Ceramic particle for adsorbing wastewater impurities

A technology of ceramic particles and waste water, which is applied in the field of water treatment, can solve problems such as difficult backwashing and desorption, increased reverse pressure, desorption of impurities, etc., and achieves the effect of improving water purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

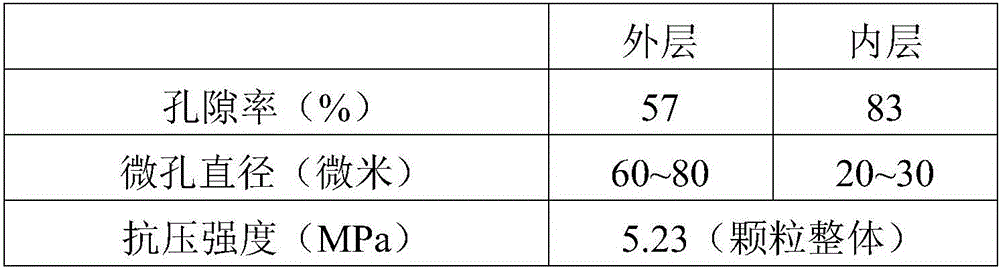

Embodiment 1

[0026] A ceramic particle for absorbing impurities in waste water, consisting of two layers, the outer layer is composed of the following raw materials in parts by weight:

[0027] Activated alumina: 35 parts; calcined kaolin: 25 parts; anatase titanium dioxide: 25 parts; glass fiber: 4 parts; vermiculite: 1 part; the average particle size of each raw material in the outer layer is 50 microns;

[0028] The inner layer is composed of the following raw materials in parts by weight:

[0029] Ordinary alumina: 45 parts; Ordinary kaolin: 25 parts; Rutile titanium dioxide: 15 parts; Quartz: 3 parts; Pretreated graphene: 2 parts; The average particle size of each raw material in the inner layer is 10 microns;

[0030] The method of described pretreatment graphene is: the hydroxyethyl hexahydro-s-triazine that the quality is graphene 6% is added together with graphene concentration and is the acetone solution of 3wt%, ultrasonic dispersion 40 minutes under the situation of stirring, t...

Embodiment 2

[0038] A ceramic particle for absorbing impurities in waste water, consisting of two layers, the outer layer is composed of the following raw materials in parts by weight:

[0039] Activated alumina: 40 parts; calcined kaolin: 30 parts; anatase titanium dioxide: 28 parts; glass fiber: 5 parts; vermiculite: 2 parts; the average particle size of each raw material in the outer layer is 60 microns;

[0040] The inner layer is composed of the following raw materials in parts by weight:

[0041] Ordinary alumina: 50 parts; Ordinary kaolin: 30 parts; Rutile titanium dioxide: 17 parts; Quartz: 6 parts; Pretreated graphene: 3 parts; The average particle size of each raw material in the inner layer is 20 microns;

[0042] The method of described pretreatment graphene is: the hydroxyethyl hexahydro-s-triazine that quality is 7% of graphene and graphene is added the acetone solution that concentration is 4wt%, ultrasonic dispersion 50 minutes under the situation of stirring, then Dry to ...

Embodiment 3

[0050] A ceramic particle for absorbing impurities in waste water, consisting of two layers, the outer layer is composed of the following raw materials in parts by weight:

[0051]Activated alumina: 45 parts; calcined kaolin: 35 parts; anatase titanium dioxide: 30 parts; glass fiber: 6 parts; vermiculite: 3 parts; the average particle size of each raw material in the outer layer is 80 microns;

[0052] The inner layer is composed of the following raw materials in parts by weight:

[0053] Ordinary alumina: 55 parts; Ordinary kaolin: 35 parts; Rutile titanium dioxide: 20 parts; Quartz: 8 parts; Pretreated graphene: 4 parts; The average particle size of each raw material in the inner layer is 30 microns;

[0054] The method of described pretreatment graphene is: the hydroxyethyl hexahydro-s-triazine that quality is graphene 8% is added together concentration is the acetone solution of 5wt% with graphene, under the situation of agitation ultrasonic dispersion 60 minutes, then Dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com