Silica gel preparation method and silica gel obtained by method

A technology of silica gel and colloidal particles, which is applied in the field of silica gel and inorganic silica gel, can solve the problems of low production efficiency, easy to damage the fine structure of silica gel, and high cost, and achieve high production efficiency, good adsorption effect, and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

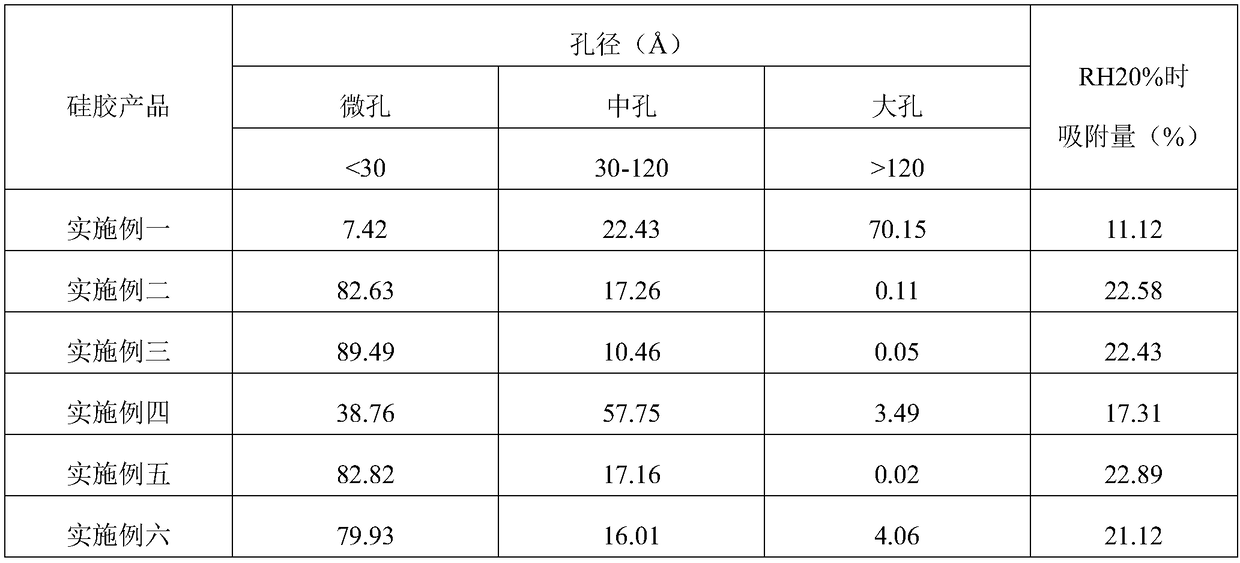

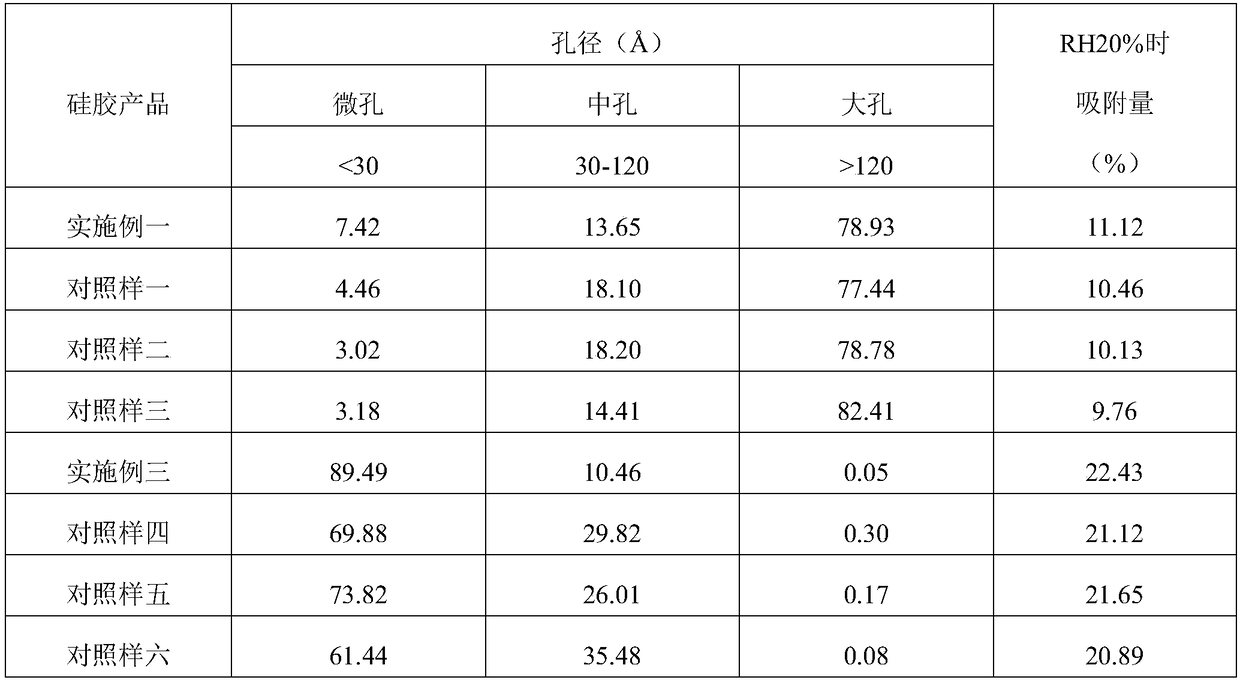

Examples

preparation example Construction

[0019] The preparation method of a kind of silica gel of the present invention comprises the following steps in sequence: glue making, aging, tapping, washing and drying; the washing step uses magnetized water for washing, the washing temperature is 20-80°C, and the washing end point is The conductivity of the colloidal particles is below 0.5mS / cm.

[0020] Preferably, the water washing temperature in the water washing step is 30-70°C.

[0021] Further, the water washing temperature in the water washing step is 45-60°C.

[0022] Specifically, the water washing end point of the water washing process is that the electrical conductivity of the colloidal particles is 0.1-0.5 mS / cm.

[0023] More preferably, the water washing time of the water washing step is 10-40 hours.

[0024] Furthermore, the water washing time in the water washing step is 20-30 hours.

[0025] More specifically, the magnetized water is obtained by magnetizing tap water through a magnetizer, and the frequen...

Embodiment 1

[0030] The preparation method of a kind of silica gel of the present invention comprises the following steps in sequence: rubber making, aging, rubber tapping, washing and drying; raw materials are sulfuric acid (mass concentration is 30%) and natron (mass concentration is 20%), acid The mass ratio of alkali is 1:4. The washing process uses magnetized water for washing. The washing method adopts single washing. The washing temperature is 80°C. It is magnetized by a magnetizing machine. The frequency of the magnetizing machine is 35KHz. After the tap water passes through the magnetizing machine, the temperature rises by 1°C.

Embodiment 2

[0032]The preparation method of a kind of silica gel of the present invention comprises the following steps in sequence: rubber making, aging, rubber tapping, washing and drying; raw materials are sulfuric acid (mass concentration is 30%) and natron (mass concentration is 20%), acid The mass ratio of alkali is 1:4. The washing process uses magnetized water for washing. The washing method adopts serial washing. The washing temperature is 20°C. The frequency of the magnetizing machine is 30KHz, and the temperature of tap water rises by 2°C after passing through the magnetizing machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com