Polyether glycol and preparation method thereof, and waterborne polyurethane emulsion

A technology of polyether diol and polyether monool, applied in the field of polyether, can solve the problems of wide distribution of polyether diol PDI, difficult to adapt to polyurethane emulsion, harm to human health, etc. The effect of cake quality and fast filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

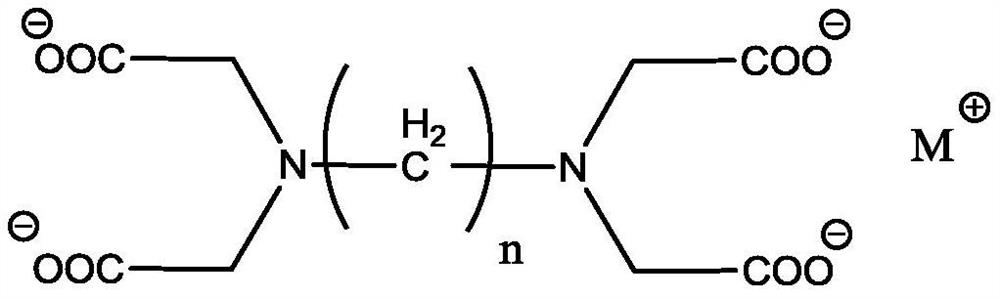

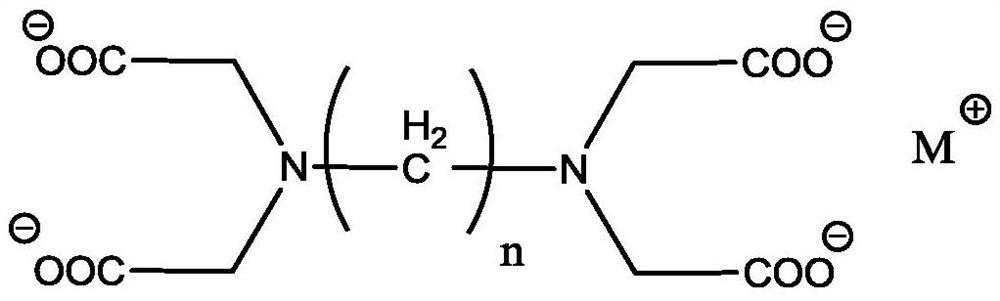

Examples

Embodiment 1

[0058] (1) Preparation of terminal halogen substituted polyether

[0059] Weigh 150g of MPEG5000, dissolve it in 200g of dichloromethane, and under stirring at room temperature, feed 2.97g of phosgene within 2 hours. After reacting for 1 hour, keep the absolute pressure at 2kpa, raise the temperature to remove the solvent, discharge 150.5g of wax, and measure the hydroxyl Value<1mgKOH / g.

[0060] (2) Preparation of end-capped polyether

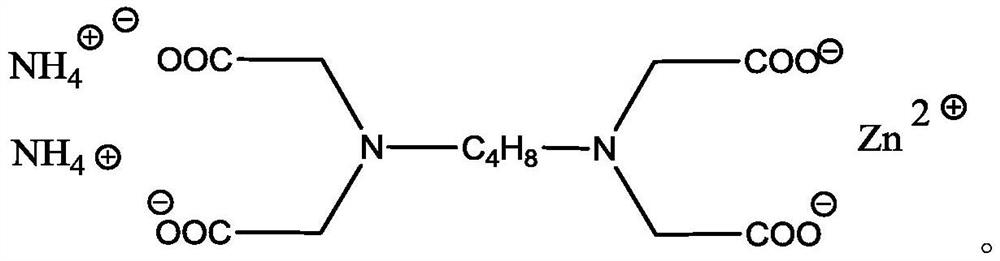

[0061] Weigh 5.20g compound I (prepared with reference to CN103193972A) was added into a three-necked flask, heated to 60°C, and then 1.62g of sodium methoxide was reacted at 60°C for 1 hour under the protection of nitrogen, then heated to 80°C, degassed at 2kpa for 3h, and added the melted terminal halogen Replace polyether, then continue to react at 80°C for 6 hours, add 30% phosphoric acid aqueous solution to adjust the pH to 8, then add 1.2g activated clay and 0.16g butyldiaminetetraacetic acid diammonium zinc (BTTA-NZ), after dehydrati...

Embodiment 2

[0065] (1) Preparation of terminal halogen substituted polyether

[0066] Weigh 150g of MPEG4000, dissolve it in 300g of chlorobenzene, feed 3.71g of phosgene within 2 hours under stirring at -5°C, continue the reaction for 1 hour, keep an absolute pressure of 2kpa, raise the temperature to remove the solvent, cool down and discharge the material, and measure the hydroxyl value< 1mgKOH / g.

[0067] (2) Preparation of end-capped polyether

[0068] Weigh 10.4g compound I Add it into a three-necked flask, raise the temperature to 60°C, and then heat 5.2g of potassium methylate under the protection of nitrogen, heat it at 60°C for 1 hour, heat it up to 80°C, degas it at 2kpa for 3 hours, add the melted halogen-substituted polyether, and then Continue the reaction at 80°C for 6 hours, add 30% phosphoric acid aqueous solution to adjust the pH to 8, then add 1g of silica gel and 0.15g of zinc diammonium butyldiamine tetraacetate (BTTA-NZ), after dehydration, filter through plate an...

Embodiment 3

[0075] Embodiment 3: preparation method of aqueous polyurethane emulsion

[0076] Add 120 grams of polyethylene glycol (molecular weight 6000), 120 grams of polyether diol prepared in Example 1 and 20 grams of polytetrahydrofuran diol (number average molecular weight 2000) into the reactor, dehydrate at 120 ° C for 1 hour, and cool down to 70 ℃, add 0.32g of dibutyltin dilaurate and 10.4g of tetramethylxylylene diisocyanate under stirring, after stirring for 5 hours, measure the NCO to be 0.60%, add 750 grams of water, and stir vigorously for 10 minutes to obtain waterborne polyurethane The dispersion has a measured viscosity of 5267cp@25°C and a solid content of 27.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com