Deep backwashing filter and backwashing method

A filter washing and deep technology, which is applied in the field of deep backwashing filters and backwashing, can solve the problems of large amount of water for backwashing, incomplete backwashing, uneven water distribution, etc., achieve thorough backwashing and improve backwashing. The effect of regeneration strength and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

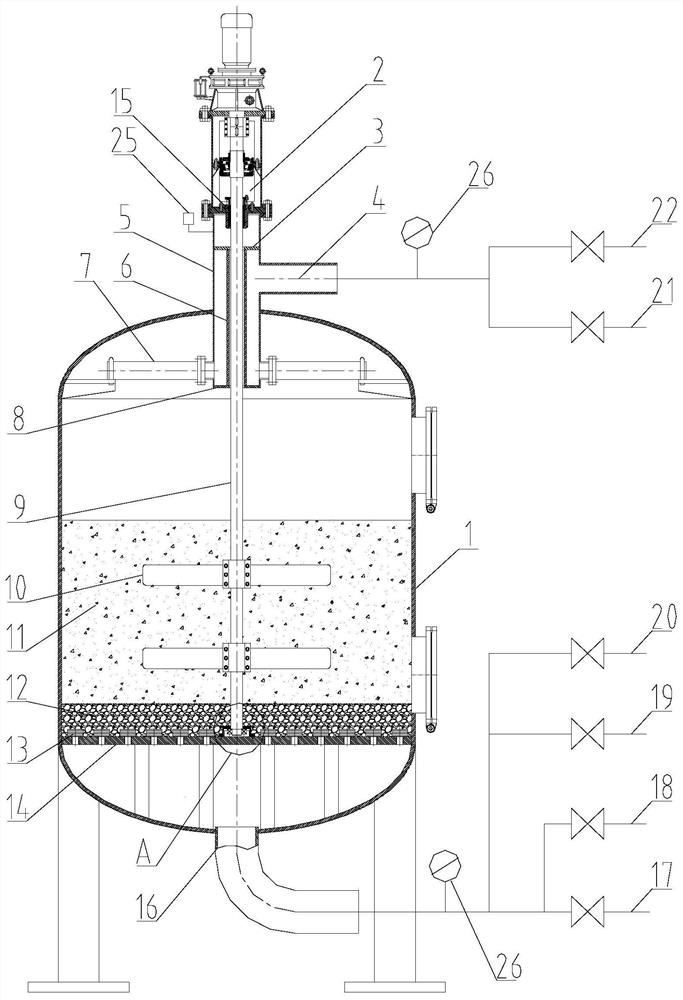

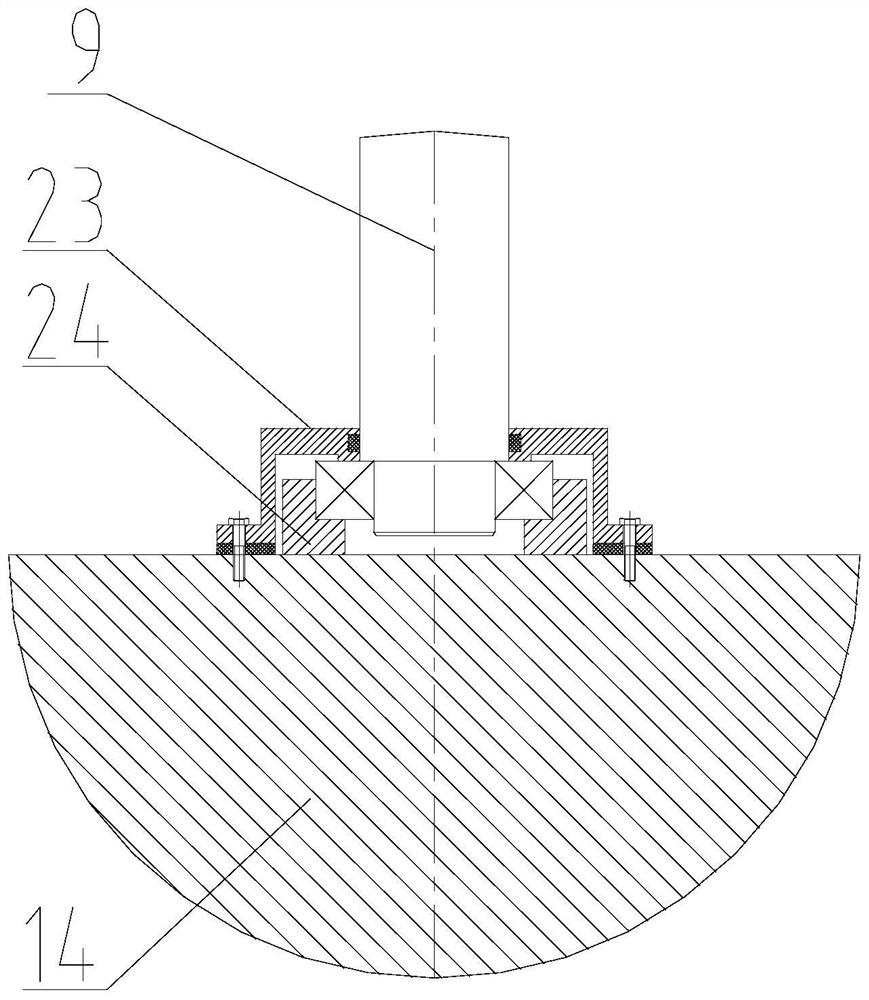

[0020] Depend on figure 1 combine figure 2 As shown, a deep backwash filter includes a tank body 1 and an agitator 2, the agitator 2 is connected to the central cylinder 5 on the upper part of the tank body 1 through a flange, the upper part of the central cylinder 5 is provided with an upper connecting pipe 4, and the upper connecting pipe 4. The upper central tube 5 is provided with an upper partition 3, a lower partition 8 and a central tube 6. The central tube 5, the upper partition 3, the lower partition 8 and the central tube 6 are all sealed and fixedly connected by continuous welding. The central tube 5. The screen pipe 7 is connected evenly distributed around the head part of the tank body 1. The screen pipe 7 is connected to the upper connecting pipe 4 and is not connected to the inner space of the central pipe 6. The stirring shaft 9 of the agitator 2 passes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com