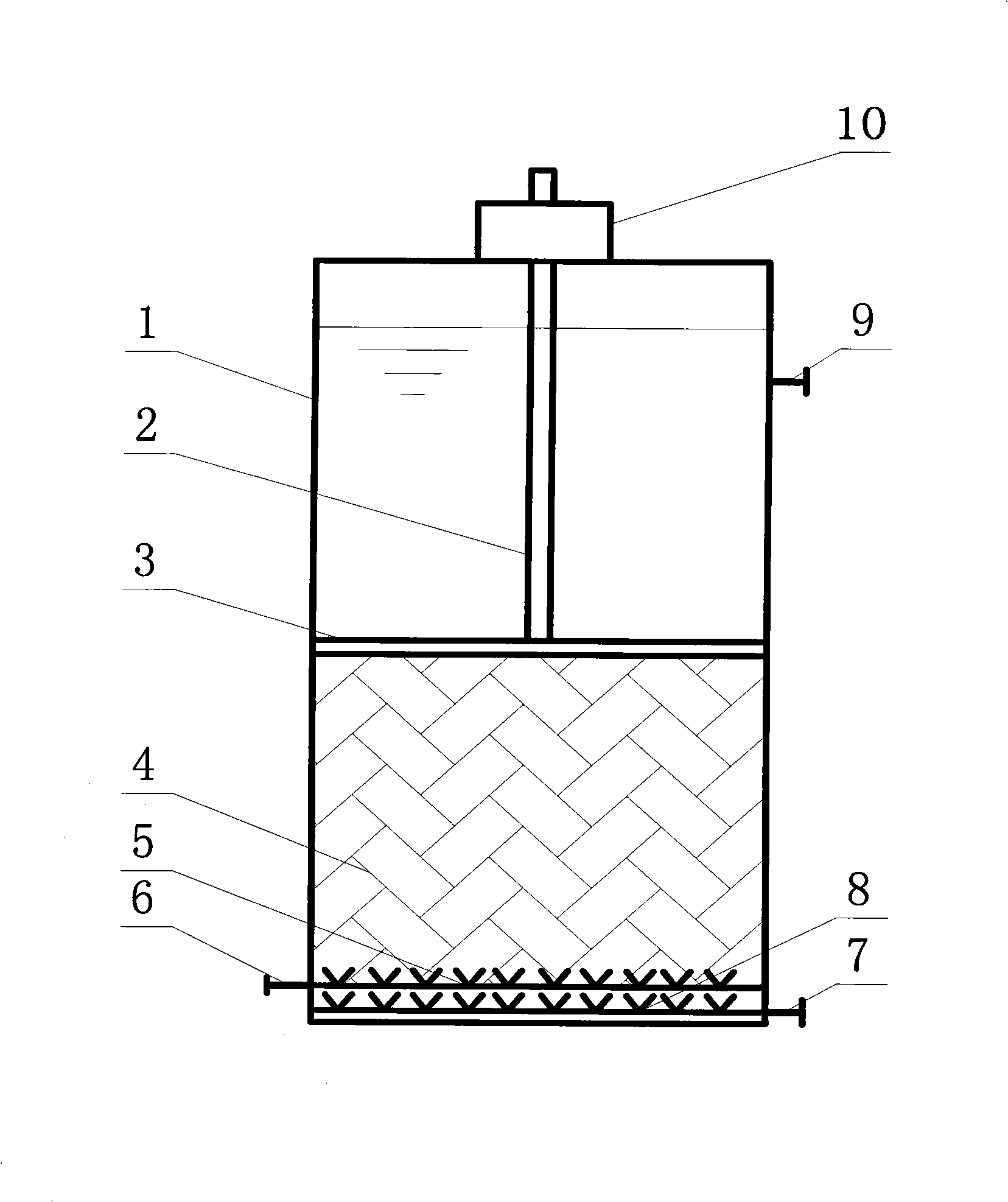

Variable-volume sewage interception and acceptance solid-liquid separator and method thereof

A solid-liquid separation and separation device technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of small filtration rate, large filtration rate, small specific surface area of granular media, etc., to achieve automatic control, device Simple operation and fast filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]The inner diameter of the filter cylinder is 230mm, the height of the filter bed is 1m, the filter medium is a cube with a side length of 10mm, the particle porosity is 93%, and the pore diameter is 0.8mm. The rate is 35m / h, the height of the filter bed is compressed to 0.6m at the beginning, the filtered water SS is less than 19mg / L, backwash after continuous filtration for 5 hours, and the airflow strength of backwash is 15L / s.m 2 , The backwash time is 12 minutes to re-enter the filter.

Embodiment 2

[0032] The inner diameter of the filter cylinder is 230mm, the height of the filter bed is 1.5m, the filter medium is a cube with a side length of 30mm, the particle porosity is 95%, and the pore diameter is 1mm. The rate is 45m / h, the height of the filter bed is compressed to 2m at the beginning, the filtered water SS is less than 20mg / L, and the backwash is continuously filtered for 8 hours, and the backwash airflow intensity is 10L / s.m 2 , The backwashing time is 12 minutes, and then enters the filter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com