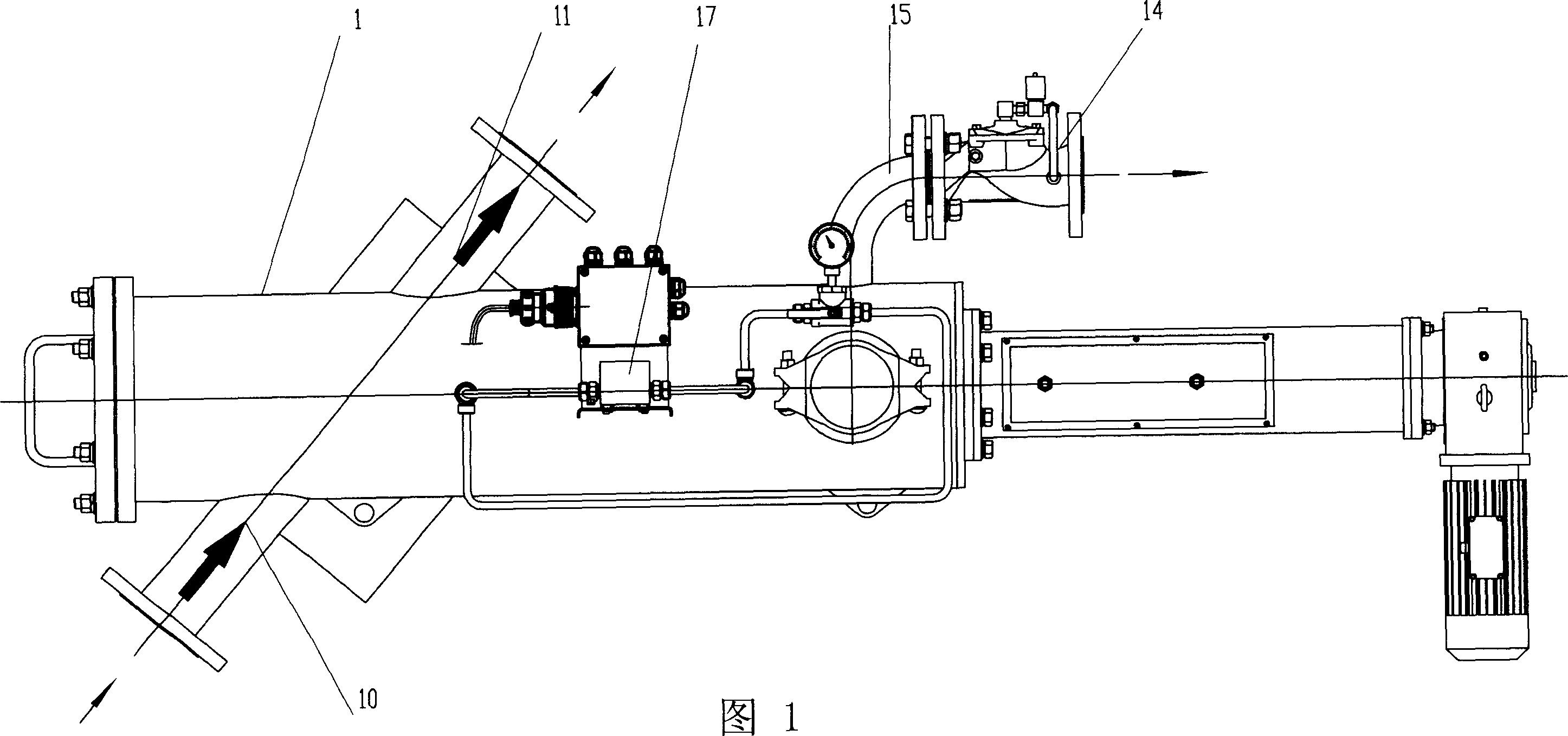

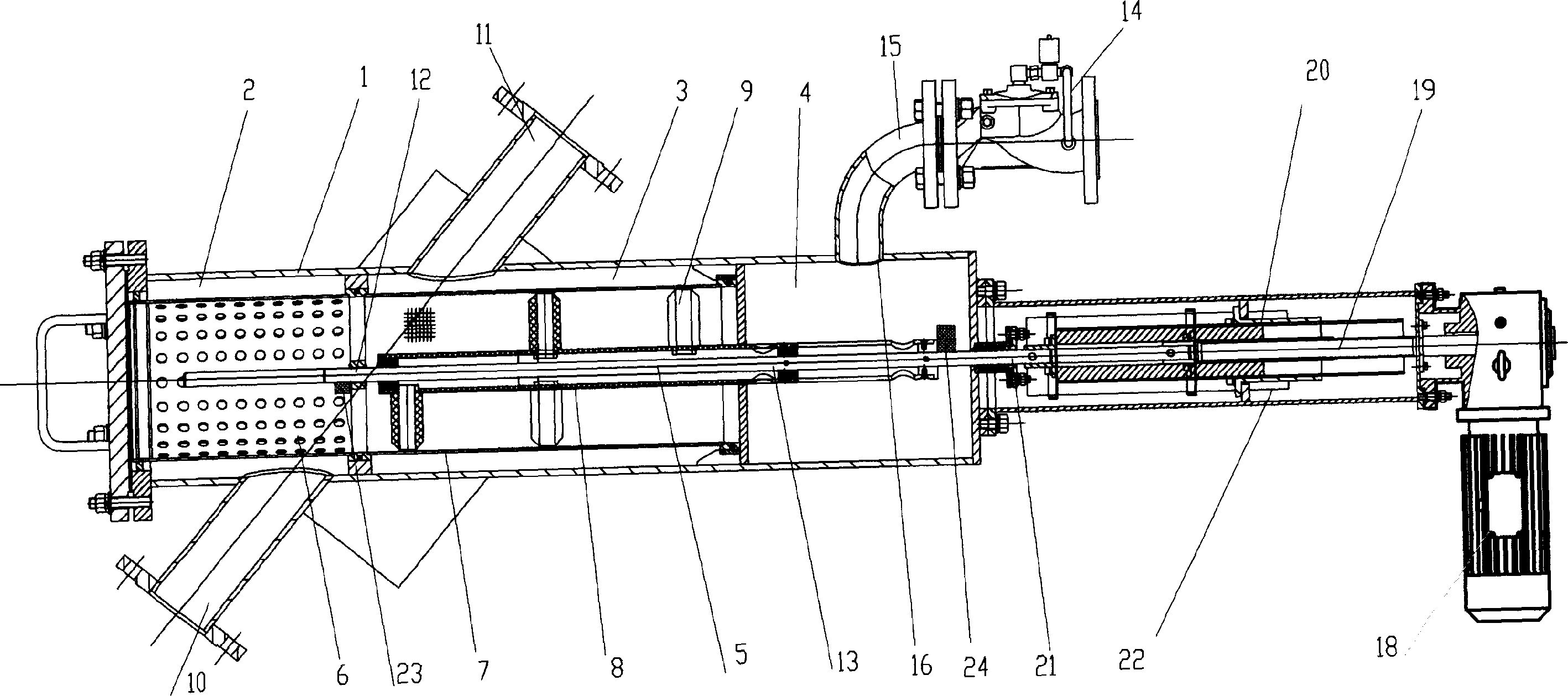

[0016] Among Figs. 1 and 2, the housing 1 of the fully automatic suction self-cleaning filter has a water inlet 10 and a water outlet 11, and the inside of the housing 1 is divided into three mutually closed chambers by a partition: the coarse filtration chamber 2, The cleaning chamber 3 and the blowdown chamber 4, the coarse filter chamber 2 is provided with a coarse filter screen 6, the cleaning chamber 3 is provided with a denser cylindrical filter screen 7, and the cavity of the coarse filter chamber 2 is provided with a pipeline (Fig. Not shown in), the pipeline connects the inside of the coarse filter screen 6 with the inside of the filter screen 7 through the water inlet 12 of the filter screen 7, and the filter screen 7 near the sewage chamber 4 side is provided with a discharge port 13, and the discharge port 13 The sewage chamber 4 is communicated with the sewage chamber 4 through a pipe, and the sewage chamber 4 is provided with a sewage outlet 16 connected with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com