Spray gun for wet-type sand blasting

A sandblasting and spray gun technology, applied in the direction of spray guns, explosion generating devices, abrasives, etc., can solve problems such as enlargement, large demand, and inability to use slurry effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

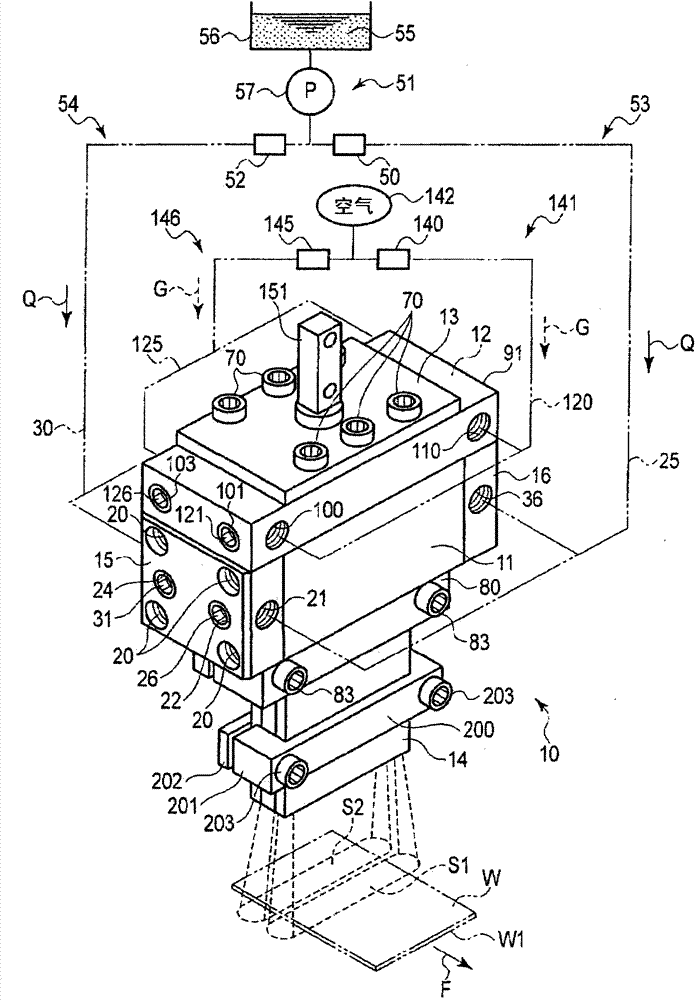

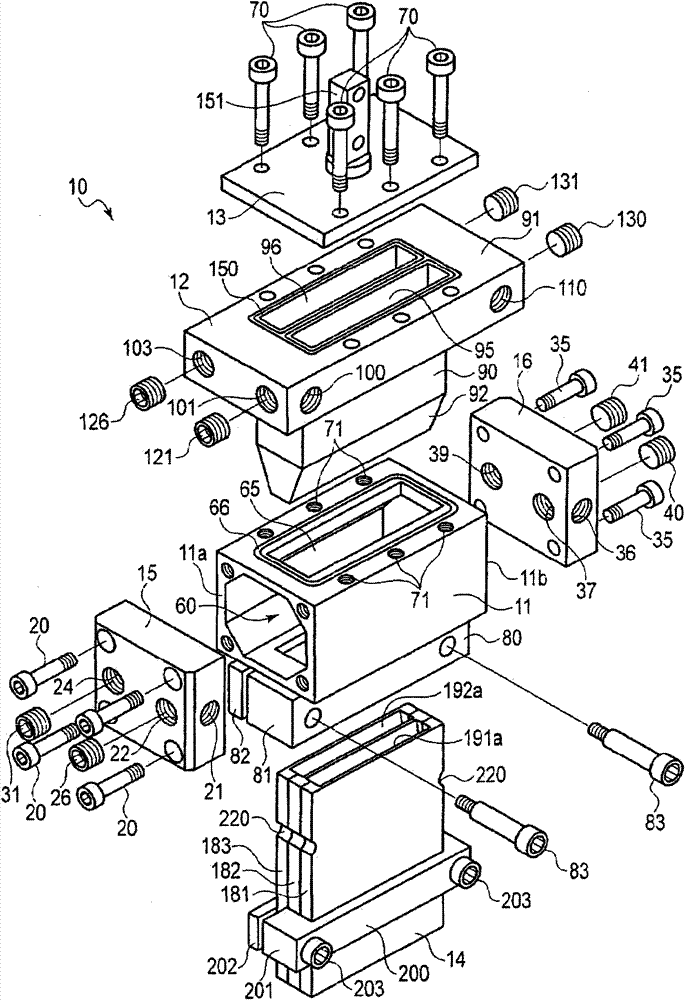

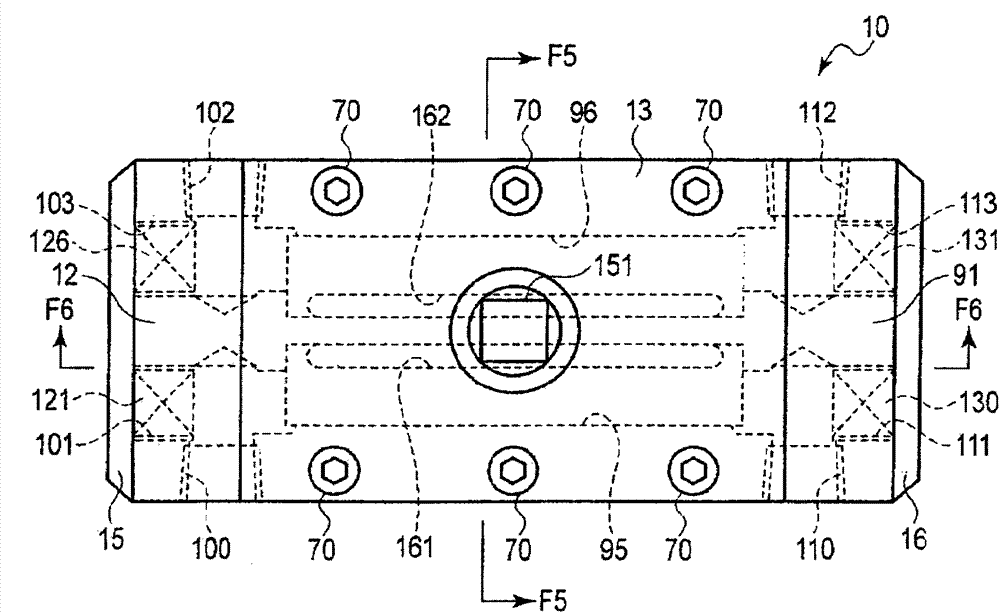

[0028] Below, refer to Figure 1 to Figure 8 , the first embodiment of the present invention will be described.

[0029] figure 1 It is a perspective view of the wet blasting torch 10 (hereinafter simply referred to as torch 10 ) of the first embodiment. figure 2 is an exploded perspective view of the spray gun 10, image 3 is a plan view of the spray gun 10 . Figure 4 It is a top view schematically showing the workpiece W and the torch 10 installed above the workpiece W. FIG. The workpiece W is continuously moved in a direction indicated by an arrow F by a conveyance mechanism 1 including, for example, a timing belt or the like.

[0030] figure 1 Shown spray gun 10 comprises: hollow gun main body 11, is located at gun main body 11 sides ( figure 2 The air injection member 12 and the cover member 13 are located on the other side of the gun main body 11 (upper side in figure 2 The nozzle member 14 on the lower side of the gun body 11, and a pair of connecting blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com