Sewage treatment method based on MBR process

A sewage treatment method and sewage technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve problems such as occupation of land resources, infiltration into rivers, soil pollution, etc. Achieve the effect of reducing pollution, fast fermentation rate and high COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

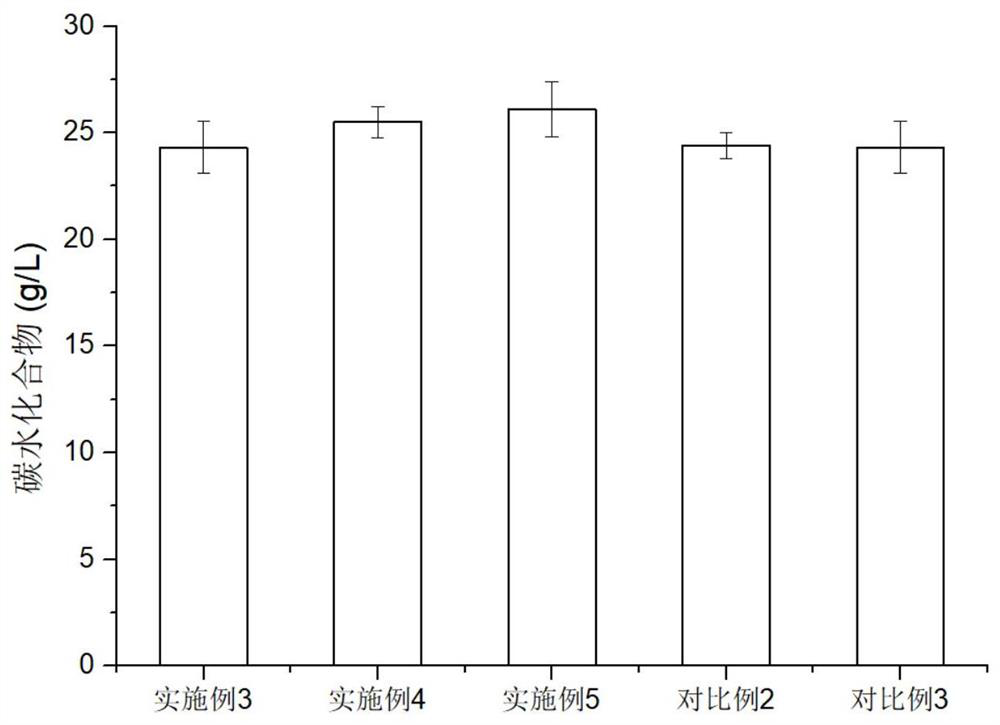

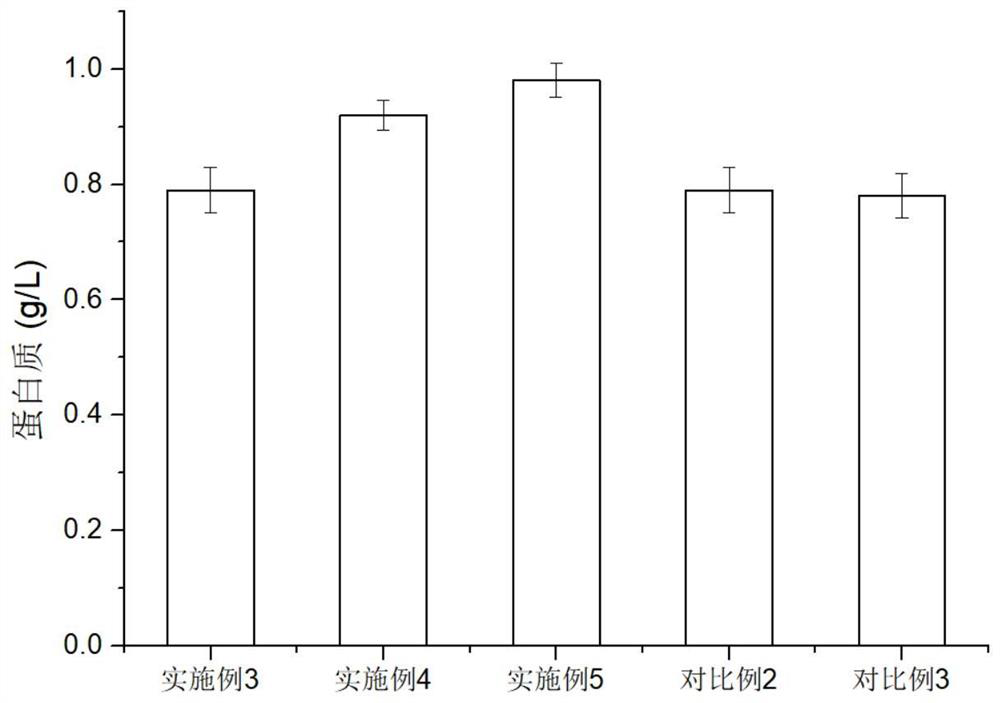

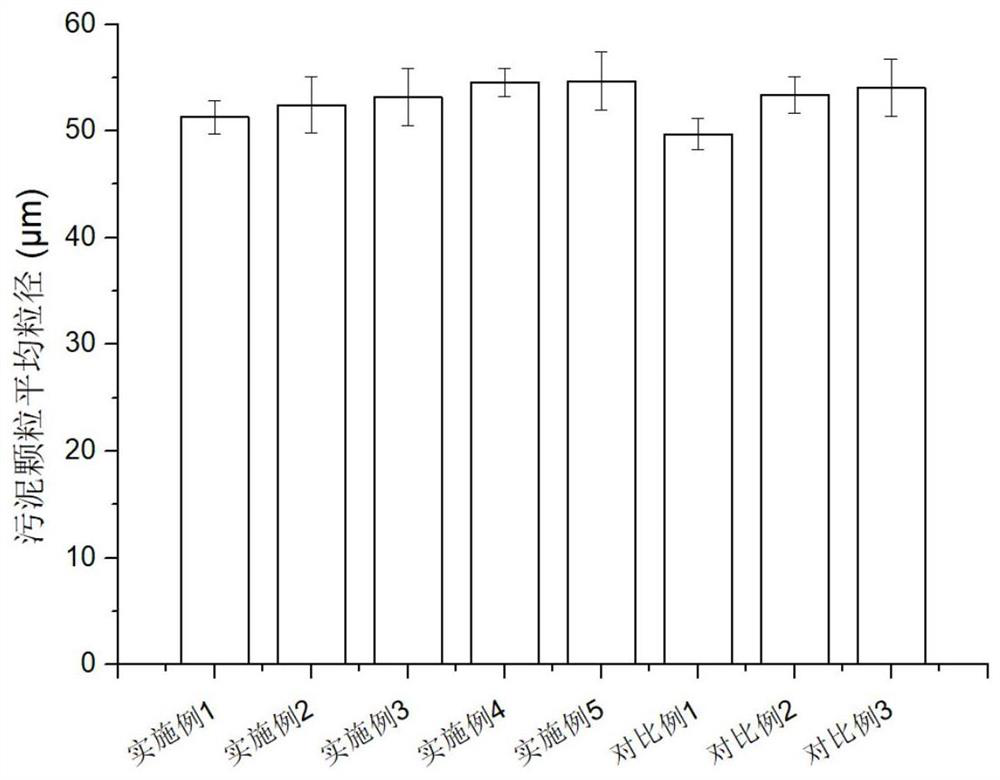

[0041] A method for treating perishable garbage fermented sewage,

[0042] Pre-treatment of perishable garbage: remove non-degradable debris from perishable garbage, add water at a temperature of 40°C, stir to make grease and fine debris float to the surface of the water body for removal, repeat 3 times, transfer to a pulverizer after water removal, After being pulverized and polished, the perishable garbage is uniformly crushed; the perishable garbage is food waste, which contains food solid residues such as steamed bread, rice, noodles, meat, protein and vegetables, and non-degradable debris is bones, paper, etc. Chips, wooden chopsticks, spoons and other sundries, the amount of water added is 500wt% of perishable garbage.

[0043] Anaerobic fermentation of perishable garbage: Add distilled water to the uniformly crushed perishable garbage, mix well and add to the fermentation tank. The fermentation process is mechanically stirred at a stirring speed of 100r / min, and ferment...

Embodiment 2

[0047] Compared with Example 1, this example differs only in that in sewage treatment, the amount of petogenin added is 1 wt% of the fermented liquid of perishable garbage.

Embodiment 3

[0049] Compared with Example 1, this example differs only in that in sewage treatment, the amount of petogenin added is 2wt% of the fermented liquid of perishable garbage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com