Automatic continuous quick filtering system

A rapid filtration and automatic technology, applied in the direction of filtration separation, membrane filter, gravity filter, etc., can solve the problems of unrealized continuous filtration and increased blocking force, and achieve low long-term operation cost, small footprint, and saving civil engineering The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

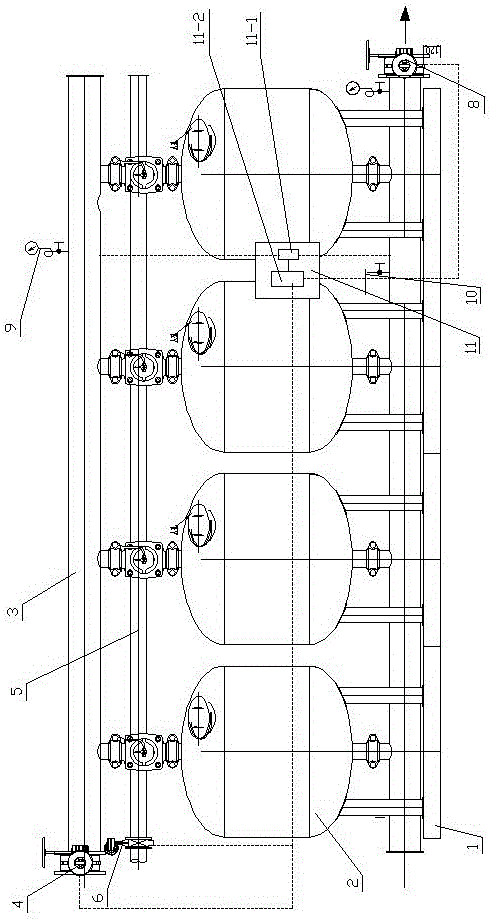

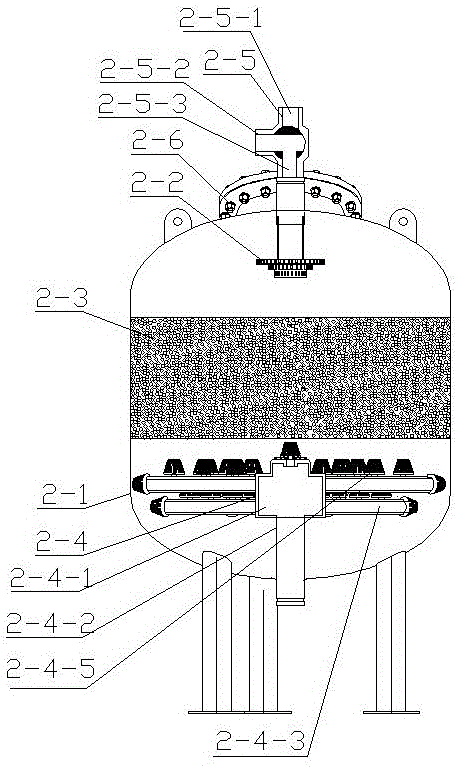

[0032] Such as figure 1 , 2 , 3, and 4, the present invention includes a support base 1 on which four identical filter tanks 2 are installed side by side.

[0033] The filter tank 2 includes a tank body 2-1. A water distributor 2-2, a filter packing layer 2-3 and a water collector 2-4 are sequentially arranged in the tank body 2-1 from top to bottom. The top is provided with a three-way valve 2-5 and a manhole 2-6.

[0034] The three-way valve 2-5 includes a water inlet 2-5-1, a first water outlet 2-5-3 and a second water outlet 2-5-2.

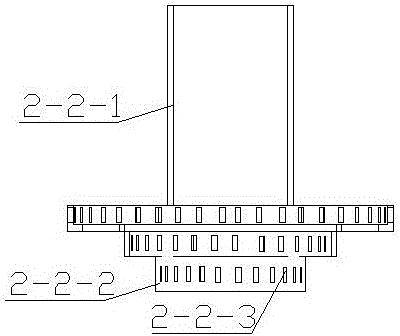

[0035] The water distributor 2-2 includes a water inlet pipe 2-2-1, and the lower end of the water inlet pipe 2-2-1 is connected to three water distribution trays 2-2 which are stacked up and down, have cavities and are connected to each other. -2. The diameters of the three water distribution trays 2-2-2 gradually become smaller from top to bottom, and the side walls of the water distribution trays 2-2-2 are evenly distributed with water d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com