Pressure sand filter and reverse flushing method

A sand filter and pressure-type technology, applied in gravity filters, chemical instruments and methods, separation methods, etc., can solve the problem of low utilization rate of backwash pumps and backwash tanks, occupying space and position, and low utilization rate of backwash pumps To achieve the effect of reducing equipment investment and corresponding water treatment costs, reducing equipment and pipelines, and shortening the time of air washing and water washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

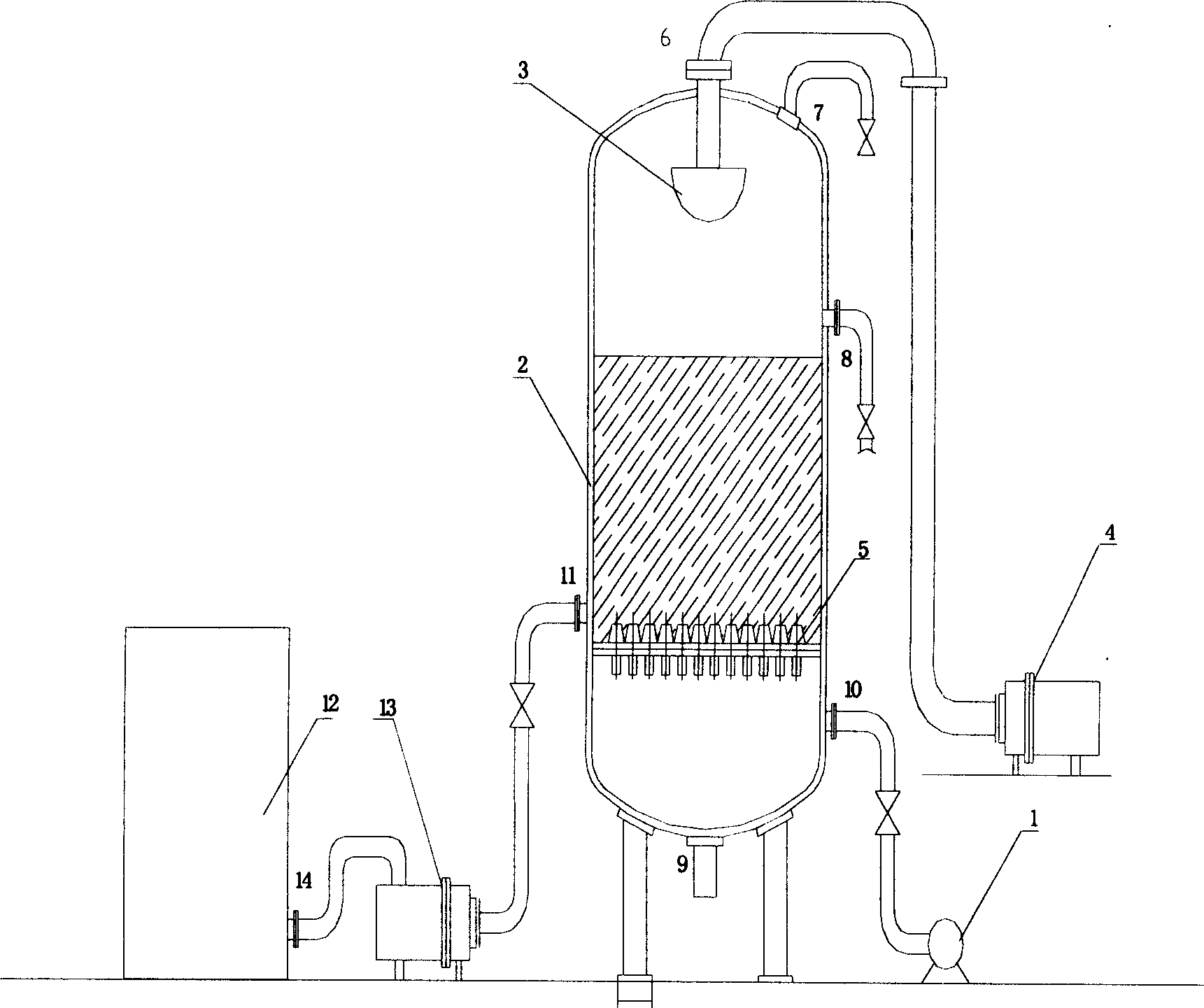

[0021] Embodiment 1: Existing equipment and method of operation

[0022] according to figure 1 For the equipment shown, after a certain period of filtration, the pressure head loss reaches 15KPA, and backwashing is required. When backwashing the filter material, first close the water outlet 9, open the exhaust port 7, and 200KPA compressed air enters from the air inlet 10 under the sand filter. After the sand layer is fully expanded, open the sewage outlet 8 and start the backwash pump 13. 10 liters / second. The flow backwashing of square meters, or air-water synchronous backwashing, takes 5 minutes.

Embodiment 2

[0023] After backwashing, close the backwash pump 13, close the backwash water inlet 11, let it stand for 1 minute naturally, then open the raw water pump 4, close the sewage outlet 8 and the exhaust port 7, open the water outlet 9, and filter normally. But first drain the filtrate for the first 5 minutes to ensure the quality of the effluent. Practical example 2: equipment and operation method of the present invention

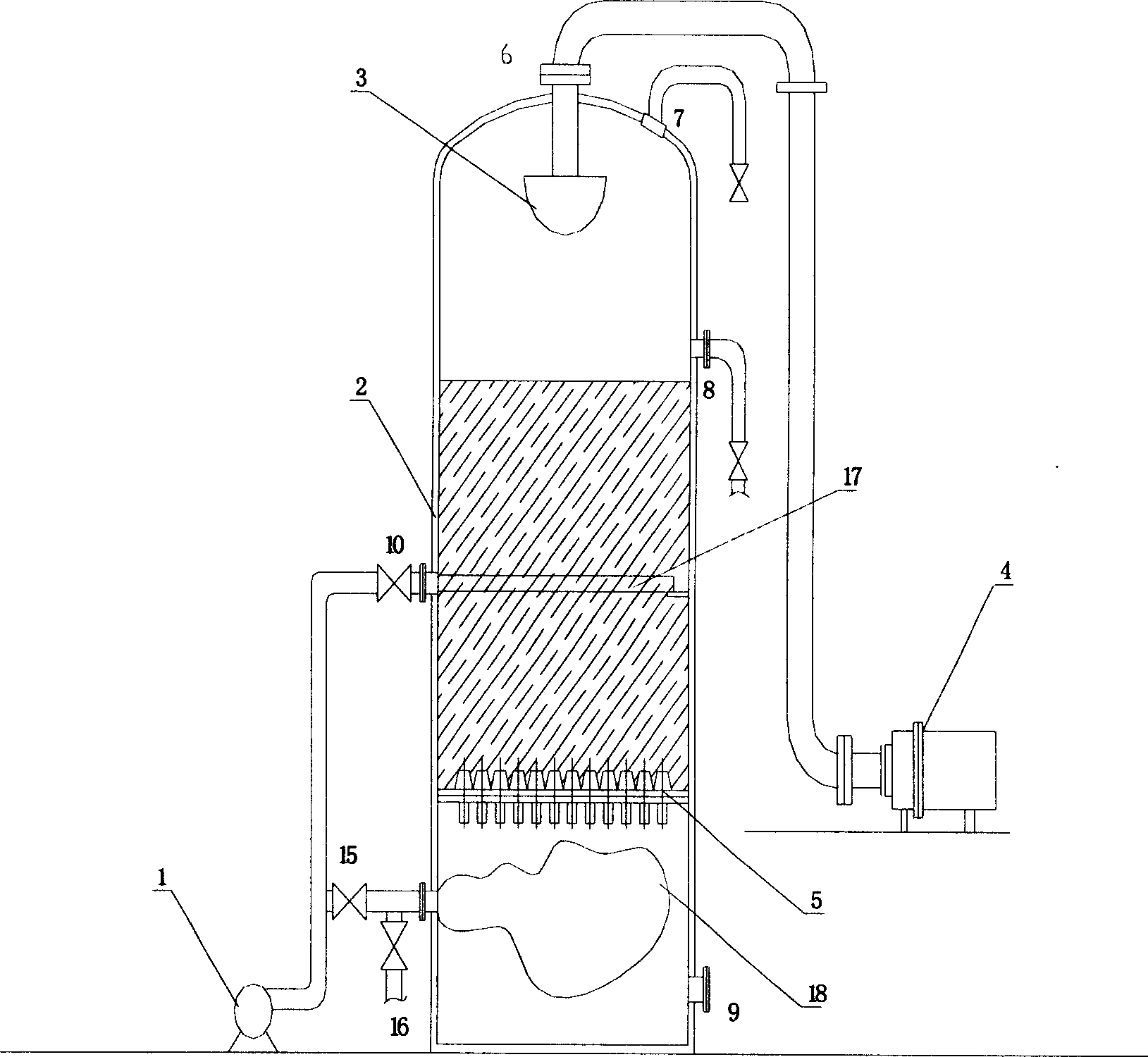

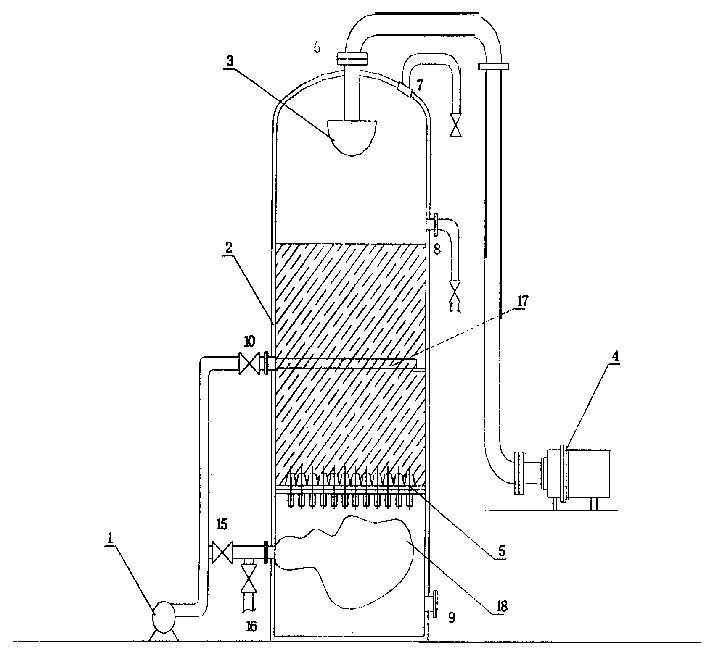

[0024] Such as figure 2 As shown: the system is composed of a cylinder body 2, a water distribution device 3, a raw water pump 4, a water distribution cap 5, a water inlet 6, an exhaust port 7, and a sewage discharge port 8; the lower part of the pressure sand filter cylinder is provided with a set The air bag 18 of water chamber, air bag is to be made by butyl rubber material. There are two pipelines between the air pump 1 and the cylinder 2, one is set in the middle of the filter material of the filter layer, connected with the air washing inlet 10, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com