Sea water, fresh water culture tail water processing up-to-standard discharging recycling system, and purifying method

A technology for freshwater aquaculture and tail water, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. To achieve the effect of easy handling, simple structure, saving backwash water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

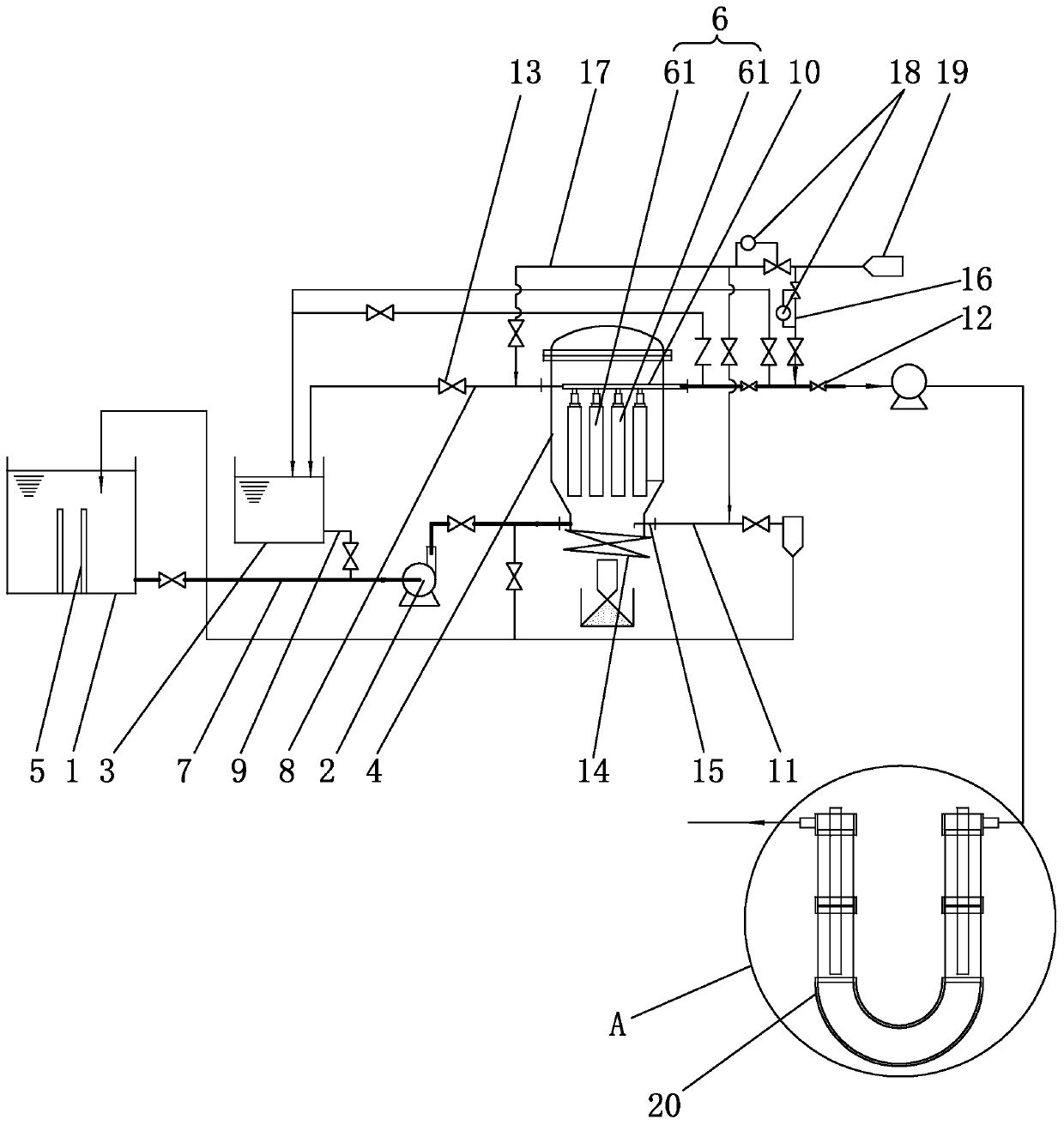

[0039] Example: figure 1Disclosed is a sea and freshwater aquaculture tail water treatment standard discharge and reuse system, including a phosphorus removal tank 1, a film coating tank 3, a filter 4 and a small molecule sterilizer 20. The aquaculture tail water in the fish pond is first pumped into the phosphorus removal tank 1 for storage. The phosphorus removal tank 1 has metal electrode plates 5 (such as magnesium plates, iron plates, and aluminum plates) that are connected to direct current. Iron and other anodes are electrolyzed to produce metal positive ions, which react with phosphate to form phosphate sedimentation, which can easily achieve the purpose of phosphorus removal, and filter these sedimentary phosphates through fine filtration.

[0040] like figure 1 As shown, the phosphorus removal water tank 1 is connected to the filter 4 through a first water pipe 7 , and a lift pump 2 is installed on the first water pipe 7 . The filter 4 is connected to the coating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com