Method for liquid filtration

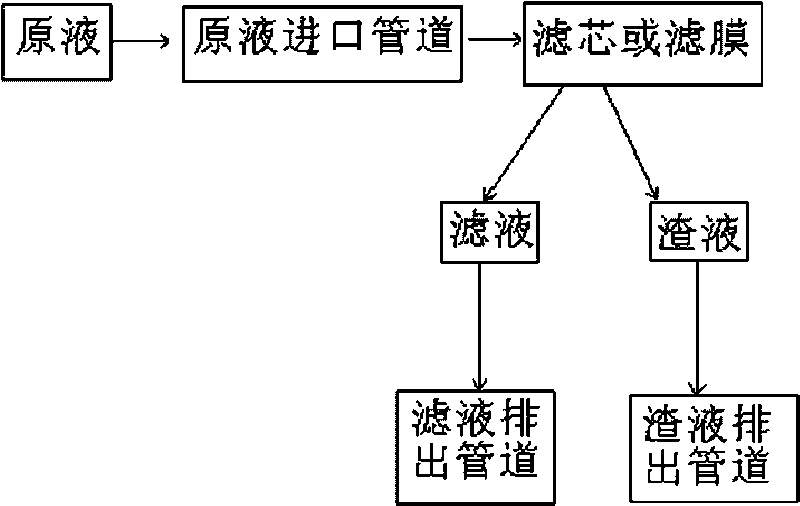

A liquid and filter technology, applied in the field of separation, can solve the problems of attenuation of filtration flux, easy adhesion of cloth bags, low filtration accuracy, etc., and achieve the effects of reducing production energy consumption, saving energy consumption costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

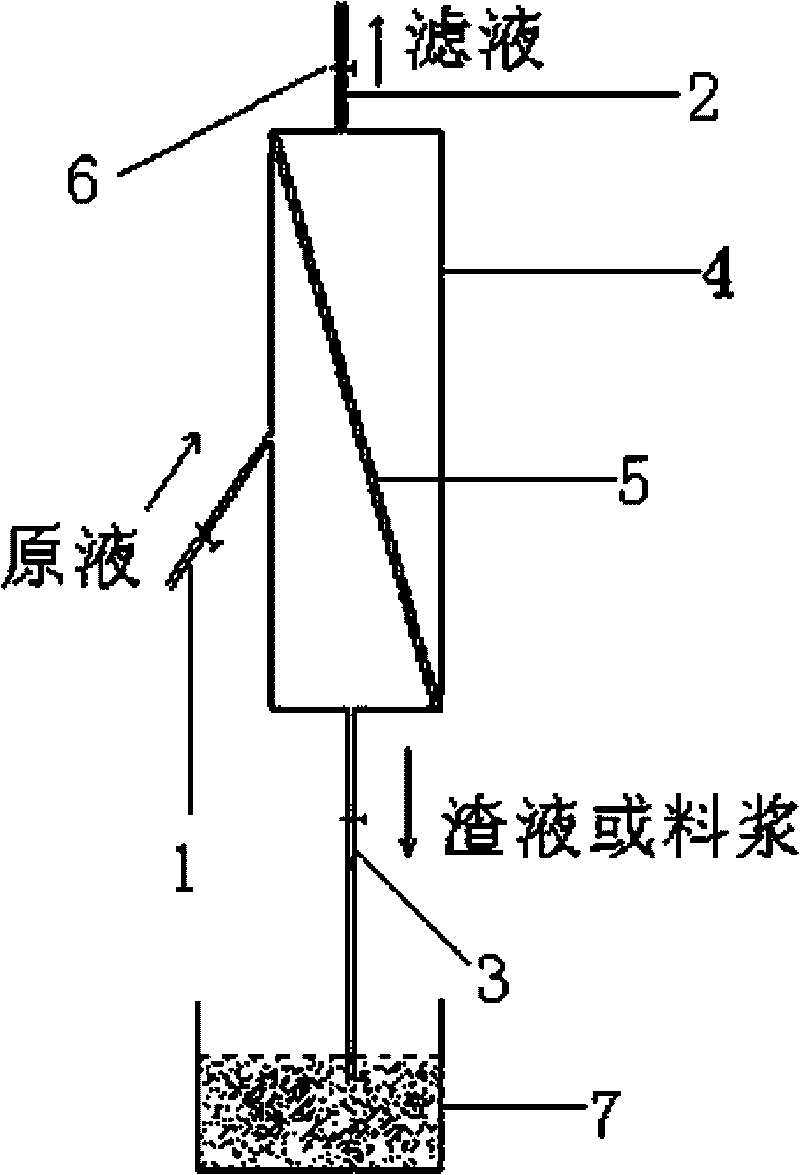

[0026] Embodiment 1 Adopt the method of the present invention to filter titanium tetrachloride liquid

[0027] Adopt the inventive method to filter titanium tetrachloride liquid, the structural representation of used filter 4 is as figure 2 shown. The outlet of the slag liquid discharge pipe 3 in the figure is hermetically sealed by a liquid sealing device 7 . During filtration, the titanium tetrachloride stock solution enters from the stock solution inlet pipe 1 of the filter 4, and is filtered through the filter element or filter membrane 5 to obtain filtrate and slag liquid; the obtained filtrate is discharged through the filtrate discharge pipe 2, and the obtained slag liquid is discharged through the slag liquid discharge pipe 3 into the liquid seal device 7. When backwashing, the raw liquid inlet pipeline 1 is closed, and the backwash liquid is reversely flushed through the filtrate discharge pipeline 3 to filter membrane or filter element 5 to obtain slurry, which is...

Embodiment 2

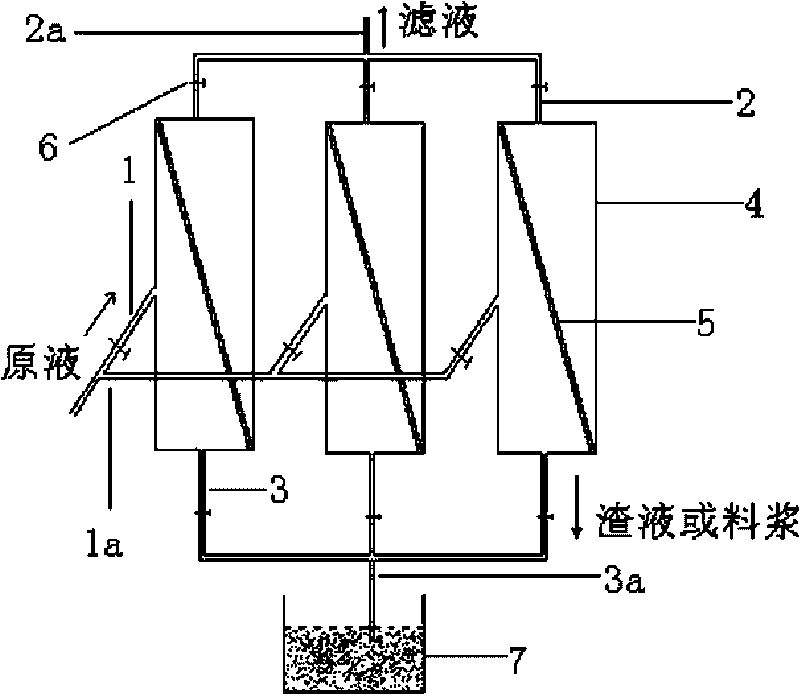

[0028] Embodiment 2 Adopt the method of the present invention to filter titanium tetrachloride liquid

[0029] Adopt the inventive method to filter titanium tetrachloride liquid, the structural representation of used filter 4 is as image 3 shown. The three filters 4 in the figure are used in parallel, and the raw liquid inlet pipeline 1, the filtrate discharge pipeline 2 and the slag liquid discharge pipeline 3 of the filter 4 are respectively connected in parallel to obtain the raw liquid inlet main pipeline 1a, the filtrate discharge main pipeline 2a and the slag liquid discharge main pipeline. Pipeline 3a, and the outlet of the slag liquid discharge main pipeline 3a is air-sealed through the liquid sealing device 7. During filtration, the titanium tetrachloride stock solution enters from the stock solution inlet pipe 1 of the filter 4, and is filtered through the filter element or filter membrane 5 to obtain filtrate and slag liquid; the obtained filtrate is discharged th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com