Patents

Literature

55 results about "Air sparging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air sparging, also known as in situ air stripping and in situ volatilization is an in situ remediation technique, used for the treatment of saturated soils and groundwater contaminated by volatile organic compounds (VOCs) like petroleum hydrocarbons which is a widespread problem for the ground water and soil health. The vapor extraction has manifested itself into becoming very successful and practical when it comes to disposing of VOCs. It was used as a new development when it came to saturated zone remediation when using air sparging. Being that the act of it was to inject a hydrocarbon-free gaseous medium into the ground where contamination was found. When it comes to situ air sparging it became an intricate phase process that was proven to be successful in Europe since the 1980s. Currently, there have been further development into bettering the engineering design and process of air sparging.

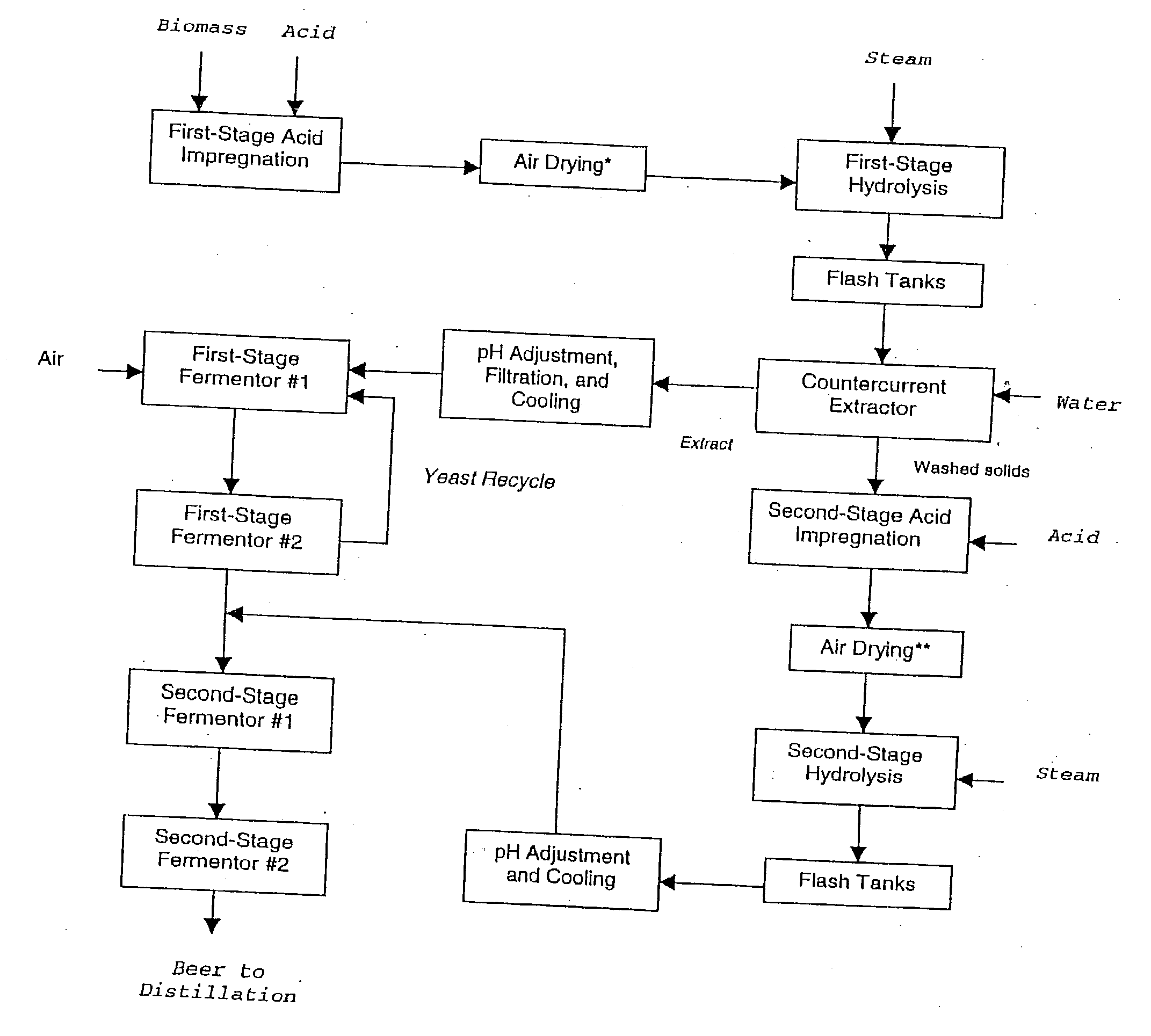

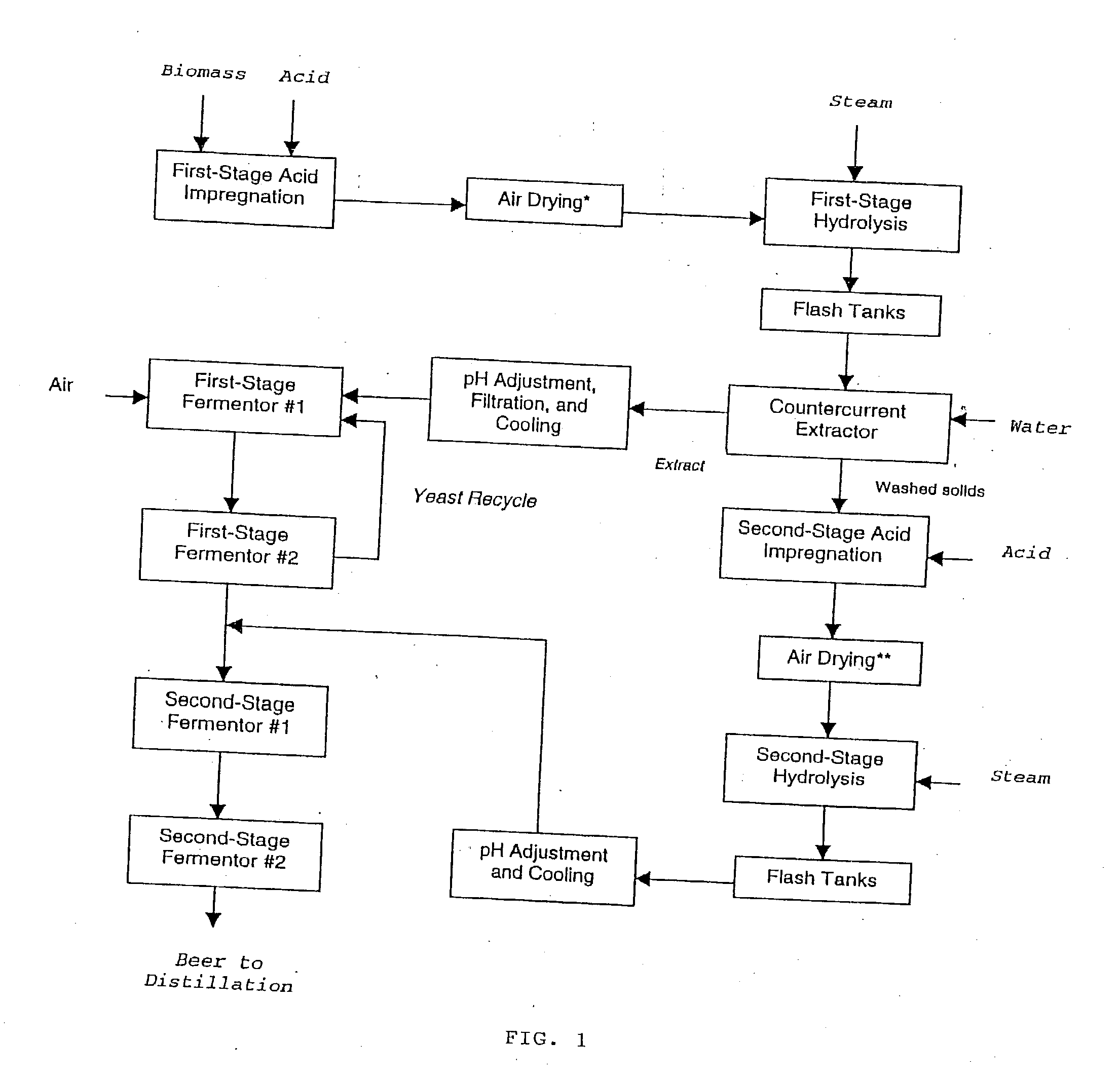

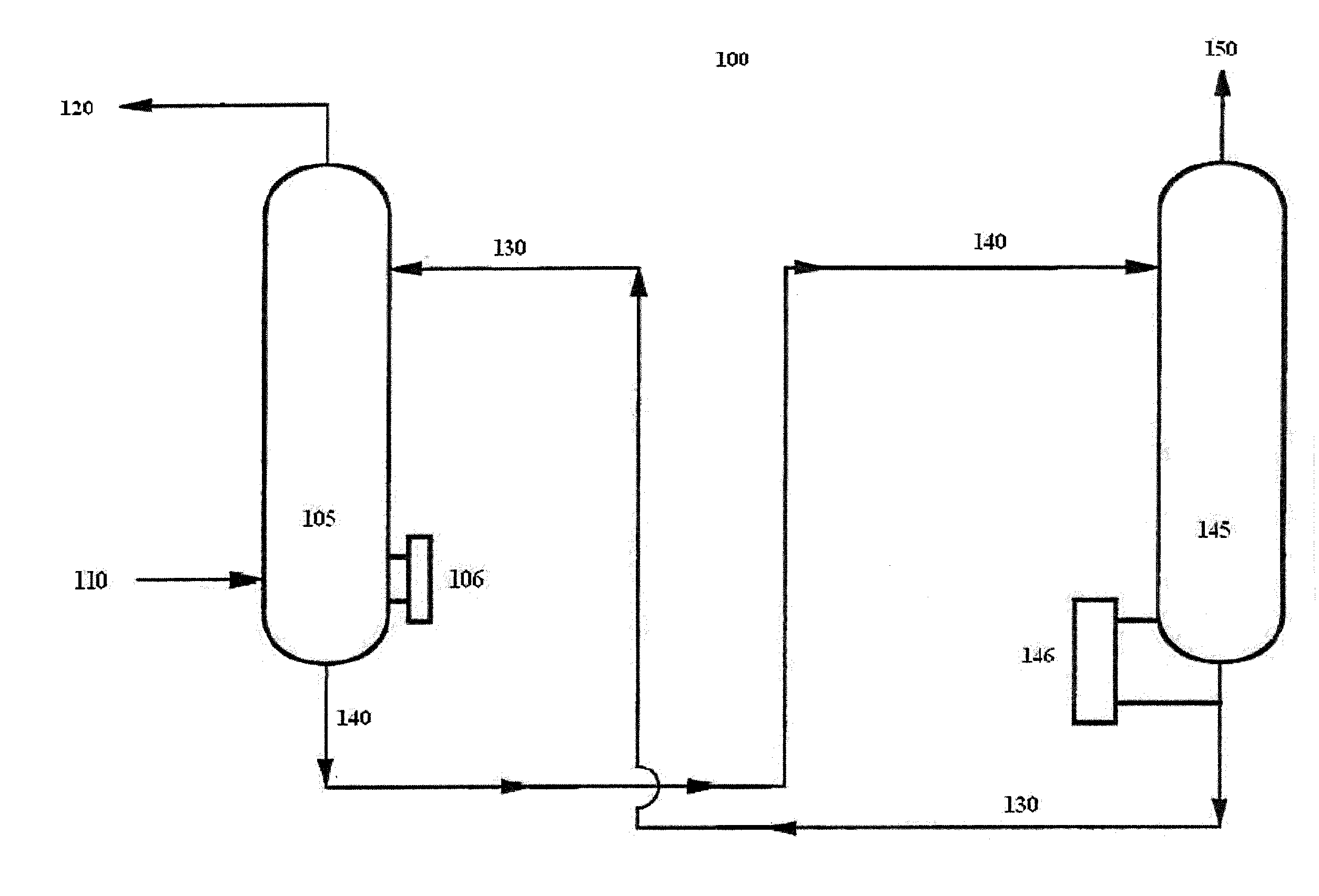

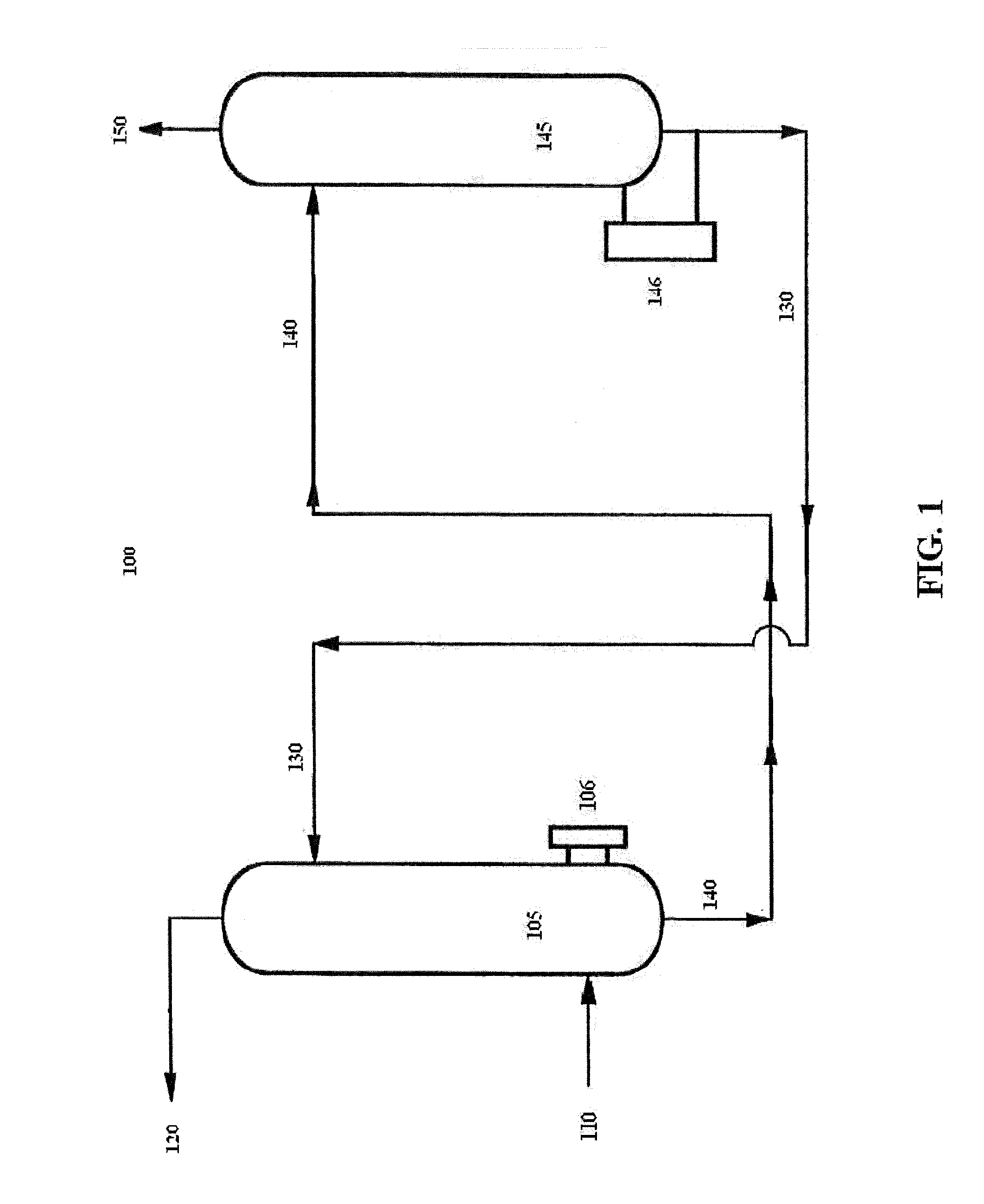

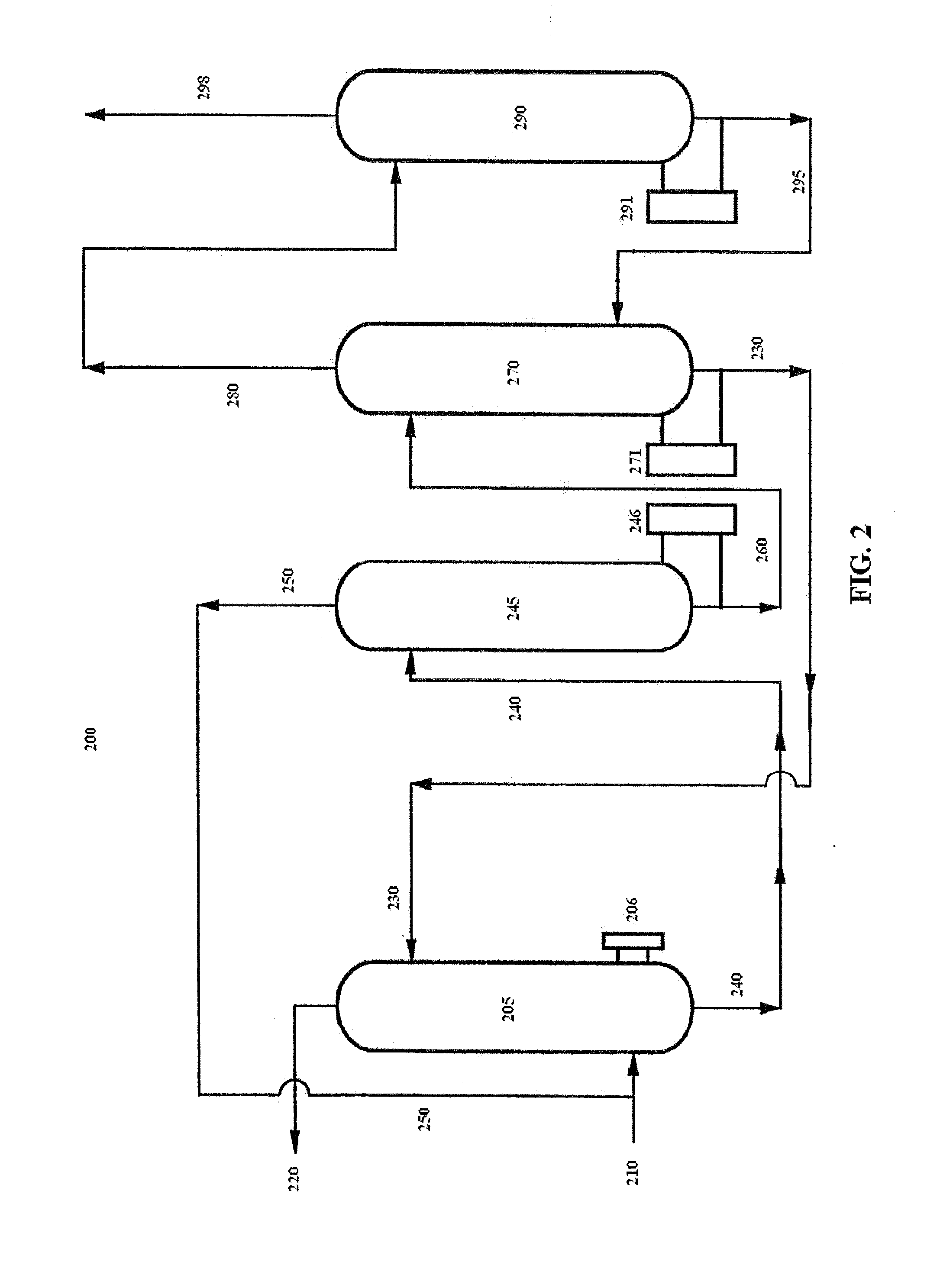

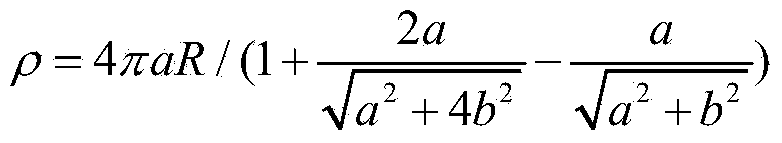

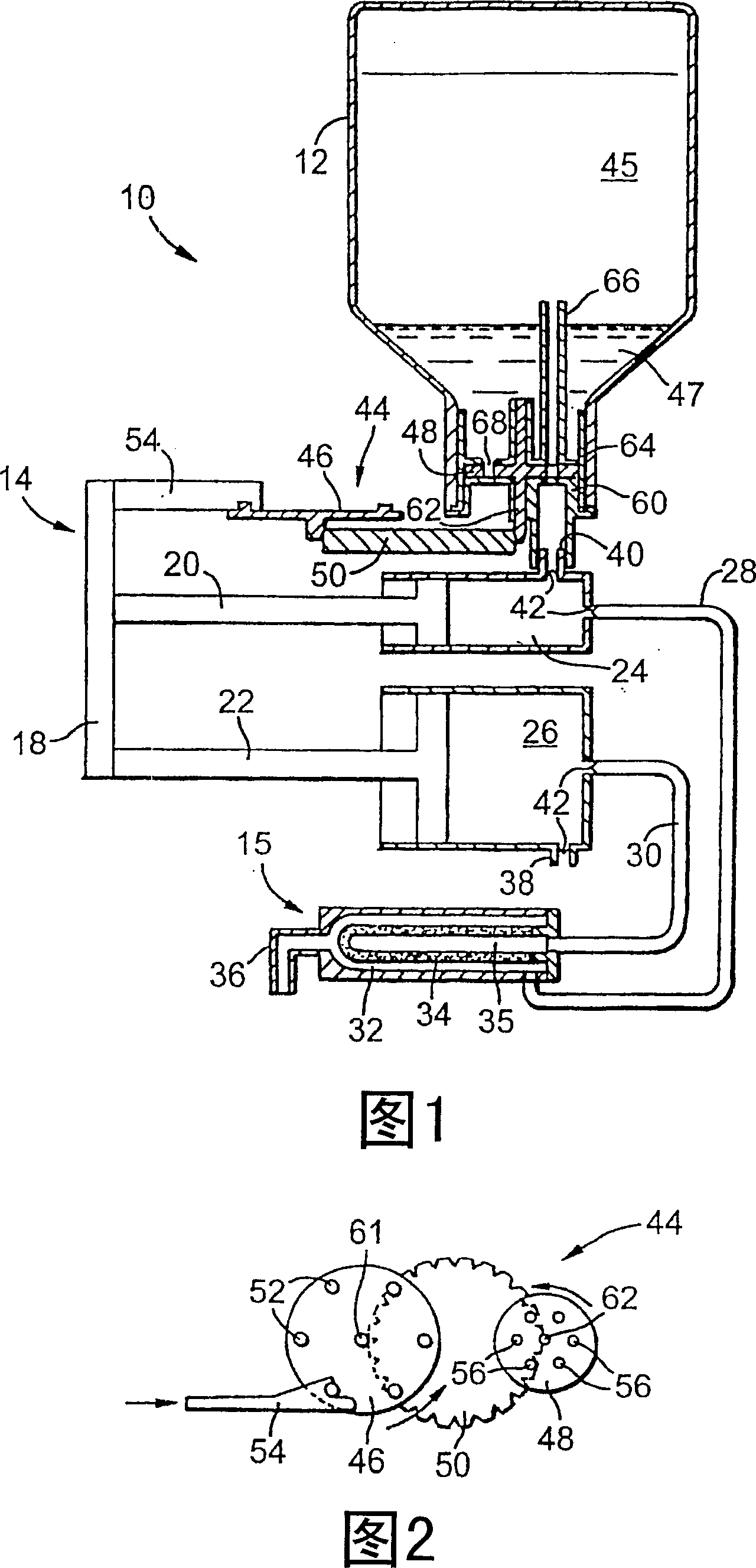

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

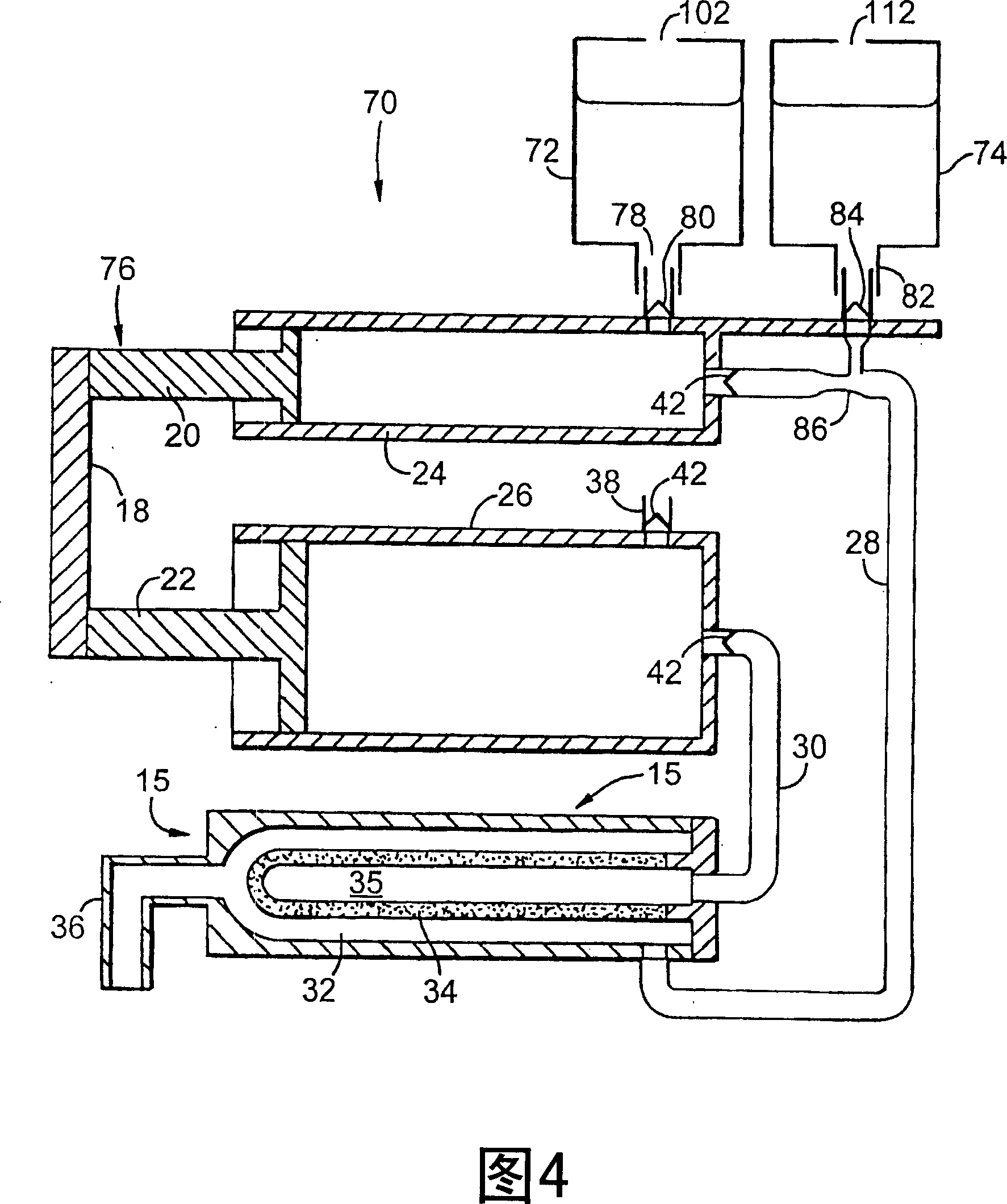

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

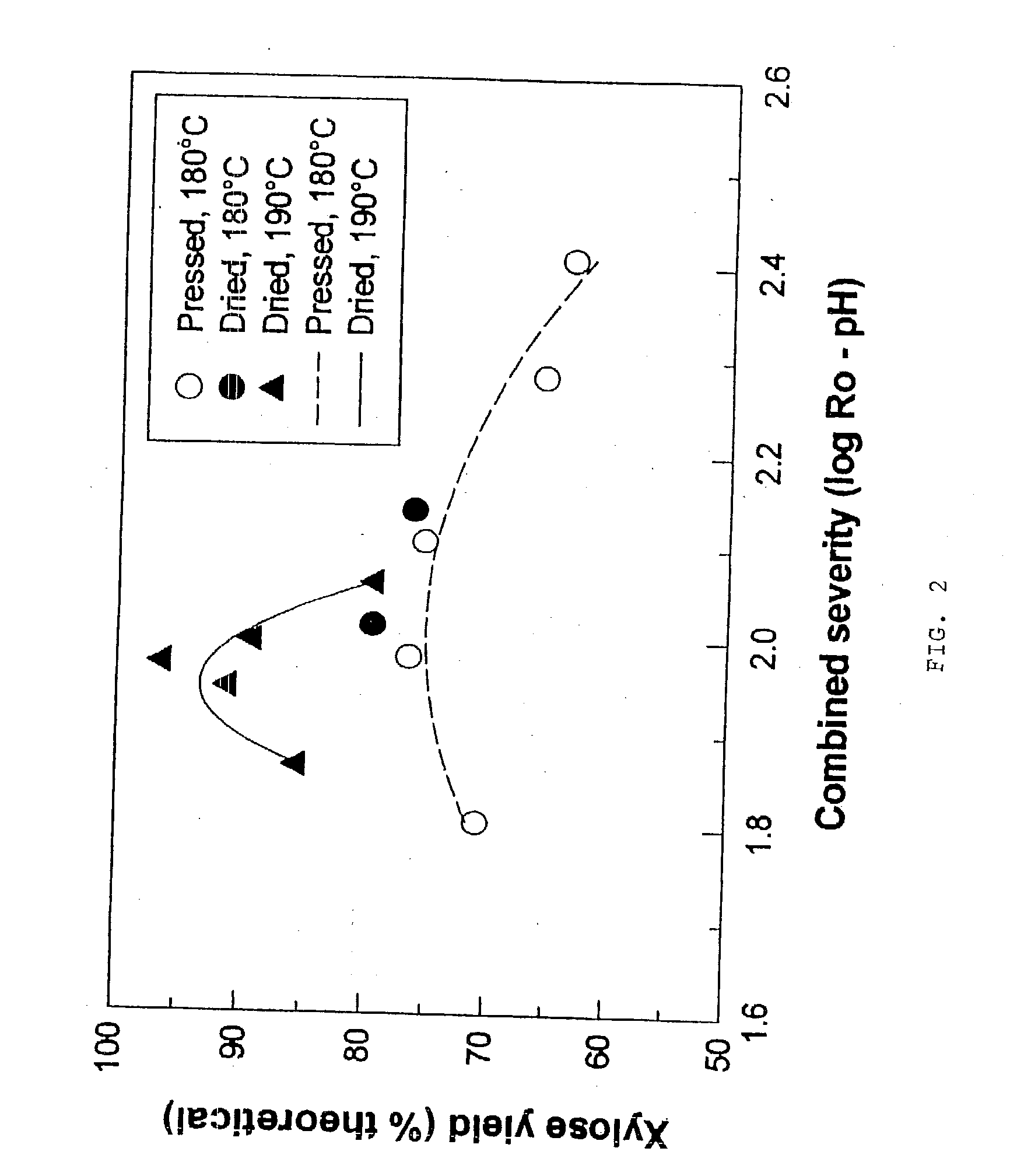

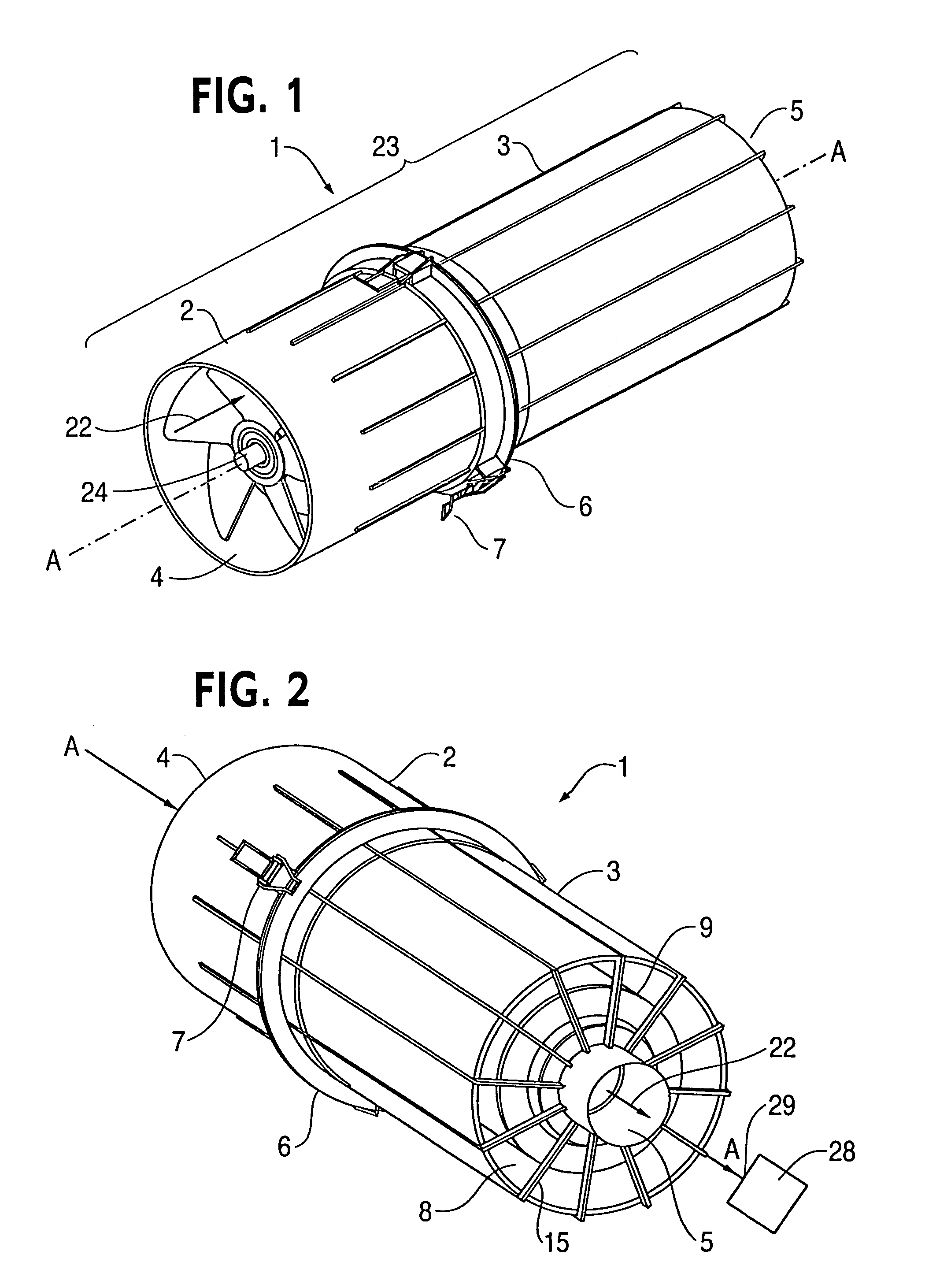

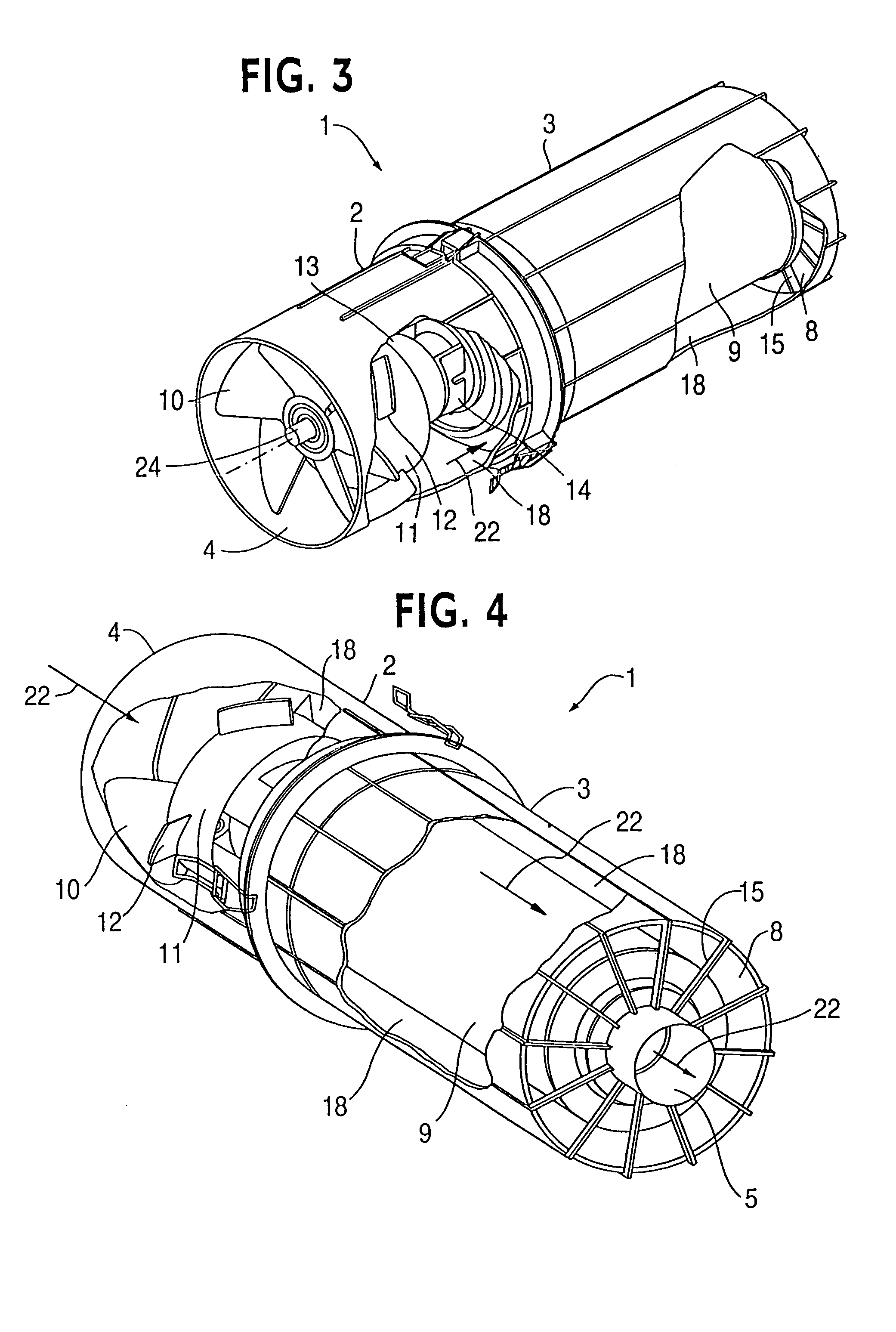

Powered air cleaning system and air cleaning method

InactiveUS7056368B2Efficient removalAvoids and reduces problemCombination devicesLiquid degasificationParticulate debrisHeavy particle

A powered air cleaning system (1) and air cleaning method are disclosed. The system has a flow path (22) extending through the system from an air inlet (4) to a clean air outlet (5). A motor-driven fan (24) located along the flow path draws particulate debris laden air into the inlet and rotates it about an axis (A—A) to form a rotating flow that stratifies the debris laden air with the heaviest particles in the outermost orbits of the rotating flow. An ejector port (25) is provided for ejecting particulate debris laden air from the stratified rotating flow in the system to the environment. An air filter (9) located within the rotating flow and across the flow path upstream of the outlet filters air from the innermost orbits of the stratified rotating flow. The motor-driven fan is operated to maintain a positive air pressure in the system on the filter even with cyclic air flow demands so that the rotating air flow continually sweeps the outside surface of the air filter to minimize buildup of debris on the filter.

Owner:SY KLONE

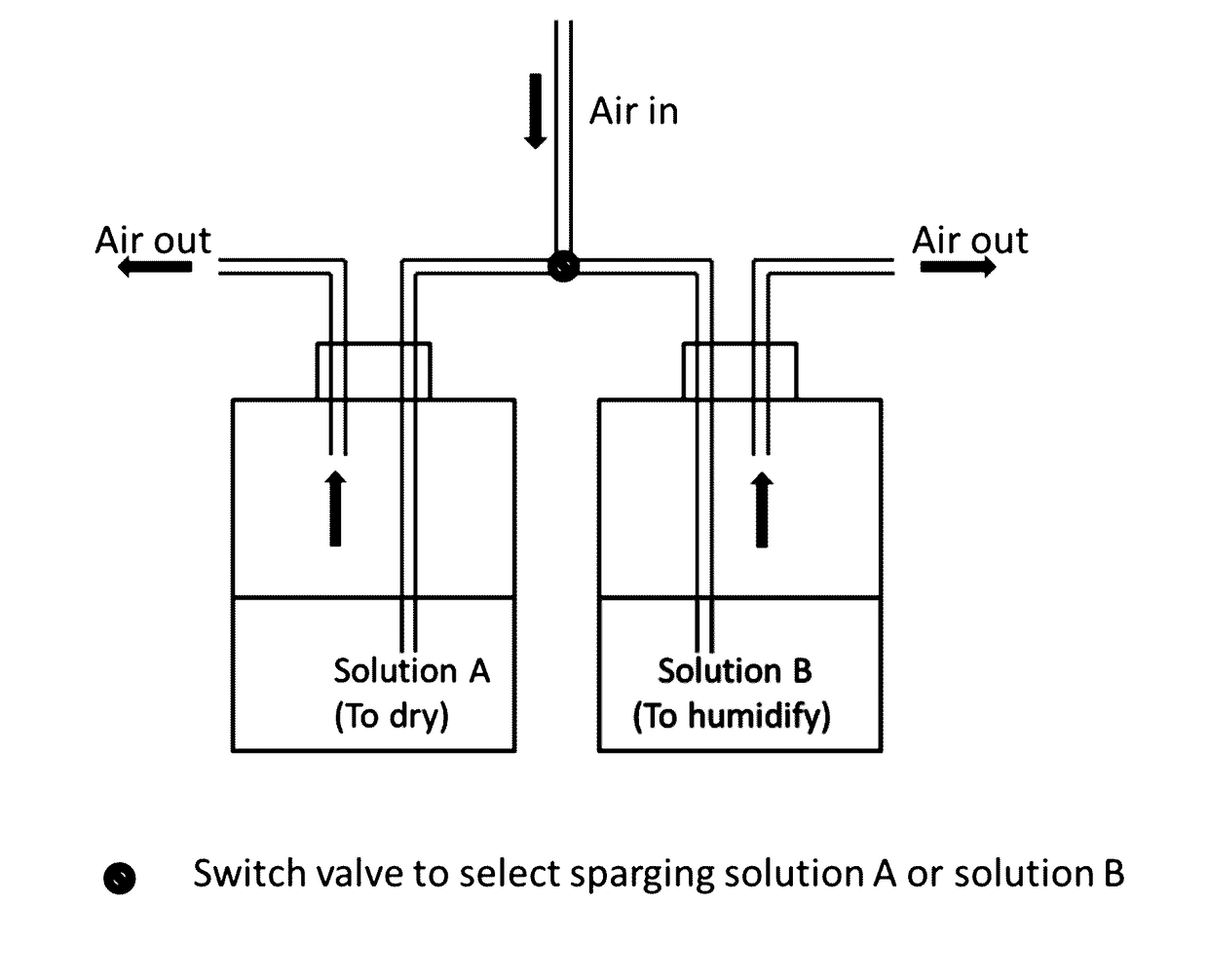

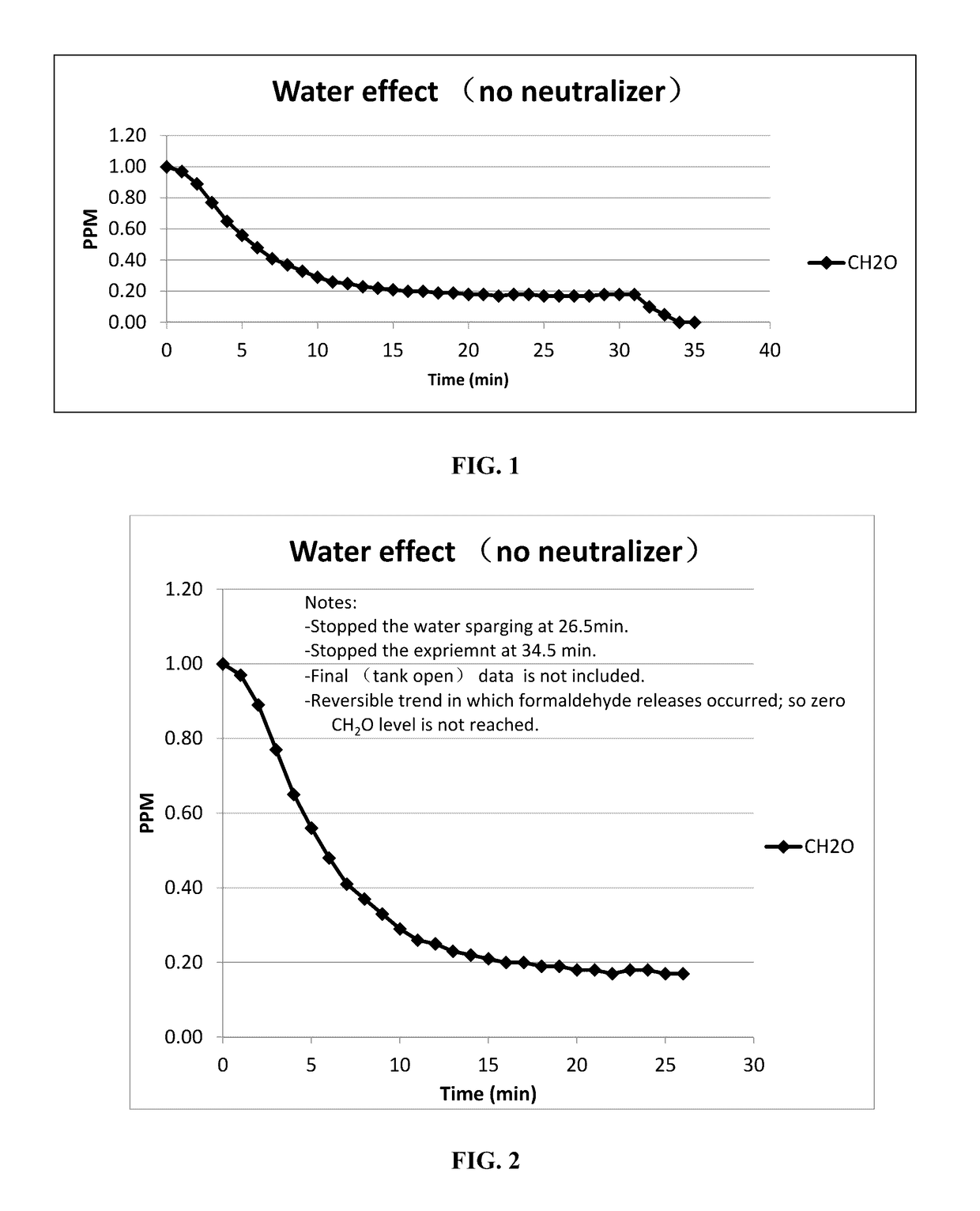

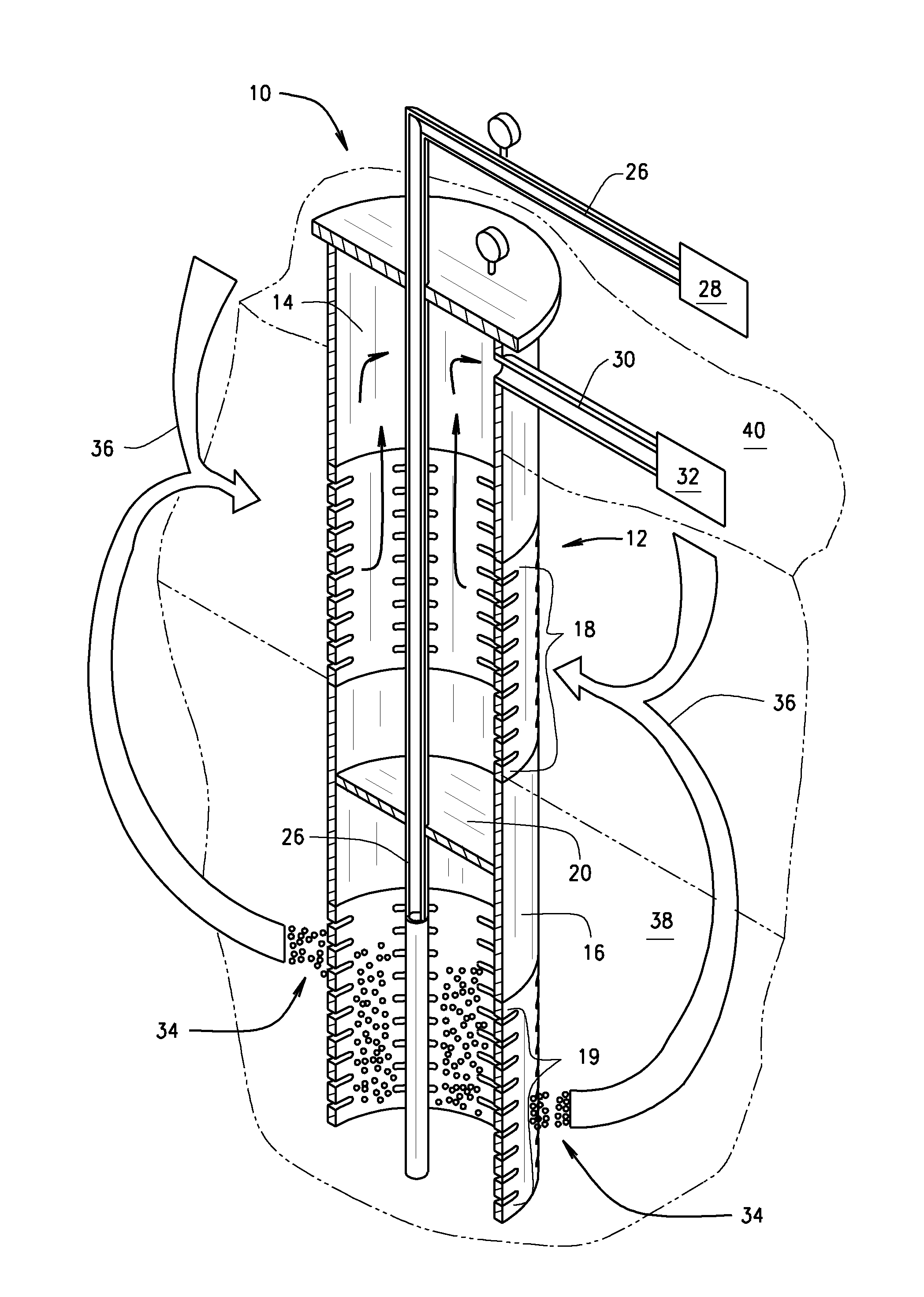

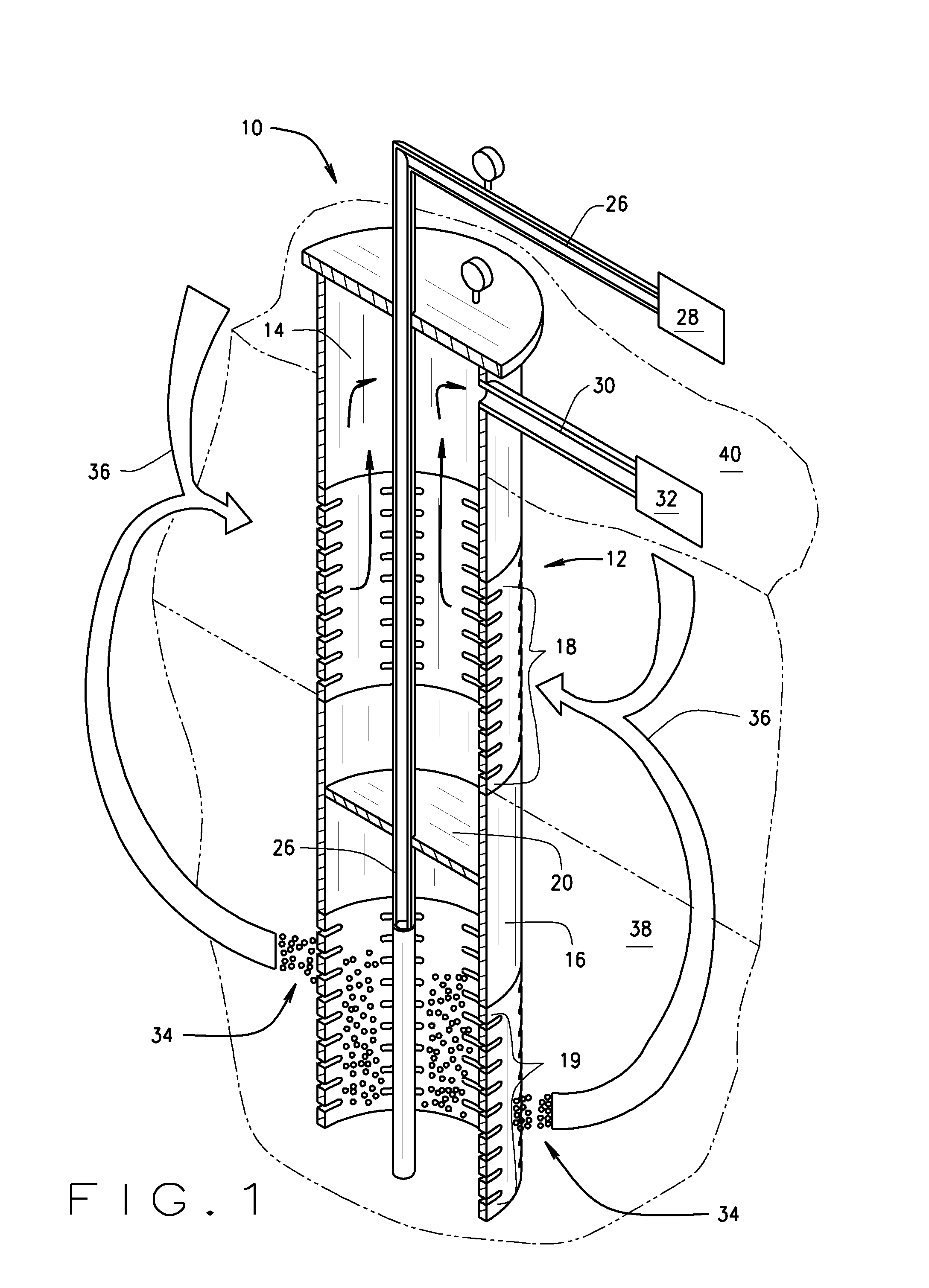

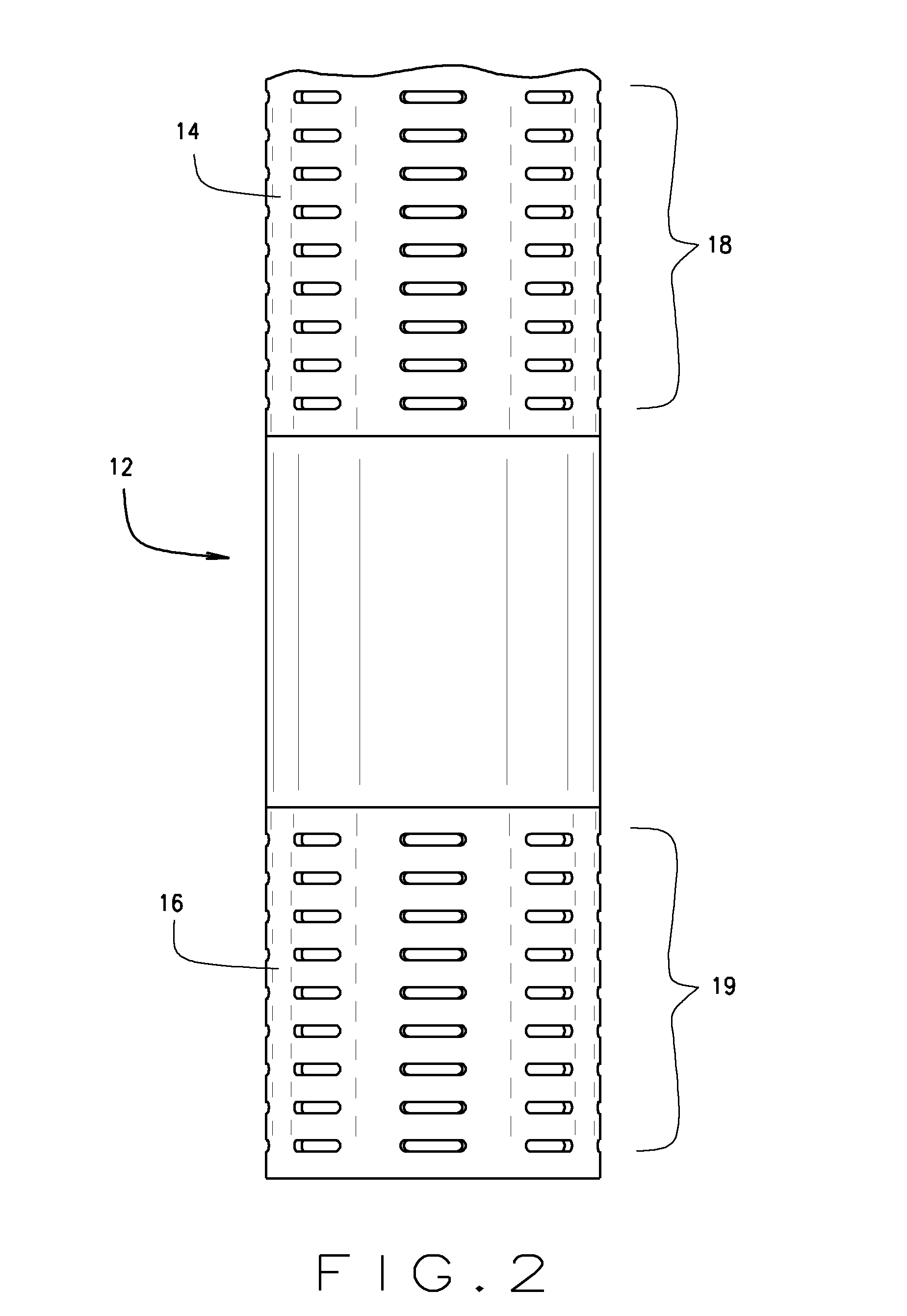

Method and Apparatus for Purification and Treatment of Air

ActiveUS20170106333A1Lower Level RequirementsIncrease temperatureGas treatmentDispersed particle separationParticulatesSolid medium

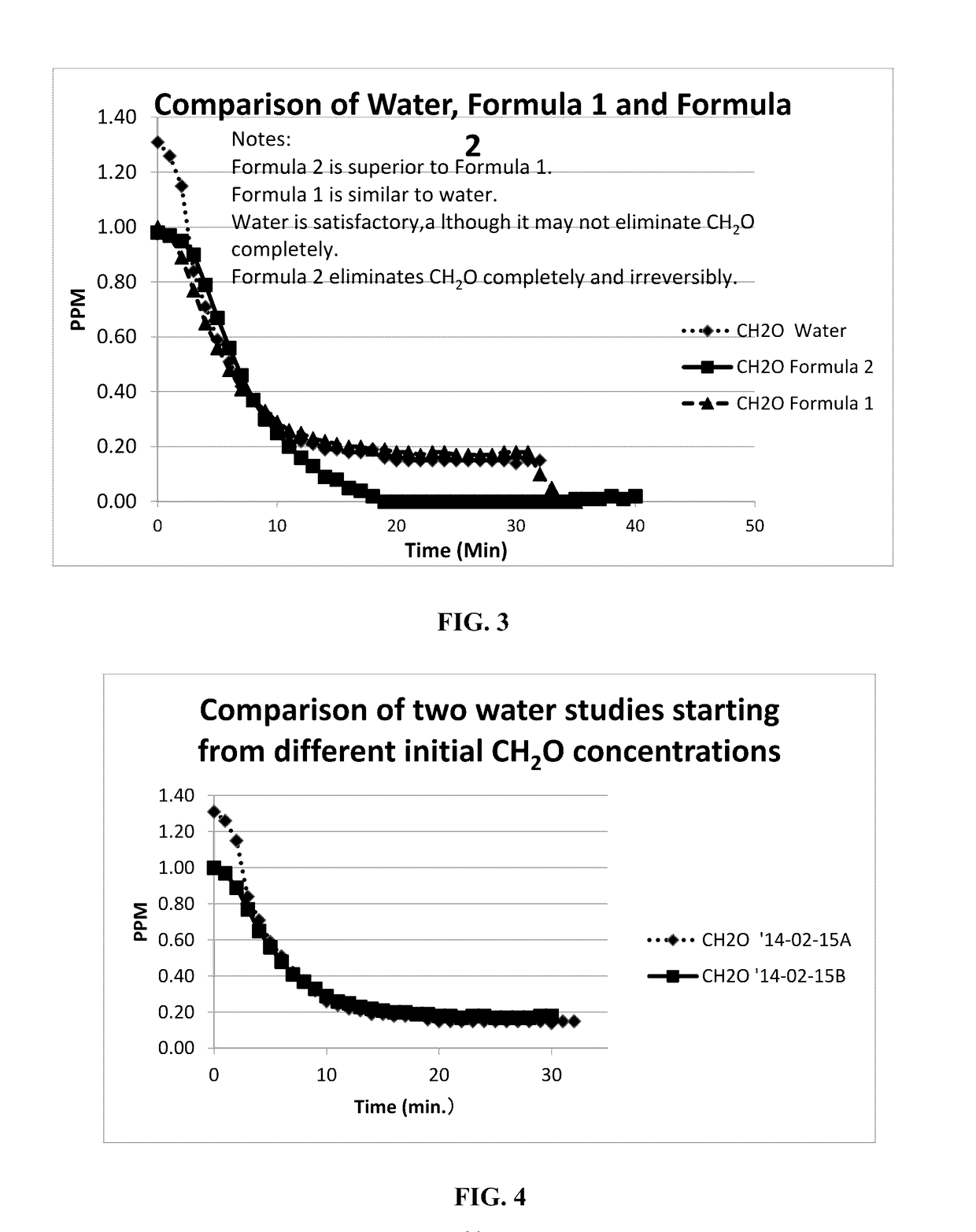

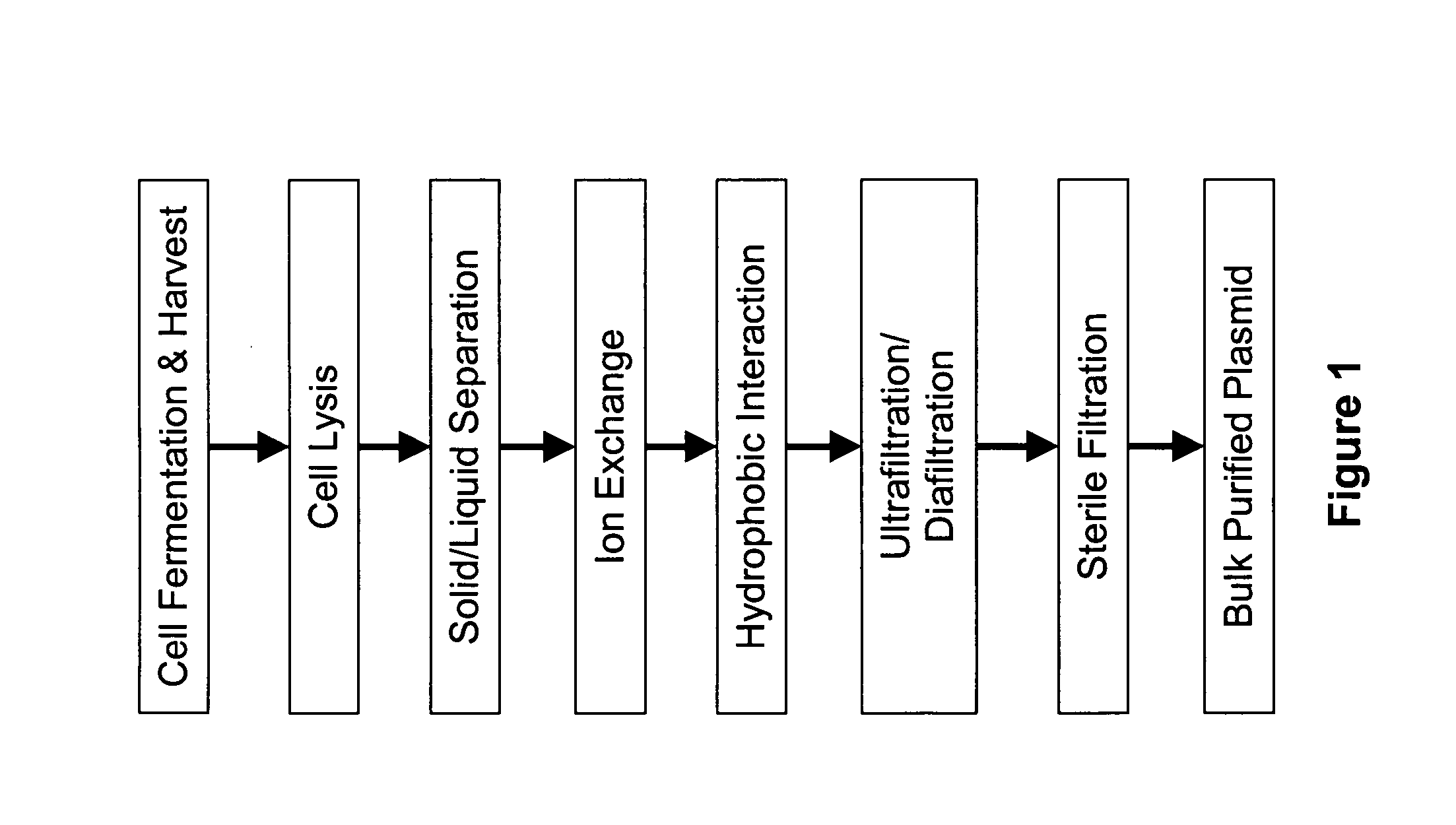

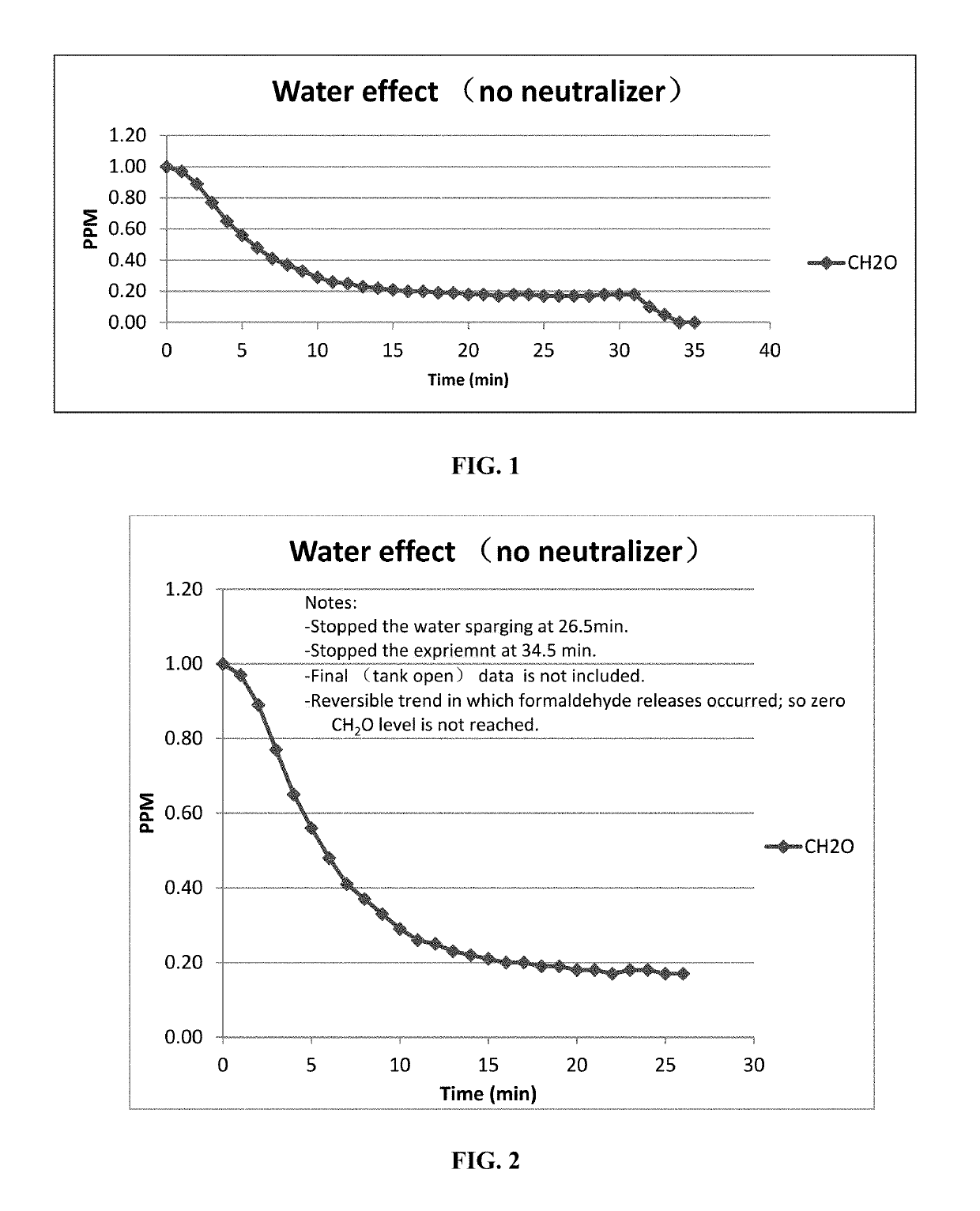

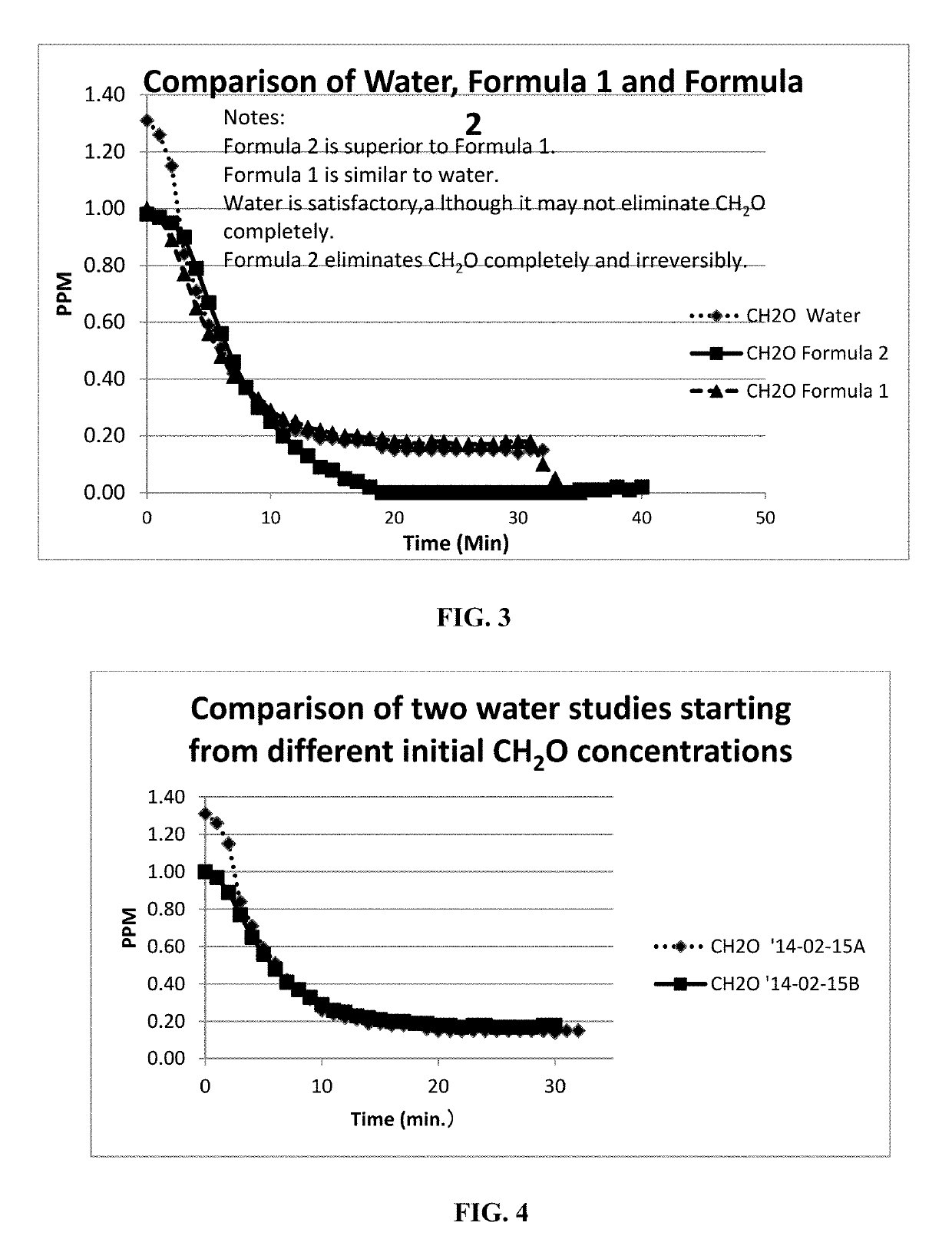

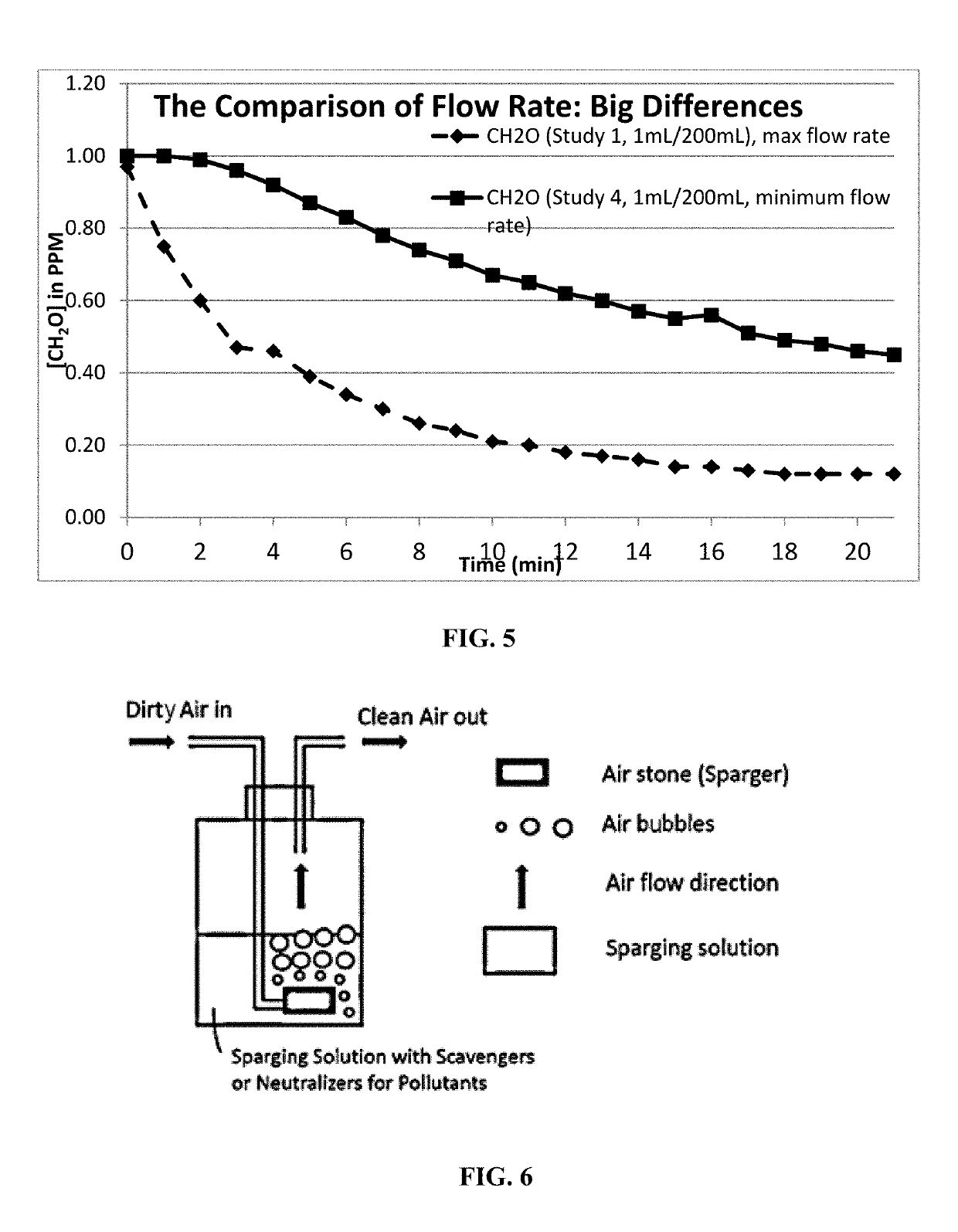

The invention discloses methods and apparatus(es) for the removal and control of pollutants such as gases and suspended particulates in the air of an enclosed space or an outdoor environment by passing the air through absorbent media. The absorbent media includes any liquid, solid or combination of liquid and solid media that is capable of absorbing a material in which it comes in contact. In one aspect of the invention, formaldehyde is removed by air sparging through a liquid such as water, optionally containing additional scavenging agents.

Owner:PALOZA LLC

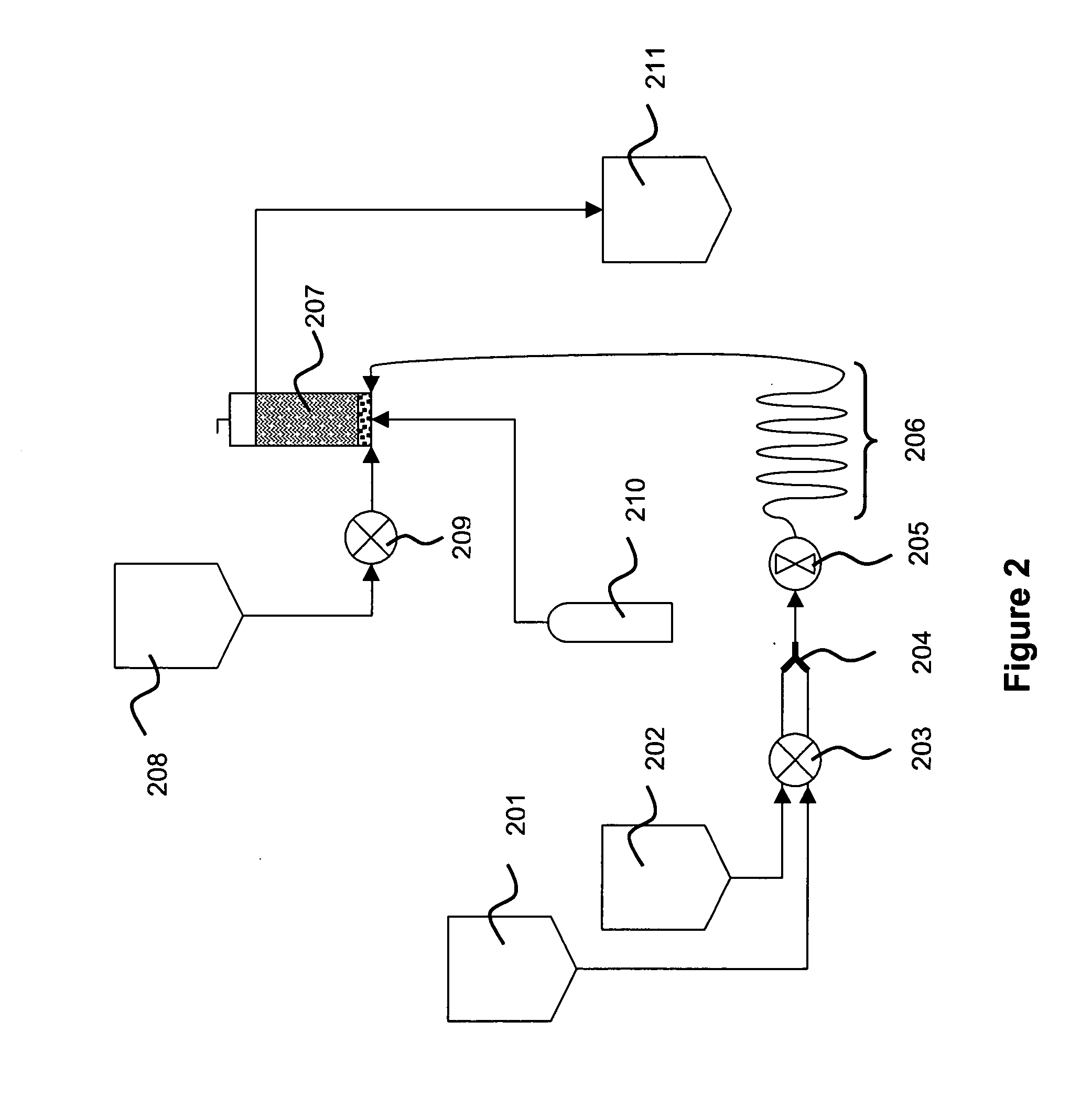

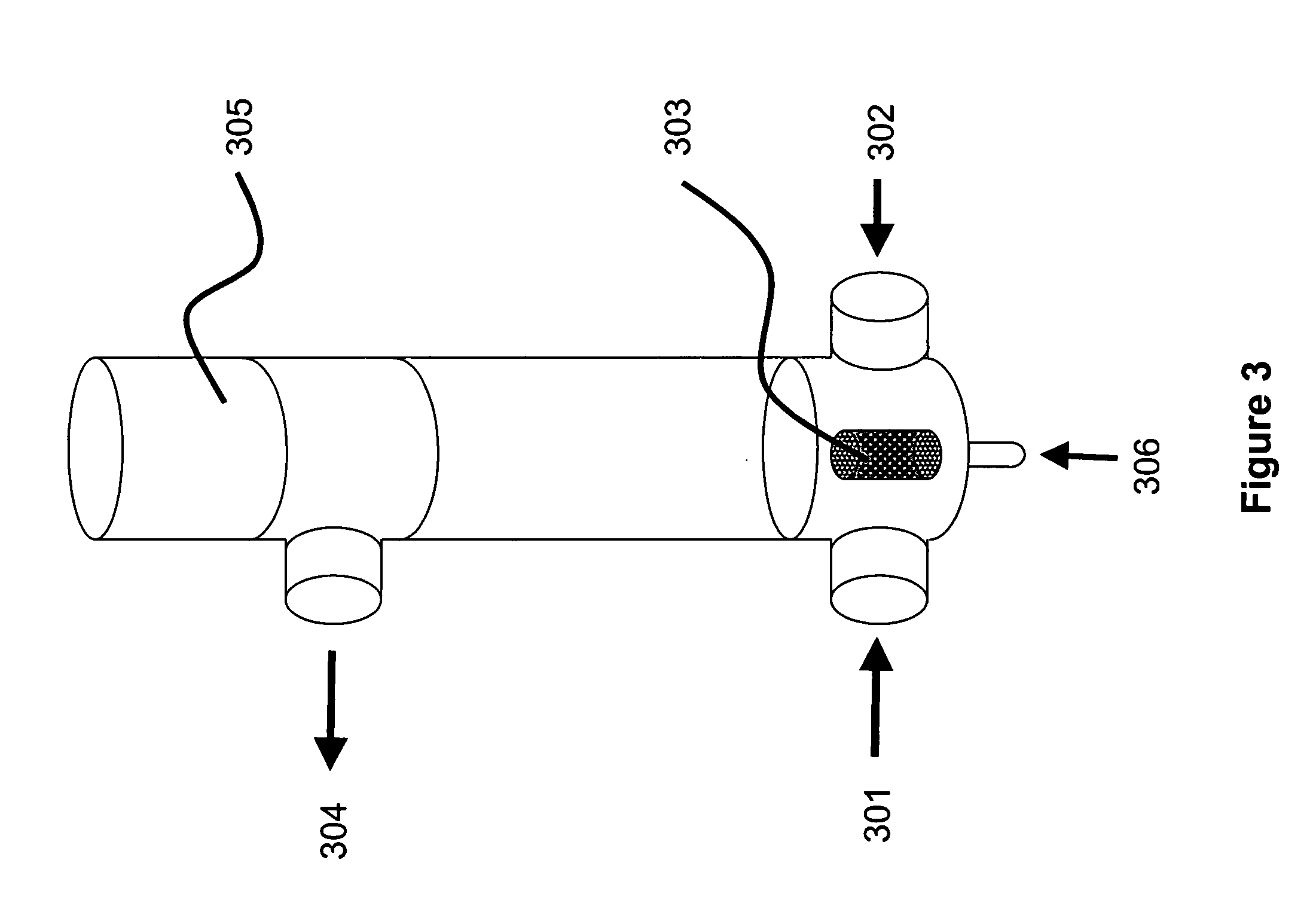

Devices and methods for biomaterial production

ActiveUS20050014245A1Avoid excessive fragmentationIndependent controlBioreactor/fermenter combinationsBiological substance pretreatmentsCellular componentUltrafiltration

An apparatus and a method for isolating a biologic product, such as plasmid DNA, from cells. The method involves lysing cells in a controlled manner separate insoluble components from a fluid lysate containing cellular components of interest, followed by membrane chromatographic techniques to purify the cellular components of interest. The process utilizes a unique lysis apparatus, ion exchange and, optionally, hydrophobic interaction chromatography membranes in cartridge form, and ultrafiltration. The process can be applied to any biologic product extracted from a cellular source. The process uses a lysis apparatus, including a high shear, low residence-time mixer for advantageously mixing a cell suspension with a lysis solution, a hold time that denatures impurities, and an air-sparging bubble mixer that gently yet thoroughly mixes lysed cells with a neutralization / precipitation buffer and floats compacted precipitated cellular material.

Owner:VGXI

Corrosion control in ammonia extraction by air sparging

InactiveUS20150175433A1Reduce corrosionSafe and reliable and long-lasting material of constructionGaseous chemical processesGas treatmentOxygenAmmonia

The present invention relates to reduction of corrosion. The present invention includes a method of decreasing corrosion during ammonia extraction. The method includes performing a process to extract ammonia using ammonia extraction equipment. The ammonia extraction equipment includes an ammonia absorber, an ammonia desorber, and an aqueous solution. The aqueous solution includes an acid or an ammonium salt thereof. The method also includes sparging an oxygen-containing gas into the solution in the ammonia absorber, the ammonia desorber, or therebetween. The invention also provides a system that can perform the method.

Owner:INVISTA NORTH AMERICA R L

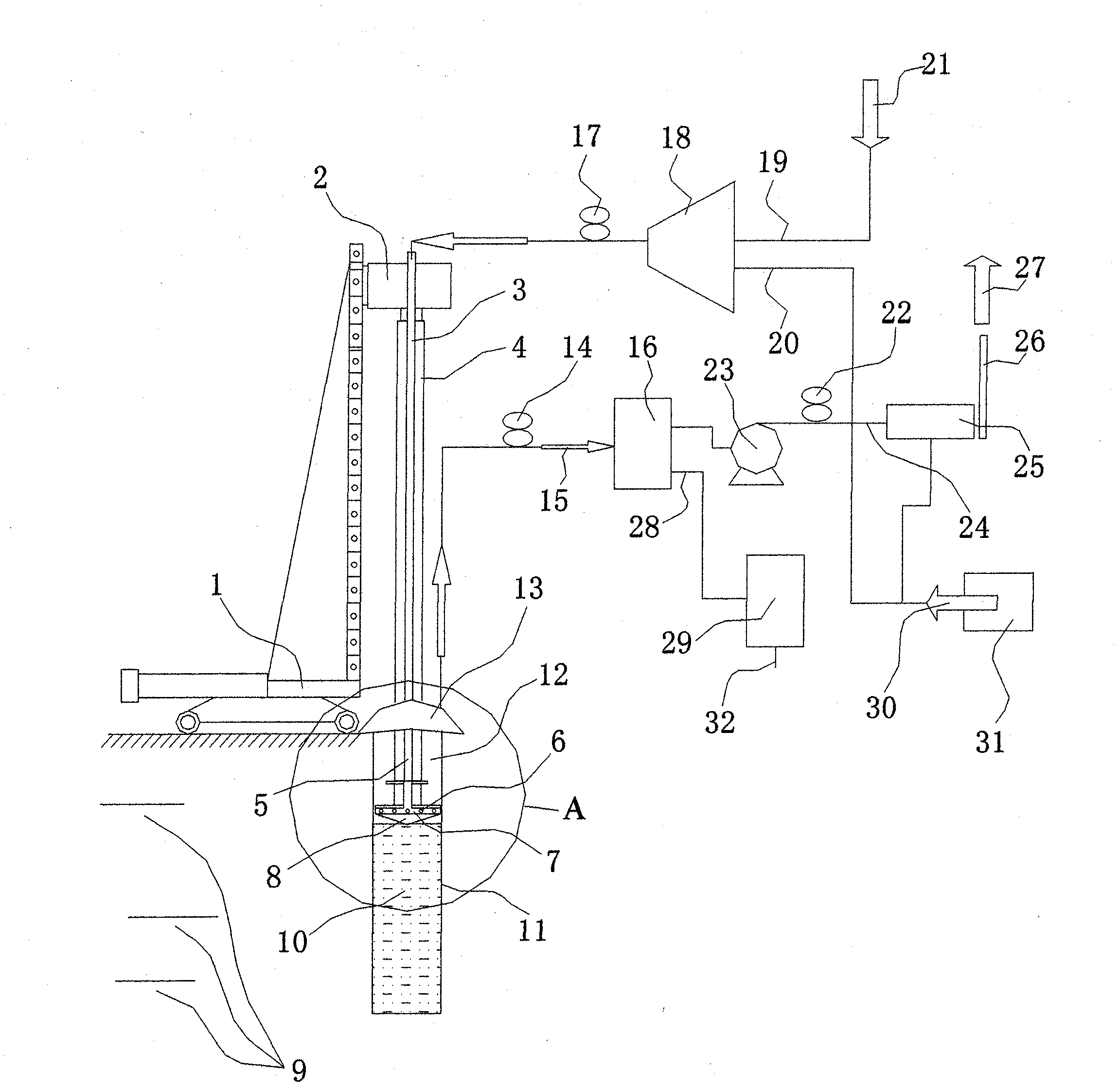

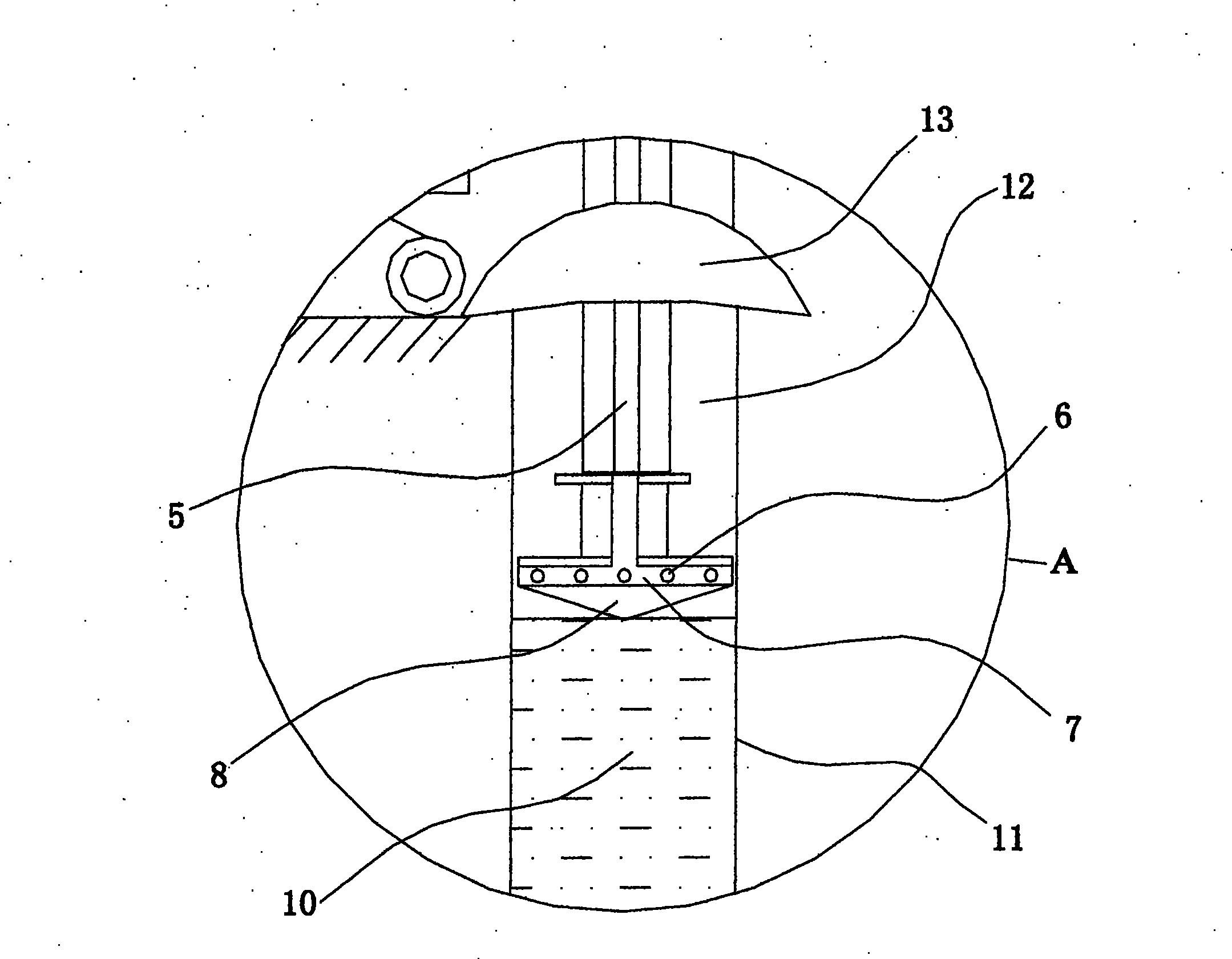

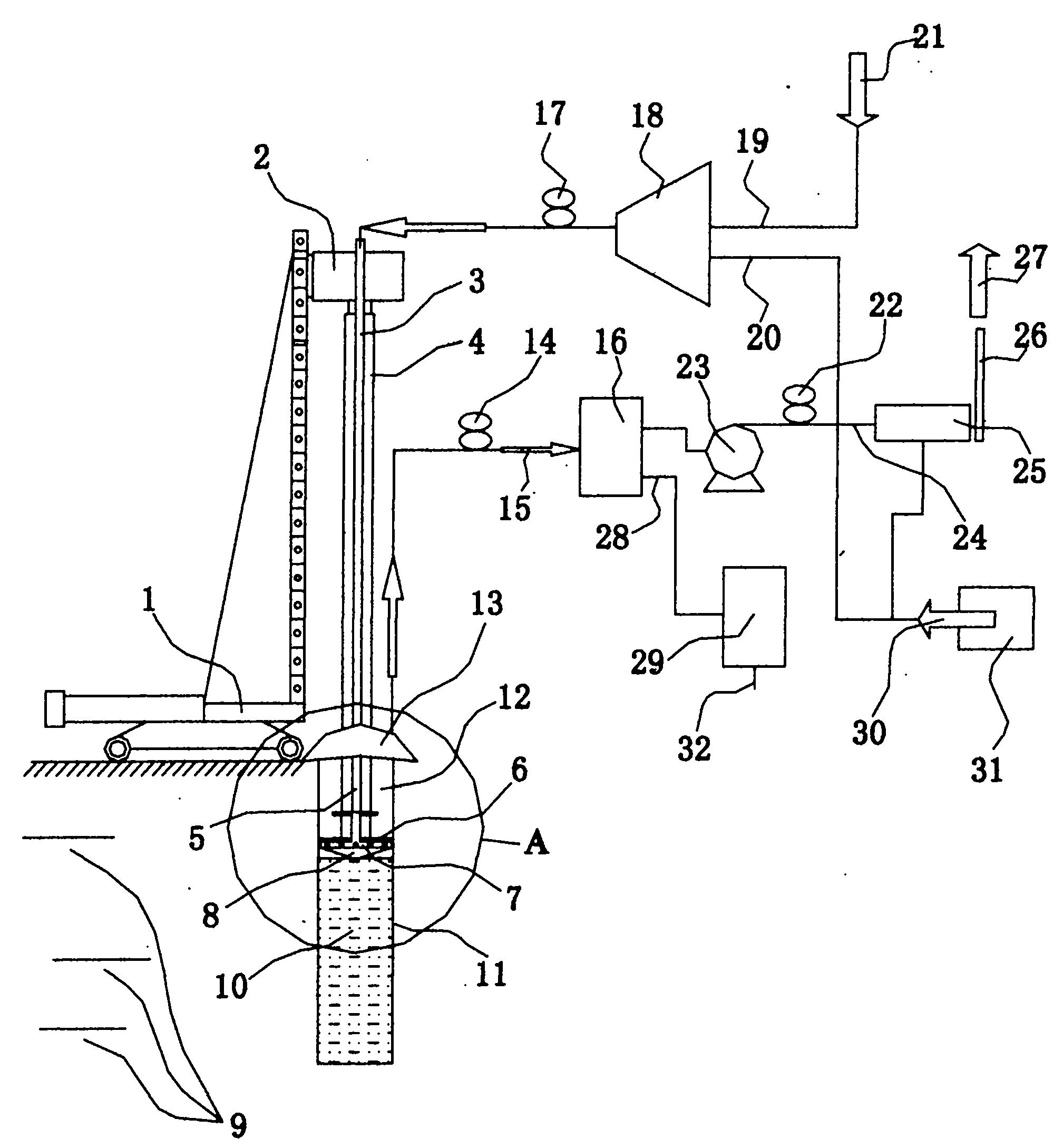

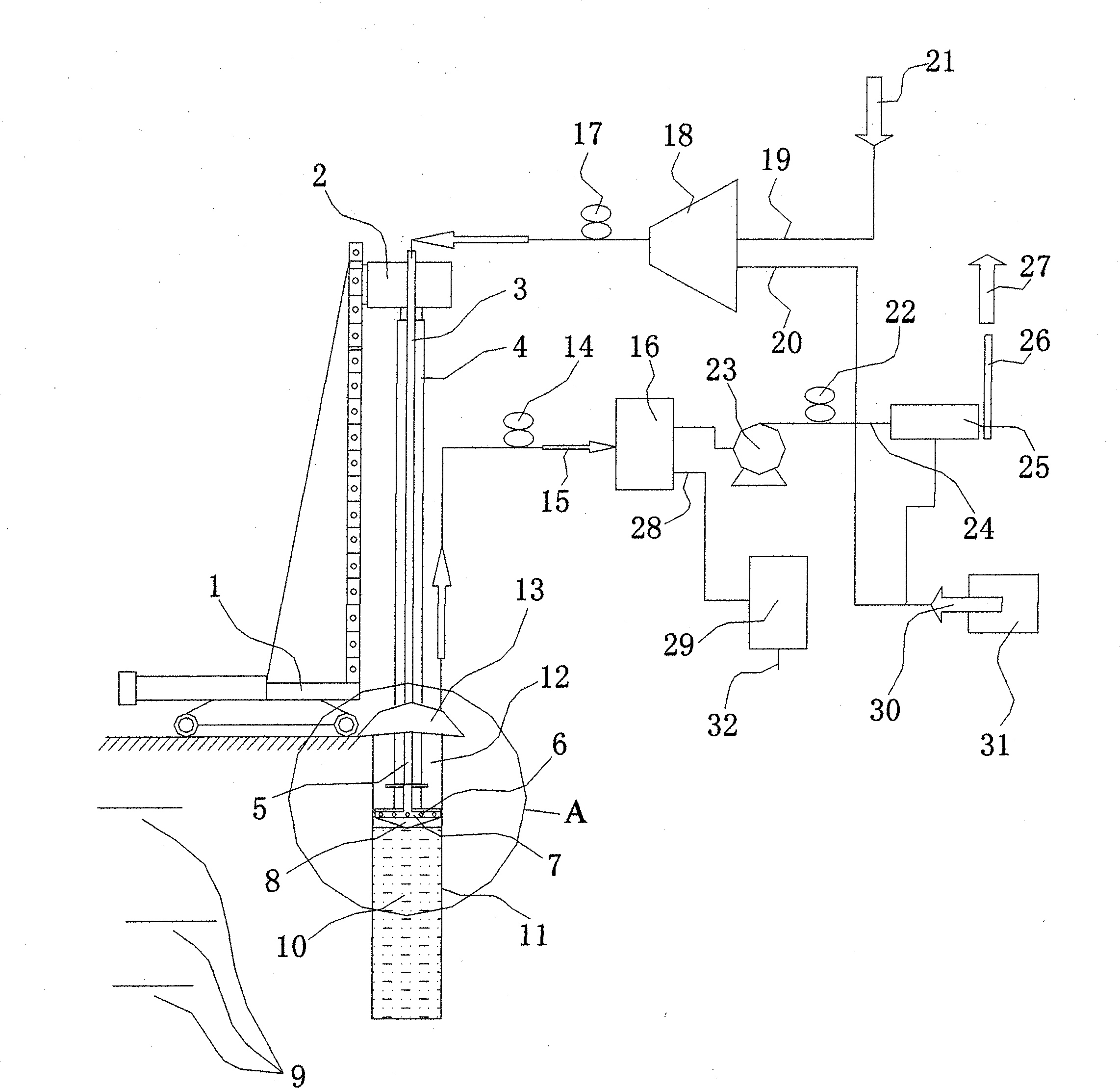

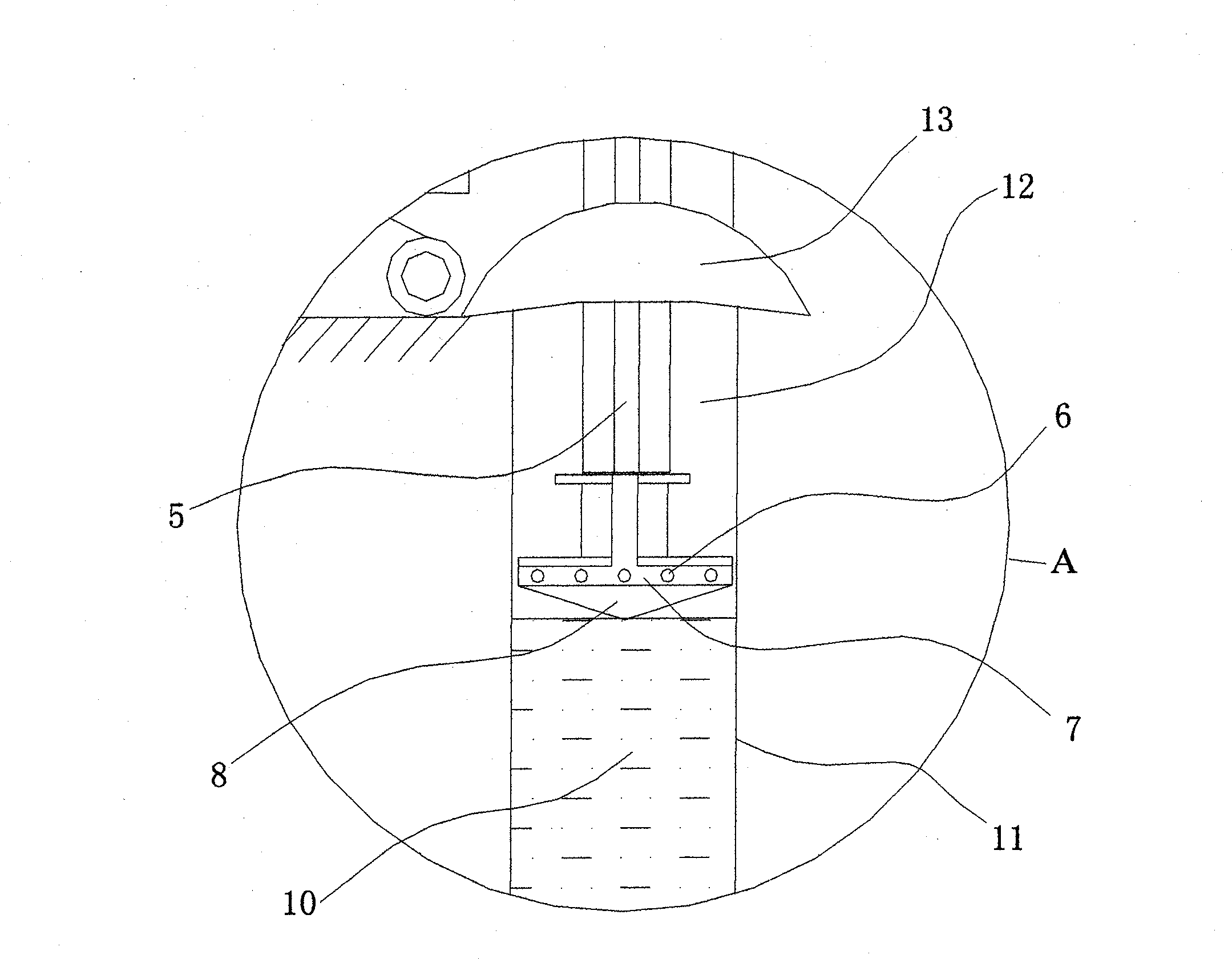

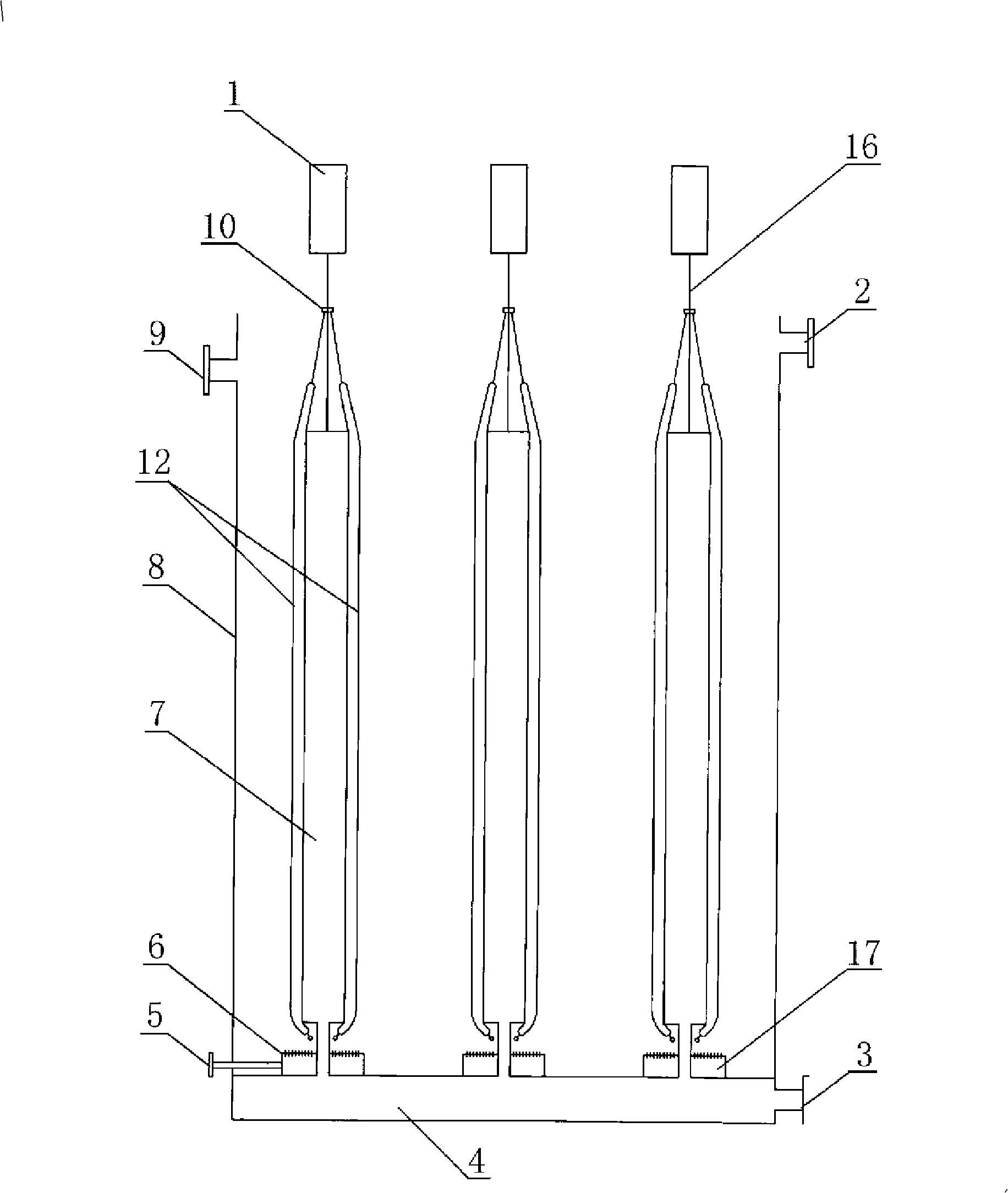

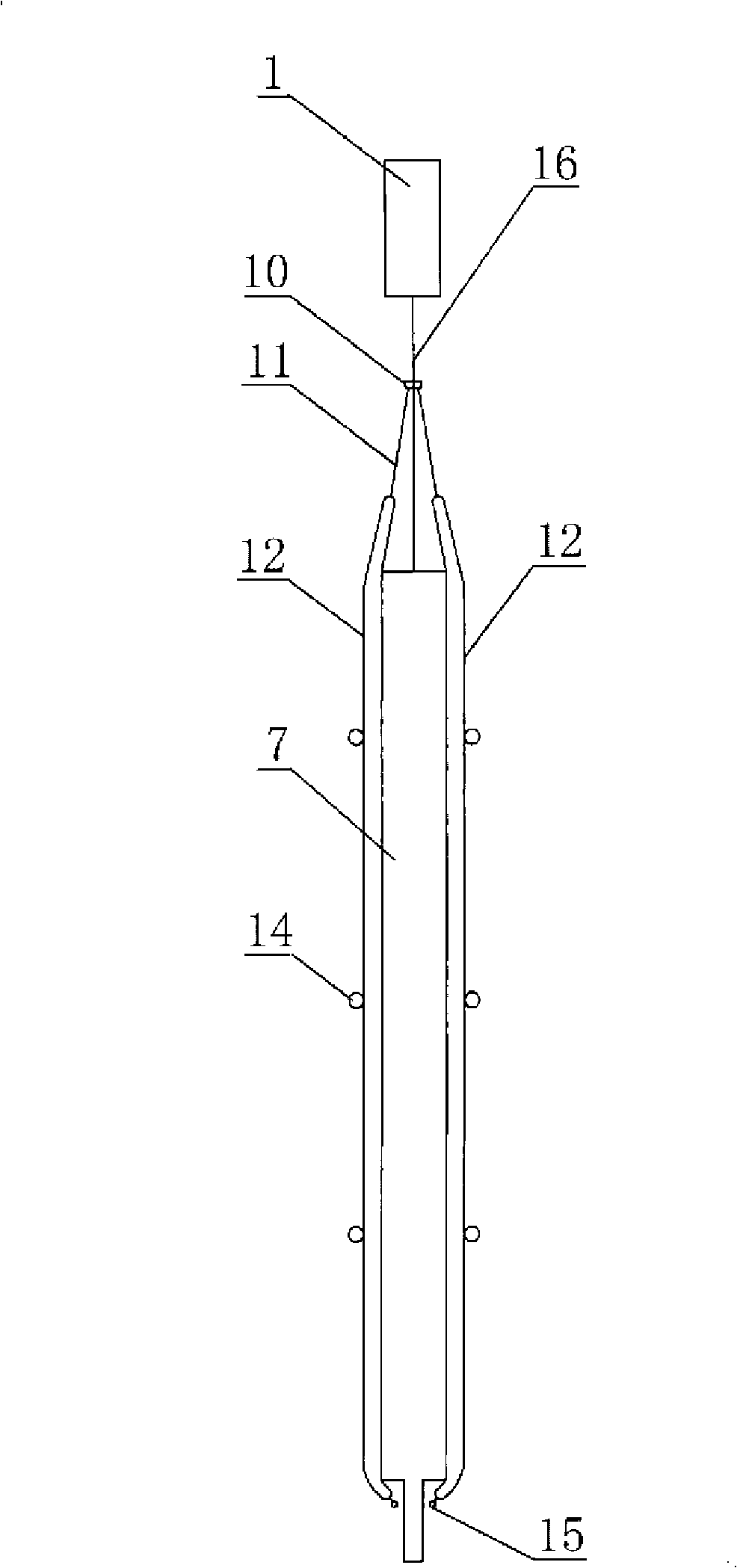

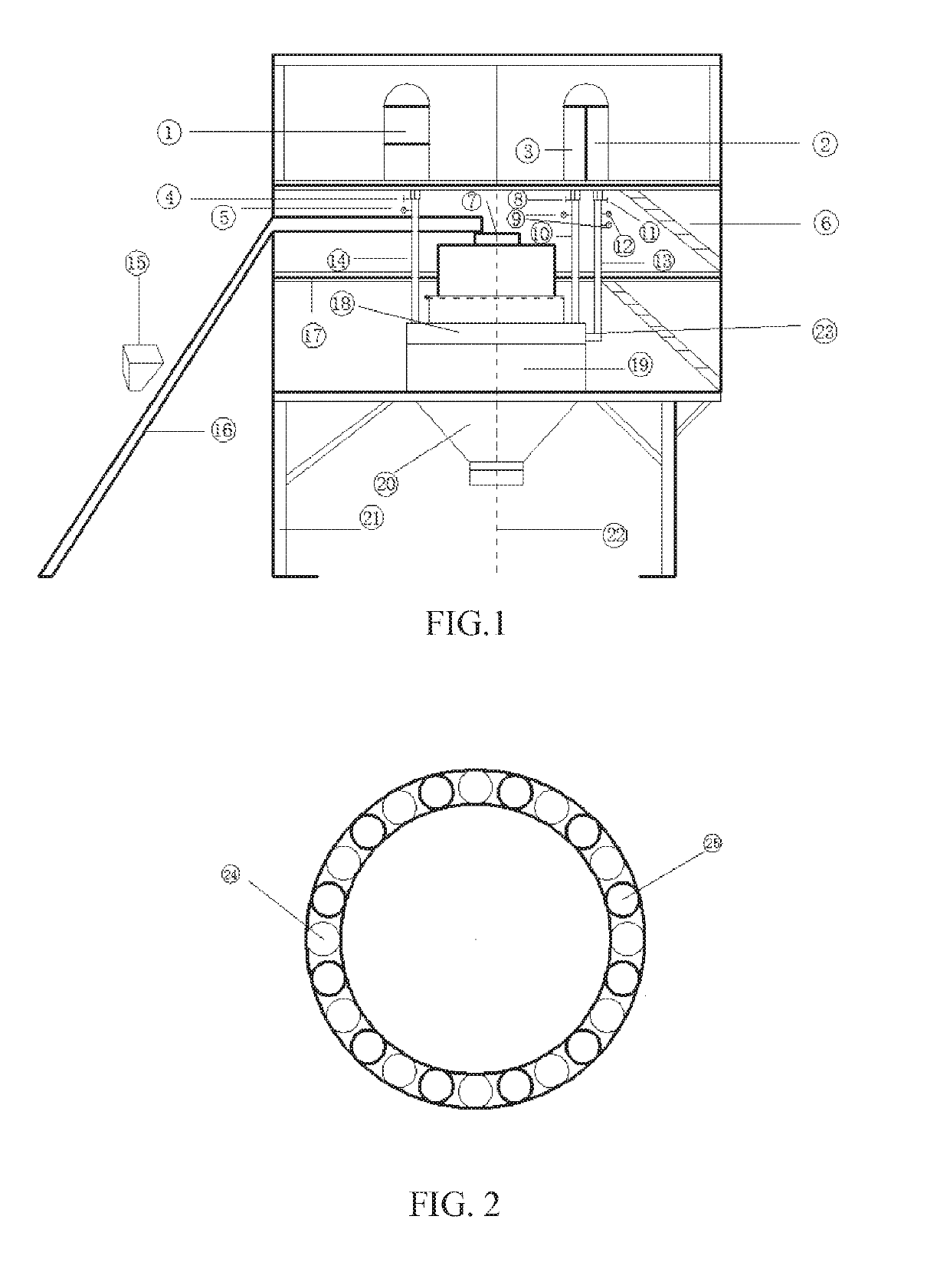

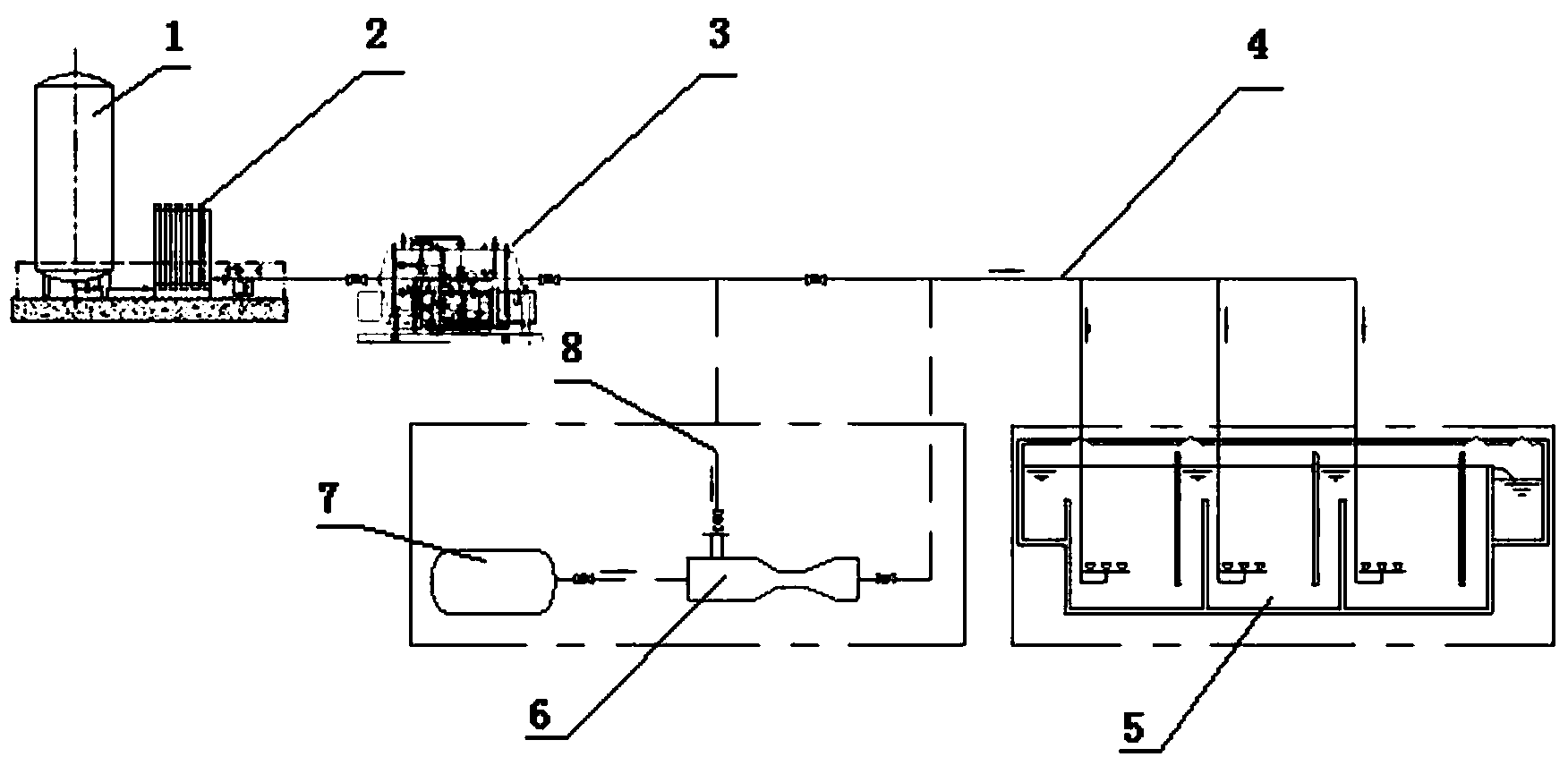

In-situ repair system and method for deep layer stirring-hot air injection of polluted soil

ActiveCN102671932ASimple designAchieve repair efficiencyContaminated soil reclamationEngineeringAir compressor

The invention provides an in-situ repair system and an in-situ repair method for deep layer stirring-hot air injection of polluted soil. According to the in-situ repair system, the lower end of a hot air spray pipe is communicated with a drill body core pipe in a drill; the upper end of the hot air spray pipe is communicated with an air outlet of a hot air compressor; and a mixed air-liquid pipeline is connected between a coverage cover and an air-liquid separator. According to the method, the drill is drilled in a target soil layer up and down in a reciprocating mode according to designed elevation, wherein the diameter of a stirring drill hole is 1.5 to 2.5 meters, the depth of the stirring drill hole is 9 to 12 meters, the injection pressure of hot air is 1 to 2 MPa, and the temperature of the hot air is 90 to 110 DEG C. According to the technology of the in-situ repair system and the in-situ repair method, the application range of strata can be expanded to low-middle permeable strata, and the range of the types of applicable pollutants is also increased, for example, the technology is still valid to semivolatile organic matters such as anilines. By the in-situ repair system and the in-situ repair method, the problem of 'smearing' of a soil vapor extraction (SVE) technology in the later period of repair can be solved, so that the repair efficiency is improved greatly, and the repair period is shortened greatly.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

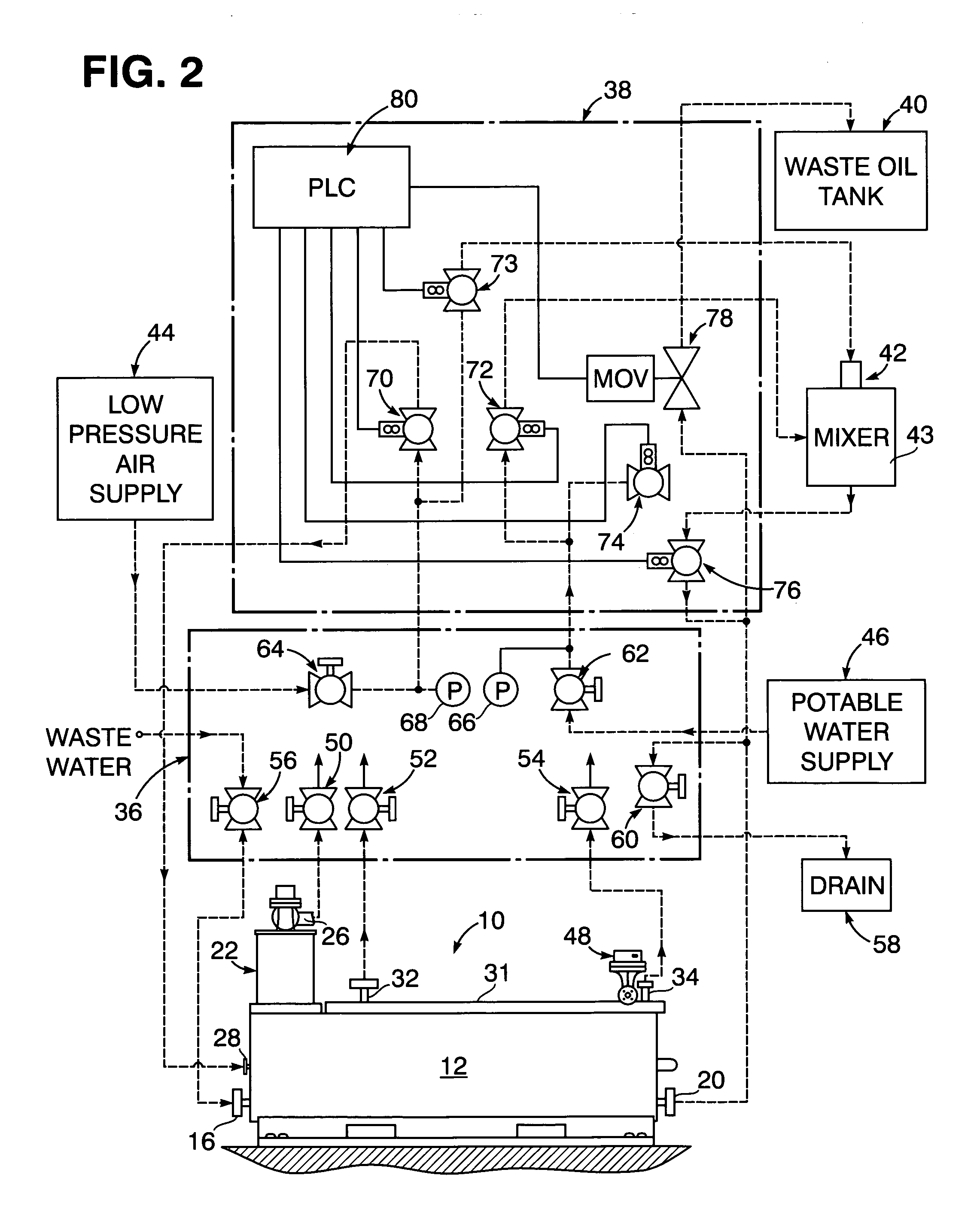

Valve automated in-situ cleaning system for oil water separator

InactiveUS7374668B1Liquid separation auxillary apparatusLoose filtering material filtersAutomatic controlMotor drive

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

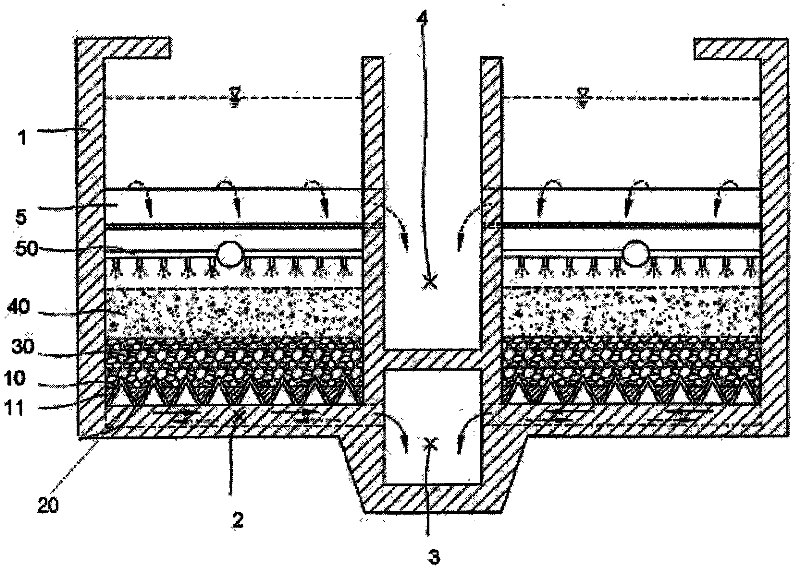

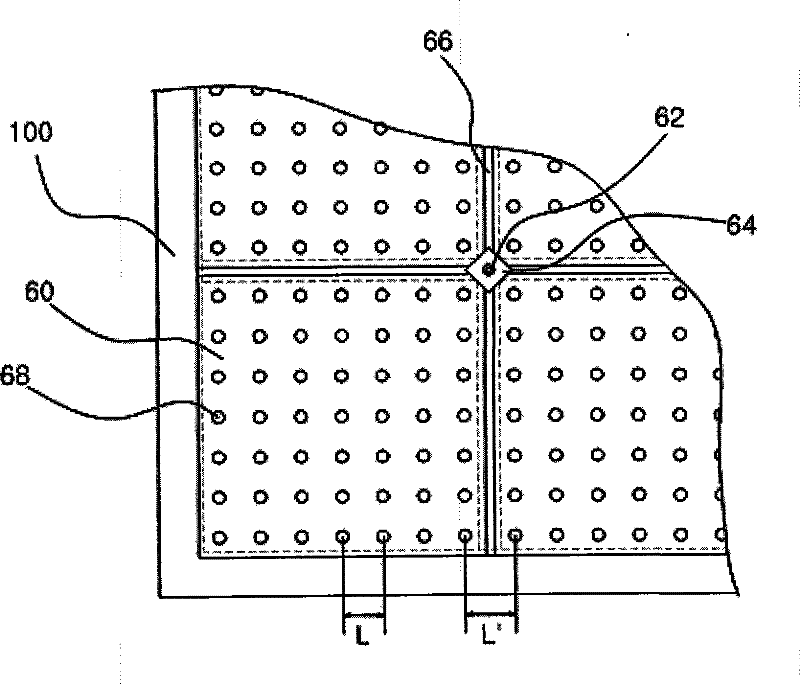

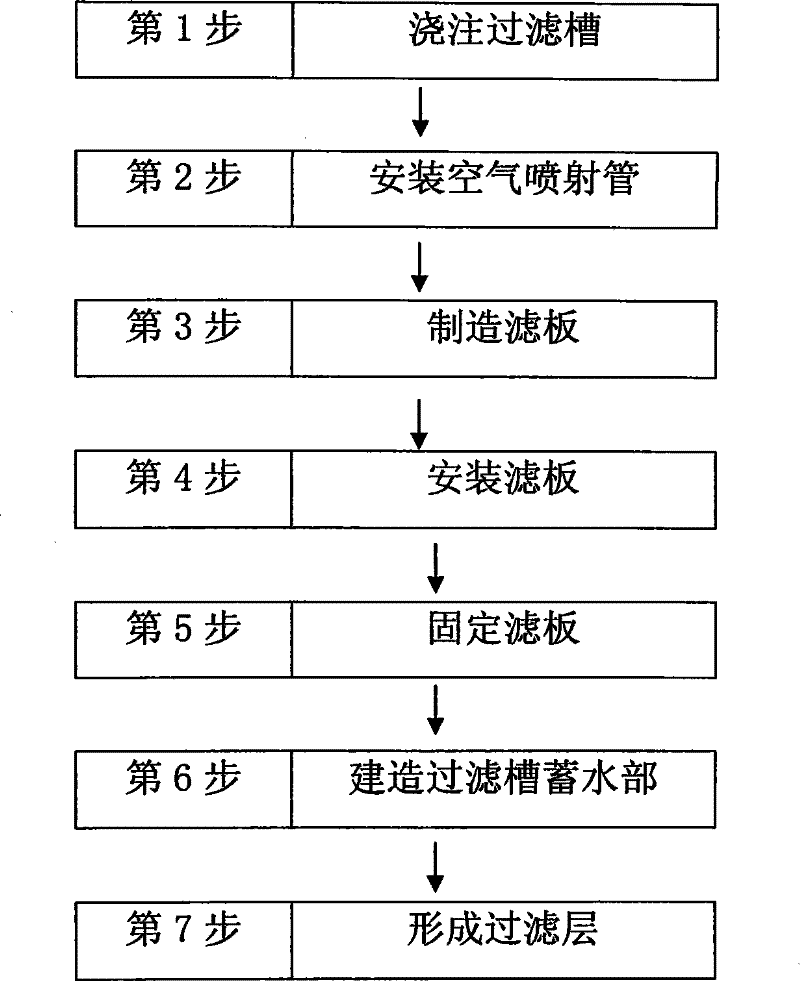

water filtration equipment

InactiveCN102284202AEasy to installImprove trustLoose filtering material filtersGravity filtersFiltrationFresh water

The present invention provides a water filtration device, which includes: a filter tank 100 with an upper opening and a partition wall 110 inside, more than one filter plate 200, a filter layer 400, a plurality of air injection pipes p, a maintenance hole 500 and a water storage The filter plate 200 is located above the filter tank 100 and the partition wall 110 to close the filter tank 100; the air injection pipe p is located below the filter plate 200; the maintenance hole 500 is located in the The middle part of the filter plate 200 ; the filter layer 400 is located above the filter plate 200 ; the water storage part is located above the filter layer 400 and the filter plate 200 . The water filtering equipment provided by the present invention avoids stagnant water areas during backwashing, improves the quality of purified water and enhances the trust of consumers. The filter plate is easy to install, can not only improve work efficiency but also shorten construction period and save installation cost.

Owner:青岛智承机电科技有限公司

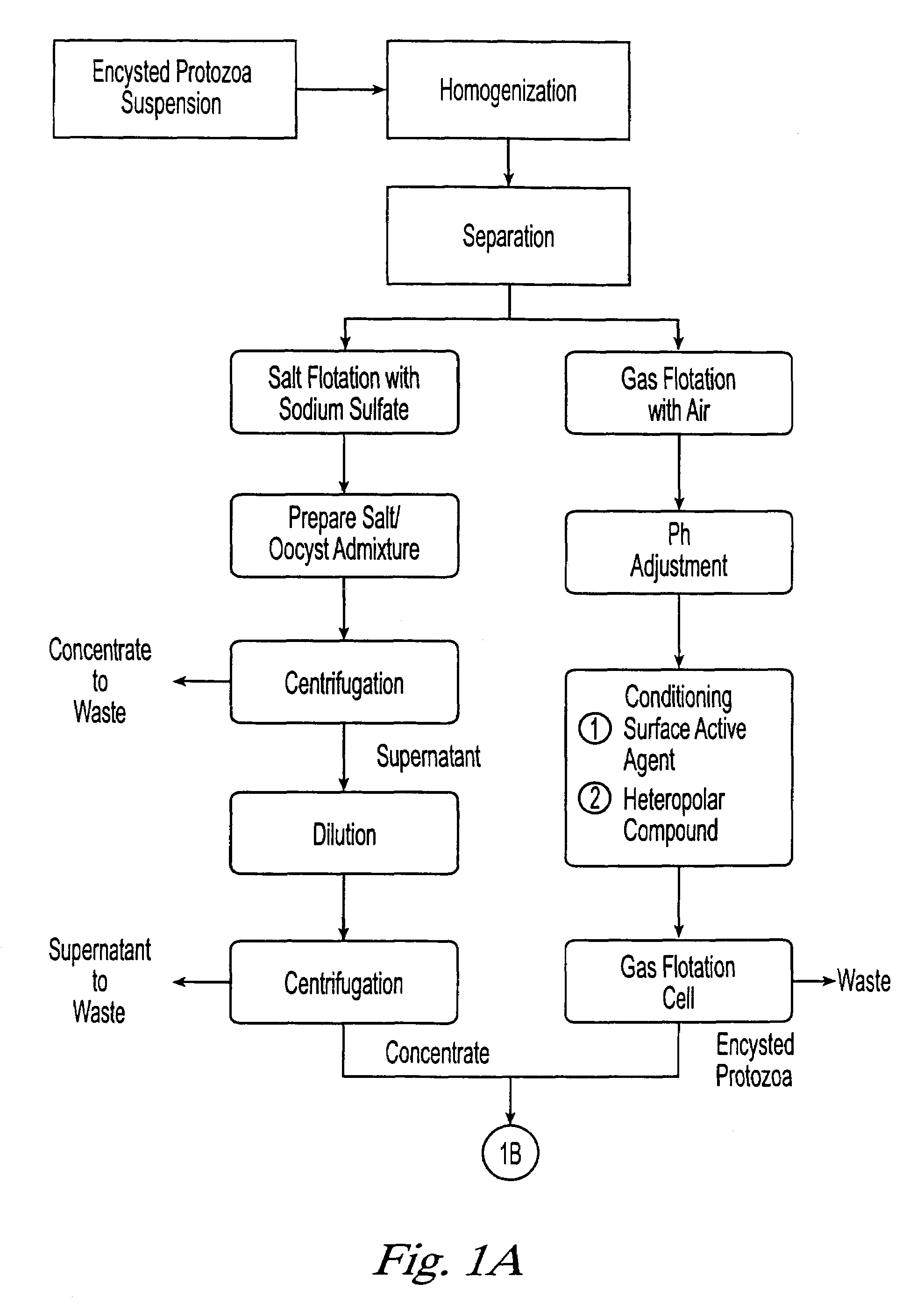

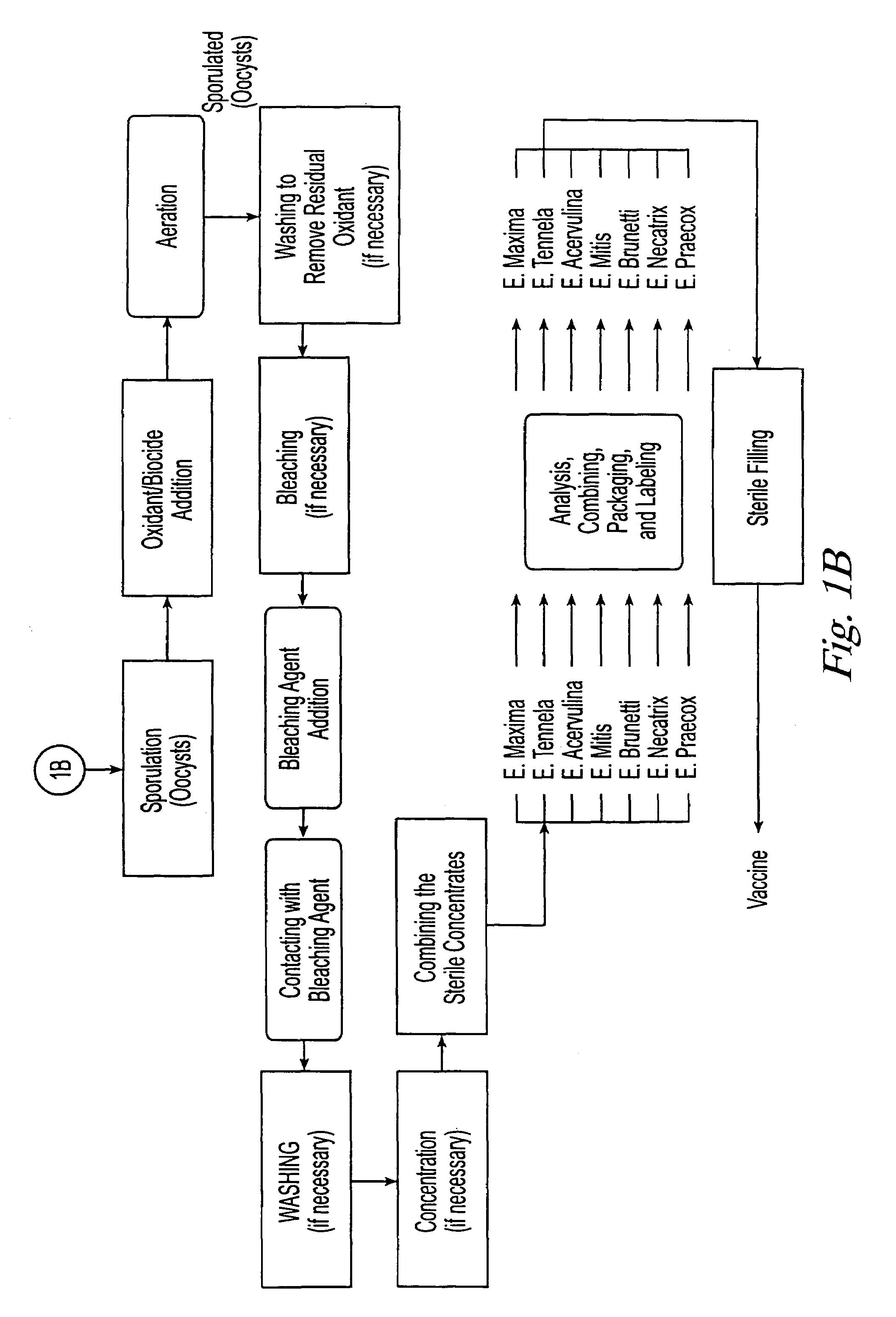

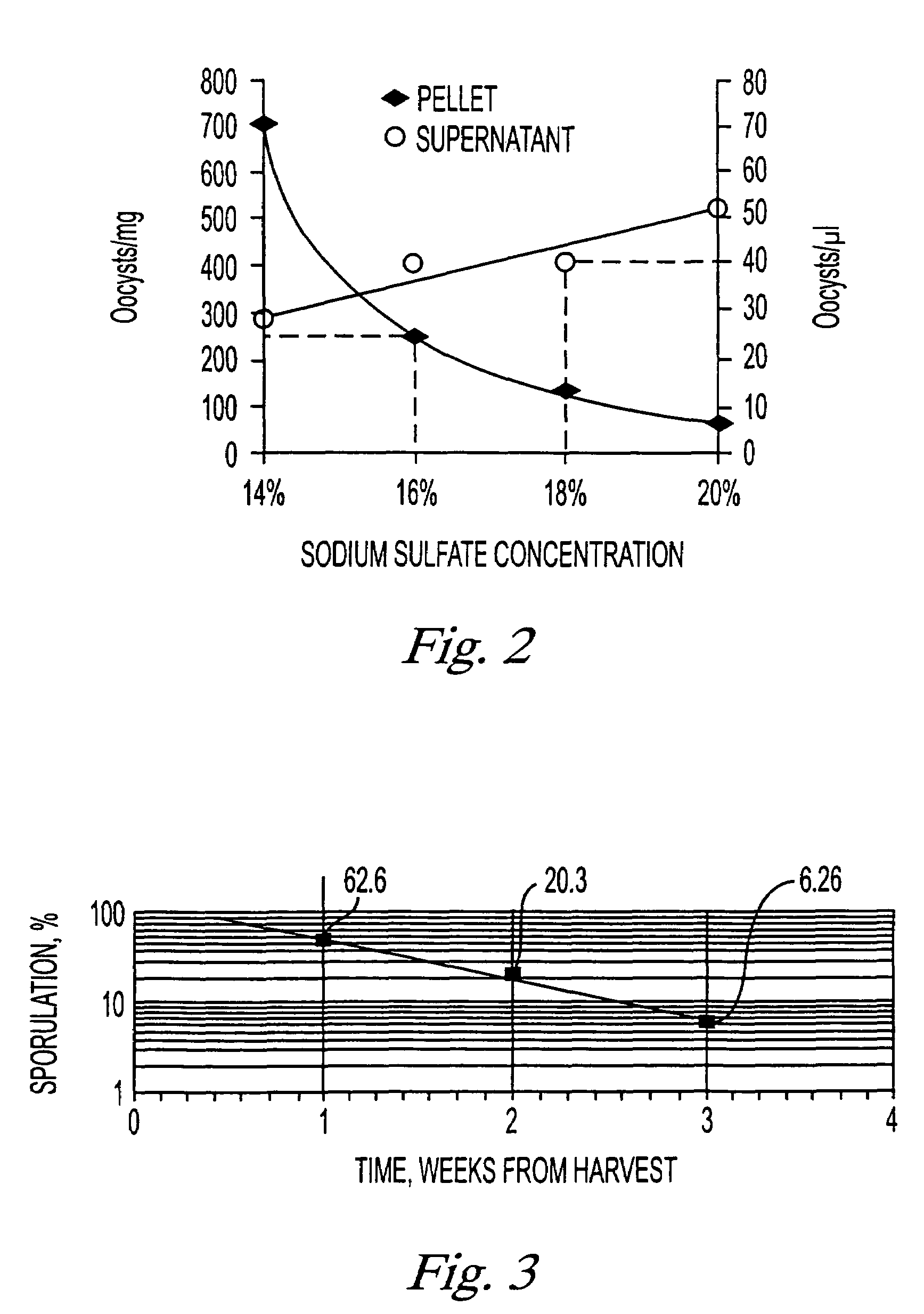

Method for the purification, recovery, and sporulation of cysts and oocysts

A vaccine for in ovo vaccination against avian coccidiosis produced by a method including obtaining the coccidial oocysts from a fecal suspension, homogenizing the fecal suspension, separating the oocysts from the fecal debris by either salt flotation using sodium sulfate or gas flotation using air, sporulating the oocysts using hydrogen peroxide and air sparging, bleaching the sporulated oocysts, washing the bleached oocysts, concentrating the sterile washed oocysts and combining the concentrates of various species of coccidial oocysts, and producing a vaccine. The method in whole or in part can be applied to other kinds of encysted protozoa to produce vaccines for various types of animals.

Owner:HUVEPHARMA EOOD

Chemical injection using an adjustable depth air sparging system

ActiveUS20090069622A1Easily damagedPrevent escapeOther chemical processesContaminated soil reclamationEngineeringInjection air

A supplemental fluid adjustable depth air sparging system which is used to remediate contaminants from groundwater within the soil. An adjustable depth air injection point injects compressed air mixed with a chemical oxidizer or nutrient into saturated or groundwater regions of the soil's subsurface to remove contaminants including chlorinated solvents from the soil's subsurface.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

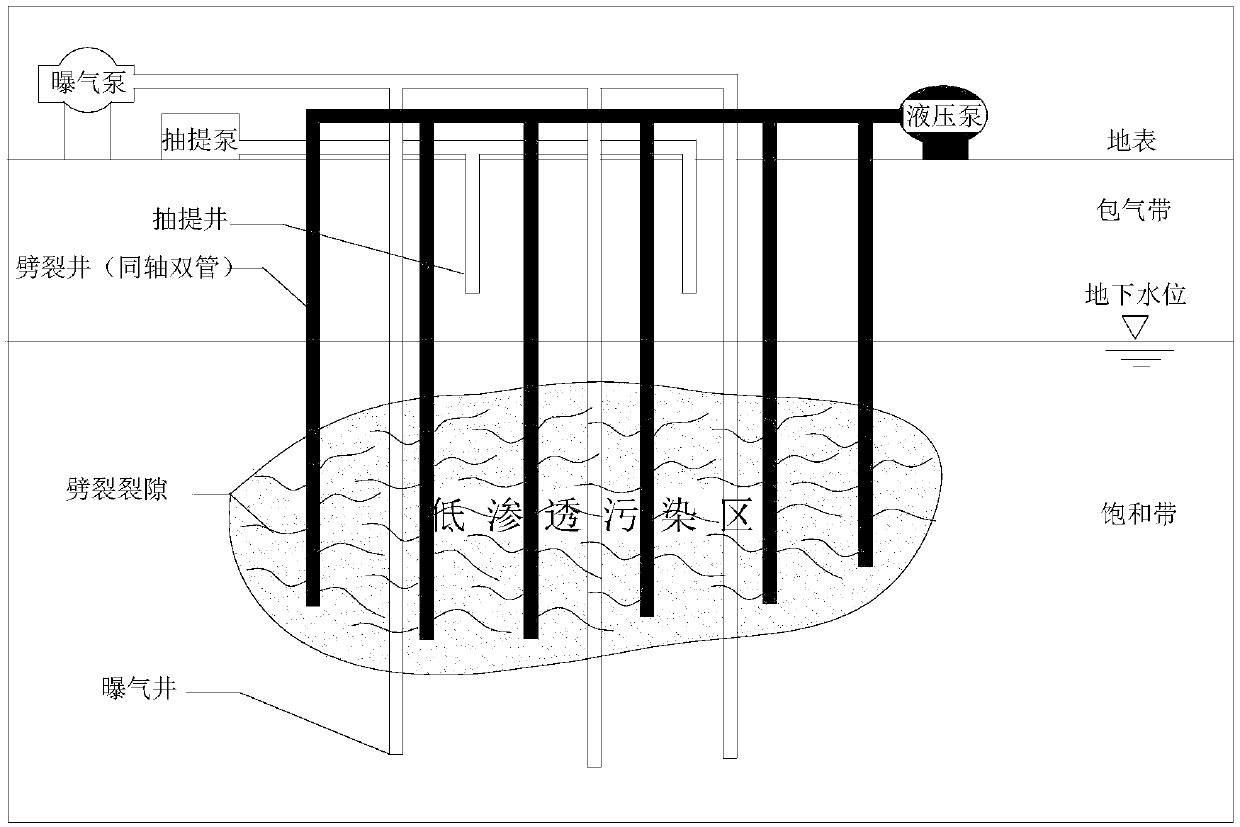

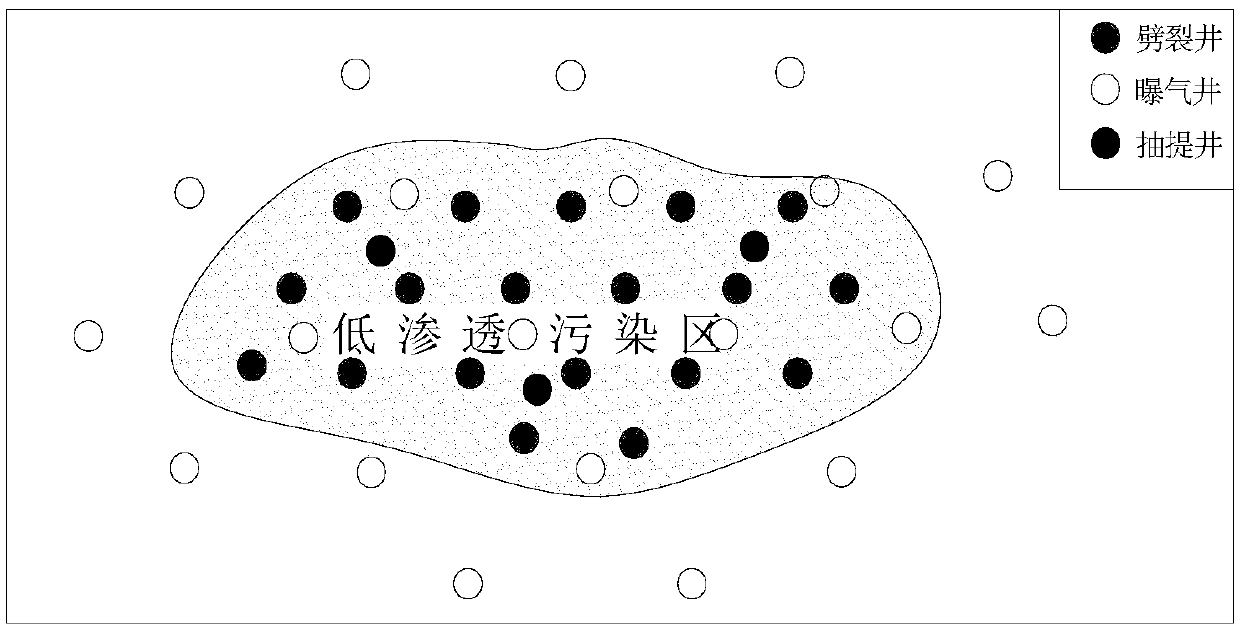

In-situ air sparging repairing method of VOCs pollution in hyposmosis area

ActiveCN109047302AImprove permeabilityImprove passabilityContaminated soil reclamationDesorptionEngineering

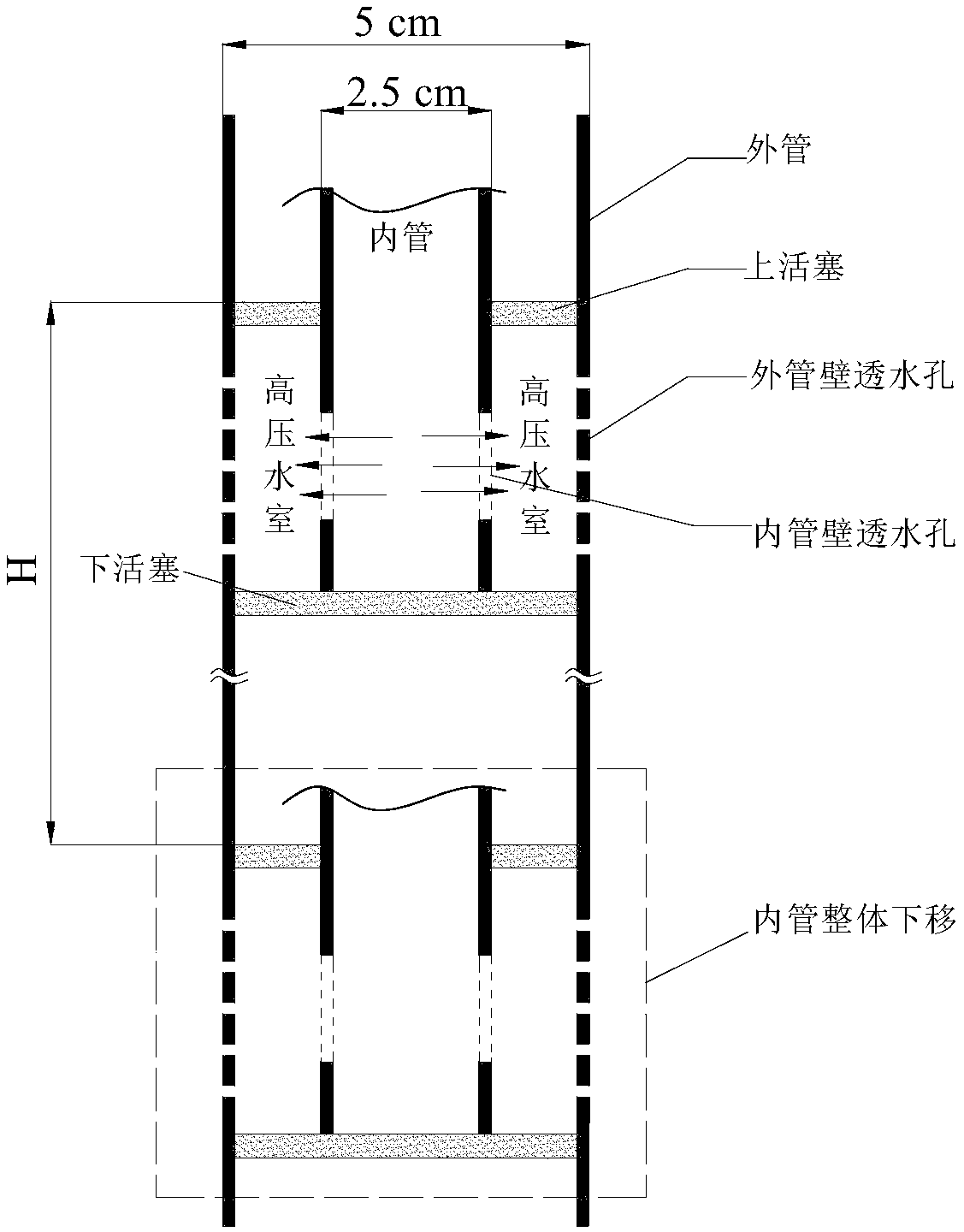

The invention discloses a in-situ air sparging repairing method of VOCs pollution in a hyposmosis area, On the basis of a surfactant reinforced aeration repair method, multi-point hydraulic splittingis carried out on the hyposmosis polluted area by adopting a point-position controllable hydraulic splitting technology, a large amount of human fractures are generated in the area; and meanwhile, a pressure solution used for splitting is a surfactant solution, and aims to enhance the gas permeability of the hyposmosis polluted area, the desorption capacity of pollutants in fine-grained soil is enhanced, so that the problem that the hyposmosis polluted area is not easy to repair is solved. According to the method, the hydraulic splitting technology cooperates with the surfactant strengtheningeffect, the pressure solution used in a splitting process is a SDBS surfactant solution, and the concentration is 200-400 mg / L; a coaxial double-pipe pipeline is arranged inside a hydraulic split well, multi-point hydraulic splitting in different areas is realized by moving an inner pipe.

Owner:SOUTHEAST UNIV

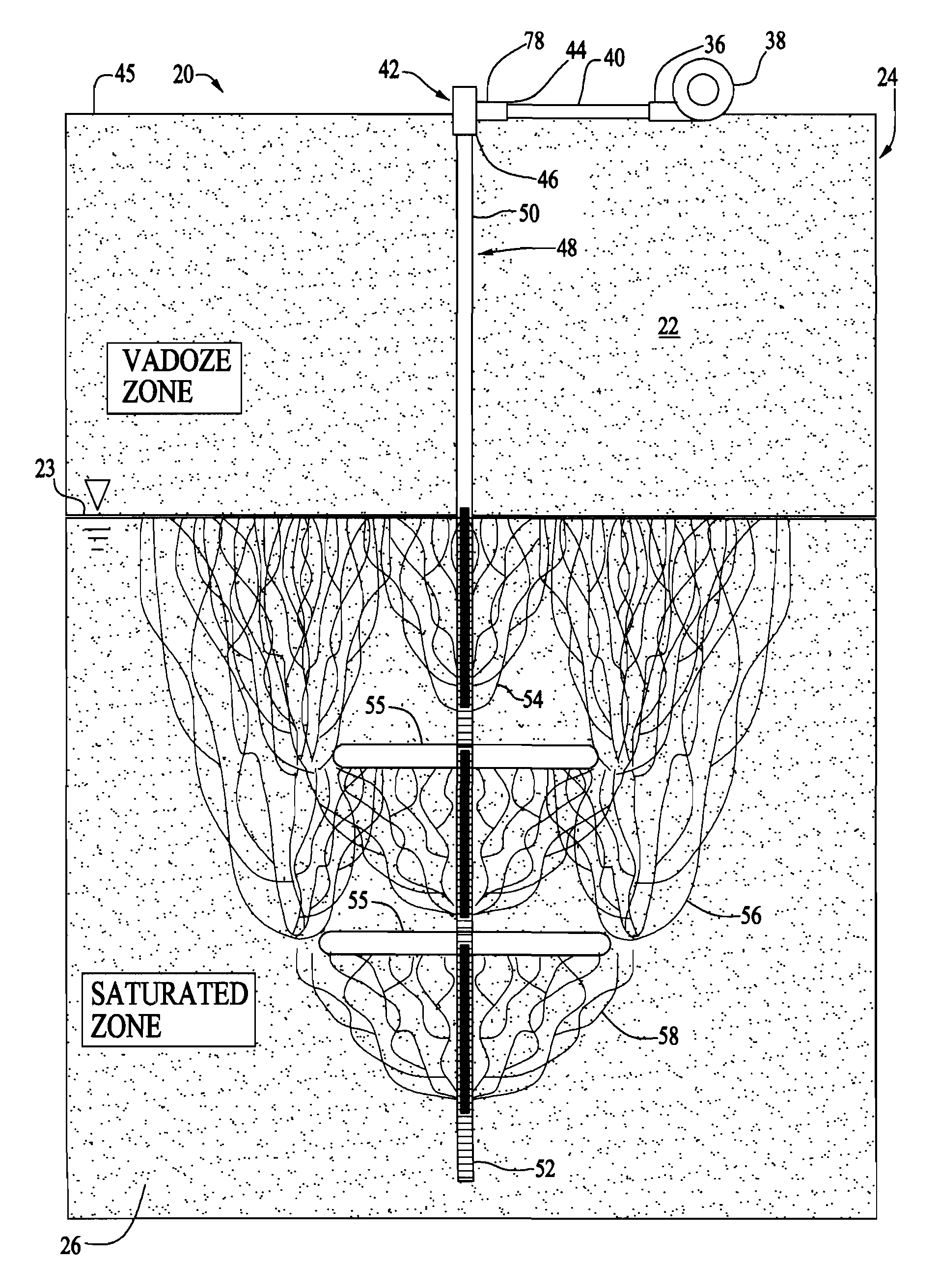

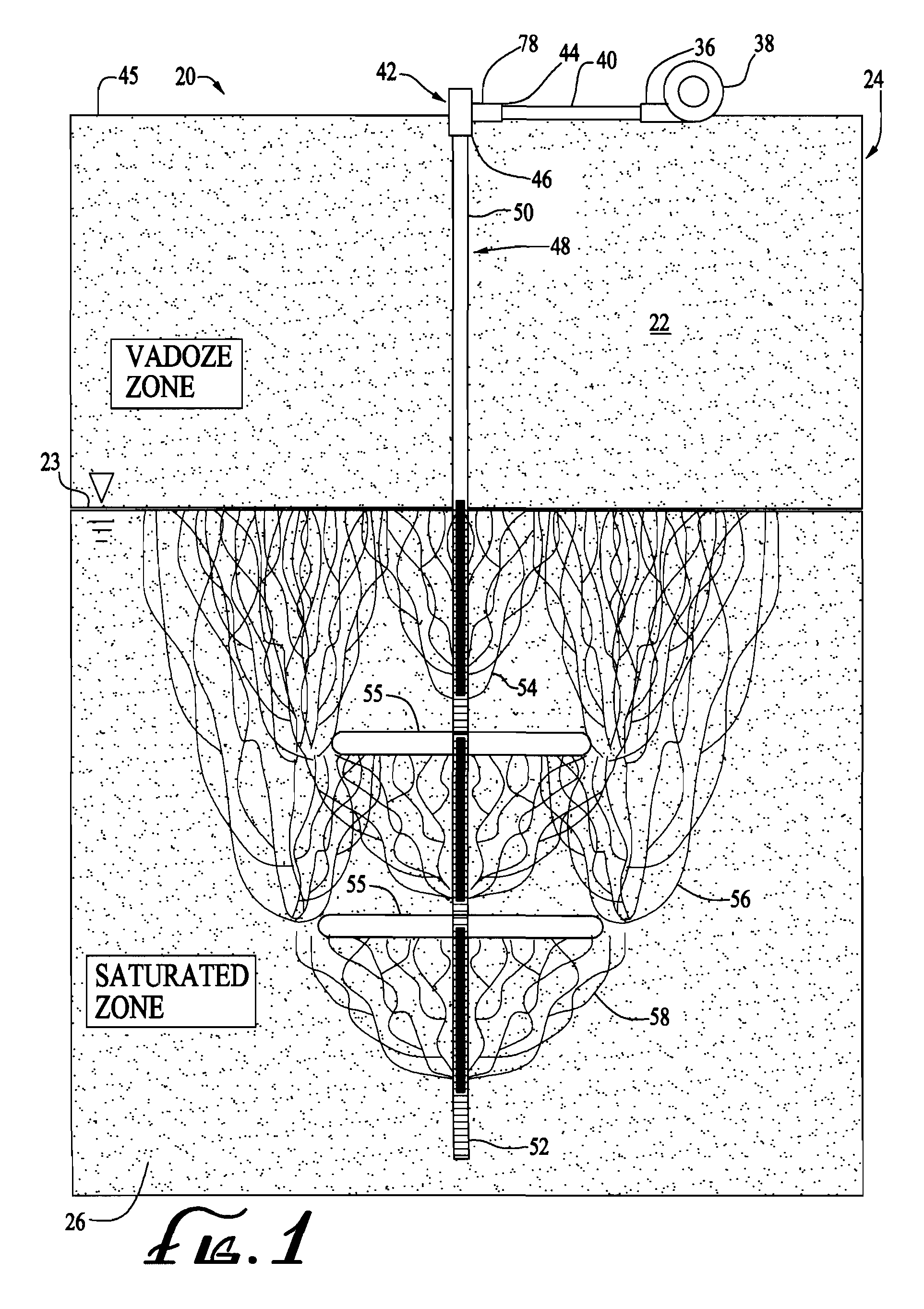

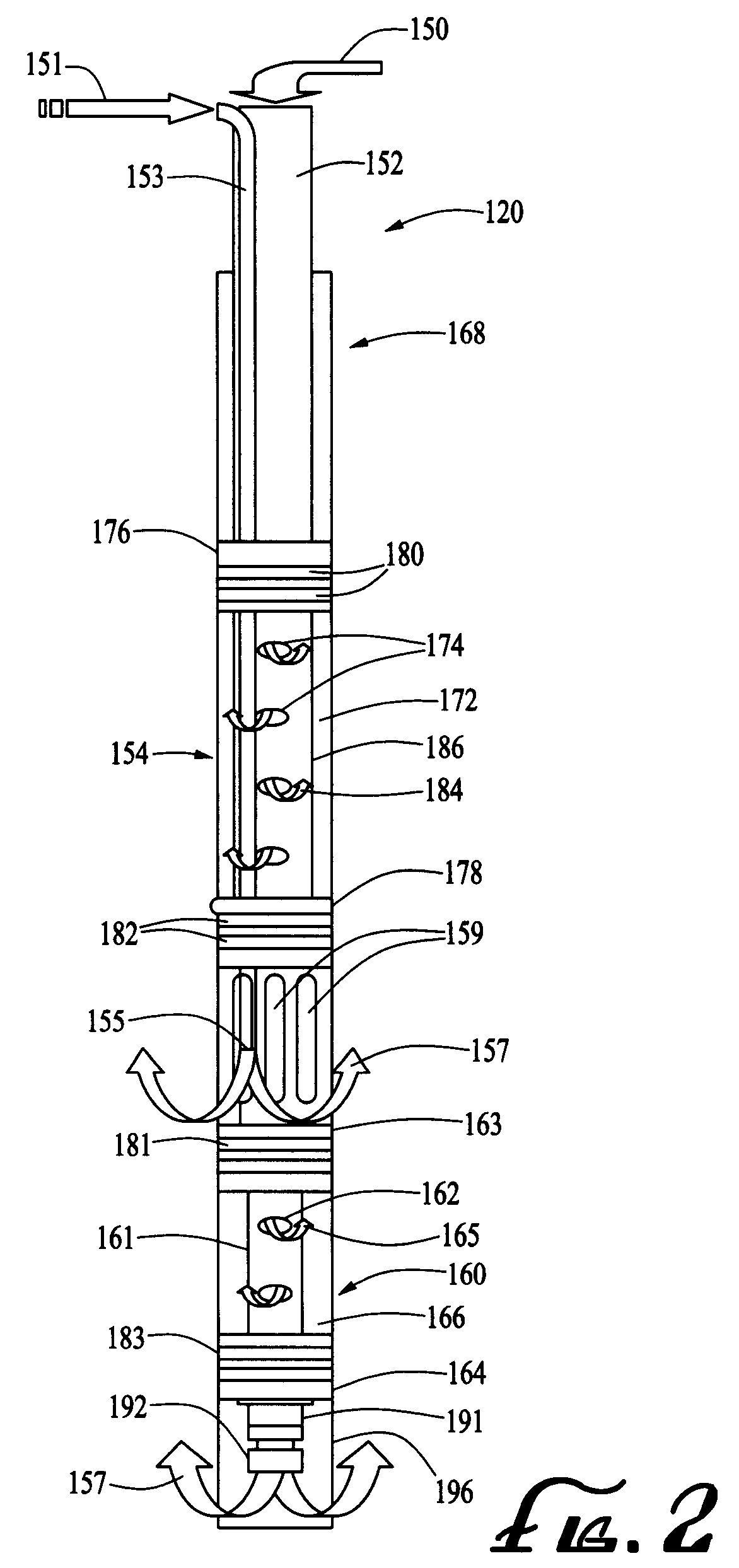

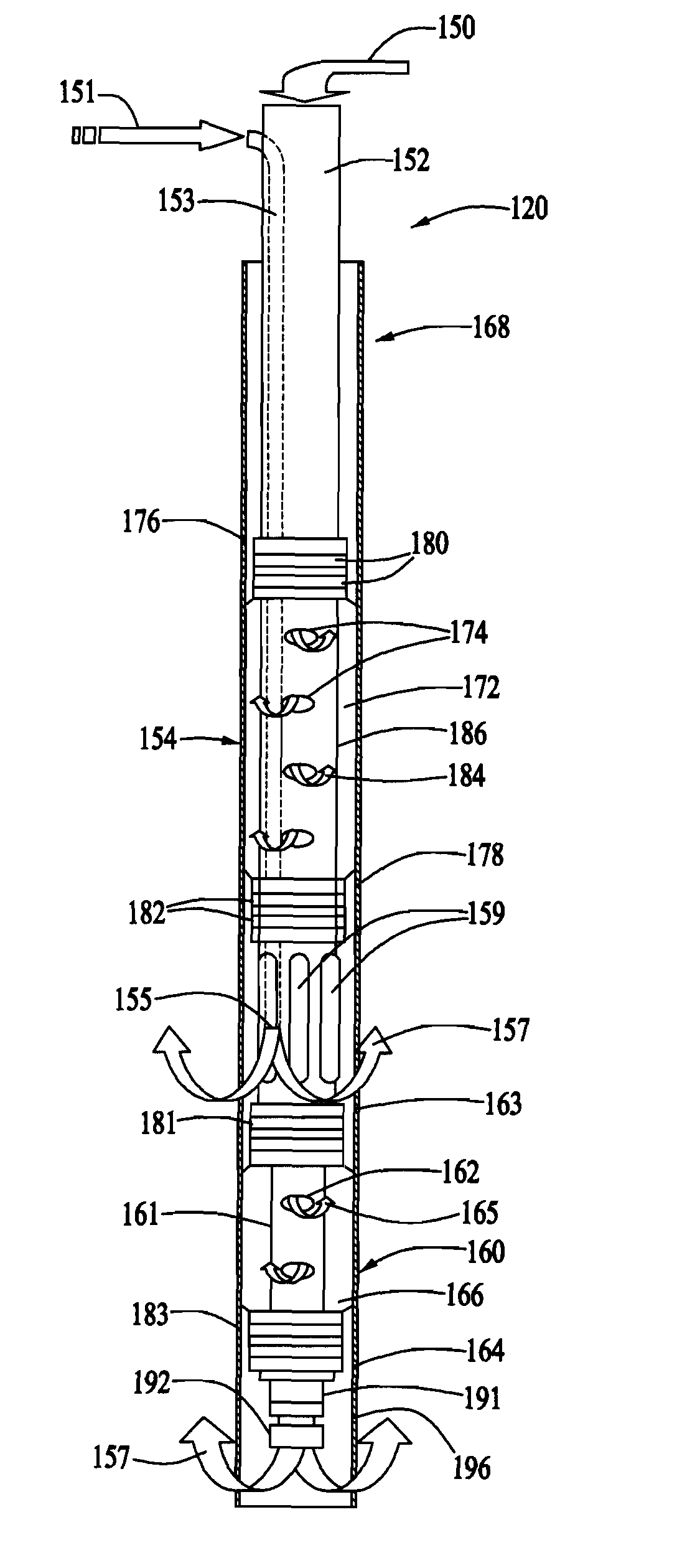

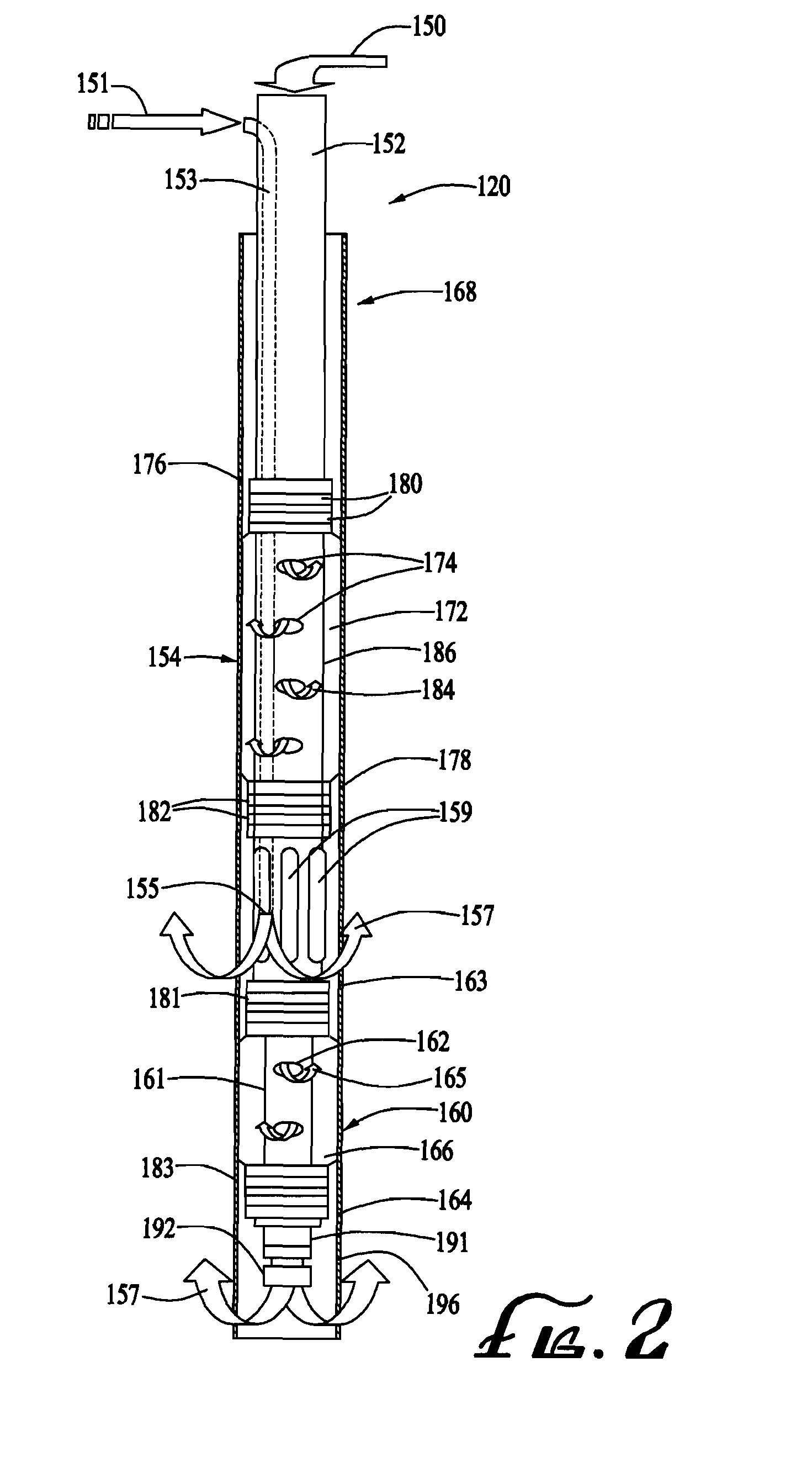

Groundwater remediation apparatus and method

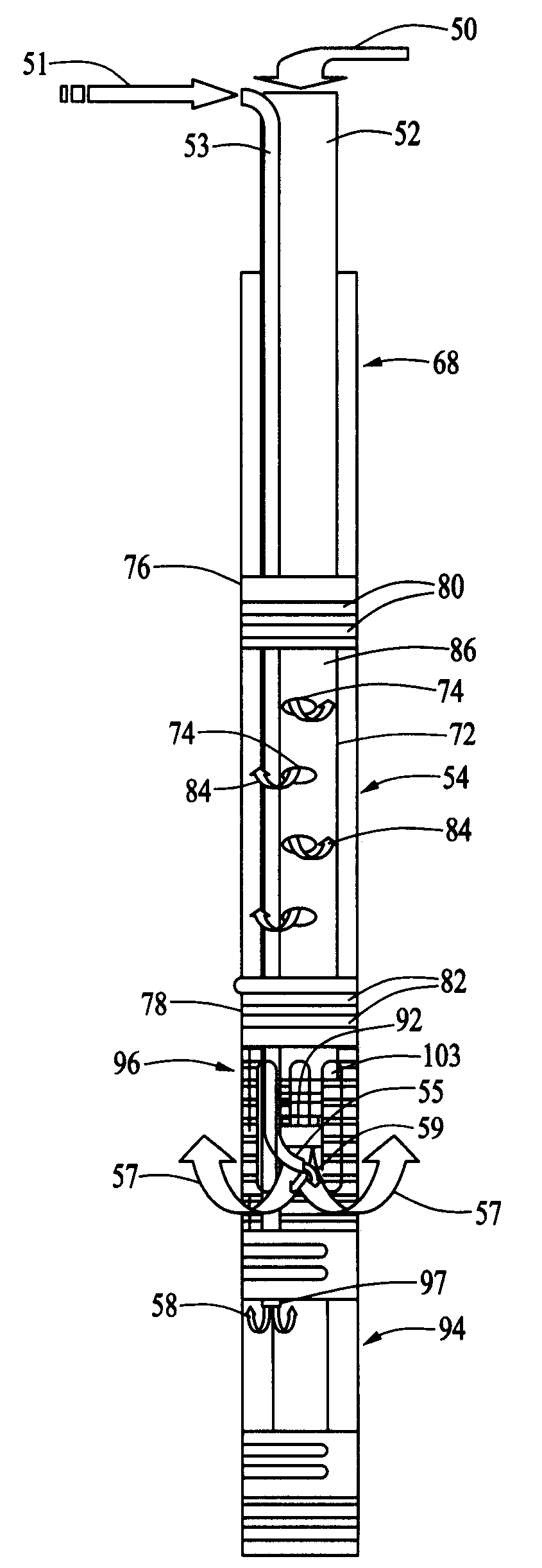

A well pipe provides for air sparging and soil vapor extraction for groundwater remediation at a single point of entry. An elongated well pipe is provided with a plurality of openings at an upper section and a lower section of the pipe and a packer member for separating the two sections. A conduit for delivering compressed air passes through the packer member into the lower section of the well tube for providing air sparging below the water table level in the ground and a vacuum source is connected to an upper end of the well pipe for drawing vapors from the vadose region in the ground into the pipe through the openings in the upper section of the well tube for transport on to a remediation destination. The conduit is adapted for delivery of remedial enhancing amendments into the surrounding ground through the lower section of the well pipe to further treat the contamination below the ground surface.

Owner:ABOUODAH MOHAMED

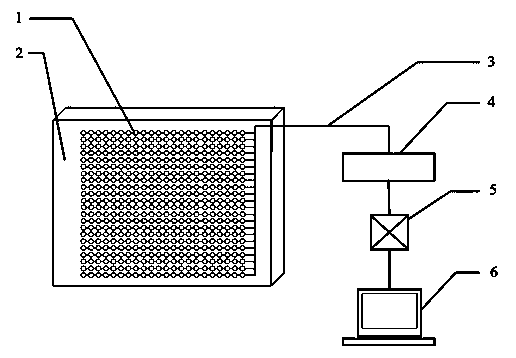

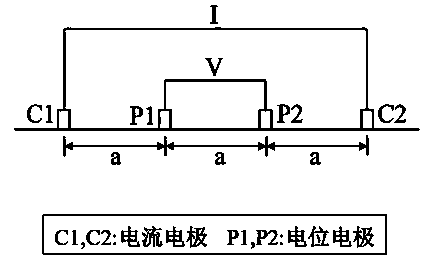

Imaging method for repairing two-dimensional model test through air sparging

ActiveCN103529087AEasy to operateHigh degree of automationMaterial resistanceEngineeringDistributed testing

The invention discloses an imaging method for repairing two-dimensional model test through air sparging. The imaging method comprises the following steps: (1) squarely distributing testing electrodes on a front panel of a two-dimensional model test tank at equal intervals, wherein the resistivity test is based on a Wenner four-electrode method by adopting a business high-density electrical method instrument; (2) filling polluted saturated soil according to research need, and then determining the initial resistivity values of all points in a space; (3) after air sparging repair tests start, measuring the resistivity at every 5-10 minutes until the resistivity of a soil body is stable after the sparging stops; (4) drawing a soil body resistivity contour map or cloud chart on the basis of linear interpolation, thus being capable of realizing the visualization imaging of the air sparging repair process. The quantitative evaluation on the vapor phase movement rule and repair effect of the sparging process can be realized by establishing the relation between the soil body vapor saturation as well as pollutant concentration and the resistivity. According to the method, the visualized image of the sparging repair process can be obtained without the sampling analysis in the test process.

Owner:SOUTHEAST UNIV

Foamed cleaser with suspended particles therein, method of producing same and a dispenser therefore

ActiveCN1980627AInorganic/elemental detergent compounding agentsCosmetic preparationsSuspended particlesCombined use

One aspect of the invention is a new foam with particles suspended therein. Another aspect of the invention is a foaming component for use in association with a foam dispenser. The foaming component includes an air sparging element, a mixing chamber, and an air chamber. The mixing chamber is on one side of the air sparging element and it defines a portion of the mixing chamber. The air chamber is on the other side of the air sparging element and it defines a portion of the air chamber. The air chamber has an air inlet. The mixing chamber has a liquid inlet and an outlet, and the outlet is down stream of the inlet. The foaming component also forms part of a new foam dispenser. The foaming component and the foam dispenser are for use in the production of foam with a plurality of particles suspended therein.

Owner:DEB IP

Method and apparatus for purification and treatment of air

ActiveUS10456736B2Lower Level RequirementsIncrease temperatureGas treatmentDispersed particle separationParticulatesSolid medium

The invention discloses methods and apparatus(es) for the removal and control of pollutants such as gases and suspended particulates in the air of an enclosed space or an outdoor environment by passing the air through absorbent media. The absorbent media includes any liquid, solid or combination of liquid and solid media that is capable of absorbing a material in which it comes in contact. In one aspect of the invention, formaldehyde is removed by air sparging through a liquid such as water, optionally containing additional scavenging agents.

Owner:PALOZA LLC

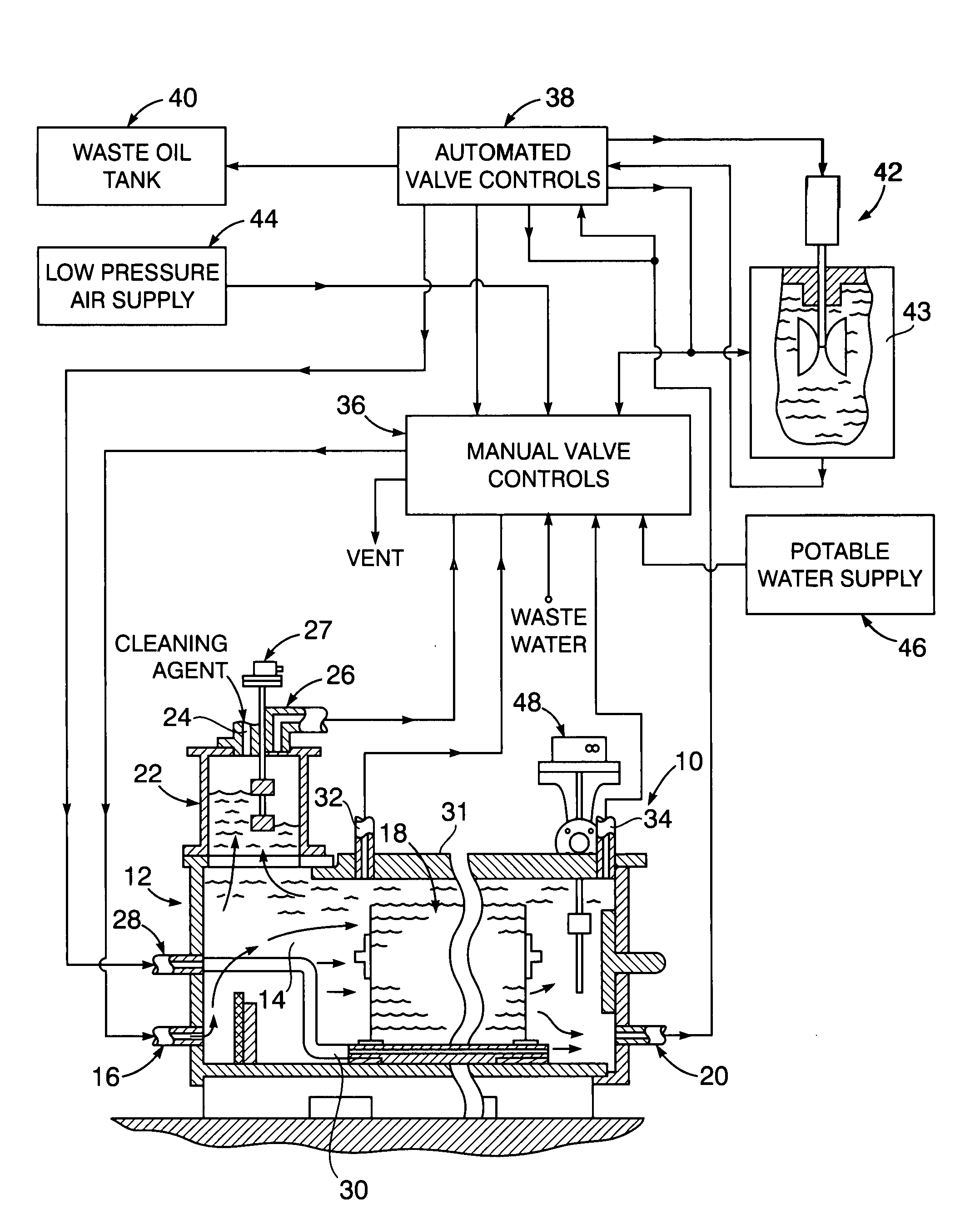

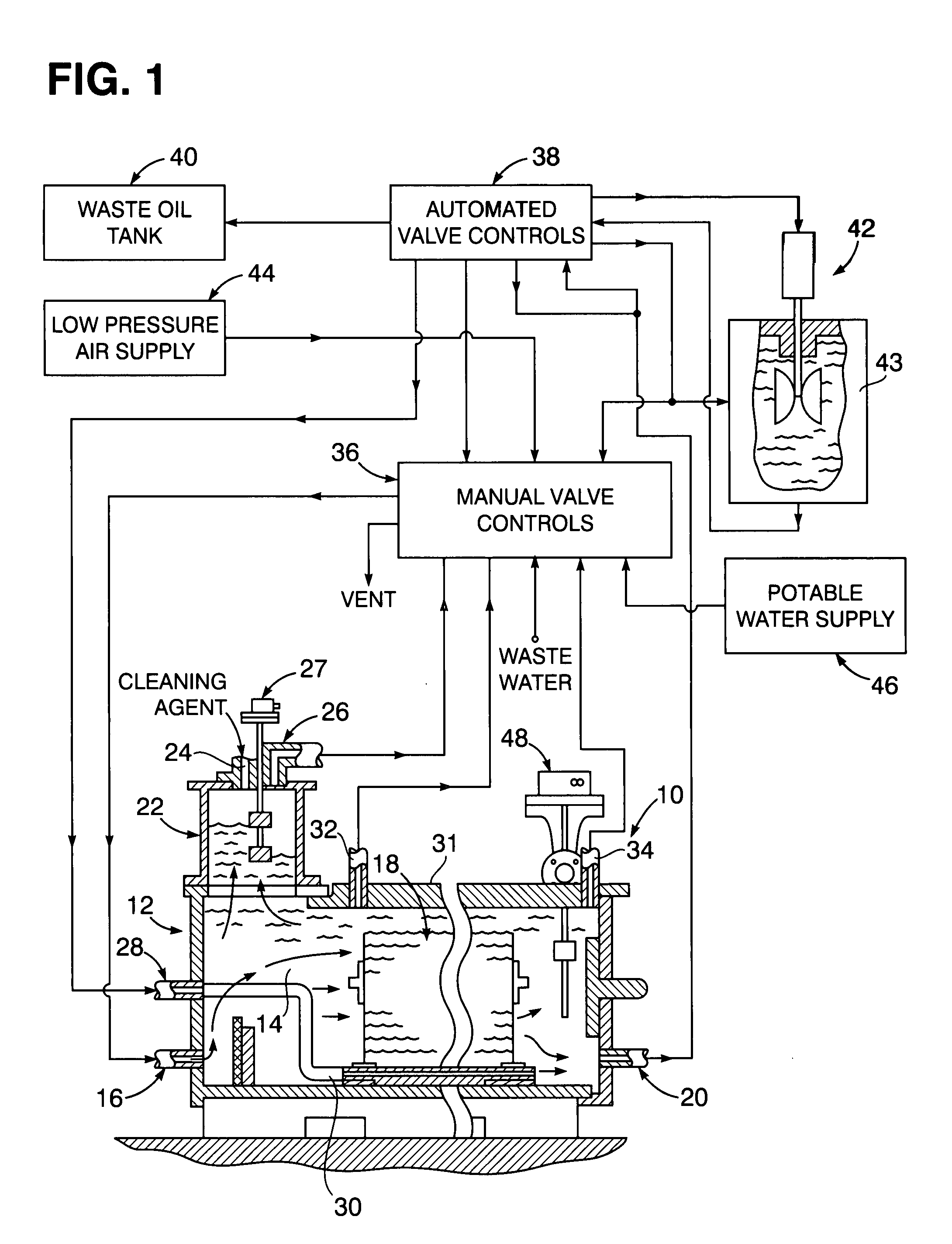

Oil/water separator with enhanced in-situ cleaning

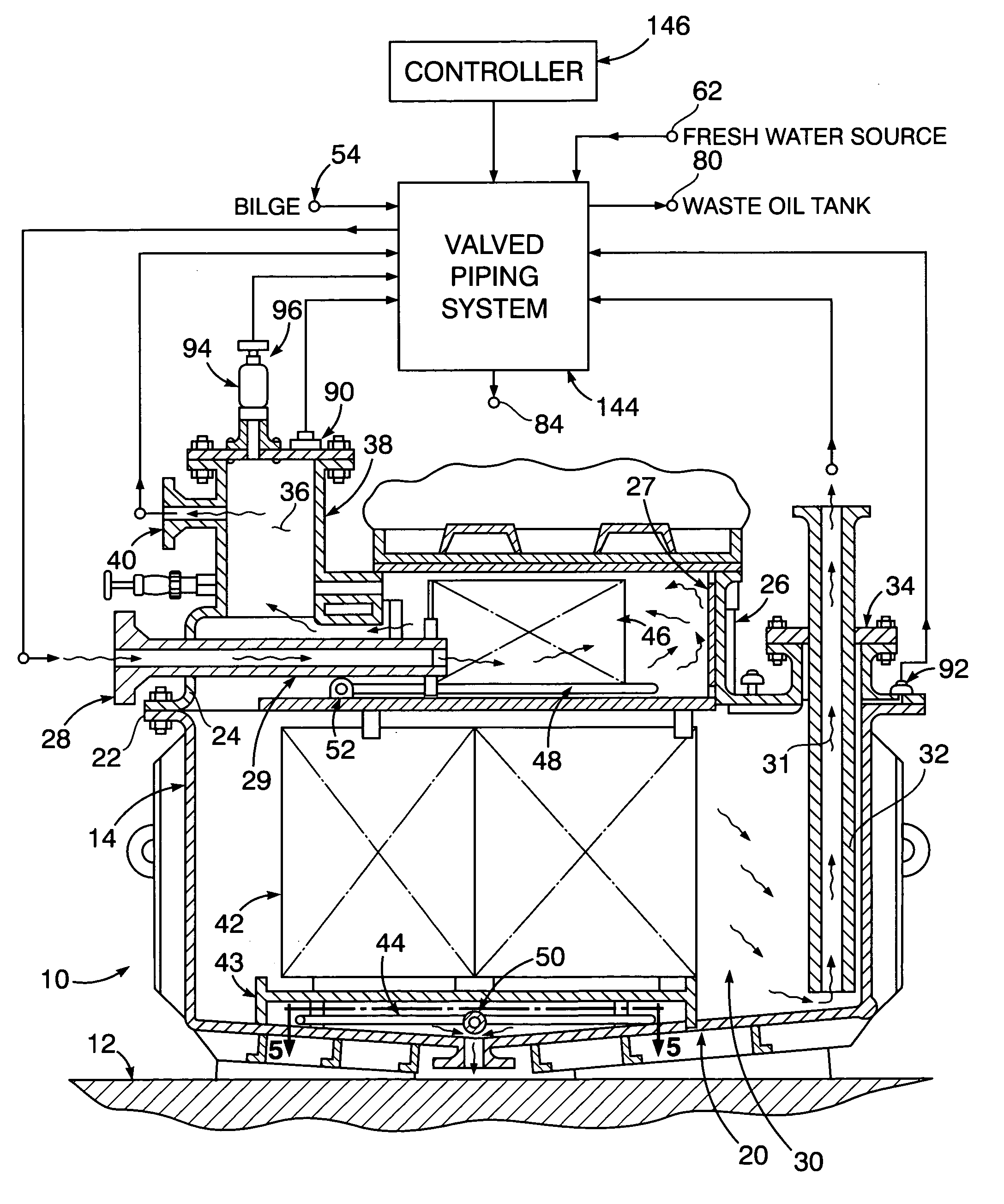

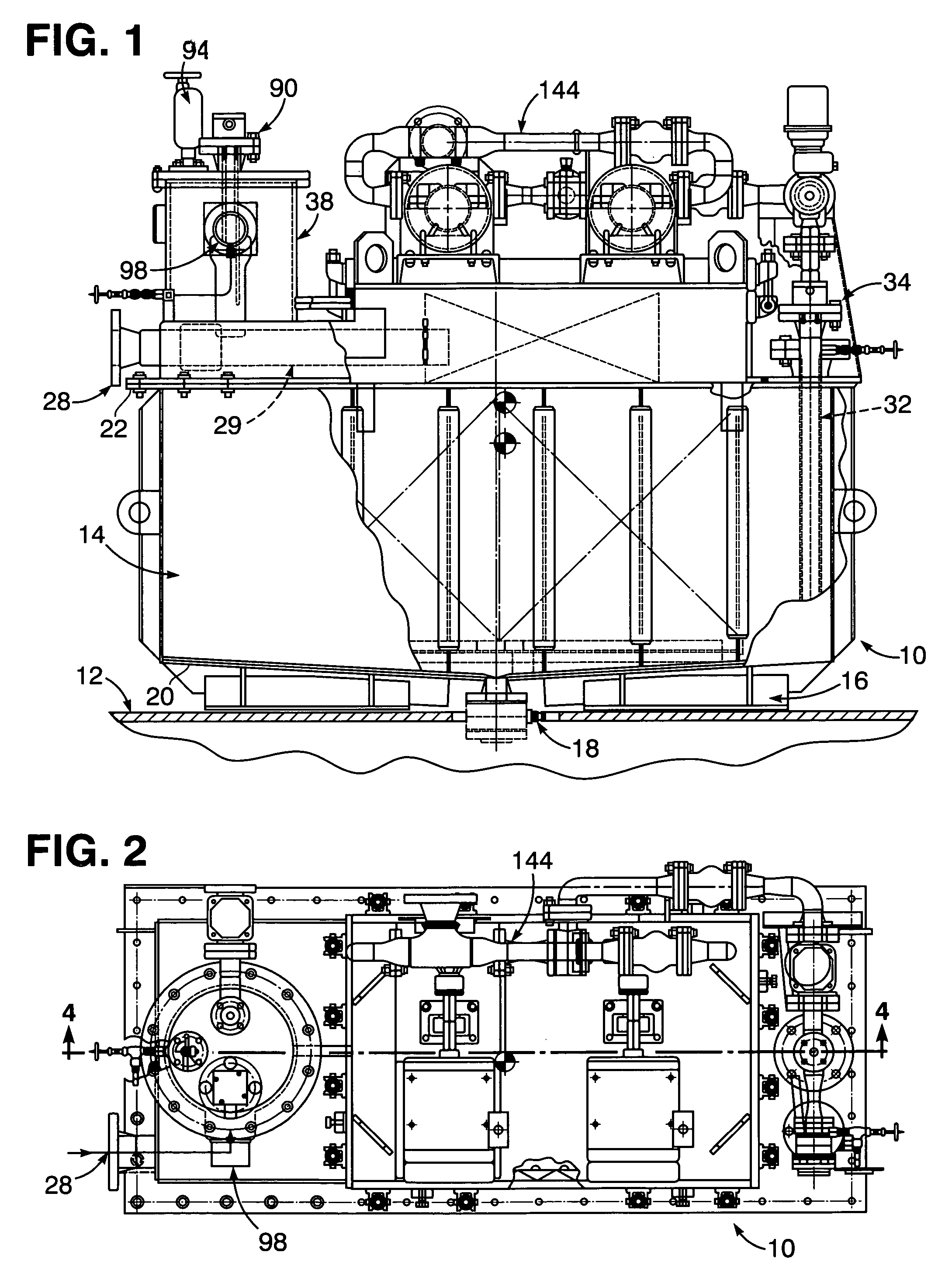

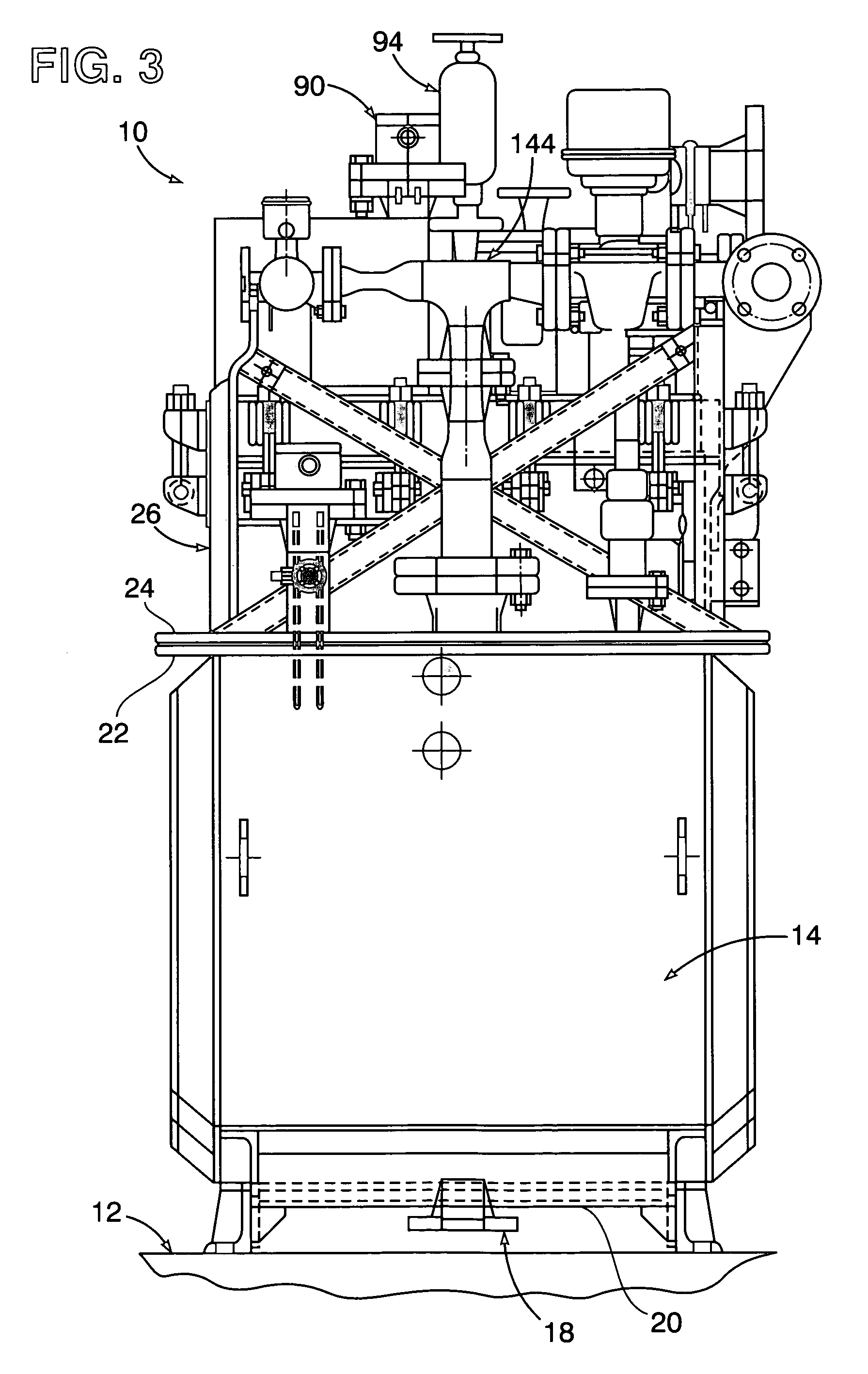

InactiveUS7163107B1Easy to assembleIncrease the number ofVessel partsLiquid displacementFuel tankChemical cleaning

In-situ cleaning of the bilgewater processing plates of stacks within a treatment tank chamber of a 50-gpm oil / water separator is performed by an injected chemical cleaning agent dispersed by diverted flow of pressurized air introduced into the tank chamber below the plate stacks by emergence of air bubbles from plural branches of an air sparging array system positioned in underlying alignment with crest formations on the processing plates. The air sparging array system consists of an upper and lower tank arrays.

Owner:NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL DEPT OF THE

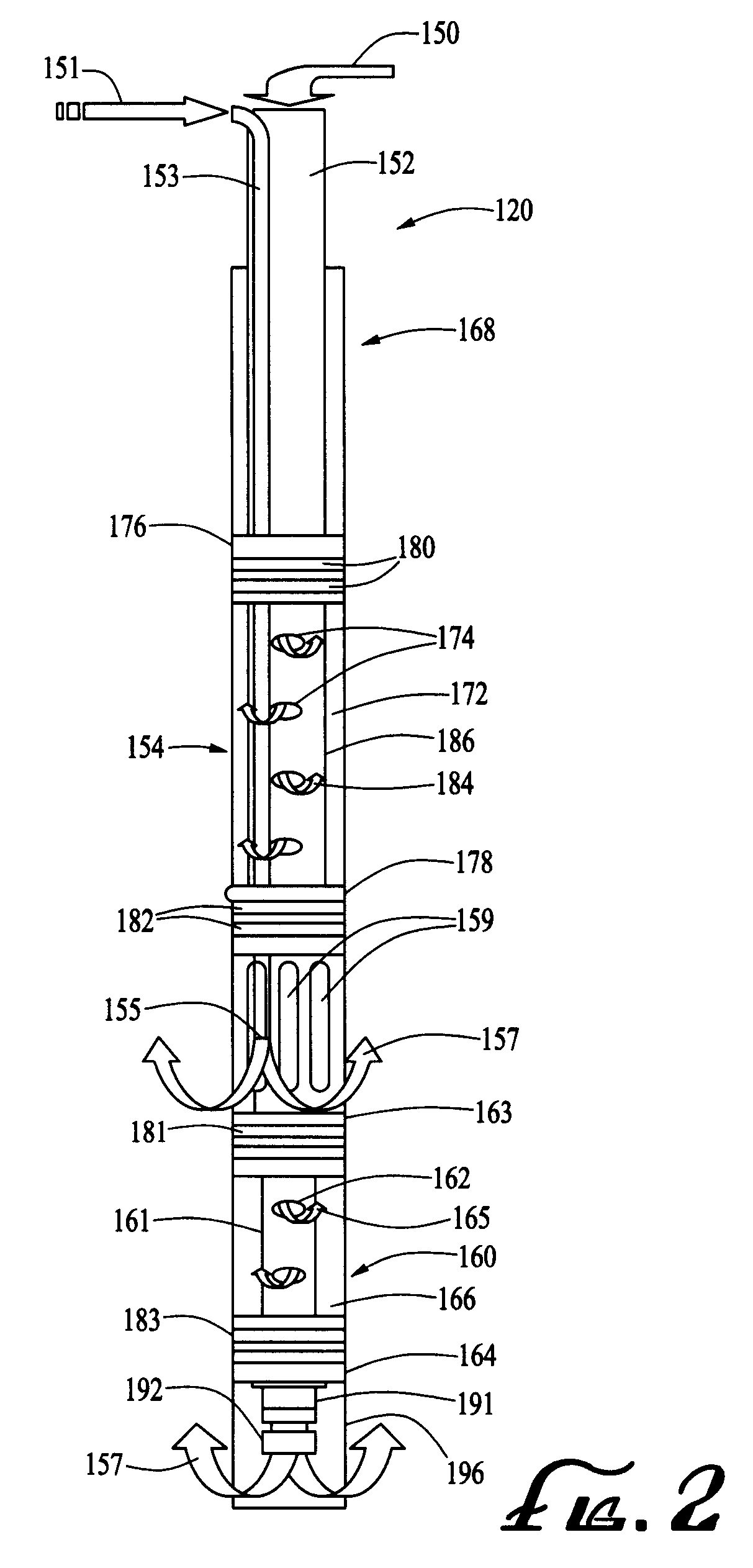

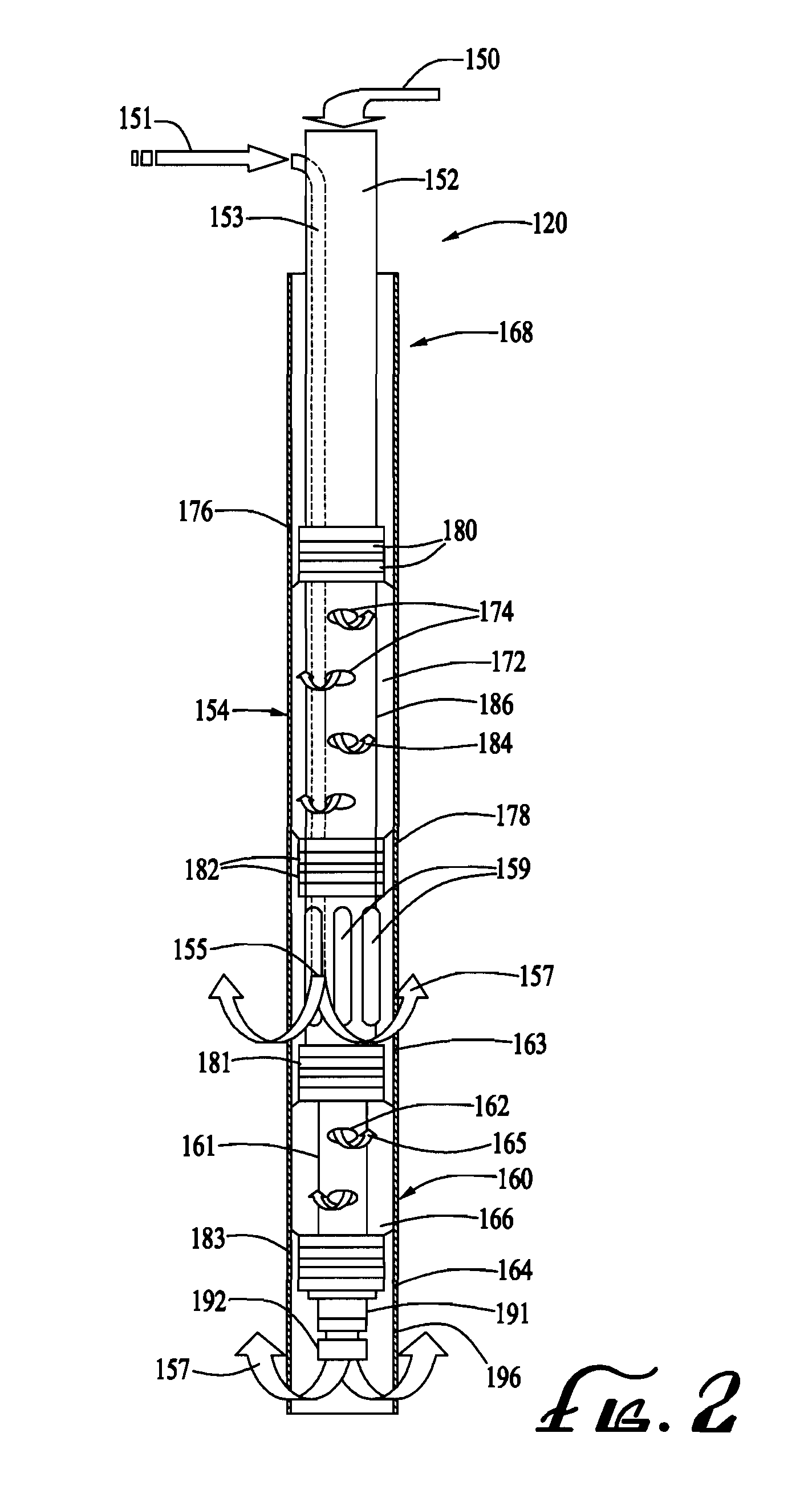

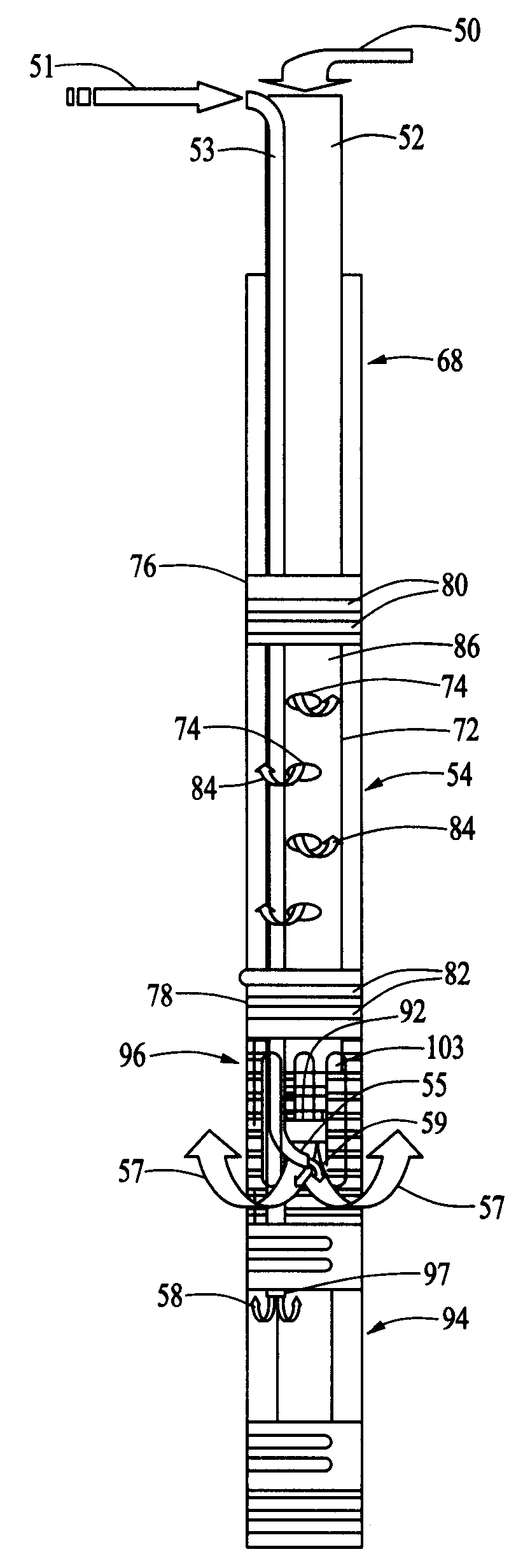

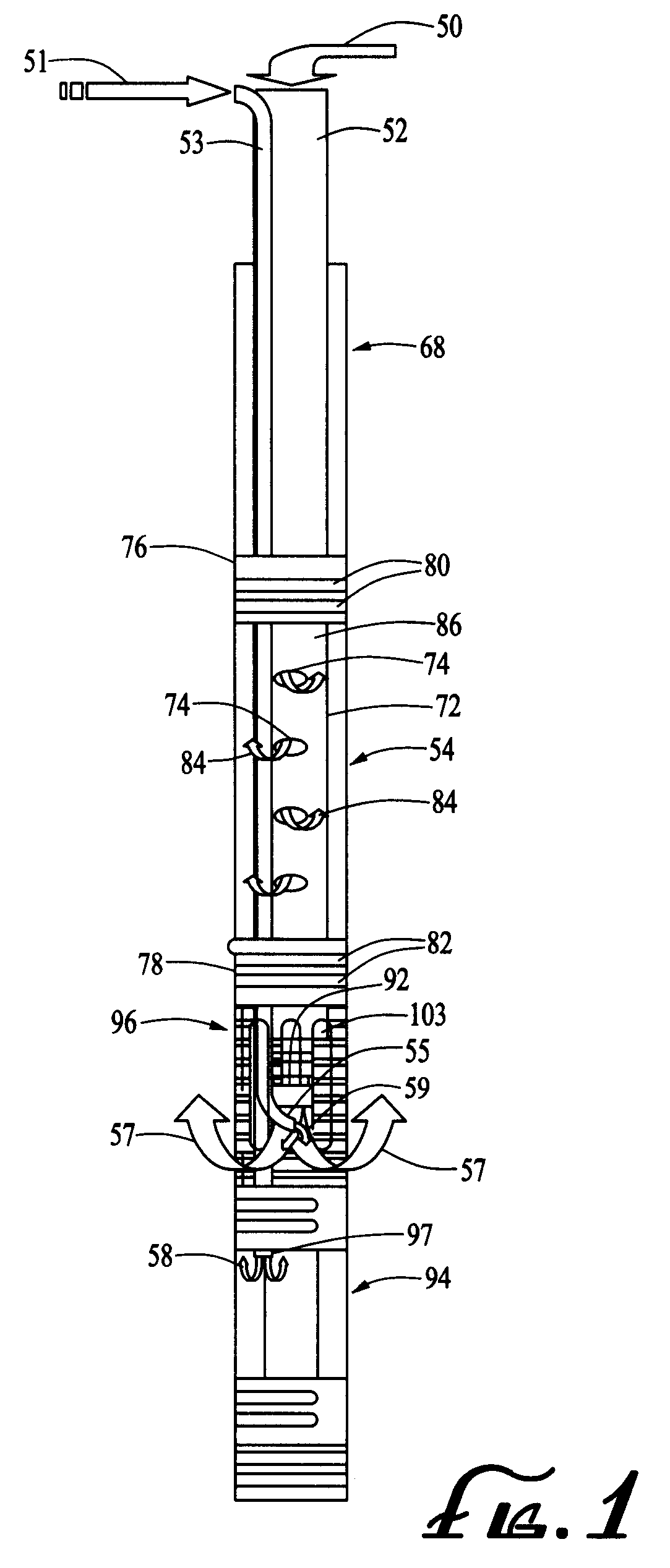

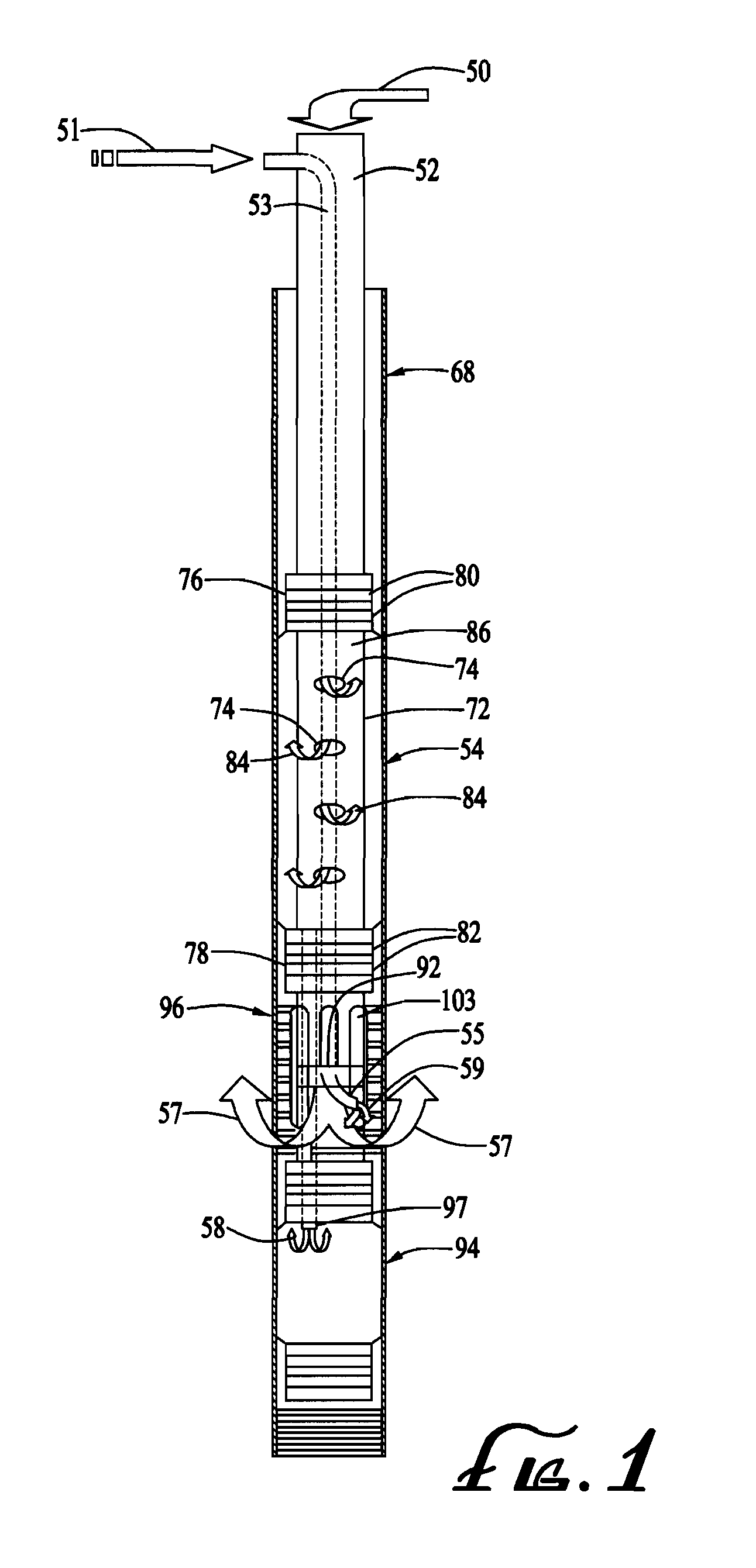

System and method of chemical injection using an adjustable depth air sparging system

ActiveUS7828495B2Easily damagedPrevent escapeOther chemical processesContaminated soil reclamationEngineeringInjection air

A supplemental fluid adjustable depth air sparging system which is used to remediate contaminants from groundwater within the soil. An adjustable depth air injection point injects compressed air mixed with a chemical oxidizer or nutrient into saturated or groundwater regions of the soil's subsurface to remove contaminants including chlorinated solvents from the soil's subsurface.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

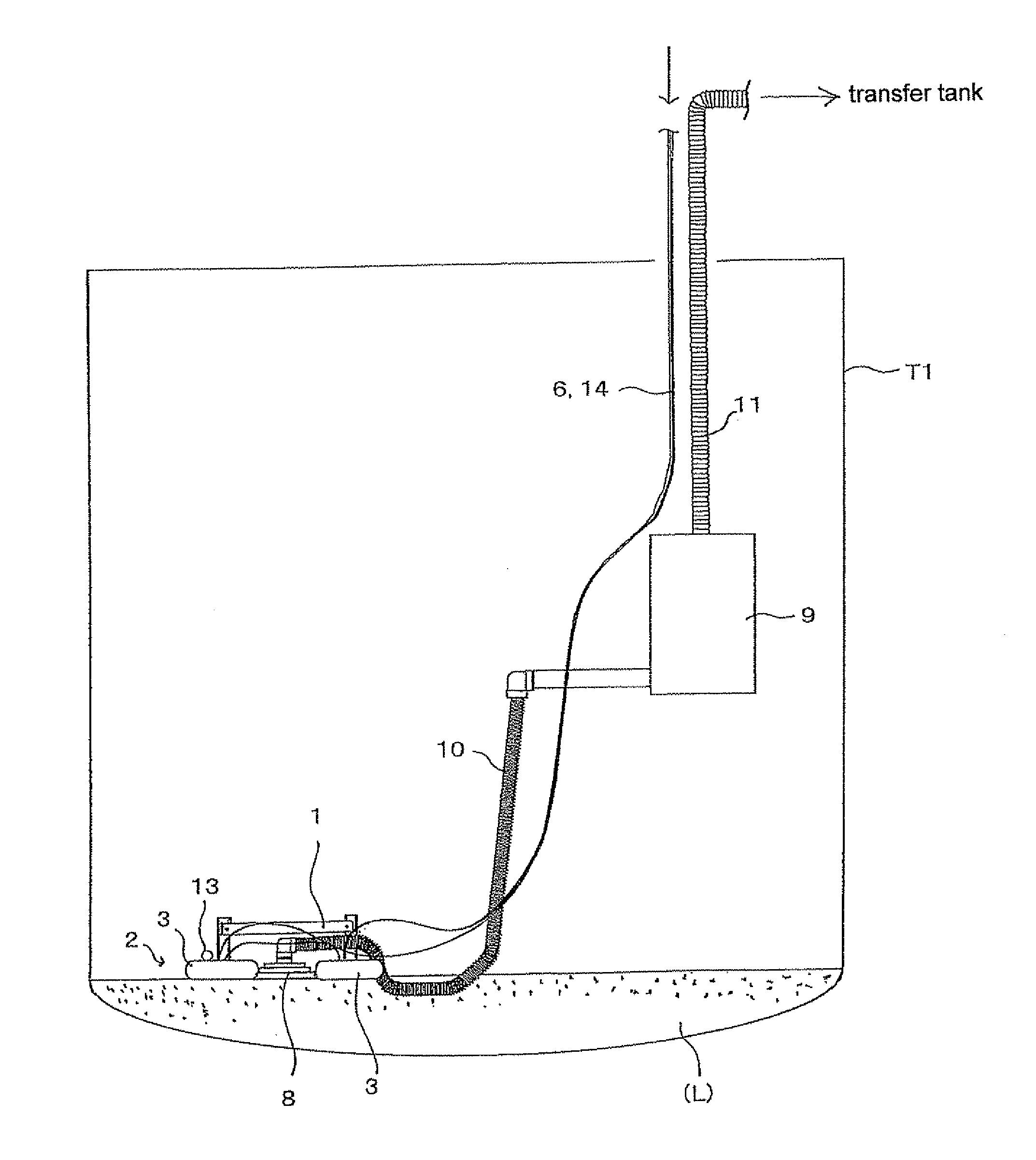

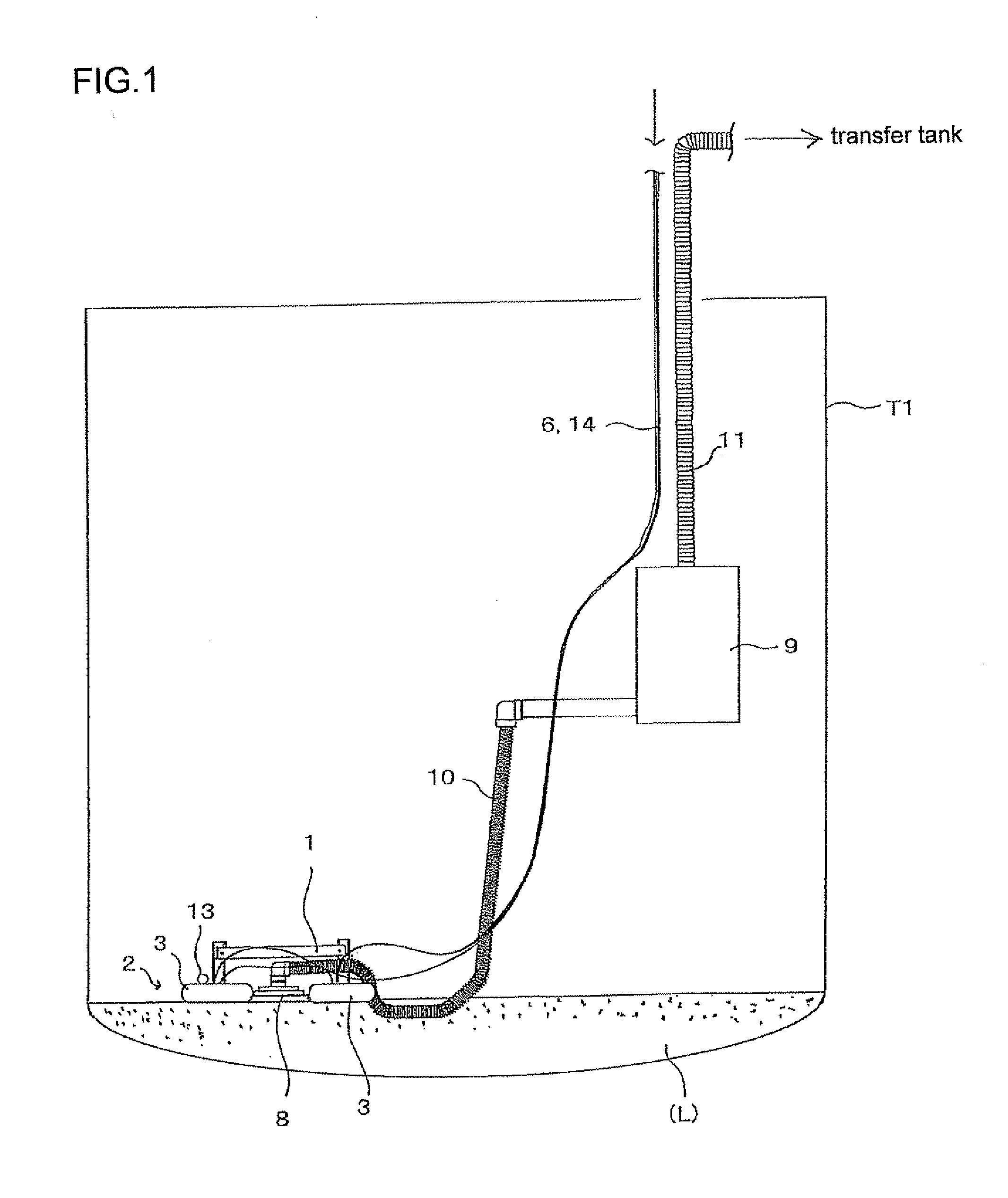

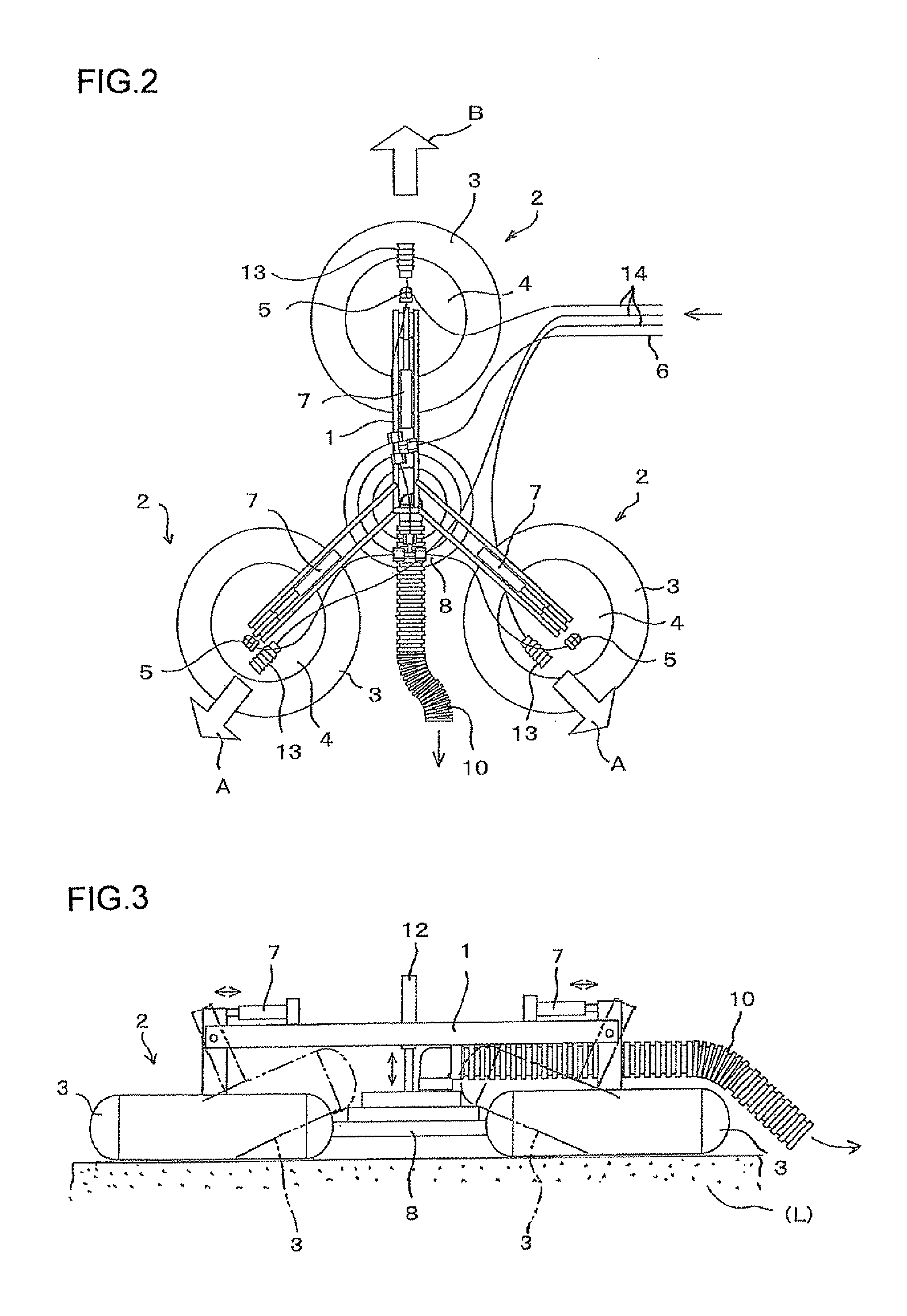

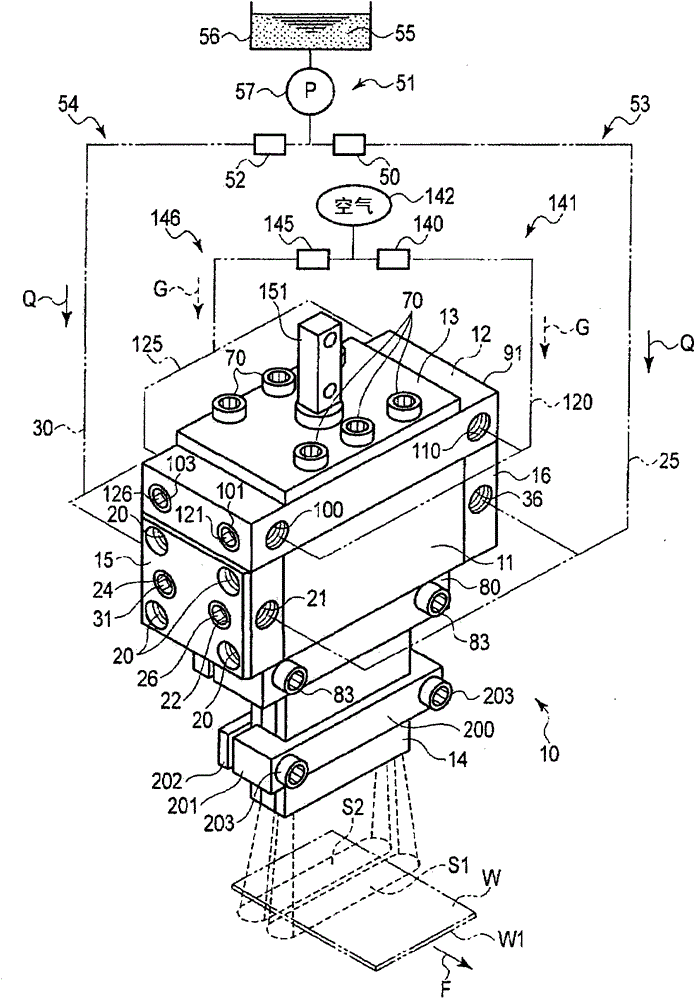

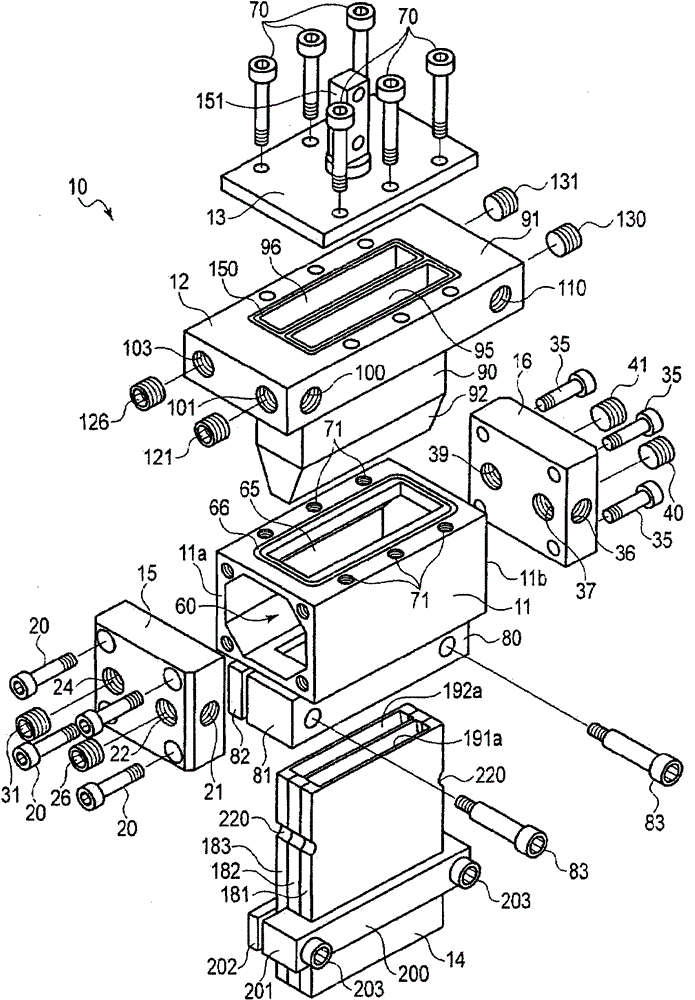

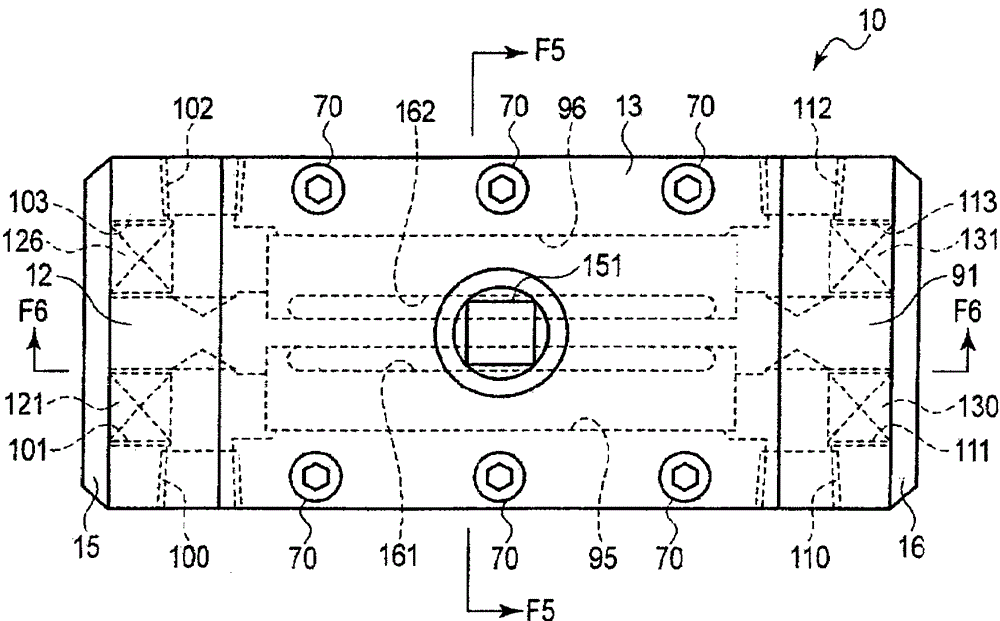

Residual radioactive sludge liquid suction apparatus

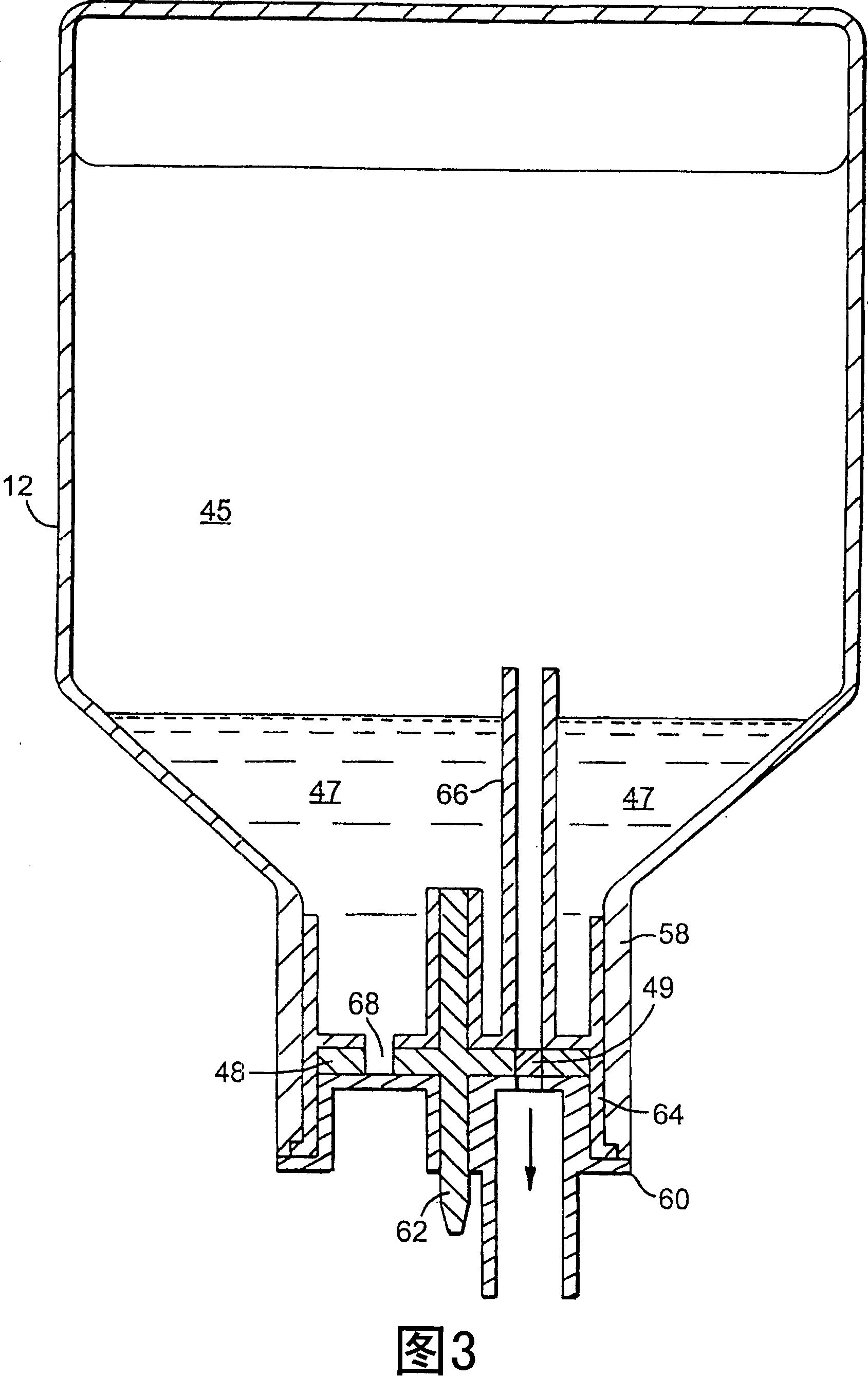

There is provided a residual radioactive sludge liquid suction apparatus capable of safely and surely sucking radioactive sludge liquid remaining in a sludge storage tank with no fear of being exposed to radiation at a time when a small amount of sludge liquid remaining in the sludge storage tank is transferred to another tank. The suction apparatus is a residual radioactive sludge liquid suction apparatus used for sucking residual radioactive sludge liquid (L) at a time when the residual sludge liquid (L) remaining in a sludge storage tank T1 is transferred, and includes: a suction apparatus body 1; three hover skirts 2 mounted to the suction apparatus body 1; a suction head 8 mounted to the suction apparatus body 1 and configured to suck the residual sludge liquid (L); air jetting nozzles 13 mounted to the hover skirts 2, respectively; and an air supply source that supplies air to the hover skirts and the air jetting nozzles, wherein the suction apparatus body 1 floats on a surface of the residual sludge liquid (L) by supplying the air from the air supply source to the hover skirts, and moves on the surface of the residual sludge liquid (L) by jetting the air from the air supply source through the air jetting nozzles 13.

Owner:TAIHEI DENGYO KAISHA

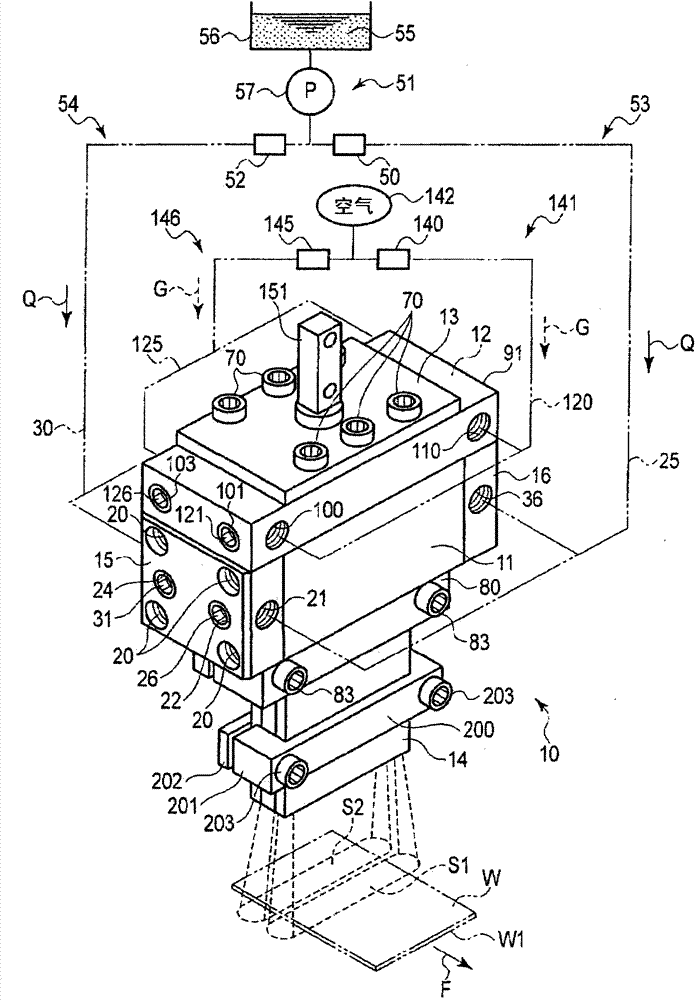

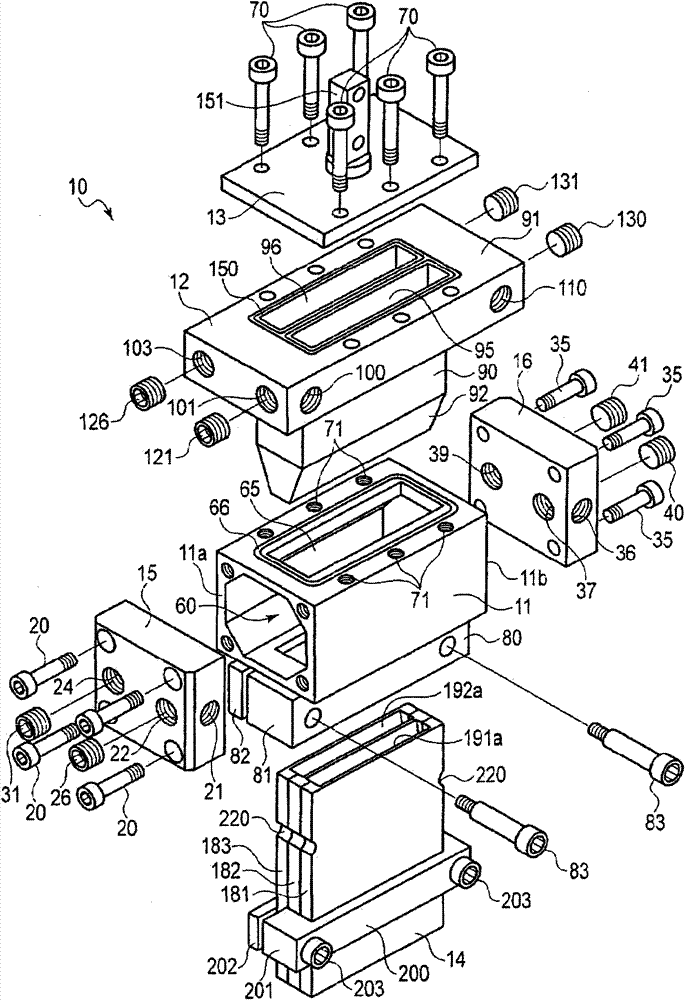

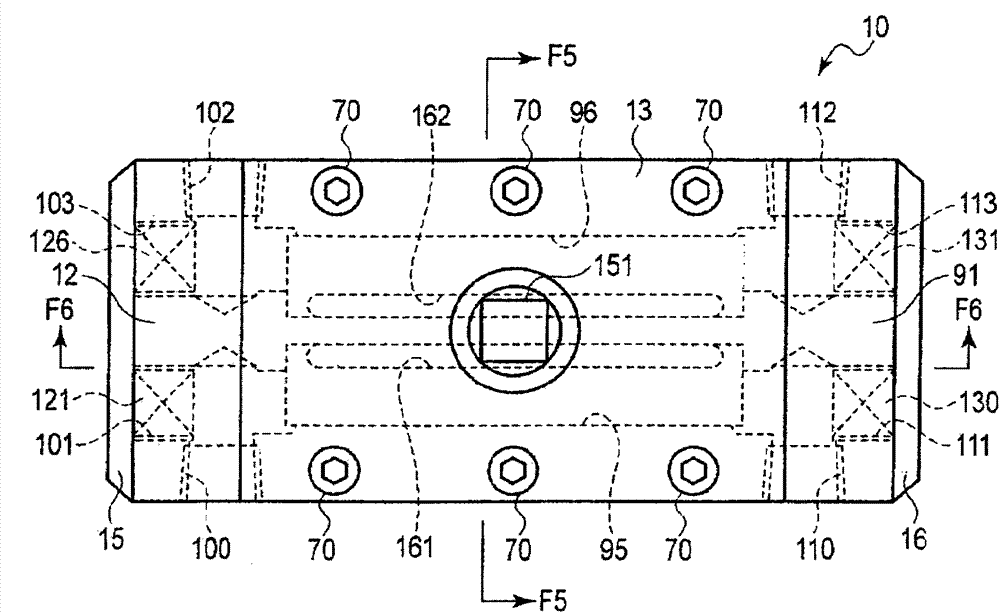

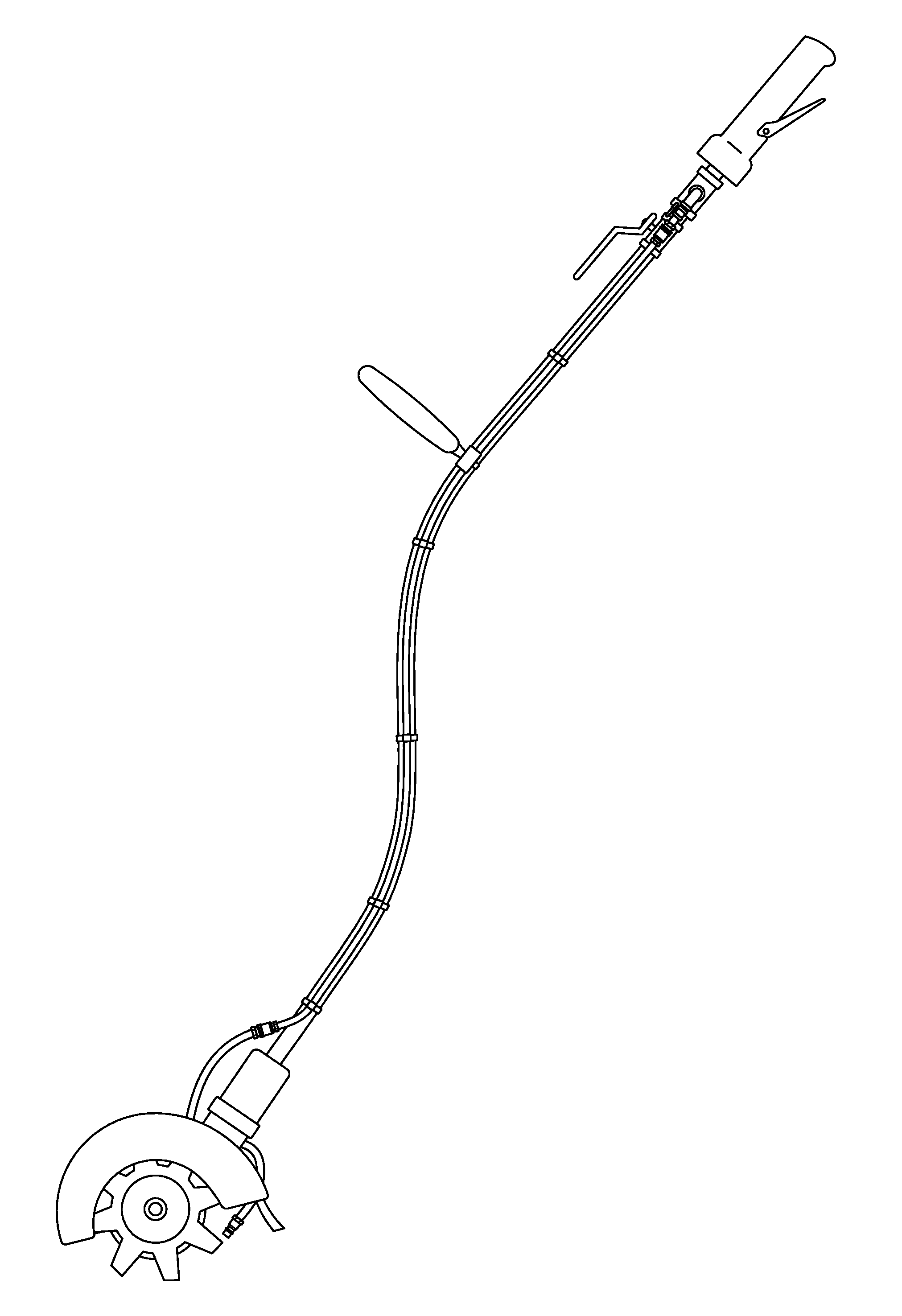

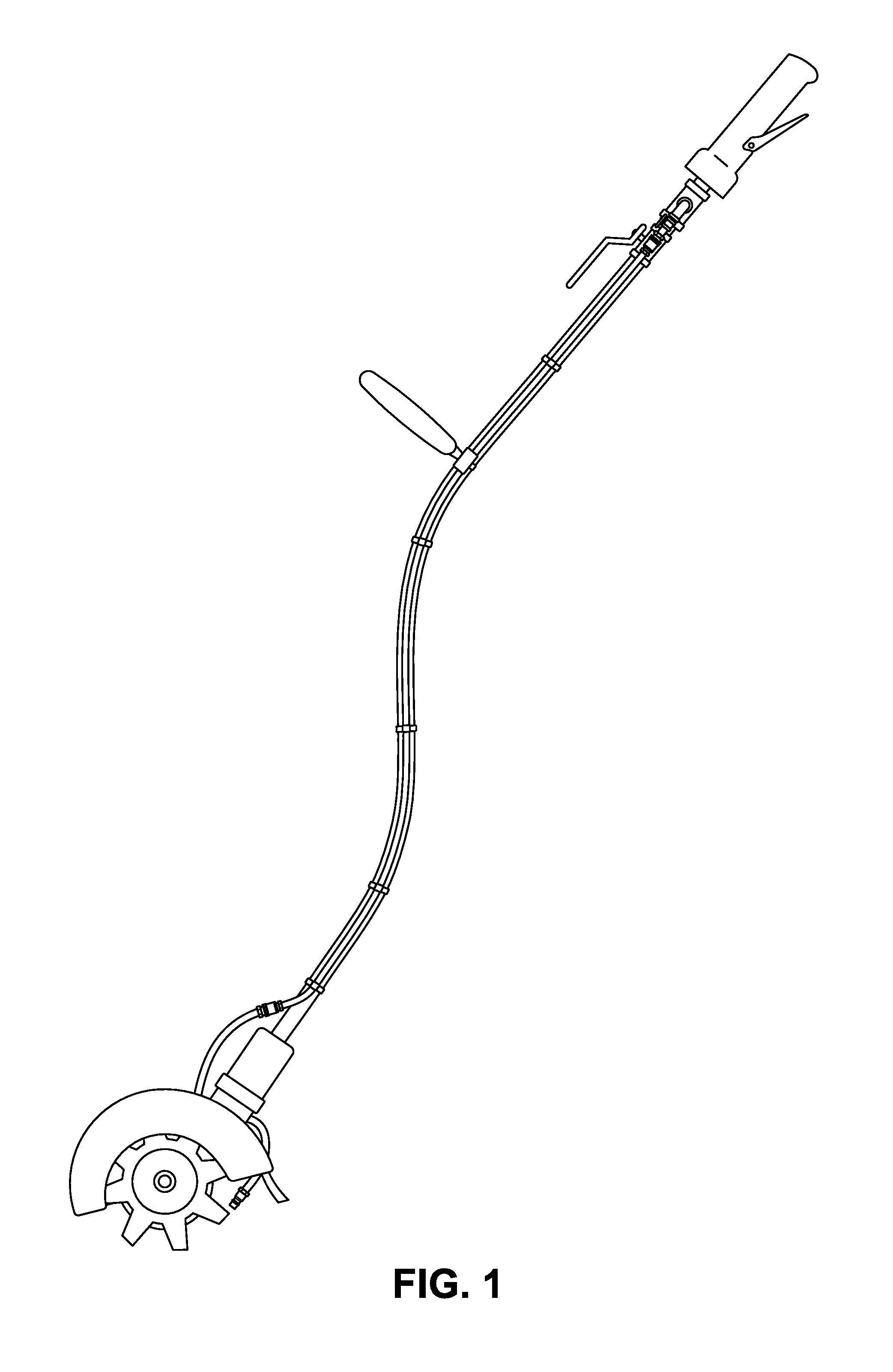

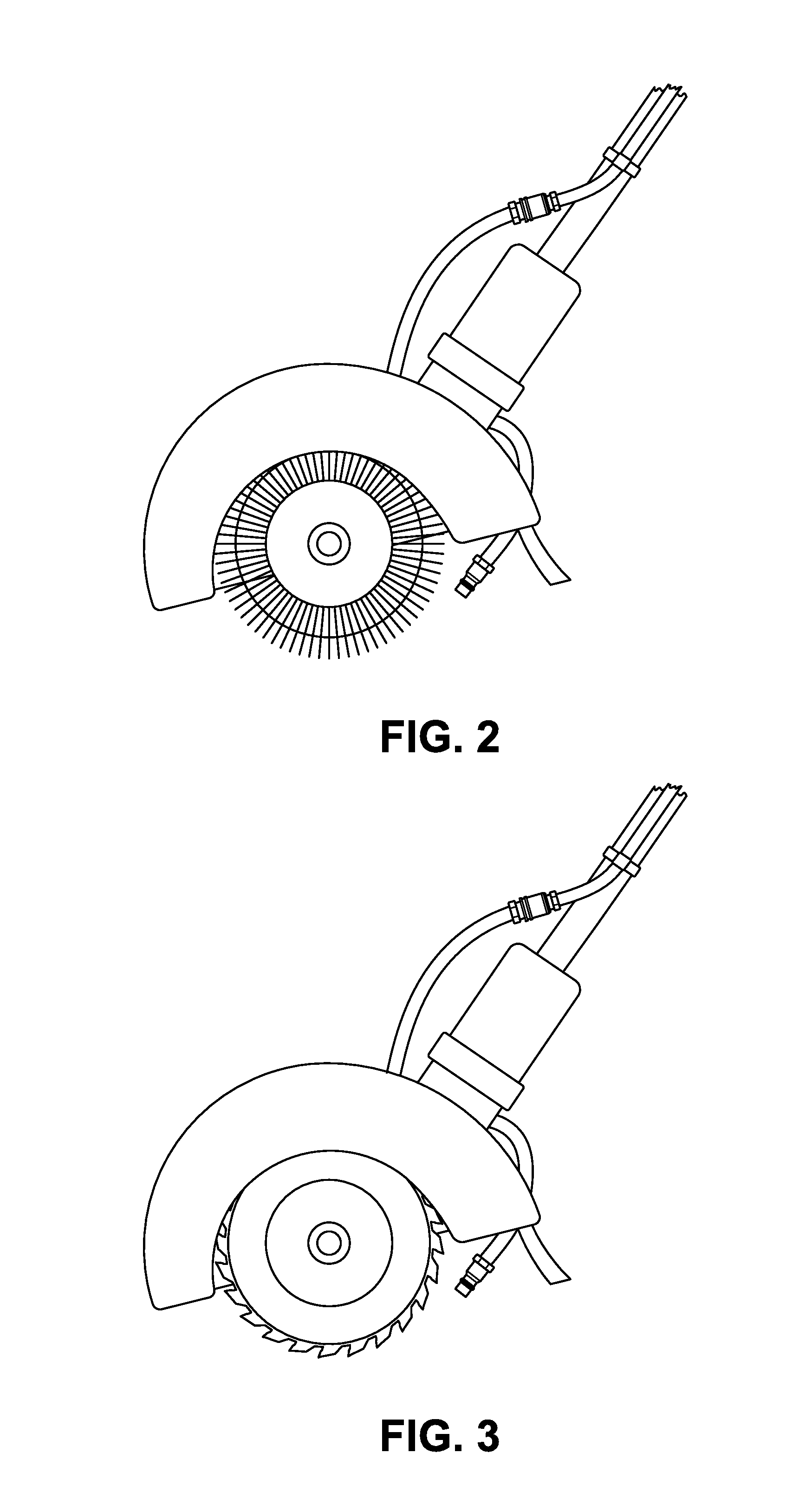

Spray gun for wet-type sand blasting

InactiveCN103770014AEfficient Wet BlastingSave spaceBlast gunsAbrasive feedersSand blastingEngineering

Provided is a spray gun for wet-type sand blasting. A first slurry chamber (61) and a second slurry chamber (62) are disposed in a gun main body (11). An air injection component (12) is provided with a first air chamber (95), a second air chamber (96), a first ventilation portion (161), a second ventilation portion (162), a first air bursting portion (171), and a second air bursting portion (172). A nozzle component (14) is provided with a first spraying circulating portion (191) and a second spraying circulating portion (192) whose flow paths sections are in slot shape, and slurry projection ports (230,231). An inlet side opening (191a) of the first spraying circulating portion (191) has an opening towards the first slurry chamber (61). The first air bursting portion (171) of the air injection component (12) is opposite to the inlet side opening (191a) of the nozzle component (14). An inlet side opening (192a) of the second spraying circulating portion (192) has an opening towards the second slurry chamber (62). The second air bursting portion (172) is opposite to the inlet side opening (192a).

Owner:TOSHIBA MASCH CO LTD

In-situ repair system and method for deep layer stirring-hot air injection of polluted soil

ActiveCN102671932BSimple designAchieve repair efficiencyContaminated soil reclamationAir compressorAniline

The invention provides an in-situ repair system and an in-situ repair method for deep layer stirring-hot air injection of polluted soil. According to the in-situ repair system, the lower end of a hot air spray pipe is communicated with a drill body core pipe in a drill; the upper end of the hot air spray pipe is communicated with an air outlet of a hot air compressor; and a mixed air-liquid pipeline is connected between a coverage cover and an air-liquid separator. According to the method, the drill is drilled in a target soil layer up and down in a reciprocating mode according to designed elevation, wherein the diameter of a stirring drill hole is 1.5 to 2.5 meters, the depth of the stirring drill hole is 9 to 12 meters, the injection pressure of hot air is 1 to 2 MPa, and the temperature of the hot air is 90 to 110 DEG C. According to the technology of the in-situ repair system and the in-situ repair method, the application range of strata can be expanded to low-middle permeable strata, and the range of the types of applicable pollutants is also increased, for example, the technology is still valid to semivolatile organic matters such as anilines. By the in-situ repair system and the in-situ repair method, the problem of 'smearing' of a soil vapor extraction (SVE) technology in the later period of repair can be solved, so that the repair efficiency is improved greatly, and the repair period is shortened greatly.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

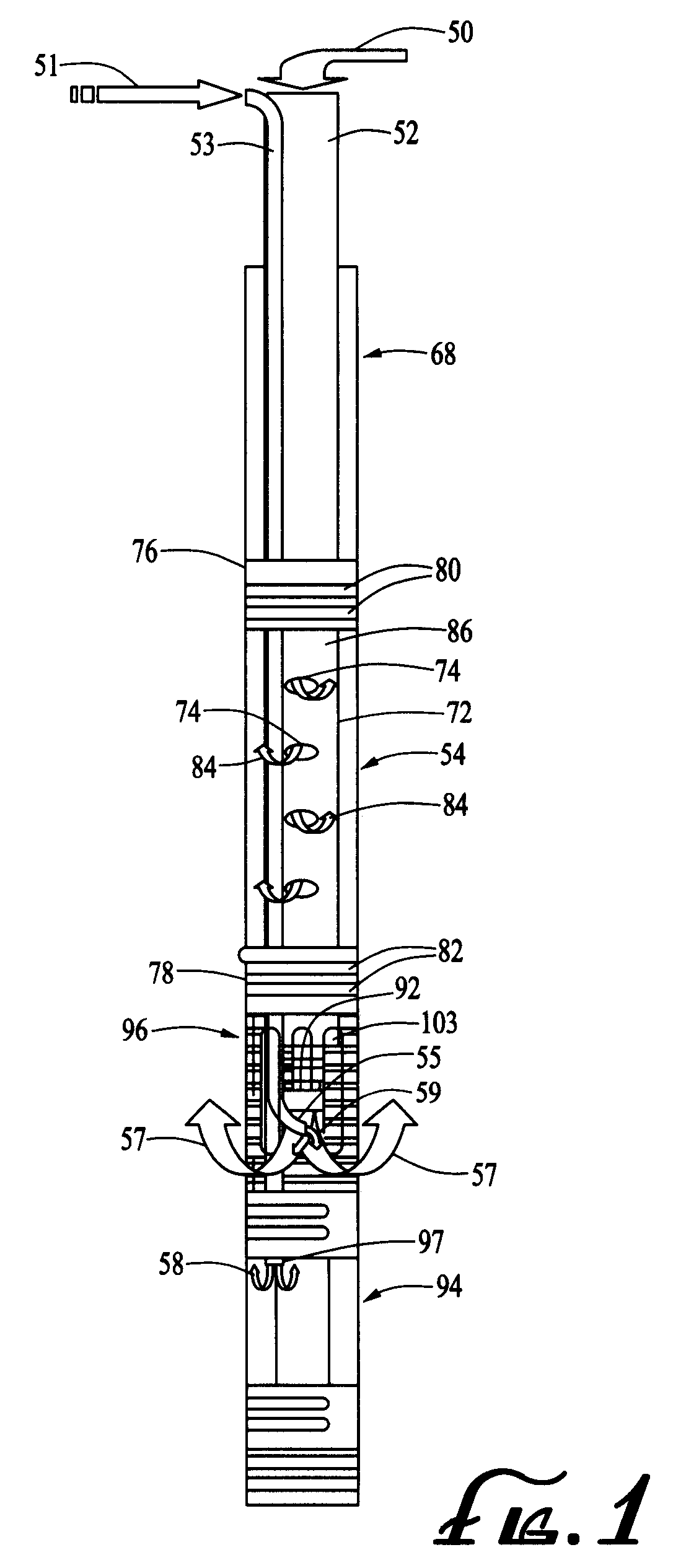

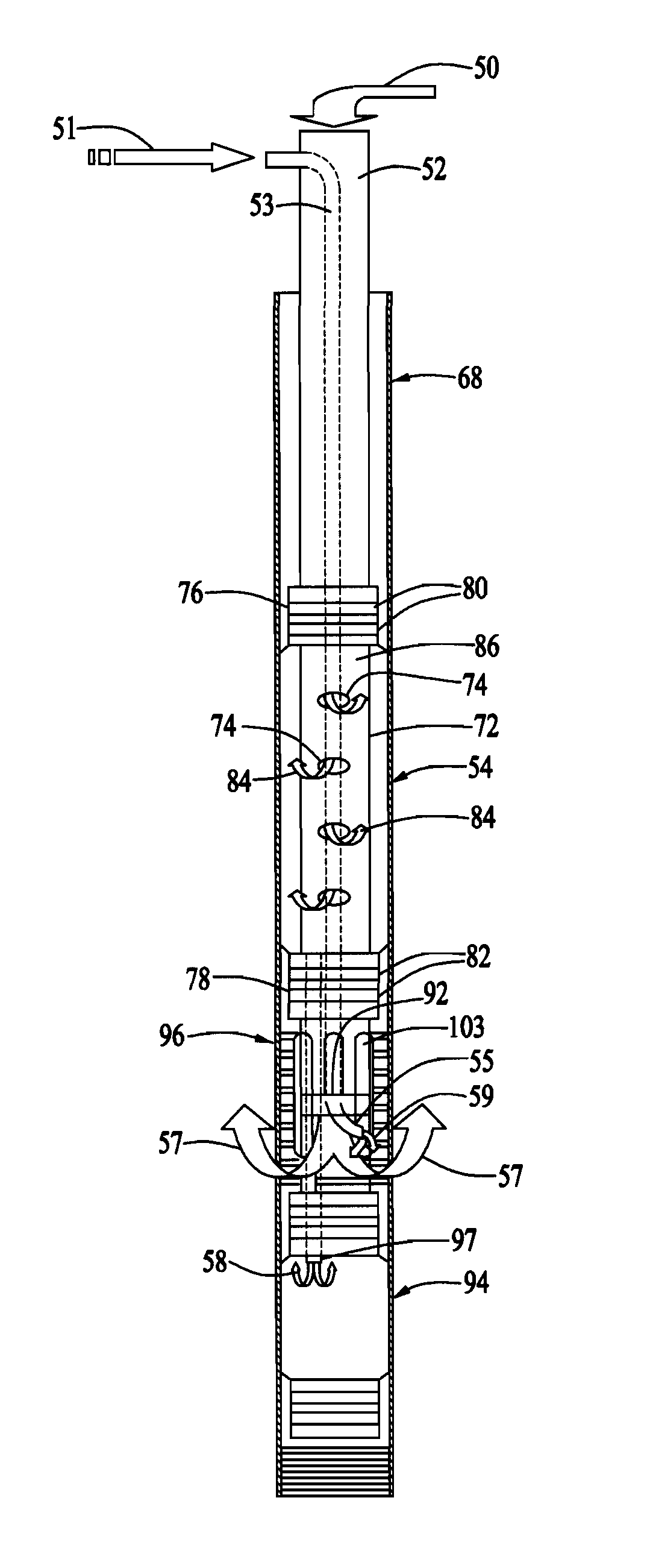

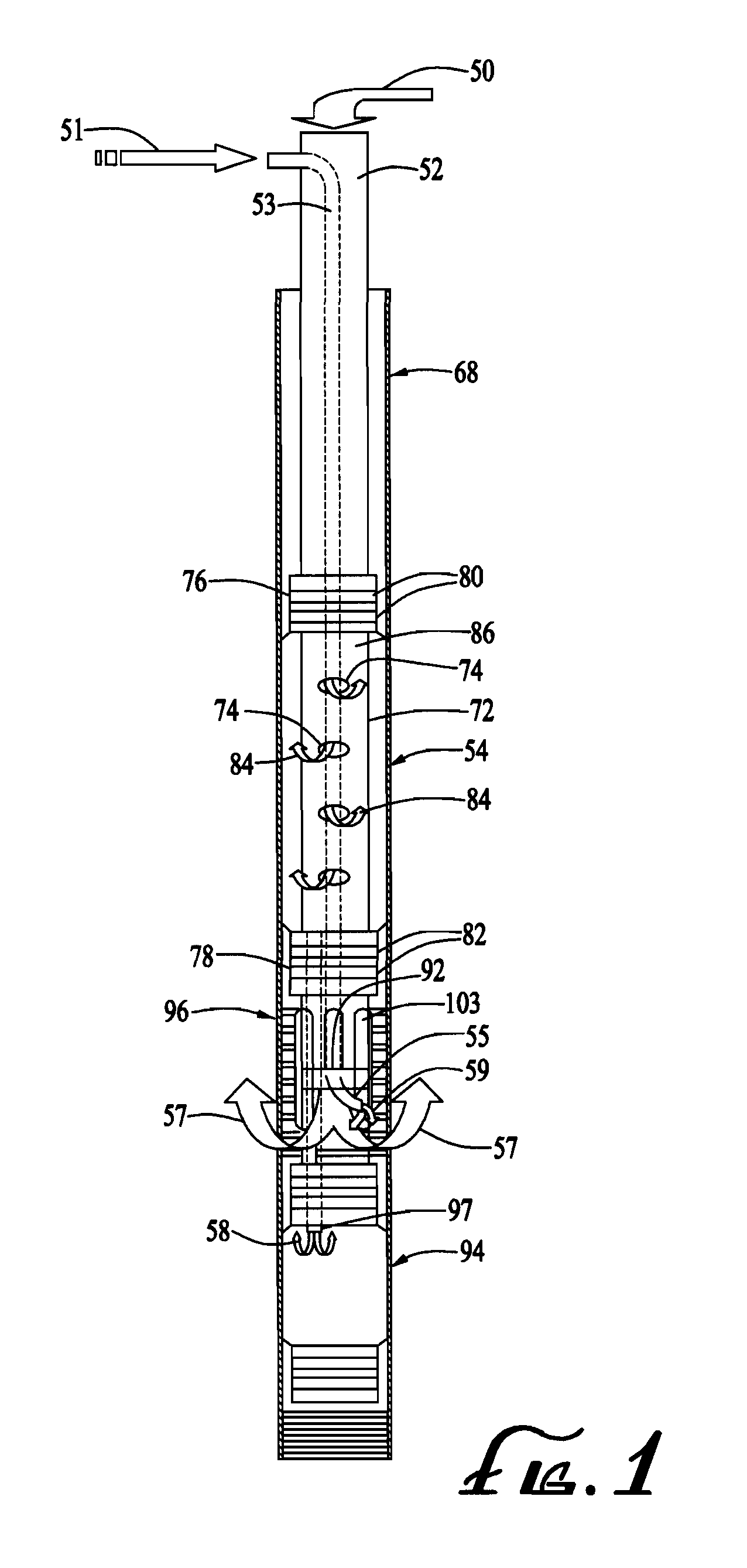

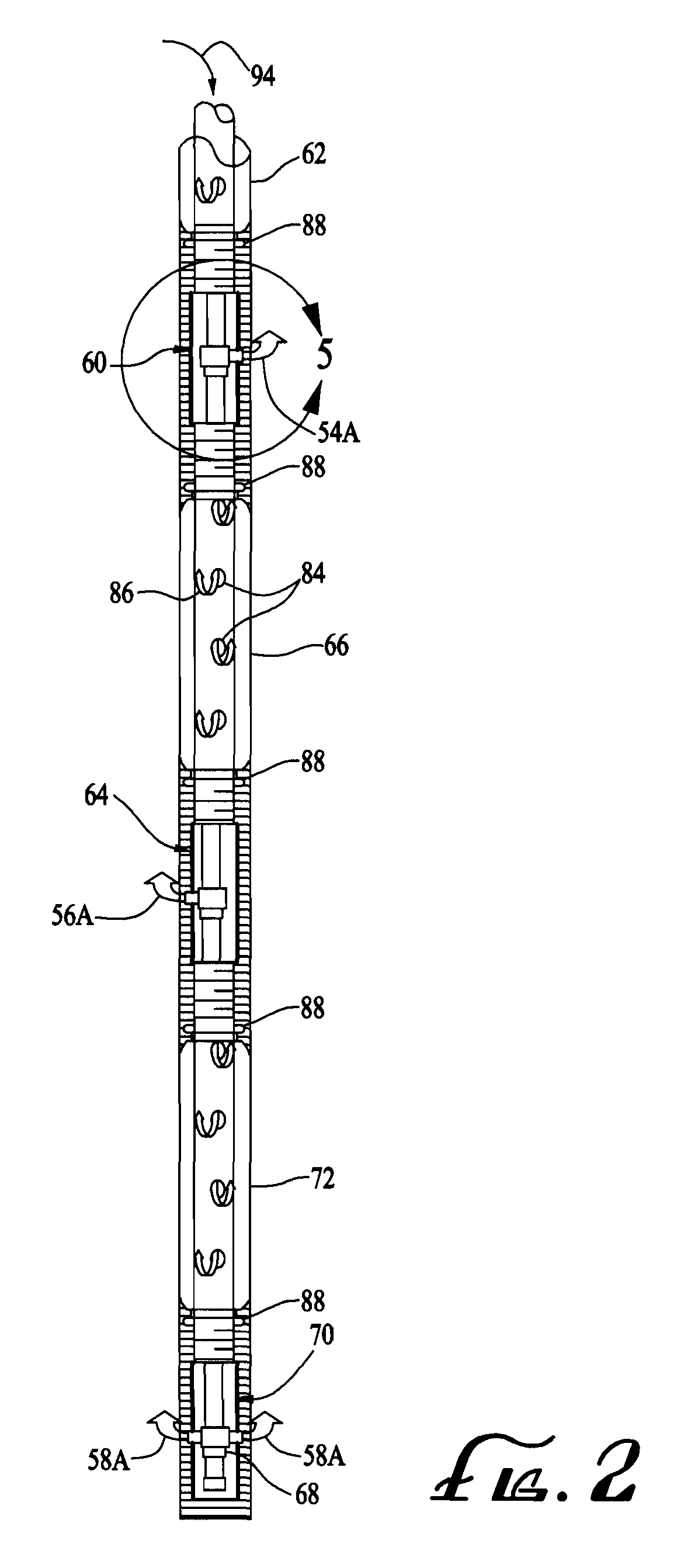

Multiple Point Adjustable Depth Air Sparging Well System

InactiveUS20090260799A1Improved air distributionPrevent escapeCleaning apparatusContaminated soil reclamationEngineeringMultiple point

An multiple point adjustable depth air sparging well system having a multiple air injection points for injecting compressed air into saturated or groundwater regions of the soil's subsurface to remove volatile contaminants from the soil's subsurface. At plurality of flow-through air sparge packer which are slidably mounted flow-through packers within the well casing of the air sparging well system allows a user to adjust the depths of the air injection points. Each packer has attached thereto a pressure regulator which provides compressed air to one of the multiple air injection points.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for treating ammonia nitrogen in acid wastewater containing heavy metals

ActiveCN106116022AEliminate the effects ofHigh removal rateTreatment using aerobic processesWater contaminantsCycloneSlag

The invention discloses a method for treating ammonia nitrogen in acid wastewater containing heavy metals, and belongs to the technical field of water treatment. The method comprises the following steps of: 1, after carrying out grinding and high-temperature plasticizing processing on zeolite and blast furnace steel slags, performing a hydrothermal reaction with water, carrying out sedimentation, filtration, drying and grinding on a reaction product, feeding the obtained product into the wastewater, and removing the heavy metals; 2, adding a cationic polymer into the wastewater to form a flocculation organism, removing toxic cyanide by an air jet cyclone floating device and a skimmer, and separating the flocculation organism; 3, leading the wastewater into a nitrification region to carry out nitrification; 4, after carrying out deoxidation on the wastewater, enabling the wastewater to enter an anaerobic denitrification to carry out denitrification; 5, filtering the wastewater by a submerged membrane to obtain filtered and purified water. According to the method disclosed by the invention, the heavy metals, the organism, the toxic cyanide and the ammonia nitrogen all can be effectively removed, and a sewage purification speed and biological purification intensity are improved; moreover, the method disclosed by the invention is low in construction investment, low in operation cost and suitable to popularize and apply.

Owner:胡大苇

Chemical injection using an adjustable depth air sparging system

InactiveUS20090065408A1Easily damagedPrevent escapeWater cleaningContaminated soil reclamationInjection pointEngineering

A supplemental fluid adjustable depth air sparging system which is used to remediate contaminates from groundwater within the soil. An adjustable depth air injection point injects compressed air, and an adjustable depth chemical injection point injects a chemical oxidizer or nutrient into saturated or groundwater regions of the soil's subsurface to remove contaminants including chlorinated solvents from the soil's subsurface.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

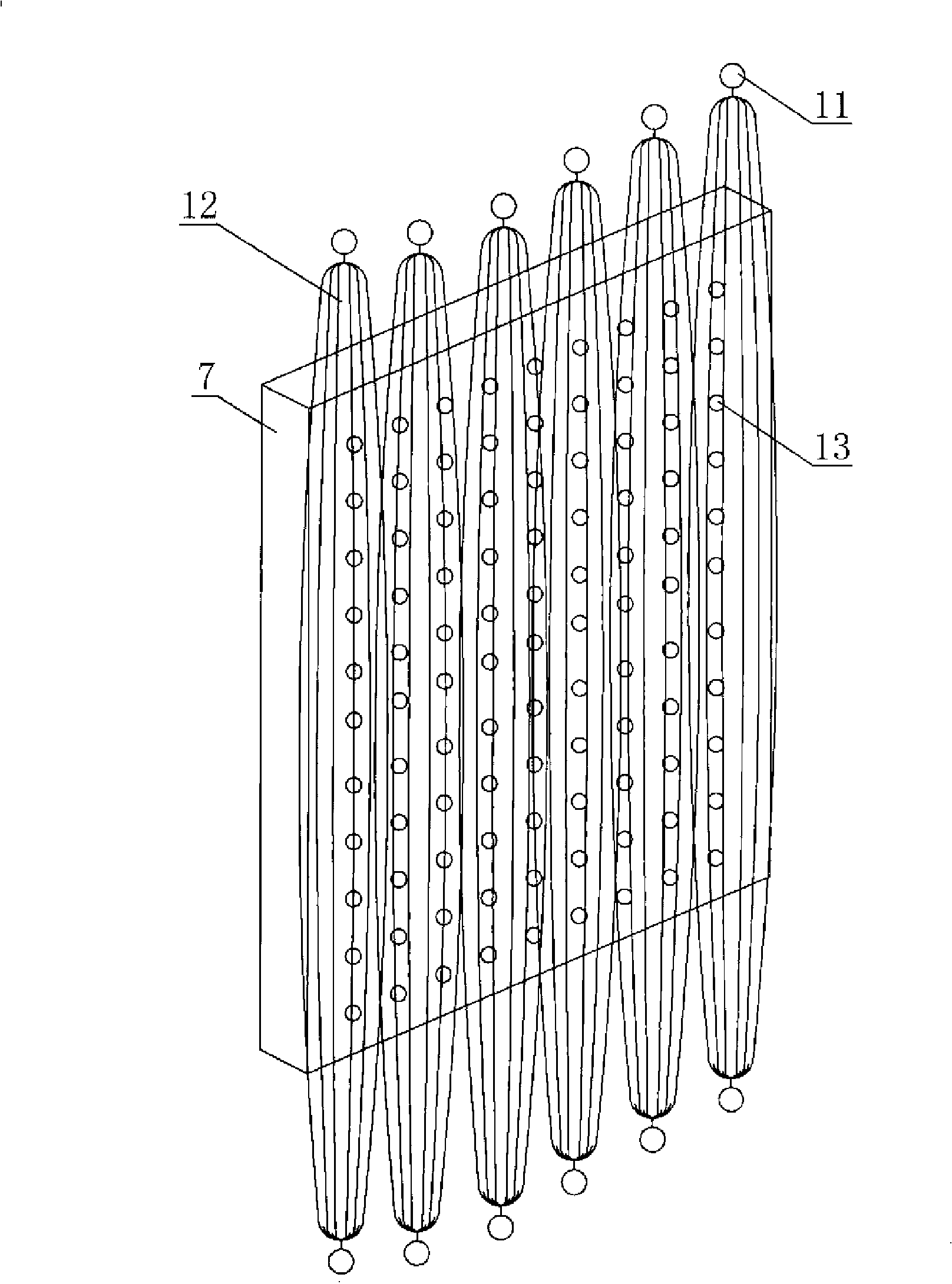

Novel fibre filter

InactiveCN101249321AOrderly rowsHigh filtration precisionLoose filtering material filtersGravity filtersFiberDrive shaft

The invention relates to a novel fiber filter, fiber beams are arranged in a pool body, the side wall of the pool body is provided with a water inlet, a water outlet and a back wash water discharge outlet, the space at the bottom part of the pool body is provided with a water collection tank of the discharged water, the side surface of the water collection tank of the discharged water is communicated with the water outlet; an upper plate surface of the water collection tank of the discharged water is connected with at least one vertical filter unit, the center of each filter unit is a hollow support body, filtration pores are distributed on the side wall of each hollow support body, the lower port of each hollow support body is communicated with the water collection tank of the discharged water, the outer surface of each hollow support body is covered with fiber beams which are vertically and tightly arranged, the lower ends of the fiber beams are connected with a wire hanging rod, the upper ends of the fiber beams and the upper ends of the hollow support bodies are connected with a wire hanging support body via a wire hanging ring and a rope, the wire hanging support body is connected with a drive device by driving via a lifting transmission shaft; the root part of each filter unit is provided with an air distributing chamber, a back wash air sparging disc is arranged on the air distributing chamber, and the air distributing chamber is communicated with a back wash air inlet pipe. The filter has small area coverage, high filtration efficiency and thorough back wash.

Owner:沙中魁

System and Method for Combined Microorganism Degradation and Air Sparging-Soil Vapor Extraction of Oil-containing Sludge

ActiveUS20190248687A1Efficient degradationEffectively remedyTreatment using aerobic processesWater contaminantsSoil remediationSludge

A system and method for combined microorganism degradation and air sparging-soil vapor extraction (AS-AVE) of oil-containing sludge can include a microorganism-adding unit, an AS-SVE unit, a metering-feeding layer, a mixing layer, a material discharging layer and a crawler-type conveyor. In some embodiments the microorganism-adding unit and the AS-SVE unit can include a microorganism storage tank and an AS-SVE storage tank. In some embodiments, the metering-feeding layer can include a valve, a pressure gauge, a flowmeter, a feeding chamber. In some embodiments, the mixing layer can include pipeline connectors and a stirrer. In some embodiments, the material discharging layer is mainly for transporting the treated soil away. The system can remove petroleum, petroleum hydrocarbons, volatile organic compounds (VOCs), and degradable and extractable contaminants from oil-containing sludge by a method combining microorganism degradation, mechanical stirring, AS-AVE and the like, thereby achieving soil remediation and automatic treatment in a large scale.

Owner:CHINESE RES ACAD OF ENVIORNMENTAL SCI

Pavement crack cleaner

Devices for cleaning and preparing pavement cracks for sealing are disclosed. An example device comprises a wire brush assembly for removal of mid and large-sized debris, an air blaster for removal of fine-grained particulate, a heat lance, and a vacuum for controlled removal of debris and particulates. The example device would also have means for attachment to an air compressor.

Owner:BOARD OF RGT UNIV OF NEBRASKA

Spray gun for wet blasting

Provided is a spray gun for wet-type sand blasting. A first slurry chamber (61) and a second slurry chamber (62) are disposed in a gun main body (11). An air injection component (12) is provided with a first air chamber (95), a second air chamber (96), a first ventilation portion (161), a second ventilation portion (162), a first air bursting portion (171), and a second air bursting portion (172). A nozzle component (14) is provided with a first spraying circulating portion (191) and a second spraying circulating portion (192) whose flow paths sections are in slot shape, and slurry projection ports (230,231). An inlet side opening (191a) of the first spraying circulating portion (191) has an opening towards the first slurry chamber (61). The first air bursting portion (171) of the air injection component (12) is opposite to the inlet side opening (191a) of the nozzle component (14). An inlet side opening (192a) of the second spraying circulating portion (192) has an opening towards the second slurry chamber (62). The second air bursting portion (172) is opposite to the inlet side opening (192a).

Owner:TOSHIBA MASCH CO LTD

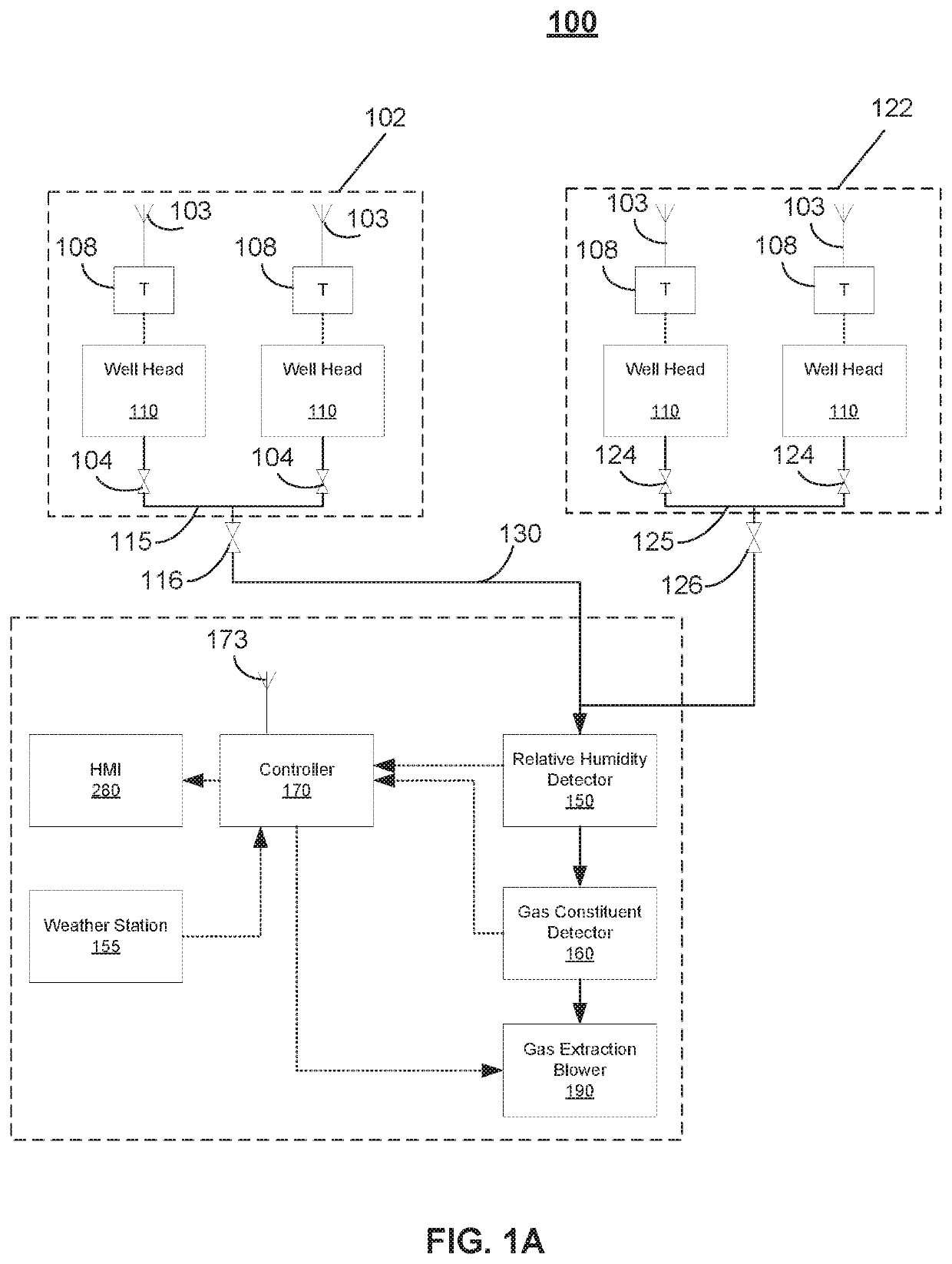

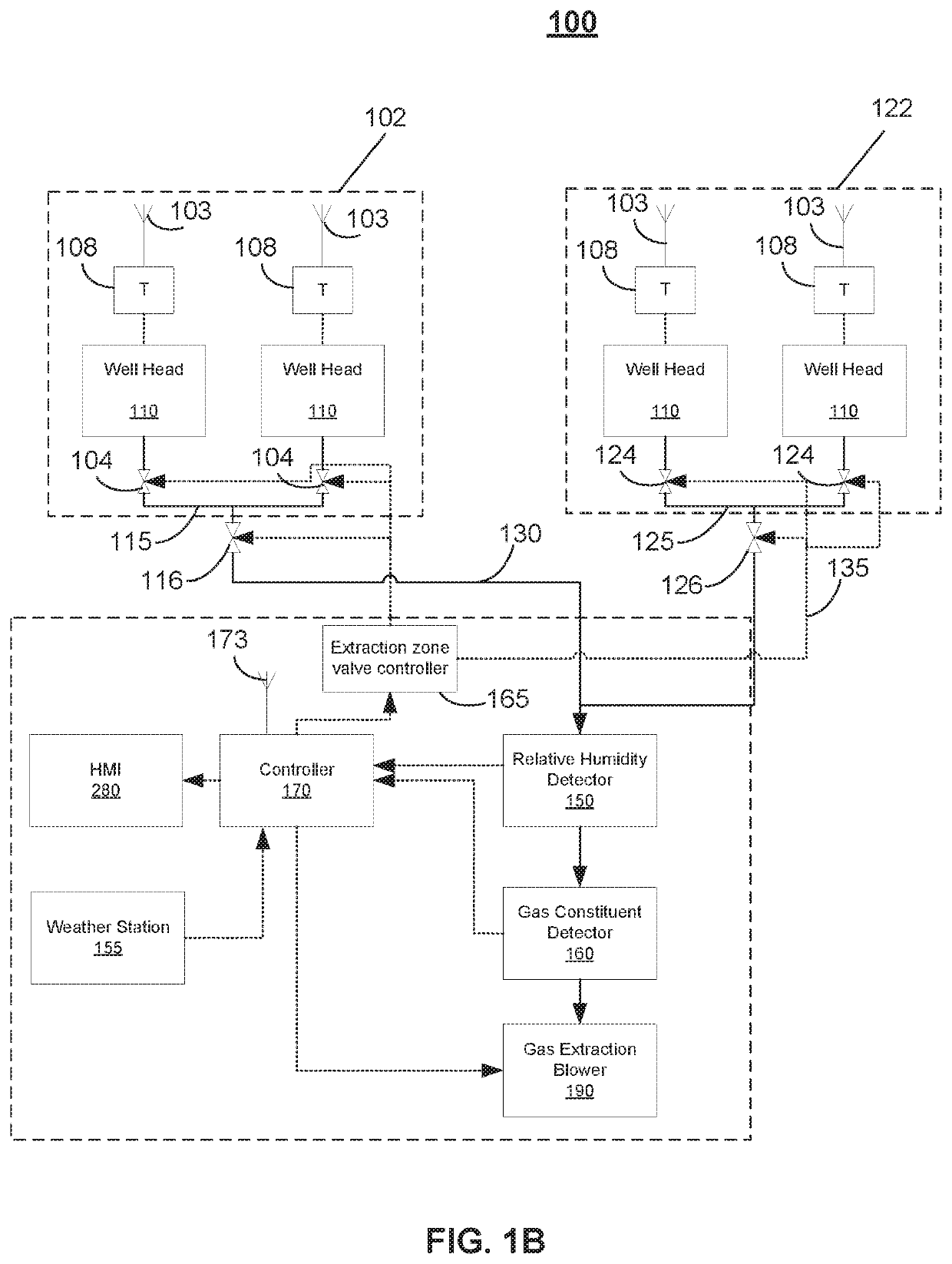

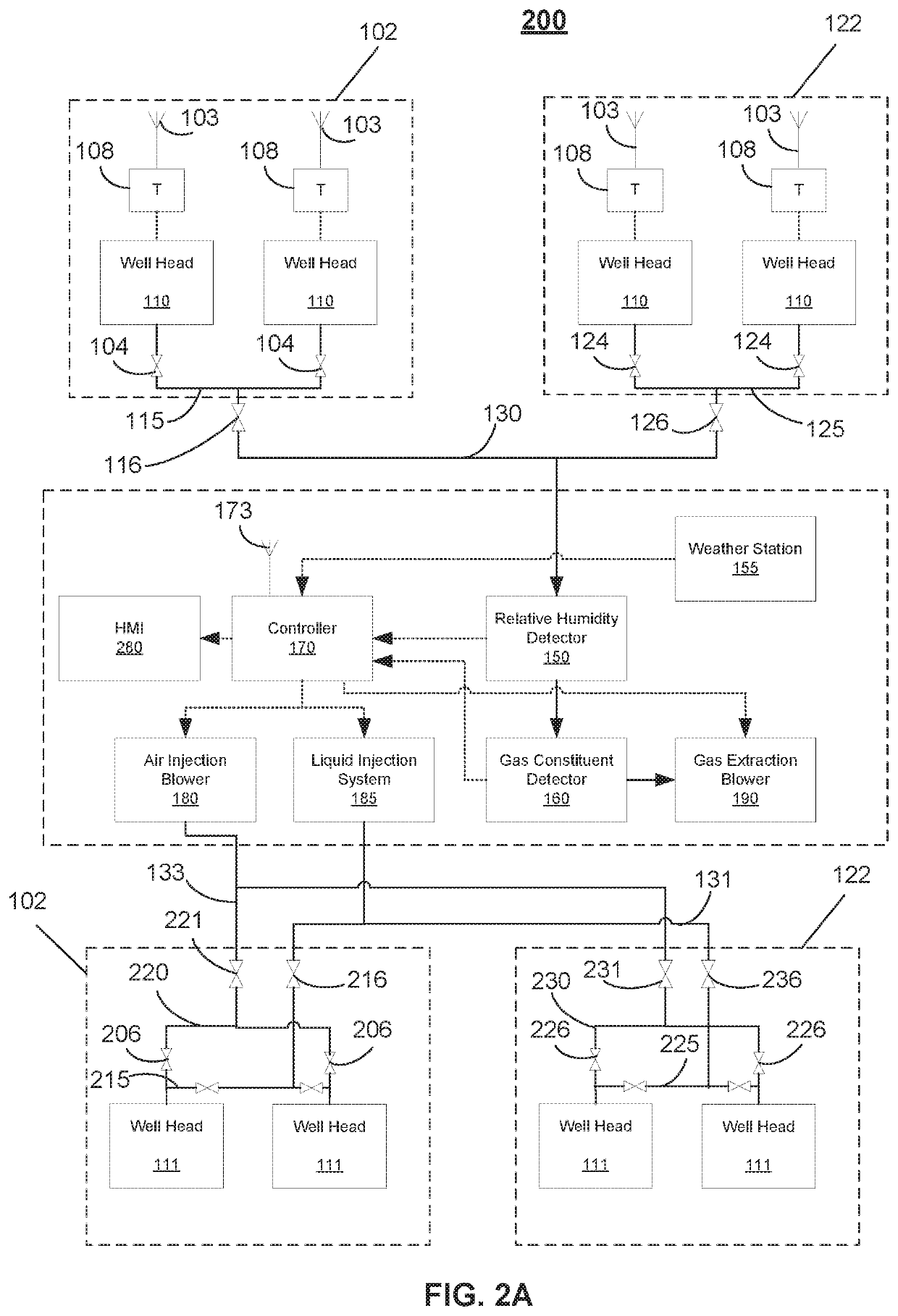

System and methods for monitoring and controlling an aerobic landfill bioreactor

ActiveUS11123777B2Bioreactor/fermenter combinationsBiological substance pretreatmentsIsolation valveEnvironmental engineering

A system and method for monitoring or controlling an aerobic landfill bioreactor having a plurality of zones each including at least one well head. The system comprises: a gas extraction blower, a plurality of temperature sensors disposed in the well heads, an ex-situ relative humidity detector, an ex-situ gas constituent detector, an air injection system, a liquid injection system, and a controller. Landfill gas is extracted by the blower and it's temperature, relative humidity, and gas constituents are measured. The system further comprises a system of headers, isolation valves, and flow control valves which serve to isolate zones for measurement and / or air and liquid injection as well as control the flow of either the landfill gas extraction or liquid and air injection. The method involves measuring: temperature, relative humidity, and gas constituents of the extracted landfill gas. Advantageously, the ex-site placement of the sensors and detectors ensure that measurements are representative of the aerobic bioreactor operating parameters. The air and liquid injection systems are adjusted, based on the measured temperature, relative humidity, and gas constituents to optimize the operation of the aerobic landfill bioreactor.

Owner:AEROBIC LANDFILL TECH INC

Chemical injection using an adjustable depth air sparging system

InactiveUS7748931B2Easily damagedPrevent escapeContaminated soil reclamationSedimentation separationCompound (substance)Injection point

A supplemental fluid adjustable depth air sparging system which is used to remediate contaminates from groundwater within the soil. An adjustable depth air injection point injects compressed air, and an adjustable depth chemical injection point injects a chemical oxidizer or nutrient into saturated or groundwater regions of the soil's subsurface to remove contaminants including chlorinated solvents from the soil's subsurface.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

Adding equipment of post-ozone air ejector

ActiveCN103539250ALow running costWater/sewage treatment by oxidationOzone generatorEnvironmental engineering

The invention discloses an adding equipment of a post-ozone air ejector. The adding equipment comprises an ozone generator, an ozone distribution pipeline and an ozone contact pool, wherein an aerating disc is installed at the bottom of the ozone contact pool, and the ozone gas enters into the aerating disc through the distribution pipeline; a bypass pipeline consisting of the air ejector is additionally arranged on the distribution pipeline, and one-off valves are respectively arranged on the distribution pipeline and the bypass pipeline; besides an ozone gas inlet, the air ejector further comprises a mixed gas inlet connected with an air blower; the mixed wind outlet of the air ejector is connected with the aerating disc through the distribution pipeline. The adding equipment disclosed by the invention can be used for solving the technical problem that a post-ozone adding system of a water plant has different demands on the ozone adding rate in different seasons and the operating cost is effectively lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com