Pretreatment equipment for water purification

A pre-treatment and water purification technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. and other problems, to achieve the effect of promoting solid-liquid separation and stratification, restoring equipment processing capacity, and improving water resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

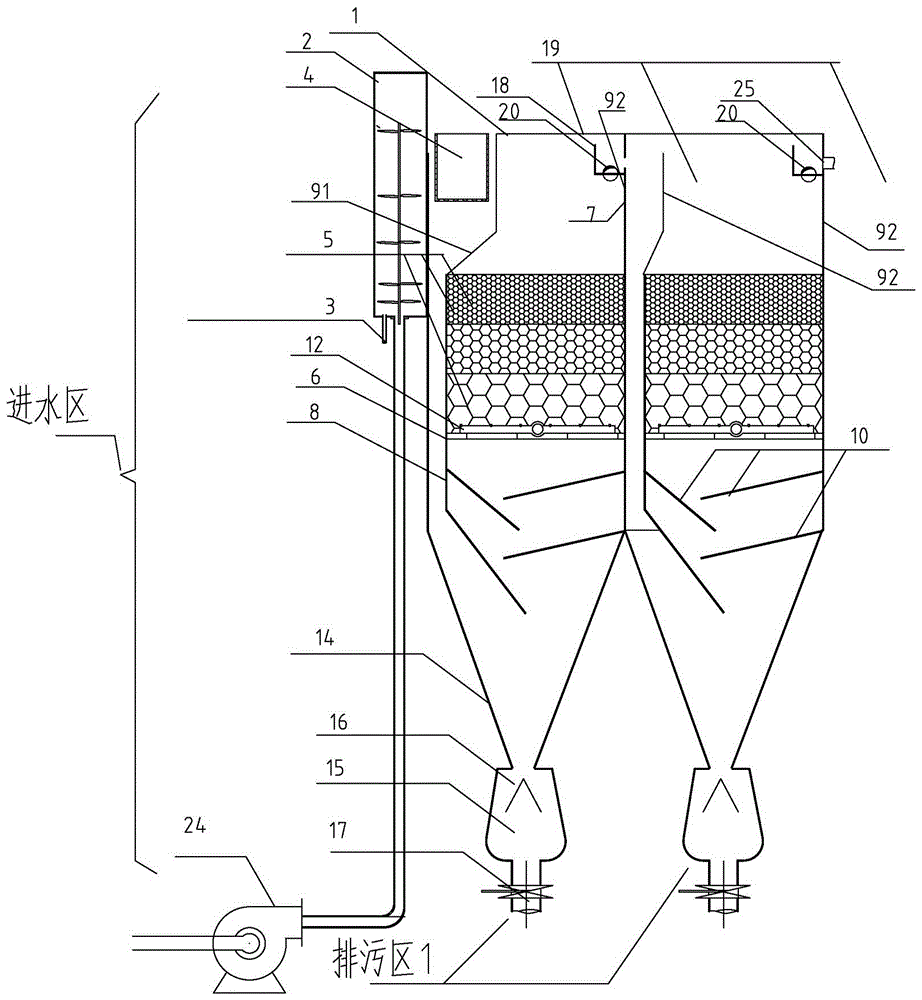

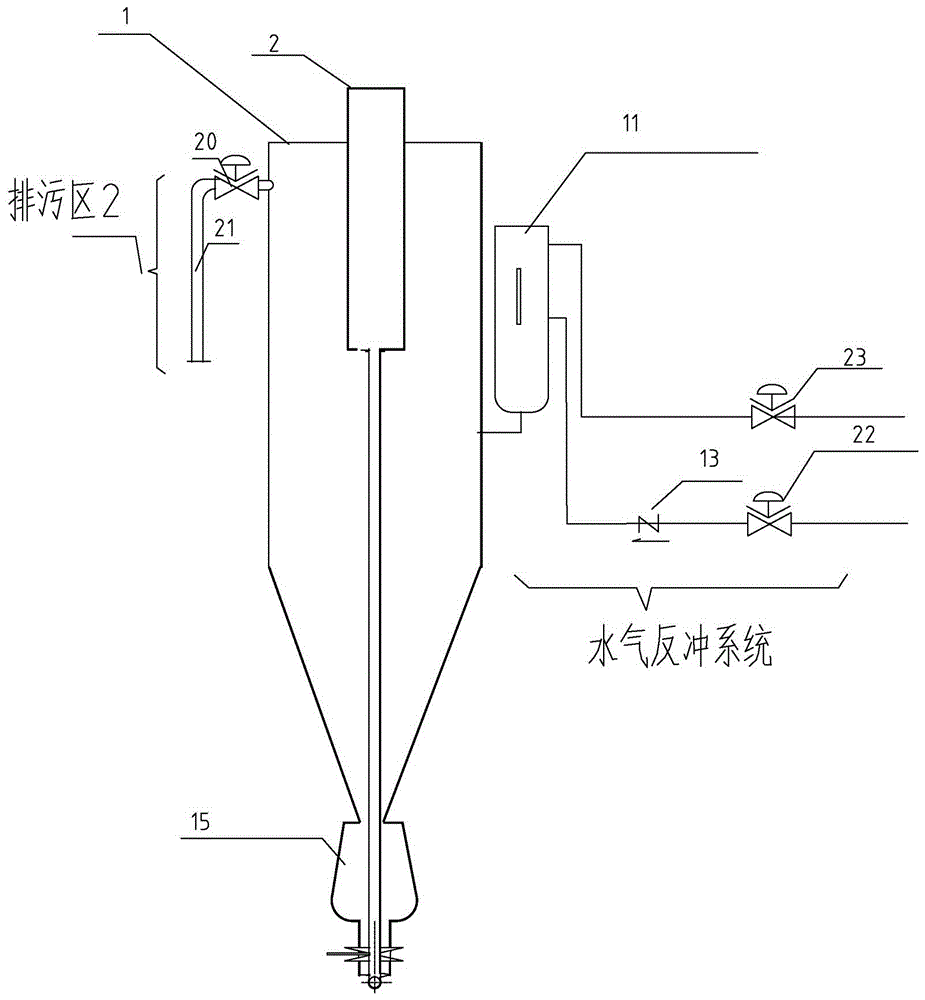

[0022] Example: such as Figure 1-Figure 2 As shown, a pretreatment device for water purification includes a housing 1, an inlet and an outlet arranged on the housing 1, the inlet is located at the lower end of the housing 1, the outlet is located at the upper end of the housing 1, and the outlet is located at the upper end of the housing 1. The water inlet mixer 2 at the front end of the body 1, the flocculation inlet 3 arranged on the water inlet mixer 2, the horizontal water distributor 4 arranged between the water inlet mixer 2 and the shell 1, Described housing 1 is provided with sub-box dividing plate 7 and housing 1 is divided into a plurality of interlinked multi-box areas 19, and interlinked water inlet passages are provided between adjacent multi-box areas 19, and the number of multi-box areas 19 Depending on the actual situation, raw water flows into the first multi-tank area 19 from the inlet on the shell 1, flows out from the first multi-tank area 19 and then ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com