Foamed cleaser with suspended particles therein, method of producing same and a dispenser therefore

A technology of a dispenser and foam, applied in the field of a foam cleaner with suspended particles, its manufacture and its dispenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

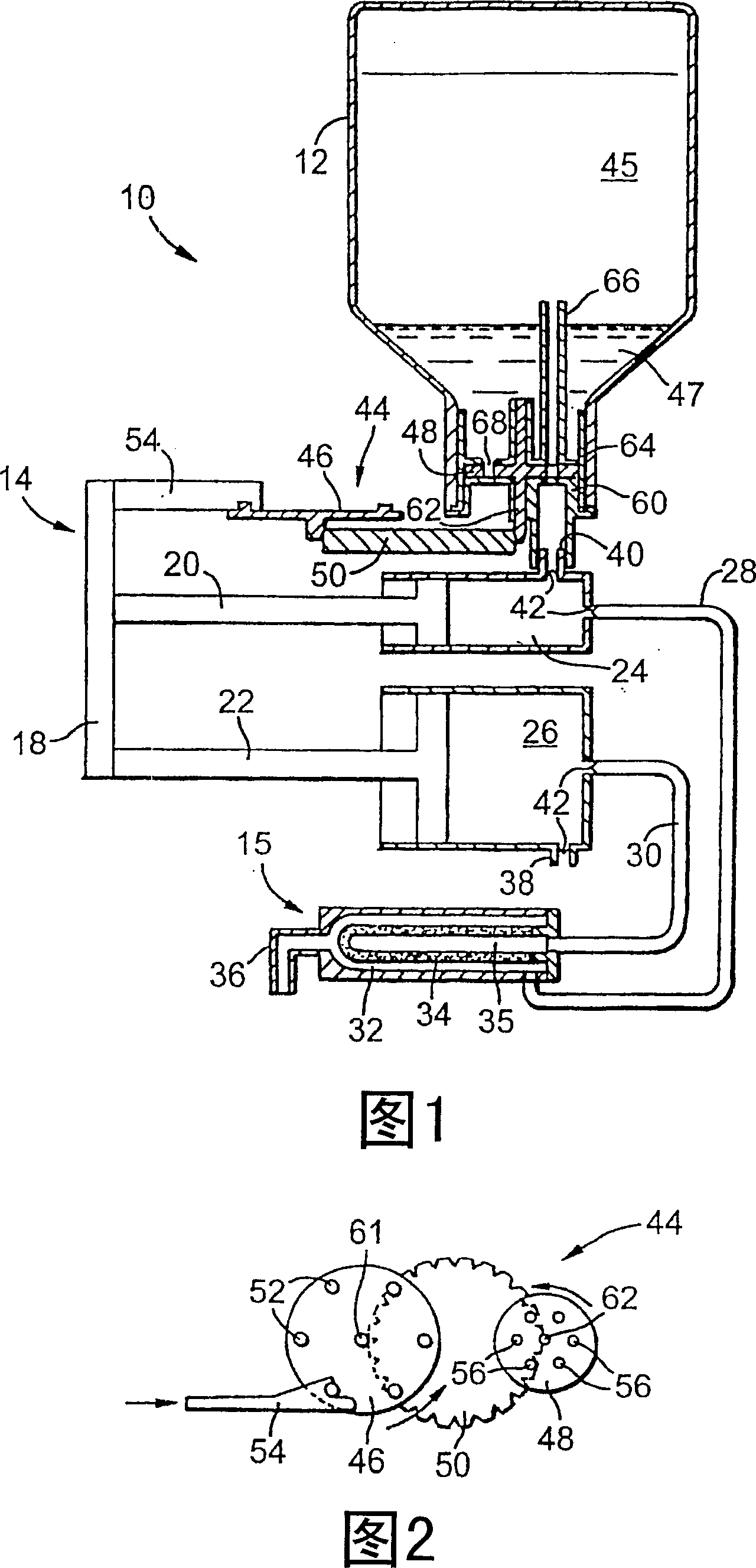

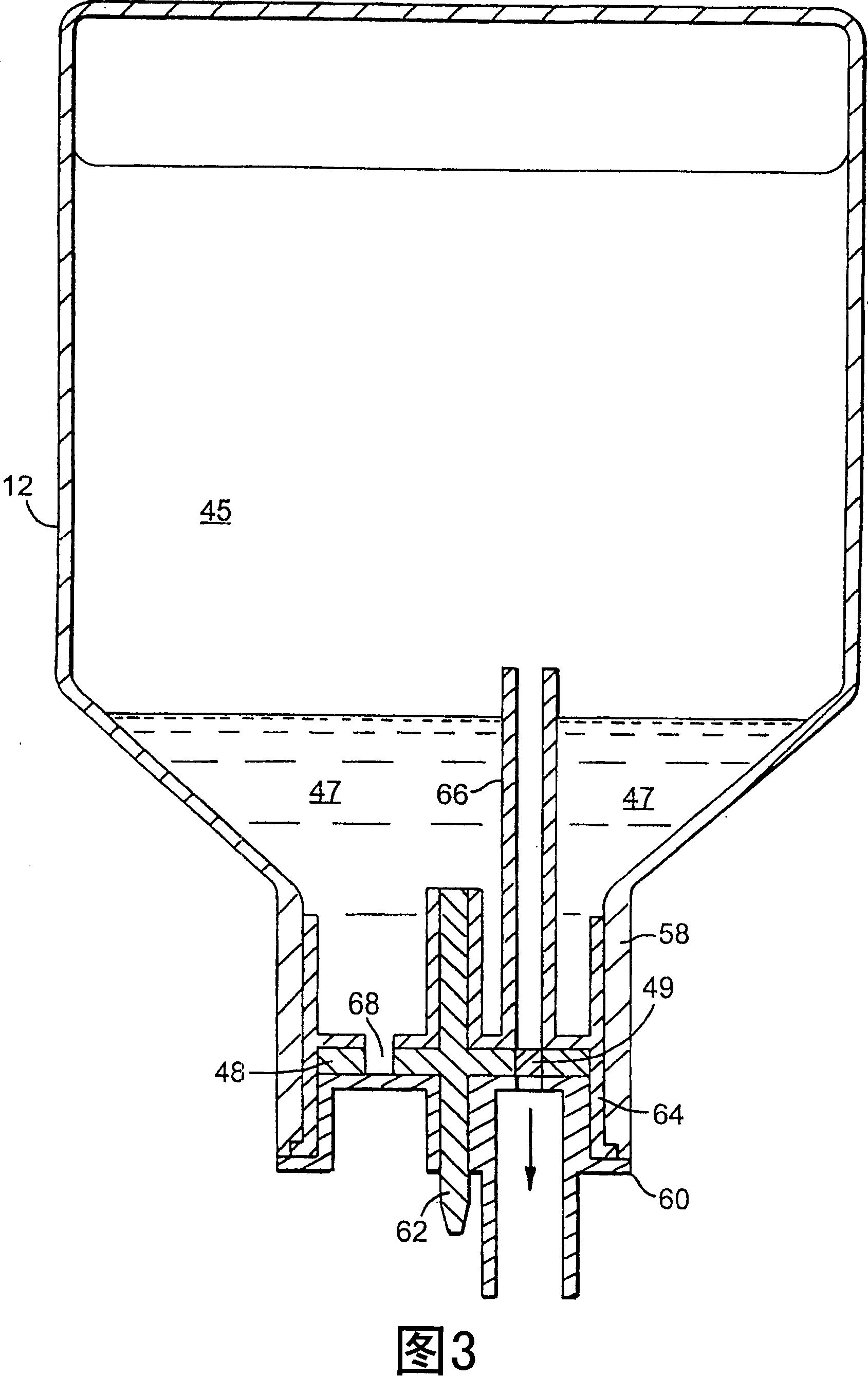

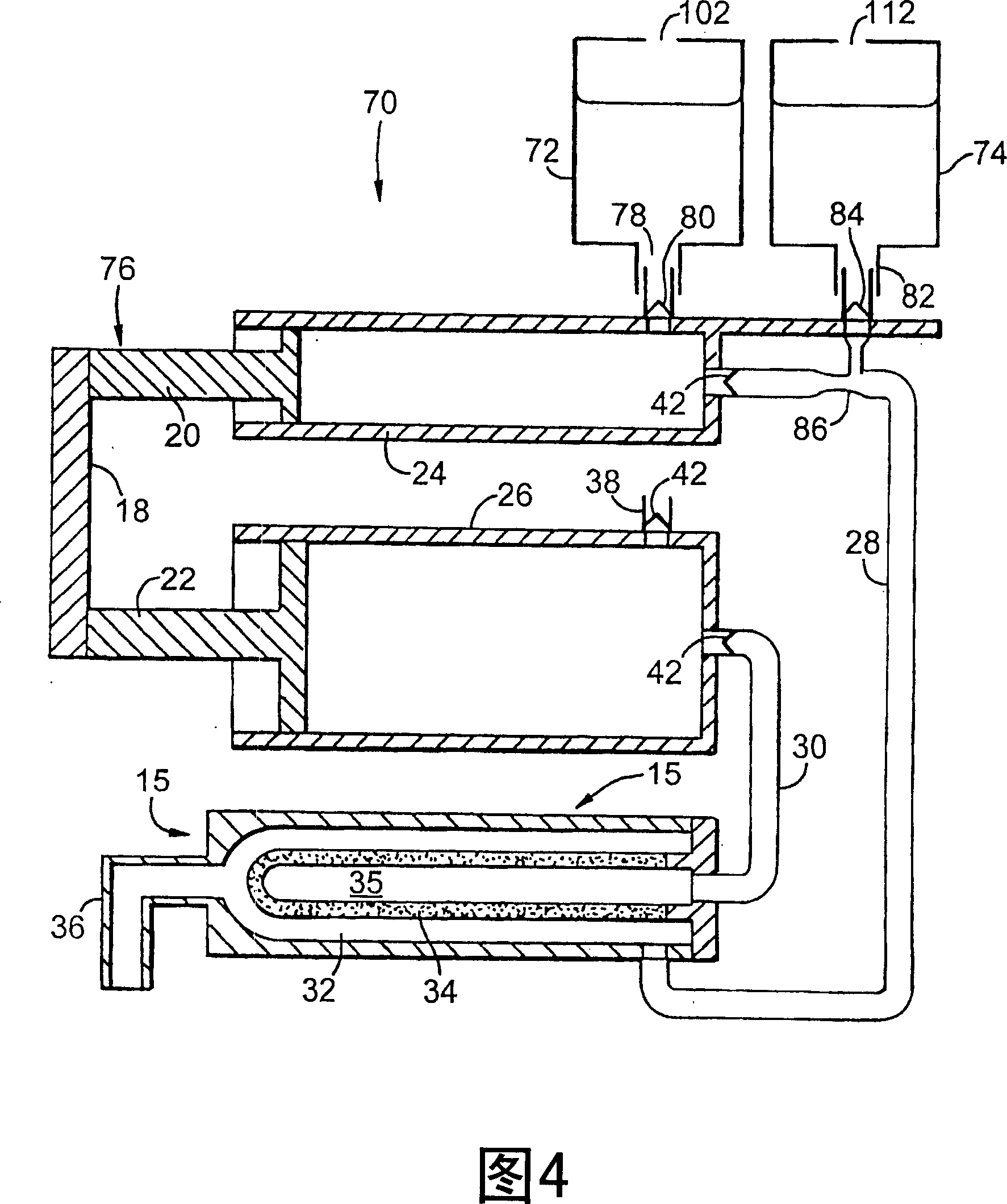

[0029] The present invention relates to a dispenser for dispensing with suspended particles. Previously, traditional non-aerosol dispensers were unable to deliver particles in foam. In a traditional dispenser, foam is created by mixing air with a liquid and then pushing the mixture through a porous material. If particles are introduced into the liquid, the porous material acts like a screen, the particles are removed from the liquid, and the resulting foam is particle-free.

[0030] Therefore, to overcome the limitations of earlier foam dispensers, the dispenser of the present invention uses an air jet process when generating foam. That is, air is introduced into the liquid through a number of small holes or air sparging elements to create foam. Those skilled in the art will appreciate that various liquids can be "foamed" by employing this air jet process. Thus by using the present invention it is possible to produce foams with suspended particles.

[0031] In general, one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com